Projects of houses from a bar

Number of projects 697

- 8 rooms

- 4 bathrooms

House project №12012

- To favorites

- 205² Total area

- 14 x 15m Building area

from 9 752 592 rub.

Construction time individually

- 4 rooms

- 1 bathroom

House project "Palace Mosaic"

- To favorites

- 133² Total area

- 11 x 12m Building area

from 2 946 700 rub.

Construction time 60 days

- 3 rooms

- 1 bathroom

House project no. 59

- To favorites

- 110.11² Total area

from 1 486 485 rub.

Construction time individually

- 7 rooms

- 3 bathrooms

House project # 13050-KB

- To favorites

- 216² Total area

- 16 x 11m Building area

from 7 550 107 p.

Construction time individually

- 3 rooms

- 2 bathrooms

House project "BK 13"

- To favorites

- 11 x 9m Building area

individual calculation

Construction time individually

- 5 rooms

- 2 bathrooms

House project "Paolina"

- To favorites

- 235.2² Total area

- 11 x 18m Building area

from 5 875 000 rub.

Construction time individually

- 4 rooms

- 1 bathroom

Peace House Project

- To favorites

- 116.2² Total area

- 8 x 8m Building area

individual calculation

Construction time individually

- 1 room

- 1 bathroom

House project "Fresh Idea"

- To favorites

- 60² Total area

- 7 x 10m Building area

from 1,025,250 p.

Construction time individually

- 5 rooms

- 2 bathrooms

Mozart House Project

- To favorites

- 146.6² Total area

- 12 x 9m Building area

from 1 600 000 rub.

Construction time individually

- 3 rooms

- 1 bathroom

Alla House Project

- To favorites

- 111² Total area

- 8 x 10m Building area

individual calculation

Construction time individually

- 4 rooms

- 2 bathrooms

Anton House Project

- To favorites

- 188.8² Total area

- 11 x 13m Building area

from 1 800 224 rub.

Construction time individually

- 3 rooms

- 1 bathroom

House project No. 16169

- To favorites

- 85² Total area

- 10 x 11m Building area

from 4 183 001 rub.

Construction time individually

- 4 rooms

- 3 bathrooms

House project "Zemfira"

- To favorites

- 240.7² Total area

- 11 x 20m Building area

from RUB 3,120,000

Construction time individually

- 5 rooms

- 3 bathrooms

Palermo House Project

- To favorites

- 248.87² Total area

- 12 x 13m Building area

from 3 475 000 rub.

Construction time individually

- 6 rooms

- 3 bathrooms

House Project MPC-1816-F0155-0337

- To favorites

- 385² Total area

from 6 774 000 rub.

Construction time individually

- 5 rooms

- 2 bathrooms

House project "4516"

- To favorites

- 158.4² Total area

- 10 x 11m Building area

from 1 645 350 rub.

Construction time 30 days

- 5 rooms

- 2 bathrooms

House project No. 14107-KB

- To favorites

- 170² Total area

- 10 x 11m Building area

from 5 404 821 rub.

Construction time individually

- 5 rooms

- 2 bathrooms

Orlovo House Project

- To favorites

- 202² Total area

- 9 x 12m Building area

from 1 360 000 rub.

Construction time individually

- 3 rooms

- 1 bathroom

Maloyaroslavets House Project

- To favorites

- 118² Total area

- 7 x 9m Building area

individual calculation

Construction time individually

- 5 rooms

- 2 bathrooms

House project Borovsk

- To favorites

- 100² Total area

- 8 x 9m Building area

from 1 100 000 rub.

Construction time individually

See all projects

Timber cottages have been actively built in recent years in Russia. There is a logical explanation for this phenomenon - timber buildings are built quickly, are inexpensive, while they are very comfortable and look great. However, timber walls shrink during the first few years of operation, as a result of which cracks can form on them. For this reason, the heat saving rate of the cottage is significantly reduced and there is a need for insulation.External insulation for buildings made of wood is undesirable - wood without contact with open air begins to rot quickly, in addition, the appearance of a wooden house is lost, which has to be hidden behind decoration. For these reasons, homeowners resort to insulating a log house from the inside.

