Types of heaters

Before starting work, it is better to familiarize yourself with the basic insulation materials for the garage. This will greatly simplify the choice of insulation for finishing the ceiling.

Styrofoam

Styrofoam sheets are considered the most common material for ceiling decoration in garages. Their main advantages are considered to be tolerance to high humidity, resistance to low temperatures, ease of use, low price, as well as long-term heat retention.

However, the sheets also have disadvantages, which are better to be familiar with before using them. These include poor protection against mechanical damage and high flammability. Experts advise using foam sheets with a size of 100 x 100 mm to cover the ceiling surface.

Mineral wool

Many people prefer to make thermal insulation using mineral wool. In this case, two main types of this thermal insulation material are used:

- Slag. It is considered to be of the highest quality and most reliable, since it is resistant to fires and temperature changes. However, builders do not advise using slag-type cotton wool in rooms with high humidity, since in such conditions it will quickly deteriorate.

- Basalt. This type of cotton wool is used in conjunction with a waterproofing material that will provide additional protection against moisture. Among the advantages of basalt material are low price and durability.

Expanded polystyrene

Some people confuse this material with polystyrene foam, but polystyrene foam has characteristics that are better to become familiar with. Its main advantage is considered to be durability, thanks to which expanded polystyrene does not deteriorate for 20-25 years. Also, the sheets are protected from fire, low temperature and humidity.

Glass wool

Glass wool is often used to save money, since it is cheaper than most other materials. It must be used very carefully, as it contains crumbling glass chips. Therefore, when working with glass wool, it is worth using gloves to protect your hands and special glasses that protect your eyes.

Expanded clay

Expanded clay is called a porous material that is made from shale and fired clay. It is considered universal, since it can be used to insulate floor coverings, walls and ceilings. Some people use it in horticulture and add it to the soil mixture.

Penoizol

Penoizol is least often used, since it has recently appeared on the domestic building materials market. People who are professionally engaged in insulation of premises are advised to use penoizol. It retains all its properties and does not deteriorate for about forty years.

Why insulate the ceiling in the garage?

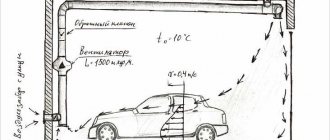

This is, of course, not about metal garages, but about capital buildings located near the place of residence. Often, such buildings have a concrete ceiling overlap, which has the property of absorbing a significant amount of moisture. For a car, high humidity from the inside is the worst enemy, as it provokes corrosion of metal parts. In addition to the humidity indicator, temperature values are also important. In winter, it will not be warm at all in the garage without insulation. Accordingly, if you place a car that is hot while driving, condensation may form inside as it cools.This will have a detrimental effect on both the condition of the body and the condition of the electrical system and all internal equipment.

The issue of insulation is especially acute for those drivers who prefer to leave the car in the garage for several cold months. Even one winter season of parking in a garage without special training can significantly worsen the condition of the "iron horse". It is also important to take into account the fact that the roof of concrete garages is often replete with cracks. During the autumn and winter seasons, the vehicle will be constantly exposed to water droplets. Summing up the above, it is easy to understand that insulation of the garage roof is by no means superfluous. The work is quite simple to do on your own, especially if they are carried out from the inside of the room.

Required tools

Before insulating the garage ceiling, you will have to familiarize yourself with the list of the main tools that will be needed to complete the work. To install the insulation material, you will have to prepare:

- Self-tapping screws. These are fasteners that are used to secure foam sheets or other thermal insulation products to the ceiling.

- Special glue. Some builders use glue instead of self-tapping screws, which is able to attach insulation to almost any surface.

- Steppler. Sometimes you cannot do without a construction stapler, which fixes the insulation with the help of plates.

- Roulette. No construction work is complete without this measuring device. A tape measure is used to measure and determine the optimal width and length of thermal insulation materials.

- Level. Builders advise using bubble levels to help determine and control the evenness of the ceiling surface.

- Saw. Used for cutting dense insulation material. When working with glass wool or mineral wool, scissors are used instead of a saw.

