14 September 2020 Stroyexpert Main page »Foundation» By construction object

The foundation of all structures must be reliable and warm. The base of the bath is no exception. However, many bath owners have the opinion that warming the base of the bath is an unnecessary waste that can be easily avoided. The main reason for this erroneous opinion is that the baths are heated quite rarely (let's say once a week) and you can sacrifice firewood and time to heat it to the required temperature. But in fact, the essence of warming the basement of a bath is to preserve its integrity for a long time. It is quite simple to insulate the foundation of a bath with your own hands, so every owner should think about this procedure.

Why is it necessary to insulate the base of the bath

The main reasons for basement insulation are the following:

- if the bath is heated in winter, then a lot of condensation forms on the surface of the foundation from the outside. This is due to the high temperature difference inside the building and outside. The formation of condensation leads to the development of processes of decay and the formation of mold, and this, in turn, reduces the service life.

- in turn, in summer, the ground under the bathhouse is cool, and inside the building it is very hot. Thus, a serious temperature difference is created, and moisture begins to collect on the inside of the building, which will be there during the warm season.

- baths without insulation on the foundation require frequent laying of firewood during the fire, since the heat quickly disappears.

- freezing of the soil in winter leads to swelling of the soil, and this, in turn, leads to deformation of the foundation. The insulated foundation is less susceptible to this damage.

- also a layer of insulation reduces mechanical damage to the base of the structure.

Thus, the constant exposure to moisture and soil leads to a slow but sure destruction of the most important part of the structure - the foundation.

Insulation of the foundation is carried out from all sides with the proper amount of funds and with the availability of the sides of the foundation. However, the most commonly used option is external insulation of the foundation. Using only internal insulation does not give the desired effect, since the foundation will freeze from the outside and gradually collapse. Only internal insulation is used in cases where the outer side of the base is inaccessible for some reason.

Thermal insulation of the walls of the bath from various materials

A wooden bathhouse built in the best Russian traditions, as a rule, does not need special insulation. But structures made of bricks or blocks must be insulated.

Thermal insulation of a wooden bath

A wooden bath is simply insulated. First, you need to close up the cracks with a sealant, bundle insulation, and other options that can be crammed into the cracks. If the climatic conditions are rather harsh, then the wooden structure can be additionally sheathed.

This will require a lathing made of timber or metal guides, insulation, protection from wind and moisture, and a final layer of finishing materials that sheath the structure with. For cladding, siding, edged board, lining, block house, and so on are suitable. From the inside, the bath can be insulated in the same way.

Details and features of the insulation of a wooden bath (log house, timber) are discussed in more detail in this article.

Warming of a frame bath

The thermal insulation of the frame bath is made according to the above technology with the help of a thick vapor barrier foil, insulation and finishing materials for the bath covering it.

Read more about warming a frame bath in a special article.

Thermal insulation of baths from foam blocks, expanded clay concrete blocks, gas silicate blocks and cinder blocks

Insulation of such a bath can be performed in the same way as insulation of a structure made of brick or wood. If a positive temperature is constantly maintained inside, then it would be ideal to sheathe the structure with decorative bricks.

Details and features of the insulation of baths made of foam blocks, expanded clay concrete blocks, gas silicate blocks and cinder blocks, we considered in a separate article.

Insulation of a brick bath

The brick bath must be insulated, because the brick has increased thermal conductivity. For external and internal insulation of the bath, mineral wool, expanded polystyrene, polystyrene foam are suitable. Styrofoam is a cheap material, but it will not work for internal insulation. It is not protected from rodents and insects, or from excessive moisture.

To increase the effect, it is better to overlap the layers of insulation. But this leads to excessive consumption of material, therefore, most often the joints of the plates or mats are simply glued with reinforced tape.

A reinforced mesh is placed on top of the insulation, primed and then plastered.

We examined the insulation of a brick bath in more detail in our next article.

Materials for insulation of foundations

Thermal insulation of the bath foundation will be performed correctly if the following issues are correctly considered:

- the selection of insulation material was carried out;

- selected method of thermal insulation;

- the types of work that are preferable for this type of soil have been thought out.

Today the choice of materials for insulation is very wide, however, there are certain materials that are used most often:

- free-flowing mixtures. The main insulation material in this category is expanded clay. Currently, it is very popular due to its environmental friendliness, high thermal insulation properties and quality. As a rule, restrictions on the use of expanded clay are associated with its high cost.