Insulation of a log house from the inside Source belprim.ru

Why is it rare to insulate a wooden house from the inside

There are at least two reasons for a negative attitude to the process of “warming a log house from the inside”.

- Firstly, after the walls are insulated, the area of the apartment is significantly reduced.

- The second reason is that many are still plagued by doubts about whether the formation of the natural internal microclimate at home is not disturbed.

Since housing can turn into a kind of thermos, although normal ventilation is a guarantee that there is no excessive humidity in the premises, even a couple of years after the walls from the timber have been insulated from the inside.

Timber as a building material for cottages

Wood building materials allow you to build beautiful, comfortable, reliable and environmentally friendly country houses. Modern timber is easy to use and practical to operate. It comes in several flavors:

- Planed

... A regular log is given a square or rectangular cross-section, and the result is a planed bar. It is cheap, but in the process of natural shrinkage it can deform and crack. In addition, such material is unprotected from decay, mold and blue.

- Profiled

... It differs from the planed one by the presence of a sample on the working side, which makes it possible to assemble a log house using the “thorn in the groove” or “comb” technology. Thanks to the availability of sampling, ideal walls can be built without cracks and defects.

- Glued

... The most expensive, but also the highest quality material. It is created by connecting thin, well-dried lamellas. A special harmless glue acts as a connecting substance. Glued laminated timber practically does not shrink, does not crack, is not exposed to the negative effects of moisture and insects.

Wall made of laminated veneer lumber Source klm-art.ru

In low-rise construction, glued laminated timber with a section of 150x150 mm is most often used. This type of wood attracts with the optimal ratio of price and quality. But in regions with cold winters, walls of this thickness may not be warm enough. This problem can be solved with the help of elementary insulation of the house from a bar of 150x150 from the inside.

On our website you can get acquainted with the most popular projects of houses made of laminated veneer lumber from construction companies presented at the exhibition of low-rise country houses.

Important points when insulating

It must be remembered that all of the above heat insulators, except for mineral wool and ecowool, disrupt the natural ventilation of the room, since they do not allow air to pass through. To ensure a normal microclimate, the following measures can be taken:

- regular ventilation of the premises;

- forced ventilation device.

Subject to all the installation rules and taking additional measures to ensure a normal temperature and humidity regime in the premises, the insulation of a house from a bar will significantly save on heating and avoid frequent repairs.

Insulation of log houses

Before starting the insulation process, it is necessary to invite a specialist who will give a professional assessment of the condition of the walls, ceiling, floor and ceilings. For this purpose, the entire building is inspected from the outside and from the inside. As a result of the inspection, you will be given a recommendation - it will be enough to re-caulk, or the house needs to be insulated with insulating materials.

Caulking of a timber wall Source hi.decorexpro.com

If you decide to insulate the cottage from the inside, you need to choose a good insulator for this, which has the following requirements.

- Efficiency

... After installing the insulation, the house should become much warmer and more comfortable, and heating costs should be reduced by an order of magnitude.

- Environmental friendliness

... This indicator is especially important for internal insulation. They should not emit substances harmful to humans.

- Fire resistance

... Most effective insulation materials ignite when exposed to open flames. You need to choose a material that either burns weakly, or generally has a tendency to fade.

- Durability

... Sheet and roll heat insulators must be replaced periodically. But the less often you have to do this, the cheaper and easier it will be to service at home.

- Ease of use

... The simpler the installation technology, the cheaper each replacement will cost.

Insulation for interior walls Source: advancedhomenow.com

On our website you can find contacts of construction companies that offer a house insulation service. You can communicate directly with representatives by visiting the Low-Rise Country exhibition of houses.

