Tile is a material with high thermal conductivity. This means that its surface for the most part remains, if not cold, then cool. In winter and in the off-season, when the temperature outside the window is low, walking on such a floor is not very comfortable.

The problem of a cold floor is more relevant for residents of the first floors. The best option would be to insulate directly from the basement side, sheathing the concrete floor with foam sheets.

Therefore, when installing such a coating, it is recommended to insulate the floor under the tiles.

What kind of insulation to choose?

- Glass wool and its modifications.

Nowadays, you can buy the following varieties of this material: glass wool, mineral wool, basalt, stone, shpak. All these heaters have a cotton wool structure and differ in the source material from which they are made. Their production method is practically the same: melting. For example, the components of mineral wool are molten glass, rocks and spats.

The thermal insulation characteristics of different types of this material are also identical. Each of them can be rolled and in the form of mats of different thicknesses. The most famous and popular brands: Isover, Rockwool, PAROS, URSA. They can insulate the floor if there is no high humidity in the room or basement. Any of these materials are hygroscopic and deteriorate when wet.

- Penofol.

Penofol is a roll material, as a rule, foiled on one of its sides, or on both sides at once.

This is a new generation of insulation. It is a roll material, as a rule, foil on one of its sides, or on both sides at once. This heat-reflecting coating distinguishes it from other insulators and is therefore a unique product that prevents heat leakage. Penofol can have a self-adhesive layer, which only increases the reliability of the barrier for cold air access. It is produced in rolls and comes in different thicknesses.

- Styrofoam.

It is a universal insulation, the most popular and used everywhere. Sheets of this material can have a thickness of 2, 2.5, 3, 5 and 10 cm. Standard sizes: 100x100 cm and 100x200 cm.

Polyfoam can be of different densities. Moreover, the higher it is, the higher the thermal insulation properties of this material. Floor insulation is made of solid and high quality, with a high degree of density. This is the most preferable option for laying under a tile.

The choice of insulation

Since there is constant high humidity in the bathroom, you cannot use natural types of insulation, and those that absorb moisture. When the insulation gets wet, it loses its properties and becomes useless. That is, in the bathroom, floor insulation cannot be done using mines. cotton wool or regular foam.

For such conditions, extruded polystyrene foam is well suited. It has a high density, almost does not absorb moisture and has some of the best thermal insulation performance. The price for this material depends on its thickness and density and starts at 100 rubles per square.

Characteristics of extruded polystyrene foam

In addition, usually the bathroom is not just insulated, but floor heating is additionally done. Provided that there is a heated room under the floor, foil insulation for the floor is suitable as a layer of insulation. It consists of several materials: a thin layer of aluminum foil on top, and a layer of polyethylene foam inside.Such material not only protects well against heat loss by reflecting heat radiation, but also insulates moisture.

Note! In order for the aluminum layer of insulation to be protected from the alkaline effect of cement, it must be pasted over with polyethylene on top. It is worth buying only these types, since only they are suitable for use with a screed. Otherwise, you risk losing the heat-reflecting layer - after a couple of weeks, it will simply corrode.

In the photo is a foil substrate

The greater the thermal resistance under the heating elements of the warm floor of an apartment or house, the more heat will go up. This is especially important for water heated floors, since they have less power than electric ones. For other types of heating mats, warming the bathroom floor will reduce energy consumption, you will not heat the ceiling to the neighbors from below.

Insulation of the concrete floor under the tiles

Tiles can only be laid on cement-sand or other masonry mortar.

Tiles can only be laid on cement-sand or other masonry mortar. Therefore, the floor in such a room will be concrete. He, like ceramic tiles, does not retain heat well, therefore it needs high-quality insulation. The technology of work in houses with and without a basement has slight differences. Let's take a look at each of these methods.

- Insulation of a concrete floor in houses with a basement.

The problem of a cold floor is more relevant for residents of the first floors. The best option would be to insulate directly from the basement side, sheathing the concrete floor with foam sheets. But in practice, this method is rarely used. Therefore, the insulation works are carried out in the apartments by the tenants themselves. Sequence of work:

- Dismantling the top, usually a wooden covering.

- We clean the surface of the concrete slab from debris and dirt.

- Using the hydro level, we make markings on the walls of the room, which should correspond to the height of the future floor, taking into account the facing. The lines must be strictly horizontal.

- We lay the waterproofing material. Roofing material is most often used, but you can use a more modern method: treat the surface with any of the bituminous mastics.

- We lay insulation between the lags. If the climate of the region of residence is warm, you can simply fill in a layer of expanded clay.

- We lay a vapor barrier material on top of it (if foam is selected, then one is not required).

