Today it has become very important to use foam as an external insulation. Indeed, it can be said with great confidence that this is a good way to keep the room warm. Let's look at what the technology of wall insulation with foam plastic is from the outside, as well as its main stages and nuances. Believe me, there really is something to talk about.

Why is it needed, or What will it give?

It is quite a logical question, because hardly anyone wants to spend an impressive amount of money without getting the desired result. The fact is that any technology of wall insulation with foam outside has several undeniable advantages. Firstly, during the heating season, you save a significant amount of fuel, and in the summer, there are less air conditioning costs. Secondly, unlike internal insulation, the area of rooms is not reduced, and this is very important, especially when it comes to a small house or apartment. The so-called "dew point" will be located behind the insulation. This completely solves the problem of wall freezing, and also prevents its early destruction due to moisture. It is worth drawing your attention to the fact that these are far from all the advantages of this method of insulation. We'll look at the rest a little later.

Advantages of wall insulation outside

By insulating the room from the outside, we acquire a number of useful qualities of our home.

- You will constantly be in a fairly dry and moderately humid climate, in addition, the rooms will retain the necessary a comfortable temperature for you.

- Improved noise isolation the properties of your building will never become superfluous for your comfort.

- The outside of the wall won't budge corrosion - the house will become durable and keep its kind aura for your children and grandchildren.

- From within we get rid of fungal formations and an unpleasant odor.

- The next reason, and the most significant one, is that external wall insulation, depending on the thickness of the layer and the quality of the insulation, can save up to 70% of your hard-earned money in heating bills.

- Another useful quality is that the walls of your house will not freeze through. "Freezing of walls" is an eternal problem of all builders, which must be constantly taken into account. There is such a thing as "dew point" (in a simple way, it is the temperature difference at which condensate forms), and due to freezing of the walls, the "dew point" is shifted to the center of the building. As a result, a slight, but catastrophically unnecessary temperature difference occurs inside the room. Warm air from the center of the room moves to colder walls and corners, causing condensation to build up on them, destroying your drywall and flaking your new wallpaper. We do not need this, so we draw the right conclusions and insulate the walls from the outside.

- Among other things, insulate the wall with foam outside - less time consuming activity than doing it from inside the room.

Wall insulation outside with foam: reviews and recommendations of consumers

Before using this method, you need to make sure that it is effective. The best way to do this is by listening to the comments of other people who have made such insulation. This source is the most informative and at the same time completely free. As practice shows, wall insulation outside with foam, reviews of which are mostly positive, really makes sense. According to consumers, electricity costs are reduced by about 15%, and gas costs by more than 20%. These are very good numbers.In a few years, the purchase of polystyrene will fully pay off. Nevertheless, professionals recommend that you carefully deal with this issue and pay attention to important details. For example, you do not need to buy sheets of the same thickness, since this does not make sense. This is due to the fact that the corners must have a larger layer, like the south wall. In addition, users recommend not purchasing polystyrene brands below C-20 (20kg / m3), since it is easily deformed, and in general there are more problems with it.

Types of heaters

The market for insulation is huge. The best materials are the most sustainable. And the price, respectively, of such heaters is higher. But it is better to pay more once than to save money, and then spend years and time, and effort, and financial resources on replacing low-quality material for years.

The most common insulation is mineral wool. It consists of quartz sand and recycled glass, and is a slab filled with fibrous matter.

It has excellent heat and sound insulation properties, therefore it is often used for external insulation of a house. It is not affected by fungal diseases.

The downside is that it contains poisonous chemicals such as formaldehyde, which adversely affect the human respiratory tract. Therefore, it is categorically not recommended for use in rooms where children are often found. When the insulation is ignited, a strong poisonous smoke is generated that affects the respiratory tract of a person.

In addition, mineral wool has hygroscopic properties, and shrinks over time.

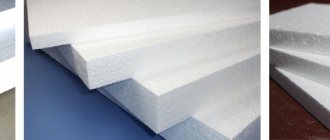

Polyfoam is also quite popular as a floor and facade insulation. This material is very cheap, lightweight, does not require special skills and tools for installation. It almost does not absorb moisture and does not require additional waterproof membranes. Of the minuses - the fragility of the material, and a high level of flammability.