Why is it cold in a wooden house?

Heat loss in a wooden house can occur through:

- walls, due to their insufficient thickness, the width of the heat seam, the method of making corner joints;

- ceiling;

- floor and foundation.

Pay attention to the tightness of the window structures, the correspondence of the number of chambers to the climatic conditions of the region.

About how to insulate a house from a bar outside, as a rule, is considered at the design stage (of course, if glued material is not used for construction). Often, houses from this material are initially built with the expectation of further exterior decoration, which is mated with the device of the heat-insulating layer.

There is a similar article on this topic - Glued laminated timber: pros and cons.

In this case, it is possible to use a material with a smaller cross-section, which reduces the overall construction costs. Houses made of chopped or rounded logs, as a rule, do not imply external cladding, but if there were errors in calculating the thickness of the material, then it will be cold in such a house, and in order not to violate the architectural style, it will have to be insulated from the inside.

Heat can also escape from the house through inter-crown joints, the so-called heat seams, despite the fact that during the construction of the log house, an inter-crown insulation for the timber was laid in them.

Even if their width is sufficient, gaps appear between the crowns as a result of shrinkage processes. Repeated caulking of the walls in many cases is quite enough to cope with the problem.

With inadequate insulation of the ceiling and floor even during the construction stage, these structural elements of the house can become the main cause of cold in the house.

If there is an attic floor, it must be done insulation of the roof of a wooden house from the inside, while the choice of materials should also be made taking into account sound and noise-absorbing abilities - otherwise, even in a house located far from megacities, one can only dream of silence.

Also, the foundation of the house should be properly insulated, since, when freezing, it will also cool the walls, and they, in turn, the air in the room.

Materials for warming a log house

Internal insulation of a house from a bar is most often performed using the following materials:

- mineral wool;

- ecowool;

- penolirutan;

- Styrofoam.

Minvata

It is a very effective insulator with low thermal conductivity and good sound insulation properties. It is quite safe in terms of ignition, resistant to temperature changes, and has a low cost.

However, this material has its drawbacks. For interior decoration, it must be laid in a thick layer, otherwise condensation may accumulate with all the negative consequences.In addition, mineral wool particles can cause an unpleasant reaction on contact with the skin. Therefore, you need to work with her in a special suit and a respirator.

Ecowool

Modern advanced material. More effective than mineral wool. The main advantages are vapor permeability, which allows you to preserve the characteristics of wood walls, and the ability to maintain thermal insulation qualities even when wet. Ecowool is environmentally friendly, durable and economical. The disadvantages here are as follows - since ecowool is made from waste (usually from waste paper), its quality is quite difficult to control even at the production stage. In addition, the installation of such insulation requires the involvement of highly qualified specialists.

Thermal insulation of the house with ecowool Source 24dom.ru

This might be interesting!

In the article at the following link, read about log houses with a terrace.

