Burner types for liquid fuels

To extract heat from liquid fuel, it must be burned, but the flammable liquid must first be prepared - sprayed and mixed with air or evaporated. The better the mixing of air and fuel occurs, the more efficiently and economically the heating boiler will work.

The difficulty of efficient combustion of fuel lies in its variety, because each combustible substance has individual characteristics. In this regard, many different burners have been developed, adapted to the specific type of liquid.

Liquid fuels:

- Petroleum products - heating oil, fuel oil, fuel oil, kerosene, gasoline.

- Oils - shale oil, waste engine oil, vegetable and animal oils.

- Alcohols - ethanol, methanol, propanol.

- Rocket fuel - ethers.

- Emulsions (mixtures) - water-fuel emulsion, oils in gasoline, ethyl alcohol in gasoline.

- Synthetic fuels - from coal, from natural gas, from biomass.

Oil burners differ not only in the type of fuel they burn, but also in their principle of operation. Some spray a combustible liquid into millions of small droplets, which mix with air and burn in the boiler furnace. Other devices vaporize fuel when exposed to high temperatures and burn the resulting vapors. The latter are subdivided into gasification burners and evaporative burners.

Read about the causes of malfunctions in domestic heating boilers here.

On how to deal with scale in the boiler, you will find information on the link -

Also read about maintenance and repair of diesel oil burners.

Universal burners with gasification of liquid fuel are one of the most efficient and economical types of equipment.

The principle of operation consists of several stages: liquid fuel is pre-filtered and enters the heating chamber, where it is brought to a boil and begins to evaporate. The resulting vapors create pressure in the chamber.

After reaching a certain value, they are fed into the combustion chamber so that when they move, an injection effect is created. This means that the flow of combustible gas (vapors) sucks in combustion air without the need for additional equipment.

Industrial oil burners

In modern markets, for boilers of various types, it is possible to use gas and diesel burners for boilers, which differ only in the type of fuel used and form an even and stable course of the combustion reaction, which is required for the full operation of the boiler equipment.

Industrial liquid fuel burners differ in a number of indicators: price, availability of fuel preheating and automatic control system, as well as one of three power levels.

What are the types of industrial oil burners, depending on the type of work?

In addition, industrial oil or gas burners are usually divided according to the type of work.

Fan burners, which are also called inflatable or blast burners, work by forced air blown by a fan, which is mixed with fuel directly in the burner itself, and then the resulting mixture is fed to the combustion site. Such burners can use both liquid fuel and gas, and have a certain advantage, since even if the gas pressure level in the network is reduced by half, the boiler will still heat up, but with some power drop.

Fan burners are more expensive than conventional burners and are quite noisy during operation - therefore, it is recommended to install a silencer for them at the junction of the chimney with the boiler.

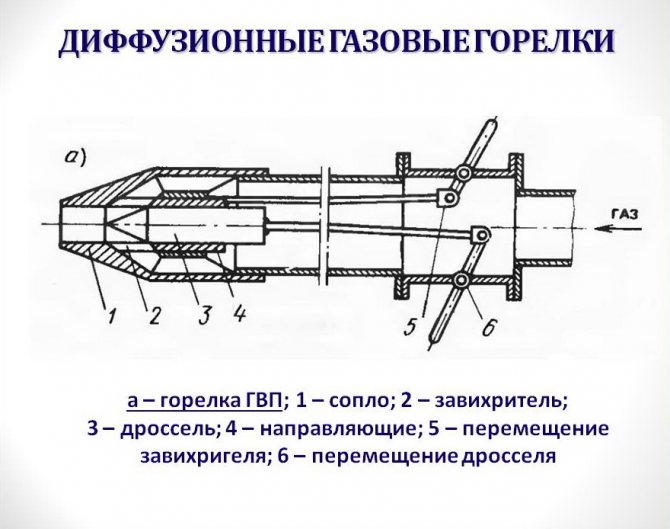

Diffusion burners obtain the air necessary for the combustion reaction directly from the surrounding space by means of diffusion. They create the most uniform flame temperature along the length of the torch, which is necessary when used in industry, but they require a higher excess air ratio than injection ones, and the gas may not be completely burned in the tail part of the torch.