- insulation of the foundation with foam. This is the most common thermal insulation material. The huge popularity of the material is due to its high thermal insulation properties. Polyfoam significantly reduces heat loss and saves on fuel. It is very easy to mount on the foundation, and most importantly, you can install it yourself.

- thermal insulation material - polyurethane foam. It is applied using special equipment, which significantly limits its use. Due to the need to use special equipment for applying to the foundation, polyurethane foam is expensive and it is rather difficult to apply it on your own.

- extruded polystyrene foam. This material is much lighter than polystyrene and surpasses it in thermal insulation properties. In addition, expanded polystyrene is more durable than polystyrene foam.

Thus, the best material for warming the basement of a bath is expanded polystyrene: it is easy to install, it is strong itself, has high thermal insulation properties, and is durable. The second material after expanded polystyrene is polystyrene foam.

How to insulate the bath outside

Sometimes, without insulating the foundation from the outside, the "builder" realizes himself, decides that nothing terrible has happened and begins to insulate it from the inside. This can be done, but is strongly discouraged. Because such actions will lead to increased freezing of the foundation walls in winter. Having fenced off the remaining heat inside, you completely give them up to be torn apart by frost through the outer non-insulated part.The soil will begin to "heave" with a vengeance, which means that the foundation will collapse much faster.

It is not worth insulating the inside, leaving the outside without insulation.

Two technologies are used to insulate the sauna outside: "wet facade" and "ventilated facade". In the first case, foam plastic, expanded polystyrene or basalt wool slabs act as thermal insulation. First, they are glued to the wall with foam, additionally fixed with umbrellas with plastic dowels, and decorative plaster is applied on top.

Inside the bath, the ceiling is insulated in the same way as the walls, and a ventilated space is arranged. Outside from the attic side, a different technology is applicable. When the rough ceiling of the boards is lined, it is covered with two layers of fiberglass. Roofing material is undesirable to use, since heating will cause an unpleasant smell of bitumen inside the steam room.

Even rolled mineral wool can serve as thermal insulation, but in order to save money, natural materials are used for insulation. The space between the beams is covered with expanded clay. Kneading clay with the addition of fine straw, shavings, sawdust is suitable.

When the clay filling hardens and dries out, plates of foam or expanded polystyrene are laid on top. The thermal insulation is covered with waterproofing, a thin concrete screed is poured. You can even walk on such a surface. If the attic of the bath is set aside for a rest room, after insulation, a final floor is laid with a final layer.

To make sure of the importance of external insulation of the foundation, it is worth considering 5 reasons:

- On a cold foundation in winter, a temperature difference forms in a heated bath. The resulting condensation destroys the concrete base.

- The problem with condensation occurs even in summer. An uninsulated foundation is warmed up from the outside by the sun, but from the inside it pulls the cold and moisture of the earth. Similarly, the temperature difference is obtained.

- The foundation not insulated from the outside cools the steam room faster. The bath has to be heated more often.

- Outside, thermal insulation in winter softens the impact of heaving soil on the foundation.

- A thick layer of thermal insulation on the outside protects the foundation from destruction, accidental mechanical stress.

The listed 5 reasons convince that the insulation of the basement of the bath from the outside is necessary. It can be carried out simultaneously with thermal insulation from the inside. It is impossible to do only internal insulation of the base of the bath. From the temperature difference, concrete will begin to collapse from the side of the street.

There are different ways to insulate the base from the outside. All of them depend on the type of soil where the bath is built, as well as on the very structure of the foundation.

