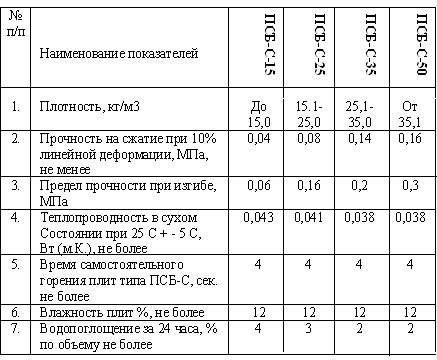

Styrofoam properties:

- Cheapness;

- Ease;

- Ease of processing;

- Environmental friendliness;

- Harmlessness;

- Fire safety;

- Resistance to microorganisms and various technical environments;

- Moisture resistance;

- Buoyancy;

- Excellent heat and sound insulation qualities;

- Strength;

- Durability.

For nearly 60 years, various foam products have found application in many areas of human activity.

Application area

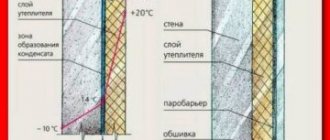

When insulating a house from the inside, it is necessary to increase the thermal insulation of the following structures:

- in the basement floor structure on the ground, if the underground floor is heated;

- in the cake of the ground floor floor when arranging a cold basement or underground;

- exterior walls;

- overlapping over the last floor when arranging a cold attic;

- covering when arranging a warm attic;

- mansard roof.

Of all these parts, polystyrene foam for home insulation is best used in wall construction. In floors, polystyrene should only be used in conjunction with logs, which will take on the main load from the floor, furniture, etc. The fact is that the density of expanded polystyrene does not allow it to withstand high compressive loads.

Ceilings with foam without logs can be used for technical purposes - attic floors, etc. Therefore, if you want to insulate the floor with high quality under the screed, the best insulation option is extruded polystyrene foam. Insulation from above should cover a layer of cement-sand screed 50 mm thick with additional reinforcement. For reinforcement, a mesh of reinforcement with a diameter of 3-4 mm is used.

Another area of application of polystyrene is the manufacture of permanent formwork for concreting. Such insulation is used in the construction of strip foundations. Allows to reduce the number of stages of work on pouring a monolith at home and at the same time to perform thermal insulation of the structure. Without fail, a reliable waterproofing must be provided on top of the expanded polystyrene.

Foam application

Packaging. The foam is lightweight and has good damping properties. It is easy to give it any shape that is optimal for protecting this particular product from damage. Spacers, spacers, corners and other shapes made of foam are widely used for packaging not only fragile items, but also for the preservation of the outer surface during transportation, for example, laminate or plastic panels.

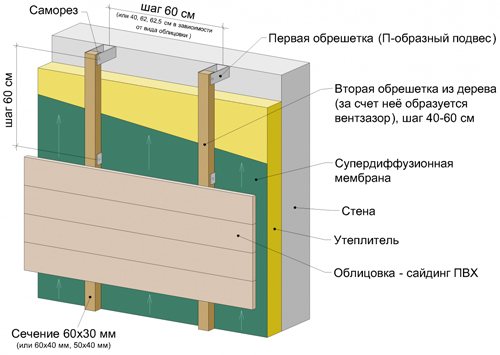

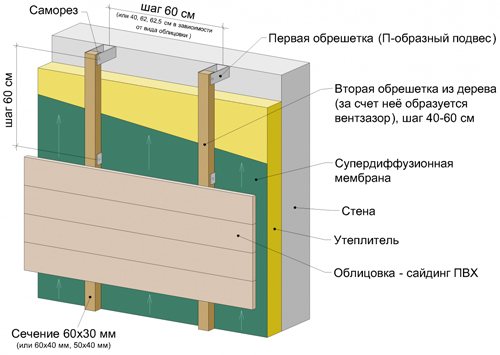

Heaters. Polyfoam consists of many cells with air trapped inside, which is an excellent heat insulator. Sheet foam is used as a heater for walls, floors, ceilings, roofs, facades, pipelines, as well as in refrigeration equipment.

Noise isolation. The foam has a structure that dampens sound vibrations well.