The most popular oil burners for boilers

Heavy oil, like other liquid fuel burners for boilers, usually use a mechanical fuel atomization system, for which compressed air or steam is used. For oil burners, it is necessary to constantly maintain the temperature of the fuel so that it is in a viscous state - a special heating system is used for this. The flammable substance is then sprayed at a pressure of 8 bar. In order to reduce fuel consumption, low pressure nozzles can be installed, as well as additional equipment - electrical panels, a motor-pump group for supplying a combustible mixture, a control system.

There are also combined types of burners: dust and gas and gas and oil. They are used for faster transitions from one type of fuel to another, and also when the gas cannot create the desired temperature or a glowing flame is required.

Burner working principle

Liquid fuel goes through several stages of filtration, and then enters the heating chamber. To start the burner, it is necessary to build a fire in the ignition tray. Then the fuel will evaporate and enter the furnace for combustion. At the bottom of the furnace there is a special sump into which drops of unburned fuel, captured by the flow of gas (vapors), flow down.

The recommended fuels for combustion in gasification burners are flammable liquids (kerosene and winter diesel fuel grades).

Due to the injection effect, energy is saved, since there is no need to use additional equipment for air injection. In order to improve injection, it is necessary to increase the vapor pressure in the fuel heating chamber, but this will lead to an increase in temperature, which will entail the formation of solid deposits and an increased fire hazard.

As a result of the evaporation of liquid fuels, solid deposits such as coke are formed, which contribute to the clogging of the fuel paths. The rate of their formation can be slowed down by lowering the pressure and temperature of the fuel.

The advantage of gasification burners is the absence of a fan for air injection. But there is also a drawback - an increased fire hazard associated with high pressure and temperature of fuel vapors.

Gas or oil burner?

The advantages of gas as a fuel are obvious. Does not require preheating of the burner. The burners themselves are structurally very simple, do not clog, do not smell, and are very easy to use. Gas also has disadvantages. At high negative temperatures, the burners begin to work unstable.

Gas advantages as fuels are obvious. Does not require preheating of the burner. The burners themselves are structurally very simple, do not clog, do not smell, and are very easy to use. They do not break, unless, of course, they are hit with a hammer, they are relatively expensive. All provide precise control of the flame power ...

Cons of gas is also there. At high negative temperatures, the burners begin to work unstably and require preheating of the gas and the gas cylinder itself. Moreover, when the burner is operating, the gas evaporates, pre-cooling the cylinder, and sometimes (if the length of the hose allows) you have to heat the cylinder on the burner, or put it on the lid of a saucepan in which you melt snow or cook food. After that, sometimes you have to put the balloon in the sleeping bag, which, you see, is unpleasant.

The second obvious disadvantage of gas is its high price.

For example, let's give an approximate calculation of the cost of fuel for a high-altitude October event.I needed to provide fuel for four people for three weeks. Conservative estimates required at least 100 g of gas per person per day, i.e. about 8-9 kg (15-16 liters) of liquefied gas. That is, at a minimum, the price of branded fuel (MSR or Primus) for me would be about $ 200. But since it is impossible to save on fuel, the required reserve would be at least another $ 100 more. And it is very problematic to take such an amount of fuel on the plane. Purchasing locally is also problematic. There are, of course, cheaper options - namely, order 1 large propane cylinder, an adapter and refuel the burner cylinders on site ... It's troublesome ... However, we note that for the July event in the Caucasus, gas will be required by 20-50% (depending on from group tasks) less.

Now let's imagine that we have a liquid fuel burnersuch as MSR XGK or Primus OmniFuel. Gasoline for the same event would take 20-25 liters, and its cost would be $ 6-10. Moreover, it can be easily bought on the spot. Feel the difference! In practice, you can buy a new oil burner especially for the trip, and it will pay off immediately.

Now let's talk about the pros and cons of liquid fuels.

In general, liquid fuel does not have to be gasoline. There are burners that run on household or aviation kerosene, specially refined gasoline, diesel fuel (diesel fuel), special fuels produced by leading manufacturers (for example, MSR White Gas or Primus fuel). There are those that work perfectly on unleaded gasoline, Asian gasoline (a separate class of gasoline, in which it is not clear what is more - donkey urine or diesel fuel), as well as pure alcohol (but this is completely perversion, it is better to take it inside).

By the way, let us remind you that almost all oil burners do not digest alcohol of varying degrees of purity poorly. it corrodes the gasket material.