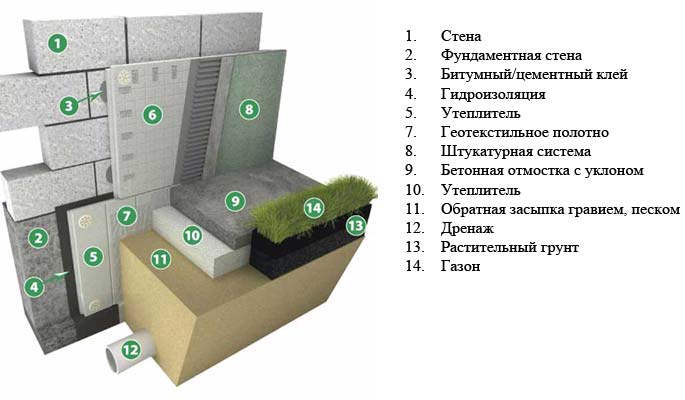

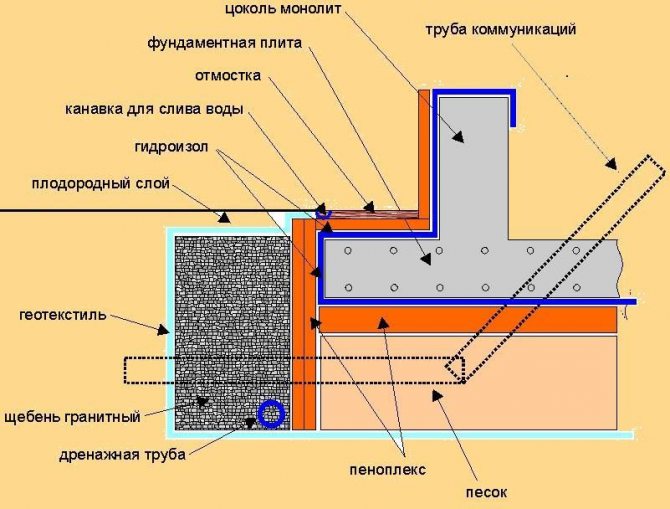

The strip foundation around the outside is dug in a trench 50 cm wide. The depth is maintained at least 80 cm. A 20 cm layer of sand is poured into the trench. The concrete tape is cleaned of dirt and treated with hot bitumen. After the waterproofing has hardened, the plinth is lined with polystyrene or expanded polystyrene. Plates 15 cm thick are glued with foam, additionally fixed with dowels with umbrellas.

A monolithic foundation is usually laid under a bath in a swampy area. The base is insulated at the stage of construction. Expanded polystyrene is embedded between the layers of the concrete screed. On the walls outside the basement of the bath, do-it-yourself insulation occurs according to the principle of a strip base.

The columnar foundation forms a gap between the soil and the lower rim of the bath. For insulation, it must be laid with bricks. First, they dig a trench along the perimeter of the bath. The parameters are the same as when insulating a concrete tape. The bottom of the trench is covered with a 25 cm layer of sand, filled with water. When the pillow is compacted, they begin to lay out the wall.

Insulation work on the outside can be roughly divided into three stages: preparation, rough work, final cladding.

Regardless of the chosen method of insulation, the walls of the bath outside must be carefully prepared. The surface is thoroughly inspected.On wooden walls, cracks are caulked with jute or linen.

The gaps between the crowns of the log house can be repaired with modern materials. The site is first primed. The gaps are pushed in with a polyethylene foam cord, and a sealant is applied on top.

The method of sealing depends on the packaging of the paste. The sealant is applied from the buckets with a spatula, squeezed out of the tubes with a pistol. When using a special tape, the protective film is removed from its adhesive layer. A strip is sealed with a strip. From above, the tape is rolled with a roller. The restored wooden surface is treated with a protective impregnation.

Preparation of brick, block walls of a bath is based on filling up all cracks and potholes. Small gaps are filled with sealant. When using putty or cement, the groove is widened so that the mortar penetrates deeper into the crack.

Tools

The set of tools depends on the selected material for work. If a ventilated facade is chosen for installation, you will need a saw, drill, jigsaw, hammer, screwdriver. For the installation of a wet facade, spatulas, buckets, and a construction mixer are needed.

Installation

Thermal insulation from the outside according to the "ventilated facade" method consists of the following steps:

- a crate is attached to the wall of the bath (the wooden structure is first sheathed with vapor barrier);

- cells are filled with insulation;

- the windproof film is shot with the stapler shackles to the crate;

- a counter-lattice is attached from the slats.

The whole cake is covered with a facing material.

Thermal insulation from the outside according to the "wet facade" method consists of the following steps:

- slabs of polystyrene, expanded polystyrene or basalt wool are glued to the wall with an adhesive;

- square plates of thermal insulation at 5 points are fixed with dowels with umbrellas;

- the insulation is covered with a base layer of plaster, the fiberglass mesh is fixed.

The final finish is decorative plaster. The method of application depends on the selected composition.

How to calculate the thickness of the insulation layer

To determine the optimal thickness of the thermal insulation material, it is necessary to know the coefficient of resistance to heat transfer, which is required for a given structure. The basic requirements for the thermal resistance of buildings are determined by SNiP II-3-79 (developed in 1979 and supplemented in 1995).