- Next, we lay the reinforcing mesh with a bar section of at least 5 mm.

- We prepare a concrete solution in a ratio of 1: 3, where 1 part is cement and 3 is sand.

- We fill the floor with concrete layer by layer, focusing on the marking lines. Each subsequent one - only after the previous one has hardened. The last layer is leveling, so the concrete should be more fluid.

- We make laying of tiles or porcelain stoneware.

- Thermal insulation of the floor under the tiles in houses without a basement.

Often these buildings stand on piles and their lower floors are located close to the ground. The technology of their insulation differs in that a large thickness of insulation is required. All work is carried out indoors. Their sequence is similar to that described above.

How to insulate floor tiles with your own hands

To begin with, roll waterproofing is placed on the base, which will protect the insulation from getting wet, and the subfloor from moisture in case of possible spillage on the floor. In no case should waterproofing be neglected, it is one of the main layers of the “pie” of insulation. Waterproofing in wet rooms is especially important, for example, when insulating the floor under the tiles in the bath and on the loggia with your own hands.

Next, a layer of insulation is laid. Everyone should decide what kind of insulation to put under the tiles based on their financial capabilities, characteristics of stone wool and the technology of its installation.So, basalt heaters should be laid on the floors along the logs, plate heaters (polystyrene, extruded polystyrene foam and technoplex) can be independently laid under the screed.

After laying the insulation, a rough screed from 3 to 5 cm is made. For a cement screed, you should find a zero level, you should not make a screed that is too "thick", as this is an extra load on the floor. You can make warm electric or water floors before pouring the screed, since there are no additional heating radiators on the loggia. In addition, you already know what kind of underfloor heating should be used.

Already before laying the tiles on the floor, when the screed is dry, the concrete surface should be primed. The primer will increase the bond strength of the tile adhesive and the screed. For wet rooms, it is worth using penetron waterproofing, this composition, due to its characteristics, penetrates deeply into the cement, reducing its ability to absorb moisture. This is important for wet rooms in saunas and baths.

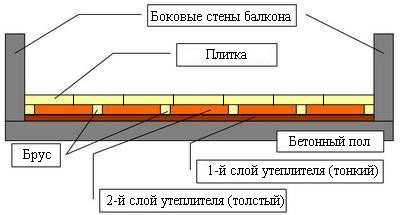

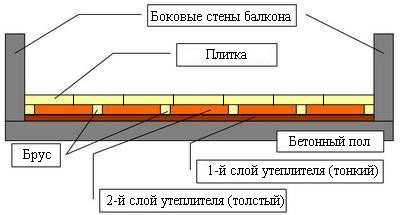

How to insulate the floor on the balcony under the tiles

Floor insulation scheme on the balcony

The first step is to remove the old coating, this is where any stage of repair on the loggia begins. Next, the floor is treated with liquid or roll waterproofing. Foam or technoplex slabs are laid on the waterproofing (these heaters are more durable and dense, and also do not absorb moisture, unlike foam). A concrete screed is made on top of this cake.

After the mortar has completely dried, the floor is treated with a deep penetration primer.

When the primer is absorbed and dry, tiles or porcelain stoneware are laid on the floor. As a result, you will get a warm floor under the tiles on the loggia, which will save heat even in the most severe frosts and it will be comfortable to walk on the tiles on the balcony floor.

How to insulate the floor in the kitchen under the tiles

The floor in the kitchen in an apartment or in a private house can be insulated with mineral insulation by making warm floors along the logs. You can also make knauf floors, on which you can lay any covering. If you decide to make a cement screed, then do not forget about high-quality waterproofing. In this room, you can also use expanded polystyrene as a floor insulation for tiles.

How to insulate the floor in the country under the tiles

Warm ceramic tile floor in a sauna

It is possible to insulate the floor under the tiles in the country house using the same technology as the insulation of wooden floors. Let's consider in more detail how to insulate the floor under the tiles in the bath. Since this room is distinguished by high humidity, then only moisture-resistant materials should be used here, which are not afraid of water and do not decompose over time.

These materials include technoplex and penoplex. And the technology of floor insulation in a bathhouse for tiles or porcelain stoneware is no different from the treatment of floors on a loggia. In the video instructions at the end of the material, you can see in more detail how to insulate the floor under the screed with foam or foam, in order to finally understand the issue.