So, why do we need a liquid fuel burner (we are considering exclusively our, Russian conditions). We want to save money, we don't want to carry fuel with us. We wish our burner to work stably at high negative temperatures, and we do not want to bother with heating the cylinder.

Thus, special fuels produced by manufacturers are eliminated immediately. Yes, MSR White Gas does not smell, it is not as volatile as regular gasoline, it does not clog the burner, but its cost is comparable to the cost of branded gas fuel, and it is almost impossible to get it in Almaty or Bishkek. Thus, in our conditions, it is important to use fuel that is easy to obtain on the spot and which is cheap. And this is either motor gasoline of varying purity (often unpredictable), or diesel fuel, also of unpredictable purity.

So the cons... When working on poorly cleaned fuel, any burner will clog up sooner or later. Those. it will need to be cleaned. Moreover, gasoline is smelly, volatile, smokes when the burner heats up and is generally nasty. In addition, gasoline vapors gathered in the tent can give you an unforgettable fireworks display. Diesel fuel is less energy intensive, and it takes more time and more fuel to boil a certain amount of water, for example. And she smokes absolutely not like a child. Another relative disadvantage of oil burners is that they all require some maintenance and are not as easy to operate as gas burners (they all require at least preliminary heating).

So, the dry residue. Your choice is an oil burnerready to digest coarse fuel, if a:

* you are ready to suffer a little or, conversely, “have fun” inhaling gasoline vapors and spending some time heating up the burner, * do not want to talk to the police at the airports about removing gas cylinders from your luggage, * ready to cook in the vestibule of tents when low temperatures, without warming up a gas cylinder in your groin, * do not want to spend money on fuel.For other cases, gas is probably the best choice.

How much fuel do you need?

Indeed, how much fuel should you take with you? The generally accepted norm for Russia is about 50-120 g per nose, depending on the conditions of the event, competent dishes, burners, the presence of wind protection and the "human factor" .... Western experts recommend 100 to 450 ml of fuel per person per day. Also depending on the above factors.

We look at it in a simpler way: the more fuel the better. You calculate the amount of fuel for your event, and then multiply it by one and a half or two. Because if you lose your mitten, you can put a sock on your hand, for example. If you run out of food, then okay…. But if you run out of fuel, then you will no longer be able to drink tea ...

A little more about the factors affecting fuel consumption:

External conditions:

On a simple short summer bike trip, even if you do not plan to cook over a fire, you will need to boil water from the initial freezing temperature ... But on a winter ascent in cold mountains, first melt snow or ice, sometimes very cold (if it is -50 ° C outside ...) only then boil the resulting water ... accordingly, and you need to take much more fuel ...

Competent dishes:

It also happens…. For example, it is very difficult to boil a 6-liter pot with snow on a low-power burner ... I would even say impossible. Heat loss at some point will become greater than the inflow of heat from the burner - and you will sadly look at your own water that has not yet boiled ... Ie. cookware should minimize heat loss. Using a double-walled, single-bottomed autoclave and saucepan can significantly reduce fuel consumption.

Burner:

In this regard, the more powerful the better. Desirable (but not required) with power control. She must also burn the fuel to the end. For example, a yellow flame near the burner indicates that the fuel is “underburned”. Or, say, the separation of the torch from the burner at maximum power ...

Windscreen and heat reflective screens:

They also significantly reduce heat loss.

"Human factor":

It's no secret that in any event, different people require completely different amounts of liquid and food. You can starve and drink less coffee - but you can vice versa ... The exception is difficult ascents and hikes, where, within reasonable limits, food is often insufficient in any case, and even more liquid. With different types of work at an altitude, for example, 7000m, the loss of fluid by the body can range from 100 to 300 grams per hour! Dehydration is a terrible scourge for high-altitude climbers. Many paid the highest price due to lack of fuel ... Well, let's remind you about the carelessness ... A current canister, a gas cylinder left in the sun, etc. can easily leave you without fuel - and, in the worst case, without life.

Afanasyev Mikhail January 8, 2012 at 13:59

Evaporative burners

The principle of operation of evaporative burners is similar to the operation of equipment with gasification of liquid fuel. The difference is that in evaporative models, fuel vapors do not accumulate under pressure, but are immediately burned.

The fuel is heated in an open vessel. In this regard, the fire hazard of equipment operation is reduced.