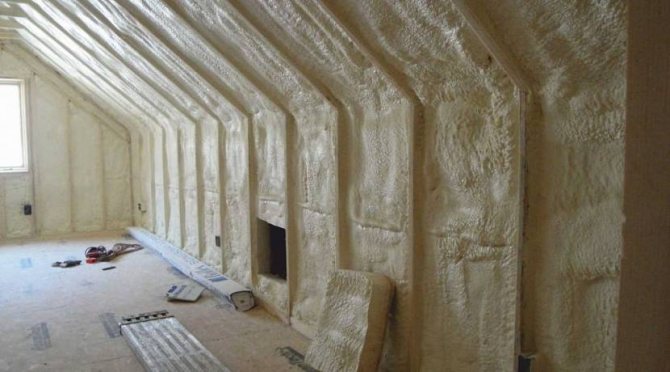

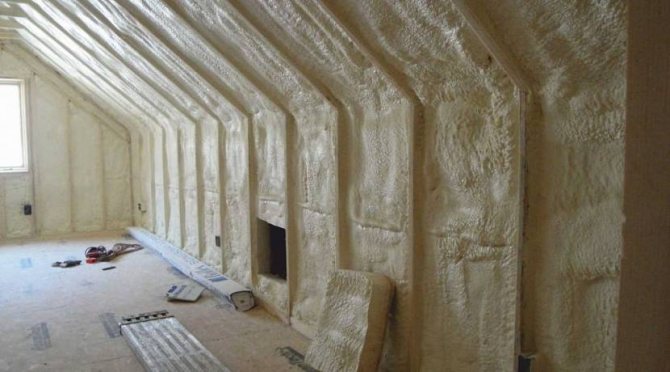

Polyurethane

Another version of modern insulation with improved properties. This is the most effective insulation to date. Its thermal conductivity is minimal. It is achieved due to the porous structure of the material. It is applied by spraying, due to which the formation of "cold bridges" is excluded. Polyurethane can be used to insulate vertical and inclined surfaces. It is vapor permeable and has the ability to damp when ignited.

Of the minuses, it should be noted the complexity of mounting this material. It is also important that polyurethane is vapor-tight, which means that when using it, it is necessary to equip a ventilation system.

Polyurethane as insulation for the attic of a log house Source vashdomtc.ru

Styrofoam

Traditional foam has proven itself as a reliable and effective insulation material. It is an excellent noise isolator, self-extinguishing, easy to work with and inexpensive. But at the same time, it is distinguished by high water absorption and low vapor permeability. Among other things, rodents love him.

Polyfoam for insulation of premises Source applesakhalin.ru

Thermal insulation technology

Sealing seams

Before we insulate a log house from the inside, we need to prepare it for finishing.

And first of all, all the cracks are required here:

Caulking walls

- All gaps between the bars are cleaned of dust and debris.

- We take the caulking material and put it in the cracks.

- Using a special spatula, hammer jute, tow or moss into the voids with the blows of a mallet until they are filled.

- We carefully cut off the excess.

Warming a house from a 150x150 bar from the inside (ie, a structure with thick walls) is sometimes accompanied by the arrangement of "warm seams":

- In the gaps between the crowns we place a cord made of foamed polyethylene.

- From above we cover the cracks with acrylic sealant, painted in the color of the tree.

Formation of a "warm seam"

This technology is more expensive, but it allows you to reliably protect all seams and crevices from moisture and blowing.

Preparation for insulation

General scheme of thermal insulation

The insulation itself inside the house from a bar is carried out according to the following scheme:

- First, we prepare the walls for thermal insulation, cleaning them and treating them with protective compounds. For this purpose, antiseptic water-repellent impregnations are best suited, which cover the wood with a thin film and prevent it from swelling upon contact with moisture.

Note! The scheme for insulating a bath from a bar inside also involves impregnating the tree. But for this purpose, it is advisable to use specialized formulations specially designed to withstand intense moisture at high temperatures.

Special impregnation for baths and saunas

- Then we mount a vapor barrier membrane on the wall, which will protect the heat insulator from contact with wood from moisture.

- On top of the membrane, we assemble a crate of wooden planks. The distance from the edge of the sheathing to the wall should correspond to the thickness of the insulation panels used.

- We choose the step of the lathing so that the slabs fit tightly into the resulting cells, but without compression.

Important! At this stage, holes are made in the crate for hidden laying of communications - pipes and wires. To ensure safety in the place of contact with wood or insulation, electrical wiring must be placed in non-combustible casings and metal hoses.

- We lay a waterproofing membrane on the ground in the underground space, leading it to the walls by about 10-15 cm.

Installation of thermal insulation material and cladding

Instructions for performing further work are also not complicated.

We start from the bottom floor and then gradually move on to the walls:

Insulated floor vapor barrier

- In the underground space, we pour expanded clay onto the waterproofing layer or lay mineral wool panels. Cover the top of the insulation with a vapor barrier membrane and mount the subfloor.