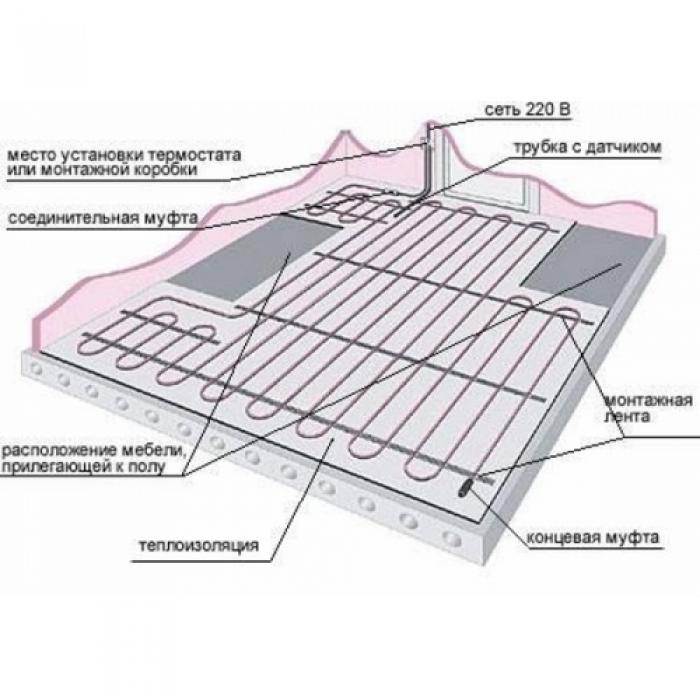

Installation of the "warm floor" system as an option for floor insulation under the tiles

- We prepare the base. We remove the old coating and clean the space between the lags.

- If necessary, we level the flaws with a cement-sand mortar.

- We install waterproofing.

- We lay the insulation. The best option is polystyrene, penofol, polyurethane foam plates 3-5 cm thick. A special insulation for the "warm floor" system is also sold, it has recesses for pipes, which greatly facilitates the work.

- In order to avoid deformation of the insulation during the heating of pipes, it is recommended to leave a gap of at least 0.5 cm between the foam and the wall. The gaps between the sheets can be sealed with polyurethane foam.

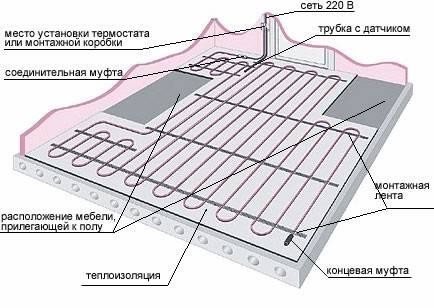

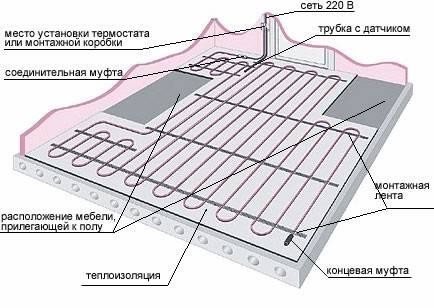

- We make pipe laying.The best option is to use metal-plastic or polypropylene, as they are durable, strong and have good flexibility. Their installation is possible in one of the following ways:

- spiral;

The distance between the pipes should be 30-40 cm.

- snake;

- a spiral with an offset center;

- double snake.

No matter how the pipes are laid, the distance between them should be 30-40 cm. We bring the supply and return ends to the collector cabinet. You can attach pipes to the insulation in the following ways:

- laying between "bosses";

- using U-shaped spring brackets;

- mounting aluminum plates;

- mounting on a special metal mesh with plastic clips for fastening pipes.

We connect the system to the water supply, set the necessary adjustments in the collector cabinet, fill the pipes with coolant, turn on the system.

Underfloor heating with water heating

This method of floor insulation is very popular, despite the rather high cost. Therefore, in order to save on installation and not involve specialists, you can install the system yourself. Installation of a warm floor under the tiles is carried out in the following sequence:

Floor heating scheme with water heating.

- Preparation of the base. The old coating is removed, all debris is removed in the intervals between the lags.

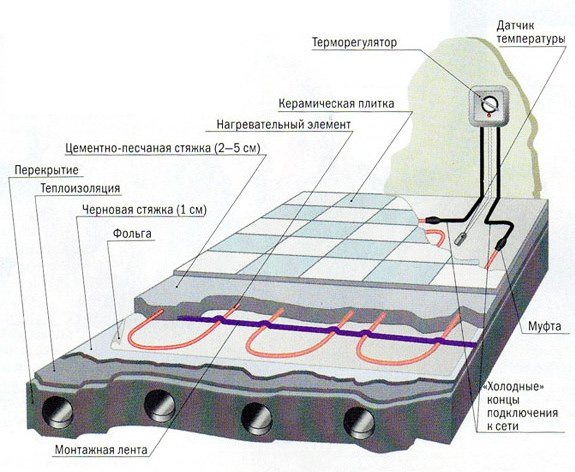

- Laying waterproofing and insulation. It is better to use penofol, foam or polyurethane plates as insulation. Also on the market you can buy insulation specially designed for the warm floor system. Its feature is the presence of recesses for pipes, which greatly facilitate installation. It should be noted that a space of at least 5 mm must be left between the wall and the foam, since when the pipes are heated, the material may deform slightly.