Expanded polystyrene is a material that is made from polystyrene and its derivatives. It has high thermal and waterproofing performance. It also boasts good fire resistance and resistance to various chemical corrosion. This is a very resistant insulator against mechanical damage, has a fairly long service life.

Polyurethane foam - sprayed insulation. Poorly conducts heat and moisture. It differs from other heaters in that it excludes the occurrence of cold bridges, since it has a low density, and closes all the cracks with itself. Excellent fire resistance and retention of its qualities at extremely high and low temperatures makes it highly demanded.

Ecowool is a fairly environmentally friendly material with good thermal insulation properties. When installing ecowool, there are no connecting seams, therefore cold bridges will not arise. The negative feature is that this material has a high moisture absorption, as well as susceptibility to various fungal diseases. In addition, it will not be possible to install it on your own, since special equipment and professional workers are required.

Stone wool, on the contrary, does not need special knowledge and equipment for installation, but it has quite good qualities of vapor and noise insulation, does not ignite, is not susceptible to being eaten by rodents and pests. It has a fairly long operational life - more than fifty years.

Such materials as expanded clay, cork and peat insulation, sheep wool, fiberboard, damask are also widely used.

All this is about theory. All these qualities are declared by manufacturers of heat insulators when they release products.But it very often happens that people, having heard from a neighbor, friend, or colleague that some kind of insulation for frame houses is bad, consider these reviews to be true of the first degree, and accept their choice not in his favor.

The following are the most common false facts about insulation materials that should not be believed.

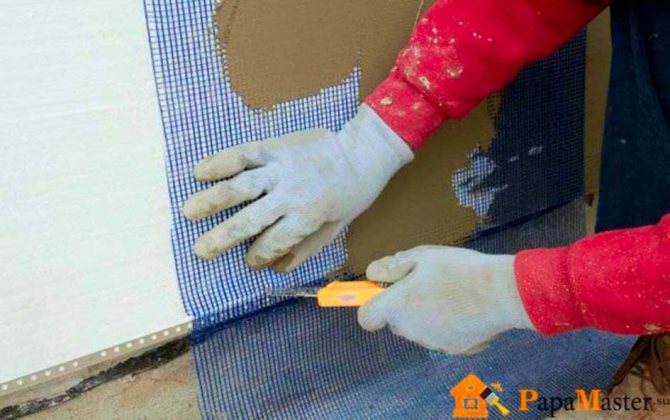

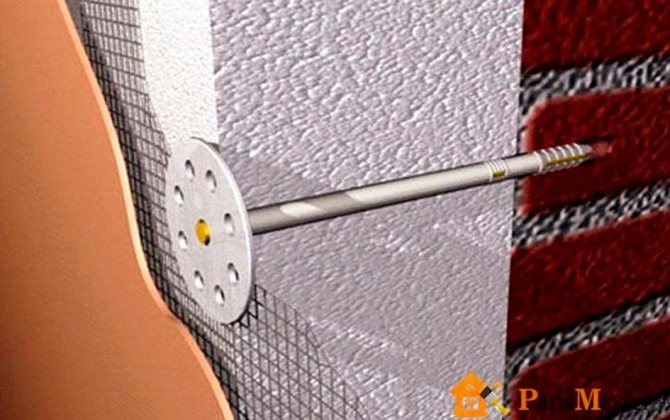

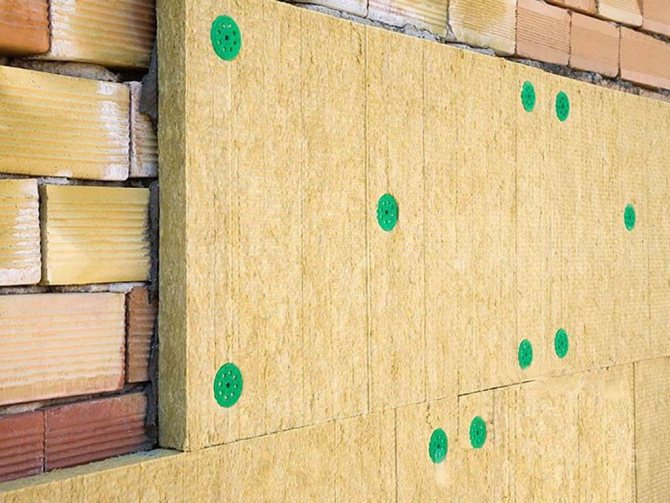

Do you need a reinforcing mesh?