Preparing the surface for insulation

Before carrying out work on the insulation of the ceiling, they are engaged in preliminary surface preparation. Despite the fact that the preparatory work is easy, it is still better to familiarize yourself with the nuances of their implementation in advance.

The indoor ceiling surface is completely cleaned of dirt and old finishing materials. After cleaning from dirt, the surface is carefully inspected and checked for mold or mildew.

If, when examining the ceiling, a fungus with mold was detected, you will have to get rid of them. To clean the surface, use bleaching agents or other solutions with similar properties. However, bleaches can help eliminate new fungus. If it is deeply embedded in the coating, you will have to completely remove the affected area and recoat it with a primer.

Experts advise, before insulating the ceiling, to cover its surface with primer mixtures, which contain antiseptic trace elements. These components will protect the ceiling from mold. Also, for priming, mixtures are chosen that are quickly absorbed.

Why, in general, do you need to insulate the ceiling?

Speech in this article, as you know, is not about iron garages, but capital ones. And they, as a rule, are made of concrete, which, without proper protection, strongly saturates moisture.

And moisture is the first enemy of the car, as it provokes the rapid development of corrosion on metal parts.

In addition to moisture, temperature also matters. If it is very cold outside, so does an uninsulated garage. This means that if you put a car heated up while driving, then as it cools down, condensation will form inside.

This harms the electrics, the body and everything that is possible inside.

The issue of insulation is especially relevant for those who put the car in the garage for a long time, for months.Just one winter spent in an unprepared garage with a car can seriously ruin it.

Also, one cannot fail to take into account the fact that roofs in concrete garages very often have cracks. That is, during the rainy and snowy season, water can constantly drip onto the car.

So, it is necessary to insulate the roof of the garage and this is not at all an excess. Moreover, it is not difficult to do it with your own hands, especially if you do not do it from the side of the attic.

Ceiling insulation technology

In order to properly insulate the ceiling in the garage with your own hands, you will have to deal with the nuances of the process outside and inside the room.

Outside

It is advised to insulate the garage outside only if there is an attic above the garage. When performing insulation work, the following sequence of actions is followed:

- The ceiling is thoroughly cleaned of old finishing materials, dust and dirt.

- The surface is upholstered with wooden bars, to which the insulation will stick.

- The thermal insulation material is fixed to the bars with a stapler, screws or glue. If there are wide gaps between the wooden beams and the insulation, they will have to be blown out with construction foam.

- The insulation is covered with geotextile or other vapor barrier material.

After the outer part of the ceiling is insulated, the heat-insulating layer is covered with a crate and finished.

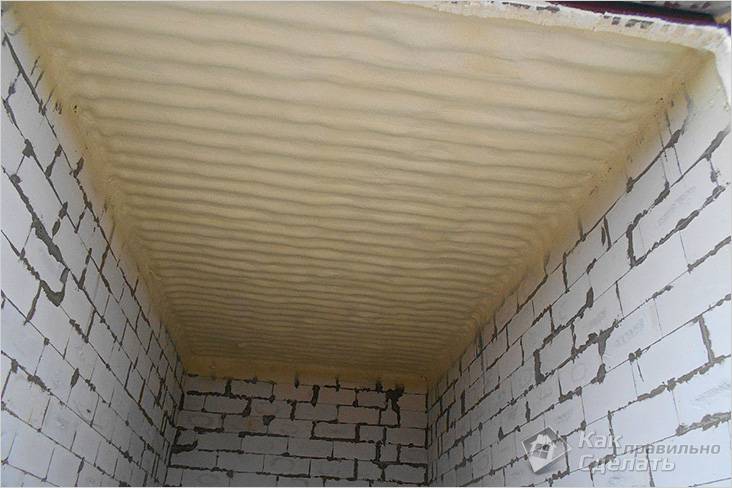

From within

For internal installation of insulation, it is not necessary to sheathe the ceiling with wooden bars, and therefore the adhesive solution is applied directly to the material and the ceiling. Cavities in the area of joining seams are filled with glue or construction foam. Some builders fix the edges of the insulation with dowels for greater reliability.