- Plates of mineral wool with a thickness of 50 to 150 mm are placed in the crate cells. If necessary, fix each panel with glue or several dowels with old-style plates.

Photo of thermal insulation panels inside the crate

- We cover the insulation with a vapor barrier membrane or glassine.

Advice! Before insulating the bath from the inside from a bar, it is worth purchasing a roll of foil film based on polyethylene foam. It will provide more efficient heat retention in high temperature conditions and better than conventional film, will protect the mineral wool from getting wet.

- On top of the glassine we fill a counter-lattice - thin wooden slats with a section of 15x15 or 20x20 mm. The main function of this structural element is to provide a ventilation gap inside the wall.

- We mount the cladding on top of the counter-lattice. It can be drywall panels (it is best to use moisture resistant) or a lining board.

The multilayer structure obtained as a result of our actions will provide reliable thermal insulation of the timber walls and guarantee the formation of a favorable temperature regime. At the same time, internal insulation disrupts natural air exchange, therefore, to get rid of excess moisture, it is worth taking care of high-quality ventilation.

Stages of work on the insulation of internal walls

Warming of the premises of a log house must be done very carefully and carefully. Poorly performed insulation work will lead to the fact that cold and dampness will still penetrate into the house, and the insulation will have to be shifted again.

Preparation of premises

First you need to remove trim, dirt and dust from the walls. After that, the wooden walls are treated with a special septic tank that protects the tree from mold and insects. In addition, it is necessary to treat the timber with a composition that reduces the flammability of the wood material. During preparatory work, all wiring must be separated from the walls. Then it can be returned to its place.

Caulking walls

At this stage, you should walk along the walls and close absolutely all cracks, including the smallest ones with jute fiber. This procedure is carried out on the outer walls every 2-3 years, and on the inner walls with each replacement of the insulation.

Vapor barrier

In order for the tree not to deteriorate from the accumulating condensate, before laying the insulation, it should be covered with a vapor barrier film. Vapor barrier is especially important when insulating internal walls with mineral wool or foam.

Vapor barrier in a house from a bar Source optopg.ru

This might be interesting!

In the article at the following link, read about log houses with a garage.

Lathing

At the next stage, a frame is constructed that will hold the insulating materials - the crate. It must be installed before insulating the house from a bar from the inside with any roll or sheet material.Spray-applied liquid insulation does not require a frame. For the lathing, bars with a cross section of 50 to 50 mm are used.

Insulation laying

Insulation is placed between the battens of the crate and fixed to the wall. It is important to cover the entire surface with an insulating material so that there are no gaps between it and the sheathing bars. Particular attention should be paid to the high-quality fastening of the upper and side edges of the insulation.

Laying insulation in the frame of the sheathing Source sovetclub.ru

Ventilation system

A too humid microclimate is created in a house that is insulated from the inside. As a result, condensation settles on finishes, furniture and other interior items. To avoid this, you need to immediately think over a good forced ventilation system when arranging insulation.

Experts recommend, in each individual case, to develop a layout for the air ducts, which will be hidden under the outer cladding and connected into a single system through the attic ventilation openings.

Finishing work

After laying the insulation, the wall is sewn up with sheets of drywall. Previously, you can lay a second layer of vapor barrier on the insulating material. After installing drywall, the walls are decorated with any material to the taste of the homeowners. This can be a natural timber finish or any other option.

Internal insulation technology

Let's start by preparing the surface of the walls by cleaning it from dust and grease. Further, with the help of a special antiseptic emulsion, the wood is processed to resist the appearance of mold and insects. In addition, fireproofing of the walls is carried out.

Caulking bar

Further, the insulation of a house from a bar from the inside consists in digging all the cracks. Use jute fiber for bleeding. This fiber, due to its structure and long-term use, perfectly closes the cracks.