A very strange question, the answer to which can only be one - of course, yes. This is due to the fact that without such an important element, cracks will soon appear, and it is quite possible that the sheets will float. Fiberglass mesh should be used as the basis for the plaster. The preferred density is at least 150-160 g / m2. It is best to attach it to glue (cement base). The latter is applied in a meter by meter area. Next, we need a wide spatula, with which we will sink the reinforcing mesh into the glue. Many people recommend applying another layer of glue on top for greater security. Periodically check how flat the surface is. It is desirable that the horizontal stripes overlap at least 7-10 cm, and the corners of the facade are reinforced with a perforated corner.

What materials are used

It should be noted that there are two types of insulation: reflective and preventative. Reflective insulation retains heat due to the fact that infrared radiation, which carries heat, is reflected from the coating into the interior of the house. Preventing materials have low thermal conductivity, which is why they retain heat.

Prevention materials are classified as organic, inorganic, and mixed.

Insulation of the facade of the house from the outside is carried out with the following materials:

- foam (expanded polystyrene);

- expanded polystyrene (extruded polystyrene);

- ecowool;

- mineral wool.

Photo: collage © Vosaduli.ru

Styrofoam

Polyfoam is often used for cladding the facades of private houses. It retains heat well and is not a favorable environment for the life of microorganisms.

The main danger of polystyrene is that, if improperly installed, condensation can collect in the building or even fungal infection can appear.

The price for polystyrene is reasonable. Polyfoam has a loose structure, which is why it is easily damaged by mechanical stress, and also destroyed by sunlight. After installing the material itself, a reinforcing mesh is laid on top, plaster is applied, primed and painted.

Extruded polystyrene foam

Extruded polystyrene foam is one of the varieties of polymer raw materials. Condensation does not form in the country house, which has received additional insulation with expanded polystyrene. In addition, this material does not lose its thermal insulation properties over the years. Unlike foam, they have a denser structure. Polystyrene foam is waterproof, has low thermal conductivity, is lightweight, easy to install and does not deform over time. Of the shortcomings, it is worth highlighting that it is prone to burning under the influence of an open fire. When the temperature rises above 80 ° C, it emits harmful chemical compounds.

Photo: © ceresit.by

Ecowool

Ecowool is produced from waste products from the pulp and paper industry. For the manufacture of this material, defective prints, remnants of corrugated packaging, and so on are used. Ecowool accounts for 80% of cellulose, 12% for boric acid, and 8% for sodium tetraborate. Boric acid acts as an antiseptic, preventing pathogenic microorganisms from settling in the insulation. Sodium tetraborate is a fire retardant. Ecowool has some disadvantages:

- Over the years, the material decreases in volume by about 20%, which increases the thermal conductivity.

- It absorbs a large amount of moisture from the environment, which increases thermal conductivity and decreases the ability to retain heat.

- Difficult to mount.

- It dries for a long time, from two to three days.

- Do not install near chimneys, chimneys due to the risk of smoldering.

Their advantages of ecowool are distinguished by a good price / quality ratio, a safe composition, an economical consumption of material for insulation, the ability not only to heat insulation, but also to sound insulation.

Mineral wool

There are three types of mineral wool:

- glass wool;

- stone wool;

- slag wool.

Glass wool is resilient and durable, but requires special care in work, because thin glass threads can easily break and pierce the skin, get into the eye or even into the respiratory tract. Withstands temperatures from -60 ° С to + 500 ° С. Stone wool is more often used for decoration. It is much safer and easier to work with, it does not inject. An example of stone wool is basalt wool. It can withstand temperatures from -190 to + 1000 ° C. Basalt wool does not burn, but melts. Slag wool is not suitable for facade insulation, because it absorbs a lot of moisture.