- Pipe laying. It is recommended to use polypropylene or multilayer pipes, as they are strong, durable and have good flexibility. There are two ways of styling: a spiral and a snake. When the pipe is arranged in a spiral, the entire floor area heats up more evenly, since the supply and outflow of water are parallel. When laying with a snake, the floor above the beginning of the pipe heats up more, but this method is indispensable when you need to bypass any obstacles or areas. To distribute heat evenly (for any installation method), the distance between the pipes should be approximately 30 cm. The pipes are attached to the insulation using U-shaped brackets, plastic brackets, clips or other special devices.

- Underfloor heating connection. After laying, the supply and return pipe ends are removed and connected to the manifold. Then the entire system is connected to the water supply.

- Pouring the screed and laying the tiles. After checking the correct installation of the system, you can proceed to the finishing screed. It is not necessary to fill the pipes with water before pouring, as they are sufficiently rigid and should not deform under the pressure of the concrete solution. It is not recommended to turn on the heating at full capacity for some time after pouring in order to avoid the formation of cracks. After the screed dries, the tiles are laid.

Related article: Design of curtains for a living room (hall) with a balcony: classic, green

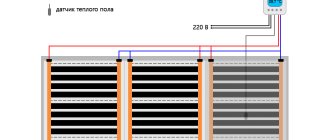

How floors are insulated with infrared heating

This method is the most modern. It consists in installing infrared mats, which act as heating elements. Despite the fact that this option is much more expensive than the previous ones, such insulation is mounted much faster. For its installation, no screed device or dismantling of the old coating is required.

Infrared mats require a flat surface. Therefore, it will be necessary to do the appropriate work. The floors are insulated with these elements directly under the tiles. The mats are attached to the base with glue.The minimum of "wet" processes and ease of installation make this method of home improvement the most preferable.

511

What type of modern underfloor heating is worth choosing

The underfloor heating system on a balcony or in any other room is a construction of heating elements.

Their role can be played by metal-plastic pipes through which the coolant passes, or heating electrical elements.

That is, the warm floor on the balcony can be:

- water;

- electric (film, cable or heating mats).

Water-heated floors on the balcony are able to heat the floor as evenly as possible over the entire area.

Water heaters perfectly save space, and operating costs will be lower than for electric floors, since water as a heat carrier is significantly cheaper.

But water-heated floors also have their disadvantages, for example, the difficulty in adjusting the temperature regime, a possible periodic decrease in pressure inside the riser.

In the event of a leak, it will be difficult to find and even more difficult to eliminate. We must not forget about the complexity of installation and the rather high cost of the structure.

As for the electric warm floors on the balcony, they have almost the same advantages as water ones. But in terms of the totality of all operational characteristics, the electric underfloor heating is far ahead of the competitor.

In addition, the electric underfloor heating provides uniform heating of the entire area.

Finding a malfunction and fixing it is much easier than in the case of a water floor. Installation is very convenient to carry out in the limited space of the balcony of a typical apartment in a multi-storey building without special equipment. And the cost of such floors is significantly lower. Among the disadvantages is only one - electricity bills.

With the electric floor, the temperature can be easily adjusted.

Weighing all the pros and cons, it is easy to make a choice in favor of an electric underfloor heating for installation on a balcony.

We make insulation and floor heating

Depending on which type of heating you have chosen, first you need to install either a thermostat (electric heating) or a manifold cabinet (for water heating).

For their installation, it may be necessary to grind the floor and walls to hide all communications inside the concrete. After installing these elements, you need to remove all dirt and vacuum the base. It should be without visible height differences.

If necessary, it is necessary to make local leveling of the floor with cement mortar. Then treat the concrete base with a primer, preferably with an anti-fungal effect.

Advice! To check the readiness of the base, lay polyethylene on concrete for several days and press it firmly. If the base is ready, after a few days the polyethylene should be completely dry.