The formula for calculating the thickness of the insulation: TU = (T - SHF / KTF) * KTU, where TU is the Thickness of the Insulation, T is the Heat Resistance, WF is the Width of the Foundation, KTF is the Coefficient of Thermal Conductivity of the Foundation, KTU is the Coefficient of Thermal Conductivity of the Insulation

Example 1: We build a foundation with expanded clay insulation for a house 6 × 8 m, freezing depth - 1.4 m. The foundation is a reinforced concrete tape 0.4 m wide. Coeff. thermal conductivity of reinforced concrete - 1.69 W / ms, expanded clay - 0.18 W / ms. Heat resistance for the Moscow region - 3.2 m2C / W.

We consider: TU = (3.2 - 0.4 / 1.69) * 0.18 = 0.53 m. Round up and get the thickness of the insulation 0.6 meters. Trench area for expanded clay = (6 * 0.6 + 8 * 0.6 + 1.2 * 0.6) × 2 = 18.24 m2. Total, taking into account the freezing depth, 18.24 × 1.4 = 25.5 m3 of expanded clay is required.

Example 2: We build a foundation with insulation with expanded polystyrene (or penoplex) for a house 6 × 8 m, freezing depth - 1.4 m. The foundation is a reinforced concrete tape 0.4 m wide. thermal conductivity of reinforced concrete - 1.69 W / mS, expanded polystyrene (specified in the technical documentation of the material) - 0.032 W / mS. Heat resistance for the Omsk region - 3.8 m2C / W.

We consider: TU = (3.8 - 0.4 / 1.69) * 0.032 = 0.114 m. Round up and get the thickness of the insulation at 120 mm. Those. it is possible to use panels of 60 mm in two layers with overlapping.

The choice of insulation

To achieve the effect, it will be necessary to insulate not only the basement, but also the foundation; it is necessary to choose the right insulation.

The cheapest is polystyrene. Its thermal conductivity and strength depend on density. If we are talking about the simultaneous insulation of the foundation and the basement, it is impractical to buy polystyrene of different density and strength. For this, only the PSB-S-35 or PSB-S-50 brands are suitable, which can withstand high mechanical loads.

In the ground, not only the soil pressure will act on the insulation, but also the bulging forces of the ground freezing in winter, which deforms even the concrete foundation. On such foam, used to insulate the basement, it will then be easy to apply decorative plaster or mount PVC panels.

Extruded polystyrene foam (penotex, penoplex, extrol - the name depends on the manufacturer). Today it is the most common material for external insulation of foundations and walls of buildings. Compared to foam, it has increased strength. Less moisture absorption. More resistant to UV rays. It has a longer service life of 50-70 years. It is more expensive than polystyrene.

The most modern material is polyurethane foam.

- It is applied in liquid form;

- The thickness of the insulation layer depends on the wishes of the builder. It is enough to change the nozzle and the amount of the applied mixture will change;

- Does not require preliminary surface treatment with a primer and waterproofing;

- Penetrates into the smallest cracks, therefore completely isolates the base and foundation from cold penetration.

Main disadvantages: special equipment is required and high price. It is profitable only if the insulation of the bath base is carried out simultaneously with the insulation of other objects.

Preliminary work consists in freeing the surface of the foundation and basement from the soil, layers of old plaster, cleaning from adhering soil. The foundation is dug in along the perimeter of the bath to the depth of soil freezing. Usually in the middle lane it is 400-500 mm. More precisely, you can find out the depth of freezing by studying SNiP 2.02.01-83 "Foundations of buildings and structures" and using the technique, calculate it in relation to the region and the nature of the soil.

- Having released the foundation, it is allowed to dry out for 2-3 days.

- They are cleaned with spatulas and a metal brush from earth layers;

- They are processed along the perimeter with waterproofing on a bitumen or polymer base, or a layer of polyurea is applied;

- The slab insulation is cut to size and mounted on the surface of the foundation and basement using dowels with wide mushroom caps. The insulation glued with glue or mastic will inevitably move during the process of ground movements and bulging during freezing, the effect of thermal insulation will be negligible.

- Using polyurethane foam, the joints between the foam plates are “foamed”. Extruded insulation has grooves that tightly fit the individual panels. It is not necessary to "foam" it at the joints.

If polyurethane foam (PPU) is used, then after cleaning and drying the surface, it is not necessary to apply waterproofing. PPU itself is an excellent waterproofing agent. There is no need for fixing to the surface with dowels. Polyurethane foam has good adhesion and it is almost impossible to peel it off from the foundation or plinth.

During the insulation process, the ventilation openings must not be covered. They must be preserved. In the cold season, they are covered with fine-perforated louvres. In summer - with larger ones.