Sandwich panels. A foam sheet in steel or plastic cladding is called a sandwich panel. They can be used for external or internal work, decoration and partitioning of premises. Due to its low weight, the installation of a foam sandwich panel does not require special equipment. The outer surface is painted or coated with polymer of any color, and therefore, as a rule, additional finishing is not needed.

Building. The technology of permanent formwork consists in filling specially made foam blocks with concrete, which are joined to each other like a child's construction set. The blocks already have technological holes for laying communications, and any openings and architectural elements can be easily cut with a saw.Due to the thermal insulation properties of foam, this type of wall can be thinner than a wall made of traditional materials, which increases the usable area of the house. There is also a technology of polystyrene concrete - foam in the form of balls is poured into concrete, making it lighter and improving its thermal insulation characteristics.

Polyfoam for insulation 100 mm thick

Polyfoam is one of the most common thermal insulation materials. It is indispensable for the construction of new buildings, and is also often used to insulate structures that are already in operation. Due to its versatile properties, 100 mm foam can be used in both industrial and civil construction.

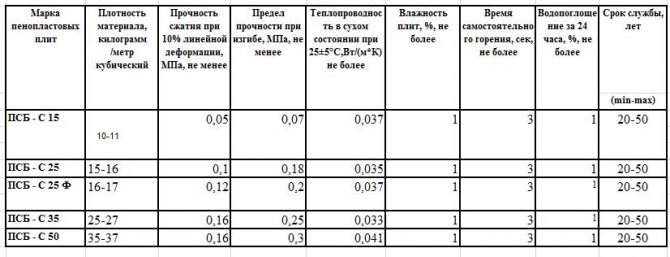

Specifications

Before starting work, you should familiarize yourself with the description and characteristics. This material is made from polystyrene, which includes a blowing agent. Has a foam structure that prevents moisture absorption and protects against various bacteria and fungi. It is also profitable to buy it because the structures do not require additional wind protection. The advantages also include durability and the ability to maintain their qualities at temperatures up to 110 degrees Celsius. It must be borne in mind that the plates are flammable, therefore, before using them, it is recommended to treat them with a special agent in order to impart the ability to self-extinguish.

Foam plastic for thermal insulation can withstand a fairly strong load, it is environmentally friendly, good sound insulation, resistant to aggressive environments and various chemicals. Due to their low weight, the boards are easy to install and can be easily cut with ordinary tools.

The material has a density of 25 kg / cubic meter, which ensures its efficient operation and guarantees high-quality insulation of the structure. In addition, the price for a 100 mm foam sheet is quite affordable. Such slabs usually have standard sizes corresponding to GOST:

- length - 1000, 12000, 2000 mm;

- width - 1000 mm;

- thickness - 20-500 mm.

The scope of application largely depends on the latter indicator. If the foam is 100 mm thick, it can be used in the following cases:

- insulation of walls, roofs, foundations, balconies and loggias;

- insulation of electrical cables, telephone lines, ventilation ducts, sewer and water pipes.

In addition, the good thermal conductivity of 1000x1000x100 mm foam plastic, as well as other sheets of similar thickness, allows them to be used for the manufacture of various containers, display cases, chests and refrigeration equipment.

Review of prices in Moscow

The cost of a product largely depends on its brand. In order to find out how much foam plastic costs in Moscow, you should familiarize yourself with the presented below overview of prices per cubic meter:

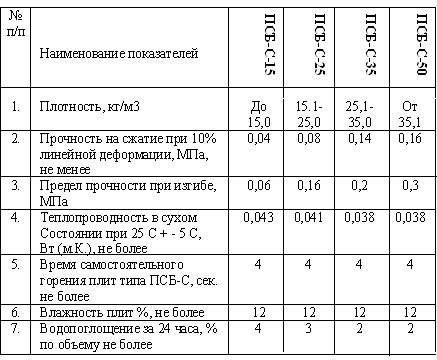

- The average cost of PSB-S 15, intended for thermal insulation of unloaded premises and pipelines, is about 1,550 rubles.

- PSB-S 25F used for building facades - from 2,300.

- The PSB-S 35 brand is universal, for indoor and outdoor work - 2,700 rubles.

- PSB-S 50 with a thickness of 100 mm belongs to the category of the hardest materials. It can be purchased for approximately 3,700.

- PSB-S 25 are slabs for insulating walls inside the building, costing about 1,850.