Photo: © ppu-protection.com

A little about finishing

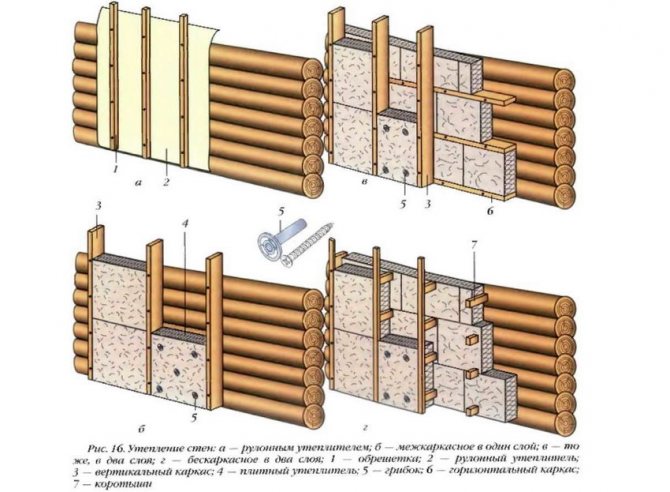

In principle, the technology of wall insulation with foam from the outside is fully considered. All that remains to be done is to take care of the exterior finish. Of course, this is a personal matter for everyone, but a painted facade looks much better than an untreated one. Remember to prime the surface before painting. We can say that the insulation of wooden walls with foam from the outside is carried out in the same way as concrete, with several minor differences. First, you need a thin layer of plaster to protect the room from fire. Secondly, it is necessary to provide an air gap, which will exclude the appearance of condensation between the wall and the insulation. Keep in mind that ideally, the styrofoam sheet should not be more than 50mm thick.

The edges of the premises are poorly insulated with polystyrene.

This happens when the material is incorrectly installed - it must be placed not in the joint, and clearly fixed. If we talk about the insulation of the outer wall, then in order to prevent the occurrence of cold bridges, the edges must be fixed with professional assembly foam. You should choose a high-quality one, you won't go wrong in the price - it is only 10% lower than the non-professional one.

If you hear that polystyrene does not insulate well, be aware that in those cases there is a poor-quality work of builders who put the material without blocking the flow of air masses at the joints. Therefore, if you want to make sure that the slabs will be laid correctly, ask the team to handle the joints with foam.

Expanded clay does an excellent job with its functions if you insulate the floor or internal partitions with it. But it will not work as a heat insulator for external walls.

So, let's figure out what kind of insulation is better for a frame house, focusing on people's reviews. It should be remembered that all these cases are private, and that it is impossible to focus on them 100%.

Ecowool often gets wet during operation, the owners had to re-install it many times. After the repairs in the house cost them a considerable amount of spent finances, time and nerves, they advise not to exchange for cheap heaters such as ecowool or foam, but once invest a large amount of money and buy basalt fiber.

Polyfoam is very difficult to dock so that there are no cold bridges.

This requires that real professionals work, who give guarantees and are responsible for the work performed. It is very difficult to achieve a perfect joint on your own. The owners believe that it is easier to work with mineral wool, and you can install it yourself without worrying about the poor quality of work.

Other forum attendees have made great comments about Styrofoam.Having lived in a house insulated with this material for more than 6 years, they note that it does not allow cold or moisture to pass through, and is environmentally friendly.

Some people prefer stone wool, believing that it has proven itself well in the insulation market. An important detail in its installation is to correctly calculate the layer thickness.

Penofol, according to other forum visitors, is an ideal option for insulating a frame house. It is a polyethylene foam covered with aluminum foil on top. Thanks to it, heat is reflected, it also gives excellent sound insulation properties, does not shrink, is hygroscopic, does not allow radiation to pass through. A significant disadvantage is the very high price. Others advise using Penofol only in tandem with mineral wool to achieve ideal conditions.

Many people find stone wool to be the best insulation material. The guest of the forum noted that he made the calculation in comparison with other materials, although he did not provide this calculation. Another opinion is that stone wool is only suitable for insulating external walls, from the inside there is a high probability of condensation formation.

The point of view was expressed that linen insulation has excellent thermal insulation properties. An additional pleasant point is that such a heater is a guarantor of the presence of a microclimate like in a wooden house.