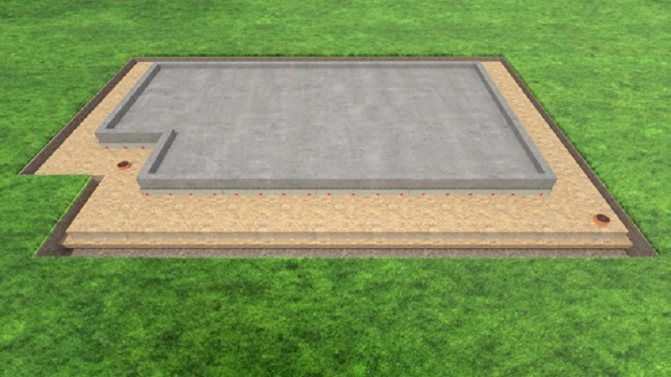

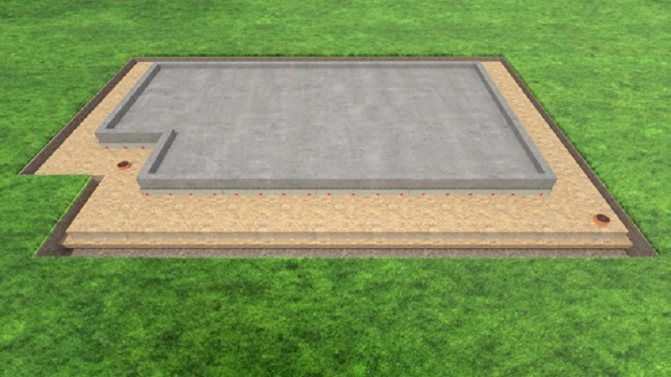

Insulation of the foundation using earth or expanded clay

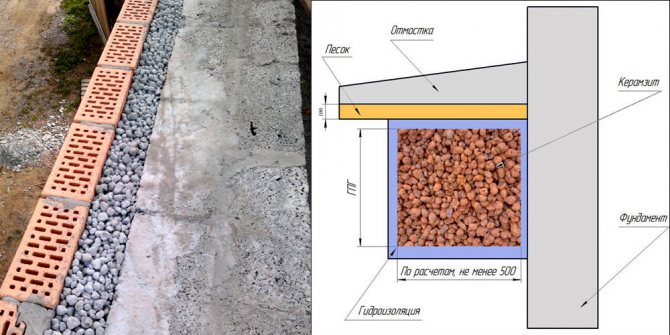

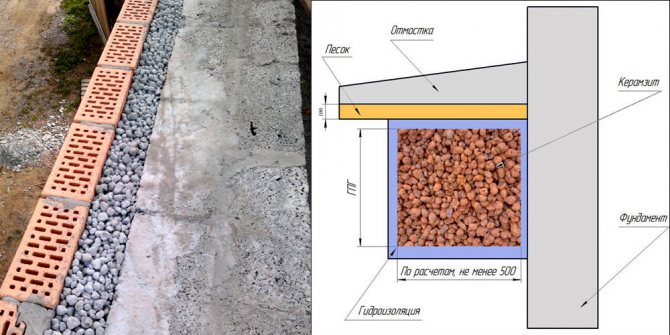

A warm foundation for a bath can be made using ordinary soil and expanded clay. As a rule, to insulate the foundation with expanded clay, a trench of about 0.5 meters is required. Thus, you can calculate the required volume of insulation: the length of the entire foundation, multiplied by the width of 0.5 meters and multiplied by the depth of the foundation. The cost of one cubic meter of expanded clay is 1.5 thousand rubles.

In order for the thermal insulating expanded clay layer of the bathhouse foundation to work as expected, it is necessary to make a drainage layer.

Drainage is not needed if the bath is located on a hill and the groundwater does not rise higher than 1 meter from the soil surface.

A drainage layer is made like this:

- we dig a trench deeper than the foundation at a distance of a meter from it. The edge of the trench should go into some kind of depression or ditch;

- we lay geotextiles in the trench. Laying is carried out with an overlap on the edges of the trench;

- rubble is poured onto the fabric;

- on top of the rubble we lay a perforated pipe. We bring its edge into a depression or ditch;

- we pour crushed stone on top of the pipe;

- then we fill in the earth and tamp it.

Before the direct filling of expanded clay, it is necessary to make waterproofing:

- near the foundation itself, a trench is dug to the sand;

- the foundation is cleared of soil;

- priming the concrete base;

- after the primer has dried, we process the concrete with bituminous mastic.

