A gas-fired sauna stove is undoubtedly the most economical option for heating a steam room. This type of fuel is much cheaper than wood or coal; it does not need to be procured and stored in specially adapted rooms. Therefore, more and more of our compatriots decide to install a gas burner in an already operating solid fuel furnace. It is much more profitable than buying a new heater for a bath or sauna.

In this article, you will learn how to choose the right gas burners for your sauna stoves. We will tell you what to focus on when buying such devices, and introduce you to several of the most high-quality and practical models from.

Benefits of using gas burners

Let's note the most important advantages of this heating equipment:

- You don’t have to waste time and effort to fire up the stove. It is enough to open the valve and simply ignite the burner. Within an hour and a half, the steam room will warm up to the desired temperature.

- You can save a lot. Gas heating is 20-30% cheaper than wood heating. And if we compare such ovens with electric ones, then the benefits will be even more impressive - about 100-120%.

- You will ensure the maximum fire safety of your bath. The gases formed during the combustion of this type of fuel do not heat up to the critical temperature that can cause a fire. Therefore, you do not have to additionally insulate the chimney at the points of contact with the roof.

Thus, a gas burner for a stove in a bath will greatly facilitate the whole process of heating a steam room and save you from the need to prepare and store firewood.

We suggest that you familiarize yourself with the varieties and features of such devices.

Basic requirements for gas burners

Gas burners for boilers should, first of all, be durable and easy to install, during operation they should not make more noise than is required by sanitary and hygienic standards, and if it is possible to work on several types of fuel, then also a quick switch from one to another ... Moreover, modern trends require that only low-toxic flue gases are emitted during burner operation, although, in principle, this applies to all types of fuel. What is low toxicity? It's simple - it's low in carbon monoxide and nitric oxide.

All the requirements mentioned above depend mainly on how the oxygen is mixed with the gas. And so we smoothly approached the classification of burners according to the mixing method. Let's dwell on this in more detail.

Types of gas burners

There are only two main types:

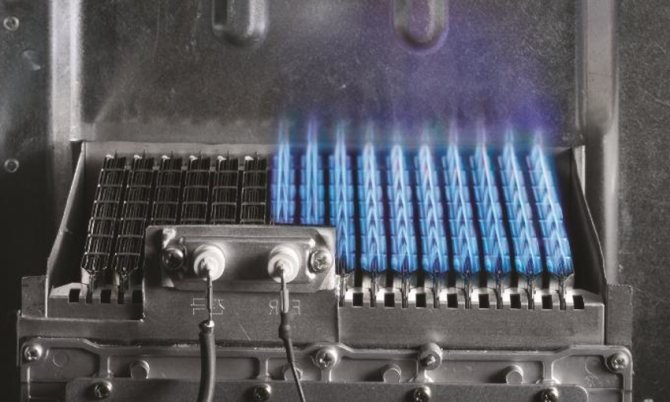

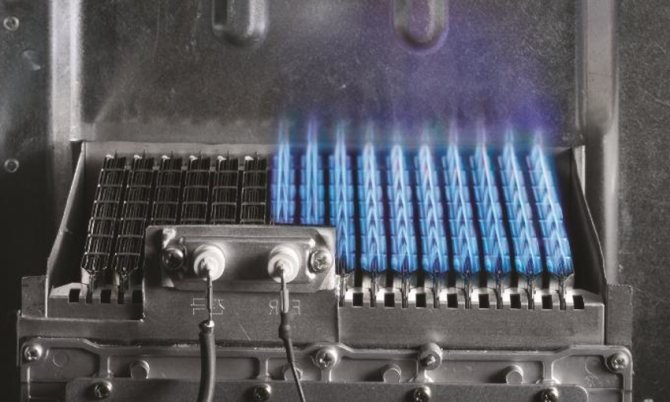

- Atmospheric burners

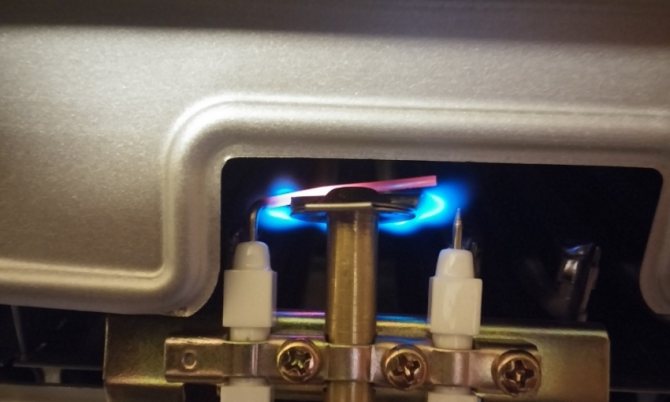

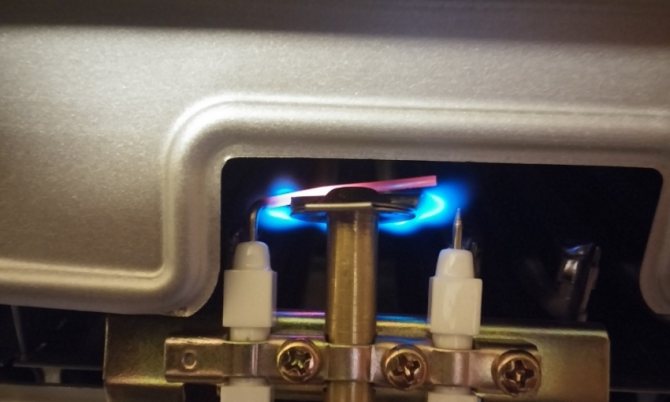

... Atmospheric GGs are distinguished by their affordable cost, ease of manufacture and operation. Such devices provide mixing and combustion of gas in the firebox due to atmospheric pressure drops. They function without electricity, but are highly dependent on the movement of air in the room where the oven is located. With any tangible movement of air, the amount of heat generated by the firebox changes in one direction or another.When using an atmospheric burner, it is necessary to equip an additional air source in the room and constantly monitor the condition of the chimney. It should also be borne in mind that the fuel in such a furnace will not be completely burned, part of the gas will inevitably go into the pipe.

When installing an atmospheric burner, you will have to seriously improve both the fuel chamber and the burner itself.This is due to the fact that in a standard-sized chamber, the flame will touch the bottom of the stove or the metal elements of the stove. To remedy this state of affairs, it is necessary to place the fire source as low as possible and strictly in the center of the firebox.