Somewhat larger gaps are sealed with tape tow, which is rolled into rollers. It must be said that the insulation of a log house from the inside will only become effective when the cracks are caulked under the throat.

Installation of vapor barrier

It is also worth noting that the correct insulation of walls from a bar from the inside cannot do without installing a vapor barrier film. The rough side of the film is laid in the direction of the timber wall, which ensures the removal of moisture from it towards the room. So that the apartment itself does not turn into a thermos, forced ventilation of the premises is organized.

Lathing

After that, the insulation of the house from a bar inside consisted in the organization of the crate, on which the mineral wool would be held. The lathing is organized using wooden blocks. A metal profile can also be used if you plan to further cover the apartment / house with plasterboard moisture-resistant sheets.

We will talk about wood, since the whole structure of a log house looks better with a wooden clapboard. To obtain even correct angles, which is required by the correct insulation of a log house from the inside, several corner posts are made in advance, the height of the walls is measured and wooden beams are cut to this size (section 5x10 centimeters).

After that, wooden beams of 5x5 centimeters are cut (the same length). Some bars are attached to others, after which a corner stand is obtained in the form of the letter "G". These racks are placed in each of the corners of the house, after which beams are vertically mounted between them (section 5x5 cm).

The distance between them is chosen according to the width of mineral wool, which is used as insulation for the walls of a log house.

It is worth noting that all wood, like walls, is treated with special antifungal solutions so that the insulation of a house from a bar from the inside lasts as long as possible.

Insulation installation

Insulation for the walls of a log house (selected mineral wool in a roll) is unwound and cut to the height of the wall, given that its width should exceed the distance between the posts by 10-20 millimeters.

After that, the mineral wool is placed between the beams and fixed on the wall itself with anchors. To do this work, you need to invite a friend, since it is rather difficult to do it yourself.

Second layer of insulation

After the mineral wool is laid and fixed, the insulation of the walls from the timber from the inside requires the organization of a second layer of vapor barrier. The membrane film, as in the first layer, is placed with a rough surface towards the wall.

In addition to the fact that with the help of the film, excess moisture will be removed from the walls, which prevents the formation of condensation, it will become an obstacle that will not let the dust from mineral wool into the living quarters.

Ventilation

Another important part of the process of "insulating a log house from the inside" is the organization of normal ventilation so that moisture does not accumulate in the dwelling, and a normal flow of fresh air is carried out. Let's immediately abandon direct external hoods, deciding in the attic to tie all the air ducts into one circuit.

As a blower, you can choose an axial fan with a low power, which, as experience has shown, allows you to ventilate the whole house in just half an hour in winter.

Finishing

It must be said that the insulation of a house from a bar from the inside should end with an "aesthetic component" - the finishing of the entire structure. As described earlier, a wooden lining is best suited as a finish, which is mounted on beams (section 30x40 millimeters) attached to the wall on top of a waterproofing film.

After the installation of these bars, the insulation of the house from a bar inside consisted of cladding with a wooden lining. It was also chosen because the insulation did not violate the original plan to create an interior with an abundance of wood.

This is where the whole process is over. If you have any questions, write in the comments at the bottom of the article.

Author: Vladimir Segodkin, Novgorod, 2014.

More on this topic on our website:

- How to properly insulate the walls in the bath from the inside - methods and options After the construction of the bath is completed, the question arises: "how to insulate the walls in the bath from the inside with your own hands?" Before proceeding to the process of warming, you must choose the appropriate ...

- Practical material from our reader Andrey Khabarovtsev from Tyumen. Insulation of a brick house from the inside, which can be done with foam plastic, private developers and owners of houses and apartments ...

- Insulation with sprayed polyurethane foam is simply necessary in our climatic conditions, since cold winters force you to spend a lot of money on heating the premises, and in summer you need to turn on the air conditioner to ...

- How to insulate walls with foam from the inside is a very controversial issue at the moment. In general, foam is an inexpensive type of material that is endowed with good thermal and insulating ...