After that, you can proceed to expanded clay insulation, and this is done like this:

- sand (15 cm) is poured into a trench dug near the foundation;

- two walls of the trench (foundation and ground) are covered with plastic wrap;

- now all the free space of the pit is covered with insulation (expanded clay);

- roofing material is laid on top of expanded clay;

- on top we make a reinforced blind area;

The basement is also insulated with expanded clay. A half-brick wall is being erected in parallel with the foundation. Insulation is poured into the created space. Waterproofing is done at the top and bottom of the heat-insulating layer.

This is how the basement of the bath is insulated with the help of expanded clay with your own hands. You can see that the insulation procedures are simple, but there is more than enough earthwork.

Insulation of the blind area

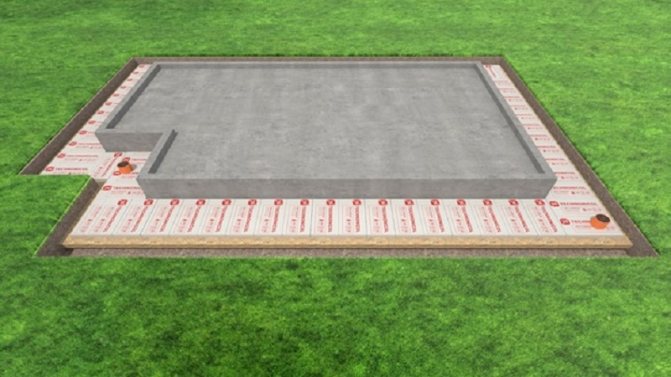

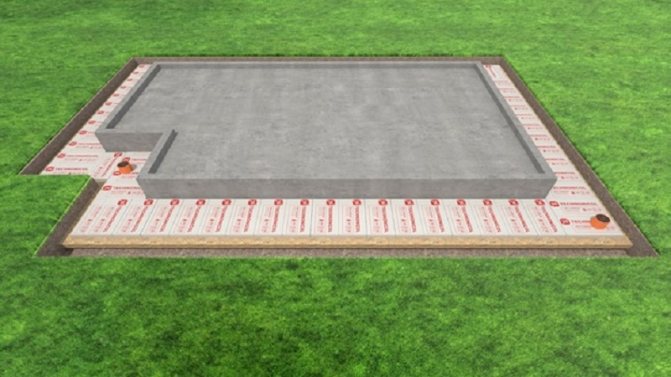

The final chord in the complex of measures for the insulation of structures in contact with the ground is the device of an insulated blind area. It will divert water from the house and protect the structure from the effects of frost heaving forces.

First of all, it is important to prepare a trench with a width of 80 to 100 cm.When determining the size, remember that the blind area should be at least 20 cm wider than the roof protrusion beyond the perimeter of the walls.The depth of the trench varies from 20 to 40 cm and depends on the soil. On heaving soils, it is at least 40 cm. First of all, a sandy base is formed, at the same stage the angle of inclination of the blind area is set, which usually ranges from two to five degrees.

The sand cushion must be tamped, spilling each layer with water and ramming with a vibrating plate. Remember that a layer no thicker than 15 cm can be efficiently compacted.

Already on the prepared sand base, XPS slabs are laid, their thickness varies from 30 to 80 mm, depending on the climate and type of soil in the region of construction. So, for Moscow, a thickness of 30-40 mm is sufficient. The slabs are laid loosely close to the plinth, being combined with each other using a thorn-groove type lock.

If the finishing layer of the blind area will be made by backfilling with gravel or laying a lawn, then a profiled membrane with a layer of geotextile must be laid on top of the XPS. She will take over the drainage function.

On the vertical part of the base, the membrane is wound to a height of 10-15 cm and fixed with plastic dowels. The overlaps of canvases 10-12 cm wide are glued with double-sided sealing tape.

In conclusion, the blind area is covered with crushed stone, sand, and after that comes the turn of the finishing layer - laying paving slabs, paving stones or lawn. It is important to remember that the insulated blind area works effectively only in conjunction with the drainage system.

Thermal insulation of the foundation is a responsible and at the same time a very technological process. Almost all stages can be completed on their own, with the support of loved ones and information assistants in the form of articles and instructions.

Insulation of foundations with foam

As already mentioned above, foam is an excellent material for thermal insulation of foundations of structures, and in particular, baths. This is due to the fact that he is absolutely not afraid of moisture. However, by itself, it is not durable, and therefore, to protect it from mechanical deformation and damage, a protective casing is made. It can be made from wood or brick.