If we talk about the price of 100 mm sheet polystyrene per piece, then on average in Moscow it is 120-300 rubles.

Author: Roman Medvedev

| Related articles: | |

| What kind of insulation to choose for the ceiling of the bath? Calculation of the required thickness of insulation Sawdust as insulation | |

Foam cost

The German company BASF became the developers of foam plastic back in 1952 and since then the popularity of this material has only grown, which is not surprising, since expanded polystyrene has a porous structure and light weight, which is very convenient in transportation.

This material has excellent thermal insulation properties, therefore it is a leader in the insulation of building walls.

If we compare this material with other heat-insulating materials in cost, then the price of expanded polystyrene per cube will be the lowest. For example, thermal insulation with mineral wool for an equal area will cost you several times more.

Polyfoam 50 mm and 100 mm, which one to choose, characteristics, how to apply

Sometimes you need to choose foam for insulation - 100 mm or 50 mm, which one will be optimal? The question of which foam is better to use often worries developers, because it is this insulation that is used most often for houses and apartments. It is important to take into account the characteristics of the foam, they can vary significantly and affect the durability and integrity of structures. On the walls of the house, on the ceilings, in the floor and in the roof, only a high-quality, durable layer of insulation should be installed. Is foam suitable for these purposes and which one ...

Pay attention to the density of the foam

It is not only the thickness of the foam sheets that plays a key role (100 mm sheet or 50 mm ...). Expanded polystyrene is available in different densities, characteristics will depend on it. According to the standards, the density of the foam must be:

- 15 kg / m cube - applied on horizontal surfaces, without load and without squeezing. Well suited for insulating ceilings and floors (horizontal surfaces) where possible.

- 25 kg / m cube - the most widely used, including for wall insulation using the "wet facade" technology, under plastering on all walls, including at a height (necessarily with additional fastening with disc dowels), as well as on facades of buildings.

- 35 kg / cubic meter is a rather dense and strong material, excellently suited for plaster, can fit under decks and withstand deformations with rare movement of people.

Old classification of Penoplex heaters

Initially, the plant produced three types of extruded polystyrene foam, depending on the density: Penoplex 35 (with a density of 35 kg / m3), Penoplex 45 (45 kg / m2) and Penoplex Standard (32 kg / m3). In addition to density indicators, heaters have different sizes, thicknesses, compressive strength, flammability group and KMO class. The scope of use of each of the heaters also differs.

- Penoplex 35 density belongs to the most popular brands of insulation, which was used to insulate various types of enclosing structures: foundations and plinths, exploited and unexploited roofs, floors and walls.

- Penoplex 45 coped with increased loads when insulating foundation foundations, floors on the ground, as well as highways and railways, runways, bridges, tunnels in the Far North and on heaving soils.

- Penoplex STANDARD most often used for insulating pool bowls, floors and shallow foundations, fire tanks, sedimentation tanks and wells.

Previously, Penoplex was extruded with a standard thickness of 20 to 100 mm, a width of 600 mm and a length of 1200 mm. We've dealt with the old parameters. It's time to find out the modern Penoplex classification.

Density table of insulation Penoplex 35, 45 and Standard

| Density | Length, mm | Width, mm | Thickness, mm |

| 35 | 1200 | 600 | 20, 30, 40, 50, 60, 80, 100 |

| STANDARD | 1200 | 600 | 20, 30, 40, 50, 60, 80, 100 |

| 45 | 2400 | 600 | 40, 50, 60, 80, 100 |

Foam quality

When all other parameters are determined, you need to evaluate the required material for quality. First, you need to ask quality certificates: Responsible manufacturers and sellers always supply the goods with the necessary documentation confirming their quality. Secondly, you need to make sure that the product stored in proper conditions, So what on its packaging the necessary marking is present, informing about the main properties of this material. Polyfoam should not be stored under the influence of direct sunlight: in this case, it loses some of its operational properties, it may begin to emit an unpleasant odor. It is also important that the material is stored in a well-ventilated area and that the humidity is no more than 60%.

Attention should also be paid to the foam granules. They must be of the same size and evenly spaced throughout the volume. If in some places there are voids, and the granules fall off easily, then such a product can hardly be called high-quality. In addition, it will not be superfluous to compare individual sheets of material with each other: they must be absolutely the same in thickness, density, with smooth edges, and snow-white in color.