We insulate the garage with our own hands

How to insulate the ceiling in the garage? When choosing thermal insulation, you need to take into account the features of the building itself. This is an unheated or periodically heated room, therefore the insulation should not lose its technical characteristics in a wide temperature range. On the other hand, a heater is bought with a minimum moisture absorption coefficient, since there is always a possibility of condensation in the garage. The effect of chemically active substances is also taken into account. These are vapors of fuels and lubricants and gasoline.

They are capable of accumulating in the inner lining of a building, increasing its flammability and changing its operational characteristics. That is why insulation with minimal vapor absorption is suitable here. Considering all of the above factors, ceiling insulation in the garage can be carried out with the following materials:

- mineral wool;

- fiberglass;

- polymer insulation - polystyrene, polyurethane foam, etc.

Materials based on mineral fibers can be used provided that a good vapor and water barrier is provided.

Insulation of the garage roof from the inside can be done with fibrous materials. If the work is carried out from the side of the attic or the roof, it is necessary to choose thermal insulation with sufficient bending and compressive strength.

Thermal insulation of the floor inside the building

The height of the lag should be greater than the width of the mineral wool.

Glass wool is selected for interior work. It is made on the basis of glass processing waste. The thickness of the fibers is in the range of 3-15 microns, when their length reaches 1 m, due to which the glass wool has elasticity. On sale you can find both roll and board material. The latter is more expensive than the former. However, it is easier to work with the plates. In addition, they are characterized by a fairly high bending and compressive strength.

Glass wool specifications:

- density - from 11 to 25 kg / cu. m;

- thermal conductivity - 0.029-0.041 W / (m * K);

- flammability - NG, G1;

- vapor permeability - up to 0.6 mg / mh * Pa;

- moisture absorption - up to 0.8 kg / sq. m.

The mats should fit snugly.

Fiberglass can be used over a wide temperature range (-60 ° C to + 250 ° C). Due to its low density, the insulation is quite light. This simplifies its installation. Also read: "Penofol insulation: characteristics, application".

How to insulate a garage roof from the inside with fiberglass? Materials installation procedure:

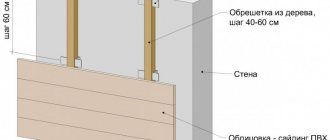

- lathing;

- hybrid barrier;

- directly insulation;

- vapor barrier;

- the second tier of the lathing;

- finishing material.

There must be a ventilation gap between the hydro-barrier and the mineral wool.

Wood or metal is taken as a structural material for the lathing. The first option is notable for its affordable cost, but the wood must be treated with an antiseptic. This will prevent spoilage. The second option is distinguished by its durability and strength, but also by its high price. Regardless of the material chosen, the height of the battens must be greater than the thickness of the fiberglass board. This is necessary for the organization of the ventilated gap.

The step of the lathing should be equal to the width of the insulation plate. This is the only way to securely and efficiently fix the thermal insulation. Installation is carried out either using self-tapping screws (in the case of wood), or using an anchor (metal frame). The lathing should not come close to the edge of the roof. The expansion gap should be maintained here.

Insulation of the ceiling in the garage from the inside is continued by the organization of a hydro-barrier. It will protect the insulation from possible roof leaks. Special membranes can be found on the market today. They do not allow moisture to pass into the thickness of the insulating cake, but they also do not interfere with steam exchange inside it. Hydro-barrier sheets are overlapped (at least 10 cm). The joints are glued with construction tape. The material is fastened along the logs using a stapler or special staples.

All work can be done by hand. However, if a person does not have the necessary skills and does not know how to insulate the ceiling in the garage from the inside, it is better to trust the specialists.

It is not for nothing that panel material was chosen as the main insulation. It is easier to lay it on the edge, that is, the slabs adjoin closely to the frame of the sheathing. Also, there should be no gaps between the plates themselves. Through them, the cold will penetrate into the garage, and the quality characteristics of the thermal insulation cake will come to naught.

Before insulating the garage roof from the inside, calculate the required thickness of the insulating material. During the calculations, the characteristics of the structural material of the garage, the climatic features of the region where it is located are taken into account. The calculation formula can be found in the regulatory documentation.