If the bath is built on clay soil, then foam is an excellent option for insulating its base. This is due to the fact that during floods, the foam will prevent the penetration of water to the foundation.However, if groundwater rises very high, then the foam is unlikely to work, since water will penetrate under the layer of the heat insulator itself.

As a rule, in most regions of the country, foam plastic is used with a thickness of 5 cm.To insulate the corners of the bath, a material 10 cm thick is used.

Before starting the installation of foam on the foundation, it is necessary to dig the soil along the foundation to the depth of soil freezing. After that, the base is cleaned and primed. Bitumen diluted with diesel fuel is suitable as a primer. This mixture will dry in about an hour. If possible, a layer of waterproofing material is applied to the primed surface. After that, you can start installing the foam itself.

The very first sheets of insulation (bottom) must be mounted on a solid base. A concrete support or gravel bed can serve as a base. You can glue the foam plates using mastic or glue. Several glue points are applied over the area of the slab. The seams between the individual sheets of heat-insulating material are fully glued. It is worth noting that it is best to buy foam plates equipped with a lock. The use of such sheets and careful gluing will create an airtight heat-insulating layer. To keep the building warm even better, the slabs are installed in two layers. In this case, the second layer overlaps the seams of the first layer.

After finishing the installation of the heat-insulating material, we proceed to the application of a layer of bitumen or rubber. You can close the entire layer of insulation with brickwork in half a brick or boards. Can also be used to protect foam and geotextiles. Next, a blind area is made.

Thus, the basement of the bath is insulated with the help of foam sheets. This is a rather troublesome business, but it is quite feasible with your own hands. However, all the troubles will be more than repulsed while maintaining the heat in the bath.

Insulation from the inside

Bath insulation from the inside - the primary task, because it is the internal thermal insulation that is considered the most effective. Wall insulation is carried out in the same way as ceiling insulation. First, a frame made of strips is stuffed onto a layer of roll paper and foil, insulation is laid between them, and then sheathing is done. For upholstery, it is best to choose aspen, pine or linden, low density materials that are extremely healthy.

You will learn even more information about insulation from the inside by reading this article.

What stones are better to use in the bath? You can find the answer here. And here is an article about the size of the foundation for the garage.

Warm foundation

The question often arises of how to insulate the foundation of a bath without attracting third-party specialists and at the same time spending a little money. This issue must be resolved during construction, at the stage of designing and erecting a foundation for a bath with your own hands. Today, there are many heat-insulating materials on the construction market. Advanced developments in this area allow the creation of materials of small thickness, but excellent heat retention.

How to insulate the structure?

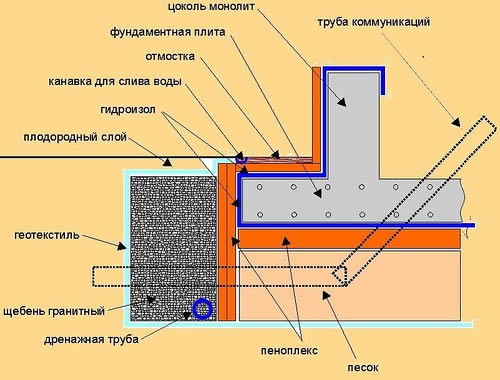

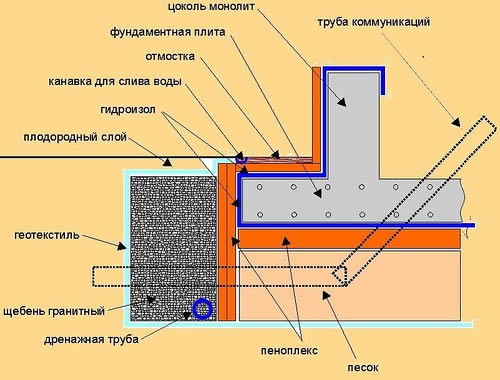

Foundation insulation scheme.

The technology of warming the basement of the bath is not something complicated. Insulation is carried out to a depth of up to the level of soil freezing. The exact value of this parameter is individual in different regions, therefore, to determine it, it is best to contact construction specialists. The lower the insulation is installed, the less the effectiveness of its use. When insulating the corner sections of the structure, it is necessary to increase the depth by about 1.5 times at a distance of at least 1.4 m and not more than 2.6 m from the corner on both sides.