By the way of heating and evaporation of fuel, evaporative burners are divided into two types - open and closed. Despite the use of the same principle of fuel combustion, their designs differ significantly from each other.

Fuel equipment for tourism

July 16, 2008 | edited by Nikolaev R.V.

Equipment Reviews

A source:

www.alpindustria.ru

Fuel equipment, presented in our store, includes everything that helps people in nature - athletes, tourists, just having a rest - prepare their own food, warm up and get an additional source of light. It is divided into several main classes:

- gas stoves and burners;

- oil stoves and burners;

- gas lamps and heaters;

- oil lamps and heaters;

- grills, barbecues and barbecues;

- gas cylinders, fuel, spare parts and accessories.

For cooking, so as not to depend on the fire, firewood and weather, it is very convenient and environmentally friendly to use gas and liquid fuel stoves and burners. Heaters serve as a reliable source of heat, and lamps allow you to enjoy constant lighting while away from city power grids. Grills, B-B-Q and braziers indispensable for people who like to eat deliciously outdoors, and gas cylinders, fuel, spare parts and accessories will allow you to keep your fuel equipment in good working order. Stoves and burners for sports and tourism are divided into three main classes. It:

- gas burners running on gas;

- liquid fuel, running on gasoline, kerosene, diesel fuel, alcohols and other types of liquid fuel;

- multi-fuel burners, such burners operate on both gas and liquid fuel.

The most common type burners - this is gas... Such burners have many tangible advantages. The most important thing that is very appreciated in the hike is ease of handling. They are lightweight, do not require heating, do not smell, smoke or clog if you do not use low quality gas. So a hot lunch in nature becomes extremely simple. This allows almost anyone to use gas burners, even if they have no experience of camping life at all. However, gas burners have several disadvantages. Gas burners can become unstable at low temperatures and gas cylinders cannot be transported on airplanes. Moreover, far from civilization, it is impossible to replenish fuel supplies.

Gas-burners differ in power and design. The power should be selected depending on the volume of the dishes and the number of people for whom the food will be prepared. Burners up to 2000 W are suitable for dishes with a capacity of about 1 liter and for cooking for 1 or 2 people. These gas burners are very light and small in size. The power of a gas burner from 2000 W to 3500 W makes it possible to use dishes with a volume of up to 5 liters and cook food for 3-6 people. If you need to use larger cookware, you should think about purchasing a gas burner with a capacity of over 3500 W, for example, the Сoleman F1 Power, whose power reaches 7000 W, however, you will have to pay for the increased power with a serious increase in gas consumption.

By design, gas burners are divided into those that are connected to gas cylinders and those that have a hose for supplying fuel. Hose burners are more stable and less fire hazardous, while hoseless burners are much lighter and more compact. Modern burners are often equipped with a piezo ignition, in addition, the flame diffuser in modern burners is designed so that the flame is resistant to blowing out.

| EtaPower EF Primus Price: 3840 |

| Micron Ti 2.5 Primus Price: 2382 |

Gas burners undoubtedly require gas bottle. Gas cylinders there are threaded, collet, plug and pierced cylinders without a valve. The advantages of the first 3x are that, if necessary, they can be disconnected from the burners and transported separately, even if they have already been used and are planned to be used in the future, because they have a threaded connection and a valve. As for the pierced cylinders, they are attached to the burner, piercing with a special needle, and it is impossible to disconnect it before all the gas is consumed. Large-sized cylinders are more convenient to use, as they are less cooled by gas expansion, in contrast to small ones, and are more profitable in price. The composition of the gas in the cylinder is also very important - it depends on the temperature at which the cylinder can be used.

| C-206 Campingaz Price: 59 |

Many people still prefer to use oil burners... Just like gas, oil burners come with and without a hose. The liquid fuel used by these burners can be different: gasoline, kerosene, diesel fuel, specially refined gasoline, pure alcohol, etc. There are also commercially available special combustible mixtures that are produced by the burner manufacturers themselves. Despite the fact that it is a little more difficult to use a liquid fuel burner than a gas burner (it must be preheated), the advantages of oil burners are obvious, for example, at low temperatures it works more stable than a gas one. In addition, liquid fuels are widely available. The oldest and most famous manufacturer of liquid fuel burners is the Swedish company Primus, which is rightfully considered the leader in the production of multi-fuel burners.