On top of the insulation along the crate there is a vapor barrier. It can be a regular plastic wrap. It also overlaps. There should be a ventilation gap under it. Condensation will be discharged through it if such falls on the insulation. This is followed by the second tier of the lathing. The finishing of the ceiling is laid on it.

You can find a drawing of a long-burning furnace, but to understand it you need to work hard.

Correct installation of a long burning stove in the house is a guarantee of safety. Continued here.

External insulation of the room

Liquid foam - penoizol.

How and how to insulate the garage roof from the inside? In this case, a thermal insulation material is selected with the following quality characteristics:

- with a low coefficient of moisture absorption;

- vapor-proof;

- resistant to deformation;

- with low weight;

- with high strength.

Insulation of the garage roof from the outside can be done with polystyrene foam, since it meets all of the above requirements. Its main properties:

- thermal conductivity from 0.037 W / sq. m * K up to 0.041 W / sq. m * K;

- vapor permeability up to 0.05 mg / cu. m;

- density - from 8 kg / cu. m up to 25kg / cu. m (depending on the brand);

- water absorption from 25 to 4% per 1 cu. m;

- compressive strength from 0.04 MPa to 0.16 MPa;

- bending strength from 0.06 MPa to 0.25 MPa;

- self-burning time from 1 sec. Up to 4 sec;

- temperature range -60 ° C ... + 80 ° C.

Due to its low density, the material is lightweight. It does not create additional load on the floor. That is why it is possible to carry out insulation of the ceiling in the garage with foam from the inside. Low vapor permeability and moisture absorption allow you to mount the insulation outside the building without fear of getting it wet. Polyfoam does not rot, does not lend itself to the action of an aggressive environment.

The main stages of the work:

- surface preparation;

- installation of the lathing;

- organization of a vapor barrier;

- laying insulation;

- hydro-barrier;

- the second tier of the lathing;

- roofing material.

The roof of the garage can be the floor of the second floor.

Before insulating the garage roof from the outside, surface preparation is carried out. It consists in removing old, roofing material, rotted sections of the rough covering, protruding nails. Next, a counter crate is organized. It is made of wooden blocks. They are pretreated with an antiseptic. The step of the crate is equal to the width of the foam. The wood is fastened with self-tapping screws.

Although the foam is vapor-tight, the installation of a vapor barrier is necessary. Moisture vapors from the room always tend upward. After passing through the wooden roof deck, they will condense on the cooled foam. A vapor barrier will prevent this. Polyethylene or a special membrane is used as a vapor barrier. She goes over the top of the crate. It is mounted with an overlap, the joints are glued with construction tape.

Laying the insulation directly. Styrofoam should go by surprise between the crate. However, for reliability, experts recommend carrying out additional fasteners using dowels with wide heads.

There should be no gaps between the foam sheets. Possible gaps must not be foamed with polyurethane foam. Everything is explained simply: foam and polystyrene have different coefficients of thermal expansion, which will negatively affect the performance of the thermal insulation cake.

On top of the insulation there is a hydro-barrier. It can be roofing material. However, the modern construction market offers to buy geotextiles as a waterproof shell. It does not allow water to pass through, but also does not interfere with the exchange of steam between the roofing cake and the environment. Geotextiles can also be used when the ceiling is insulated in the garage with your own hands from the inside. This vapor-permeable material helps to maintain the desired microclimate in the room. On the geotextile, the second tier of the sheathing is mounted and roofing work is carried out.

What materials are used for cladding

After the ceiling is insulated, the surface is finished using various materials. Traditional cladding uses:

- Plaster. Most often they use plaster mixes, which not only level the surface, but also additionally protect it from high humidity. Also, when plastering, a finishing putty is used, which can be painted in the future..

- Tree. Some people prefer wood, which will make the garage space cozier. For finishing, sheathing boards, wood paneling and beams are used. The main advantages of such materials are considered their aesthetics, thermal insulation and environmental friendliness.

- PVC. Another common facing material is PVC panels. Their advantage is the simplicity and speed of installation. Even a person who has never been involved in repair and construction work will be able to sheathe the ceiling with such panels.