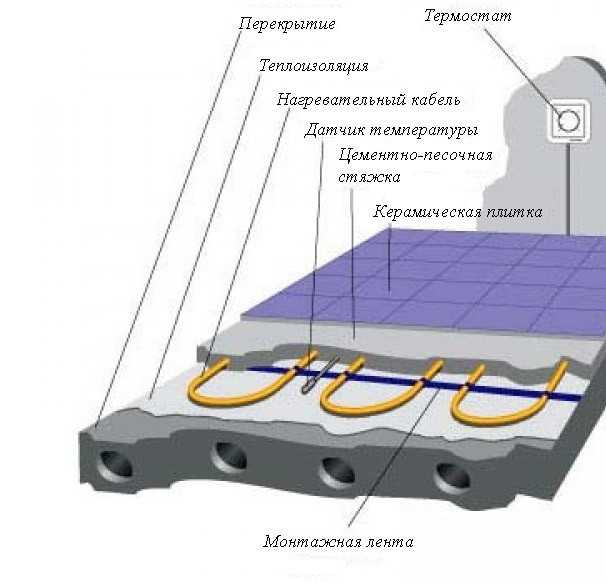

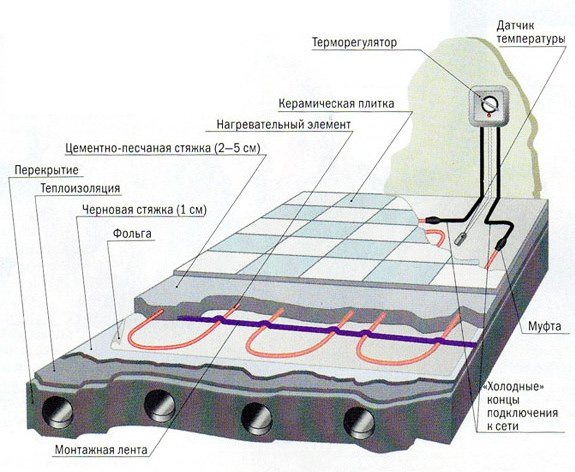

The final cake of heated insulation will look like this:

- First comes the concrete base (floor slabs);

- Waterproofing;

- Insulation layer;

- Heat-reflecting foil layer;

- There is a damper tape around the perimeter of the room;

- Mounting mesh;

- Heating elements;

- Concrete screed.

Floor heating cake

Insulation laying

When the primer is dry, a layer of waterproofing should be applied. Most often, a layer of plastic wrap is used for this.

Now you can start laying our insulation. Some foil types (for example, Energoflex) have special markings on the surface, which simplifies the installation of heating elements. Lay a roll of insulation and glue the canvases together with foil tape.

If you use extruded polystyrene foam, then there are special grooves at its ends to dock it with each other. Join the slabs tightly throughout the bathroom.A layer of Uponor Multifoil can be placed over it to increase efficiency and distribute heat evenly.

You also need to fix the damper tape to the wall around the perimeter of the room. If you buy a special tape, it has a self-adhesive base, and if you use thin foam or a foil backing as it, you need to fix it on self-tapping screws.

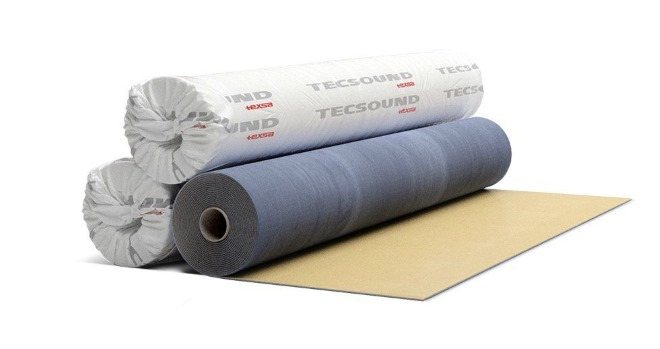

Soundproofing materials for tiles

Reinforced concrete floors do not provide sound insulation. Soundproofing the floor using additional layers is the optimal solution to this problem. Masters distinguish several types of soundproofing material:

- membranes;

- bung;

- substrate.

The substrate is cheap, but the cork is more appreciated due to its composition. Membrane protective sheets for tiles are an optimal alternative, since the floor covering ceases to perceive shock vibrations from the outside and the noise level is reduced.

Membranes are suitable for private houses, but they will not solve the problems of apartment buildings. If a person lives in a high-rise building, then it is better to use more serious material or create multi-layer sound insulation. Rockwool or Isover slabs are great. Their thickness ranges from 5 to 10 cm, they are able to isolate sound vibrations even through concrete floors. Noise is guaranteed to be reduced by 30 dB or more.

We recommend: Types of window seals and features of its installation

If the floor screed is tight, one layer of insulation is sufficient.