Multi-fuel burners can run on a variety of fuels, allowing you to use any liquid fuel you can get where you go. Also, Primus multi-fuel burners run on gas. The advantage of multi-fuel burners is their versatility: depending on the situation, you can choose the type of fuel that is more convenient and easier to use at the moment.

| Dragonfly stove MSR Price: 5978 |

For real gourmets who cannot live a day without real delicacies, our store offers camping stoves, grills and B-B-Q... These devices are powered exclusively by gas cylinders, since the gas burns odorlessly. Depending on the design features, grills and barbecues are equipped with one or more burners, cooking trays, and other useful devices that will allow you to cook food according to all the rules of the culinary art. Camping stoves, grills and barbecues are presented in our store with Campingaz and Coleman products.

| Camp bistro Campingaz Price: 990 |

If it becomes cold and dark outside, the camping enthusiast will be helped out lamps and heaters... They can also be operated with gas and liquid fuels, just like burners. Unlike burners, lamps and heaters work mainly on the principle of catalytic combustion of fuel. These devices have a catalytic mesh, which is a luminous and heating element. On this mesh, gasoline vapors and gas are burned. More powerful heaters use a porous ceramic element for this purpose. Ceramic heating elements of such devices work for their entire service life, in contrast to catalytic meshes, which need to be periodically replaced.

| 1 Mantle Kerosene Lantern Coleman Price: 3401 |

| BLACKCAT PZ Coleman Price: 4525 |

In our online store, the above-described devices are represented by the products of several world-famous manufacturers, such as Primus, MSR, Campingaz, Сoleman and Snow Peak.

Have a pleasant and comfortable stay!

comments on the article

There are no comments yet

Algorithm of operation of an evaporative burner of an open type

The fuel storage tank is located above the burner. This eliminates the use of a fuel pump - the fuel is supplied by gravity to the evaporating surface, which is located directly at the bottom of the combustion chamber. It is a flat surface with a large evaporation area. Fuel vapors are ignited by an external source (automatic igniter or match). Next, the required amount of air is supplied to maintain the combustion process. Due to the increase in temperature, the evaporation process becomes more intense, and the release of thermal energy begins.

Combustion air can be supplied in either forced or natural way.

The process of supplying fuel to the evaporating surface is controlled by automatic systems with fuel overflow protection. For this, a float, dispenser and other sensors are used.

Closed-type burner operation algorithm

The evaporation of fuel in a closed-type burner occurs due to heating from the heat released in the boiler combustion chamber. But the fire does not come into direct contact with the fuel, heat exchange is carried out through a metal partition.

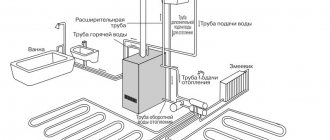

The scheme of operation of a closed-type evaporative burner: the fuel tank is located in the upper part to ensure the gravity flow of fuel into the evaporator. The fuel level in the evaporation chamber is regulated by automatic float systems and emergency drains.

The ignition of the evaporative burner is carried out by means of an igniter. Blowing air is supplied to it, the flow of which, due to ejection, sucks fuel. Then air and combustible liquid are mixed, sprayed and fed into the combustion chamber, where a pieza or match ignites.

The pilot flame heats the fuel in the vaporization chamber and the vaporization process begins. After the process of fuel vaporization reaches a steady state, gas (vapors) is supplied to the furnace, and the igniter is extinguished. The intensity of combustion is controlled by valves that reduce or increase the amount of vapor supplied to the boiler furnace.

The closed circuit of the evaporative burner operation is safer, since it is impossible to ignite the fuel due to overflow, as in an open type burner.

Read about the differences and features of the installation of autonomous heating of a house and an apartment in a high-rise building in the article.

You can read how to make an autonomous heating of a garage with your own hands at the link -

Also read on how to descale an electric boiler.

Advantages and disadvantages

Advantages of universal oil burners:

- increased efficiency;

- complete combustion of fuel;

- the ability to work without forced blast.

Disadvantages of universal burners for liquid fuels:

- increased fire hazard;

- fine tuning of equipment operation;

- high pressure coke release;

- high price.

The use of liquid fuel boilers is a fairly effective way of heating, provided there is constant access to cheap fuel. When operating boilers on liquid fuel, less harmful emissions are emitted than when operating solid fuel counterparts.