If you use insulation such as extruded polystyrene foam, then you do not need to use additional protective materials for waterproofing.In the case of using other heaters, you will need to lay a protective coating, which will prevent mechanical damage to the waterproofing. It is best to use geotextiles for these purposes.

Insulation is laid before pouring the foundation into the formwork, which is made more by the width of one or two sheets of insulation along the edges in a vertical position. The thickness of the insulation, as a rule, is at least 10 cm (a more accurate value depends on the climatic conditions of your region). The insulation is attached to the part of the structure that is located above the ground after removing the formwork. Finishing is carried out directly on it.

Thus, it is not at all difficult to insulate the foundation. The most important thing is to provide insulation even before the foundation is laid. Use only high-quality and effective materials to insulate the structure, it depends on whether its insulation will be beneficial.

Which material should you choose?

For external insulation of the foundation, like other parts of the structure, it is convenient to use sheet foam. This insulation is easy to install, and its thermal conductivity is very low. In addition, this material does not absorb moisture, which is important for a bath, so its service life is quite long. However, it is not as long as the lifespan of a concrete foundation. Ideally, it is recommended to select insulation that will last as long as the object to be insulated. Such material can be called foam glass. This material is more durable and at the same time is not inferior to foam in terms of thermal conductivity. An excellent material for warming the basement of a bath is also extruded polystyrene foam, which is produced specifically for these purposes.

Characteristics of polystyrene (expanded polystyrene).

Extruded polystyrene foam is a special insulation that is lighter and stronger than polystyrene to a large extent. It is made in the form of slabs that are moisture-tight and have low thermal conductivity. This is ensured by a special closed-cell structure. An additional advantage of extruded polystyrene foam over foam is that it is much less likely to be spoiled by rodents.

This material is available in various versions. For the insulation of private construction facilities, you can use expanded polystyrene with a lower compressive strength than for vertical insulation of industrial facilities. This is due to the shallower depth of the foundation, since in this case the soil and underground waters exert significantly less pressure on the insulation. For private construction, it is advisable to use slabs with a strength of 200 kPa.

Materials for thermal insulation of the foundation

The problem of thermal insulation of the base of the bath arose a long time ago, it was solved by various materials. The most accessible was expanded clay - it was filled up along the foundation, after having built an external false wall of boards and ceramic bricks.

When expanded clay was used to insulate the outside, a mixture of sawdust and small chips was used for the internal surfaces. They built similar supporting structures as for expanded clay, but only from the inside. Required no less time and expense. Plus sawdust, when moisture gets in, began to rot intensively.

More than half a century ago, polystyrene foam was used in construction for thermal insulation; it differs from extruded foam in its low density and strength. But as a heat insulator - a good material. They began to be used for thermal insulation of foundations from the inside. The disadvantages of conventional foam include attractiveness to rodents.

In an effort to create a more perfect material, chemists changed the technology for the production of foam. A more complex extrusion process was applied. Extruded polystyrene foam (EPS, XPS) was obtained.The only significant drawback was flammability (like wood), but now fully fire-resistant EPS brands are being produced.

Photo of the external thermal insulation device

Bath constructions requiring insulation

For long-term preservation of heat in the bath, it is necessary to apply insulation at all stages of construction. Thermal protection measures are as follows:

- warming the walls of the bath;

- warming the ceiling of the bath;

- warming the basement of the bath.

The following types of materials are used to insulate walls and ceilings:

- mineral wool;

- ecowool;

- expanded clay;

- penoizol;

- Styrofoam.

You can also use clay and straw when working on the ceiling. The walls are insulated both outside and inside. With the correct implementation of these measures, heat losses are significantly reduced, and, accordingly, you save on fuel used to heat the bath.

Why do you need to do it

It is estimated that heat loss with an uninsulated foundation is from 10 to 25%. In winter, buoyancy forces lead to distortion and swelling of the foundation, as a result of which it collapses, posing a threat to the entire structure. It is not always possible to save the situation with a simple repair.

Fig. 1 Bath with insulated foundation

In summer, the uninsulated foundation is covered with condensation. Its walls on the inside will be wet for a long time. As a result, mold and mucus can appear, again destroying the foundation.

With the correct thermal insulation of the foundation:

- its service life increases;

- waterproofing is protected from mechanical damage;

- reduced heat losses and reduced heating costs;

- condensation does not form on the inner surfaces of the foundation;

- the temperature in the bath remains stable for a long time.

It is necessary to think over the competent insulation of the foundation at the design stage of the bath.

Fig. 2 Styrofoam sheets