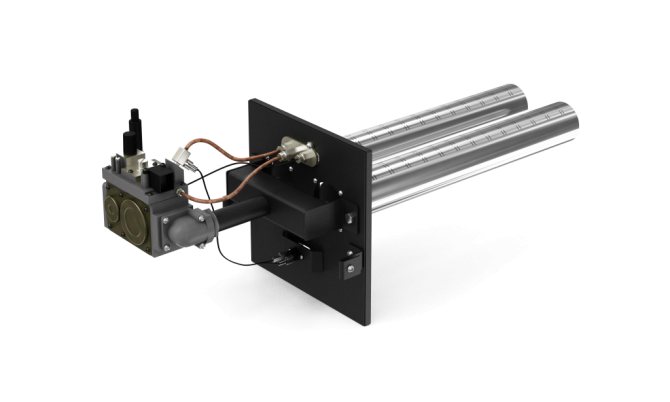

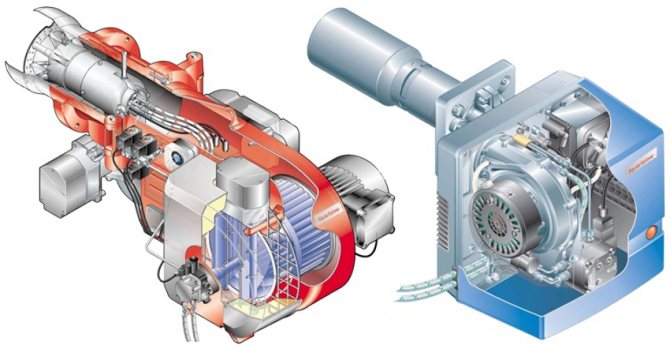

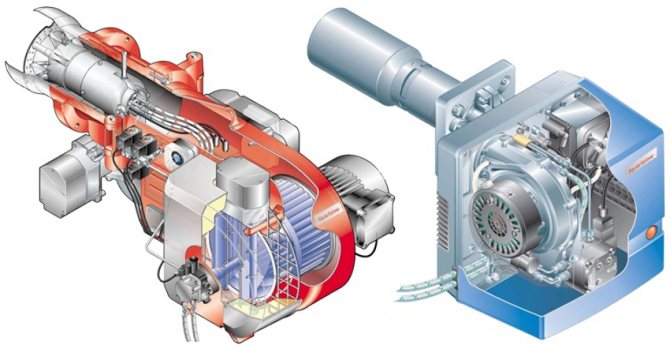

- Pressurized burners

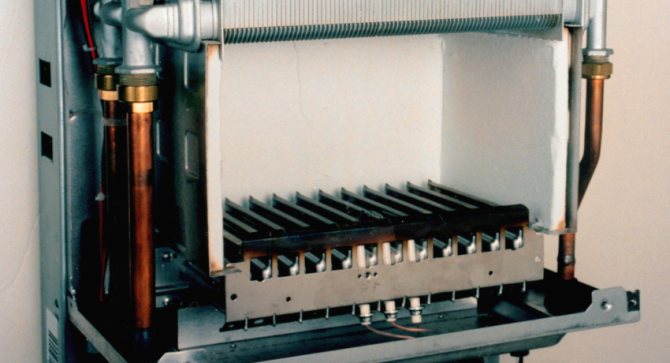

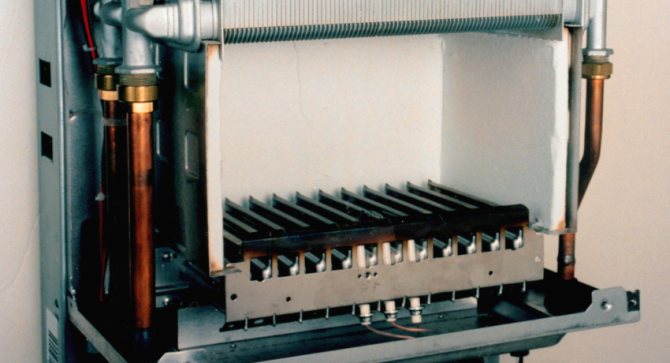

... Supercharged gas generators are considered to be more practical and convenient in operation, since they provide a forced flow of air into the fuel chamber. Such devices are equipped with a special fan, the rotation speed of which determines the speed of fuel combustion in the chamber.The pressurized gas burner for the sauna stove is powered by electricity - and this is perhaps its only significant drawback. In the event of a power outage, she will not be able to start the process of heating the steam room, so for such situations it is good to have an alternative option. When choosing such devices, it is important to take into account the depth of the fuel chamber so that the fire does not hit its rear wall.

Burner AGG-40P for the Siberia 30 LK furnace, Siberian cliff 20 with a remote fuel channel.

Gas oven models

All types of gas heating devices are united by ease of use... Let's take a look at some of them:

- Gas fired heaters connected to the cylinder... They are lightweight, compact and easy to use. They can warm up the house well in a short time.

- Ovens with coaxial chimney have a very high cost, but can be installed not only in a private house, but also in an apartment.

Gas oven - perfect solution to create warmth and comfort.

Better contact a specialist, which will help to establish it, observing all the rules and regulations, which will ensure a safe and comfortable stay in the house.

ogon.guru

Which burner should you choose?

Thinking about re-equipping the stove for gas fuel, sooner or later you will be faced with the question of choosing the most suitable burner for this purpose.

There are the following alternatives:

- Atmospheric or supercharged.

The owners of large baths and saunas are increasingly preferring more expensive, but convenient pressurized burners. Their important advantage is that they require a minimum of attention and personal participation from the user, working regardless of external conditions and air pressure drops. For heating a small steam room, an inexpensive atmospheric burner is quite suitable. - One- or two-stage.

Devices of the first type automatically turn on and off the fuel supply, while the latter have an economical heating mode. There are also models with floating control, which allow you to change the power of the equipment as smoothly as possible. The choice of a gas burner for a sauna stove depends in this case on the mode in which you plan to heat your steam room. - Exclusively gas or combined.

Gas burners are distinguished by a relatively simple device and an affordable price. However, they only pay off if there is an uninterrupted supply of fuel. Combined burners are designed to work with natural and liquefied gas, as well as with diesel fuel. The latter option is especially good for large baths, since it provides quick heating of rooms of any size.

Advantages of gas stoves

The main advantages of operating gas burners in boilers for baths and heating are the following factors:

- High level of security;

- Automation of the ignition process and control of the temperature level;

- Efficiency - thanks to flexible adjustment systems, fuel consumption can be reduced;

- Ease of operation - all burners are equipped with a remote control that does not require special skills and careful study of the instructions for use.

Heating area - as a rule, 1 kW of power is enough to heat 10 m2 of a room. However, this statement is true only in the case of high-quality house insulation. In addition, this rule applies only to central Russia. In the conditions of the Far East and Far North, certain correction factors must be used;

https://www.youtube.com/watch?v=https:4-nOKlgT4-g

The presence of ventilation systems - if in the room where the heating boiler is installed there is a low speed of a small volume of air circulation, then it is safest to use models with forced pressurization;

Furnace type and model. The burner model is selected depending on whether it is a hybrid furnace - a forced-draft device or it can work only on gas - an atmospheric burner is sufficient.

If you are interested in where to buy a gas burner for TMF bath and heating stoves, Contact our managers by phone or submit an application in the appropriate section of the site.

For a stove with a gas burner in a bath or house, the following qualities are characteristic:

- High efficiency. With a minimum level of fuel consumption, stoves provide high performance.

- Saving space. Gas is supplied to the equipment directly; there is no need to free up additional space or room for fuel.

- Durability. There is practically nothing to break in this equipment, and the gas burner for heating furnaces is very easy to change, so you can count on a long equipment life.

- Environmental Safety. Gas stoves are practically harmless to nature.

- Ease of use. Convenient mechanisms are provided for temperature adjustments.

For the durable functioning of a gas stove for a bath, it is necessary to select a high-quality gas burner for it.

Gas burner selection criteria

Experts recommend, first of all, to answer the following questions:

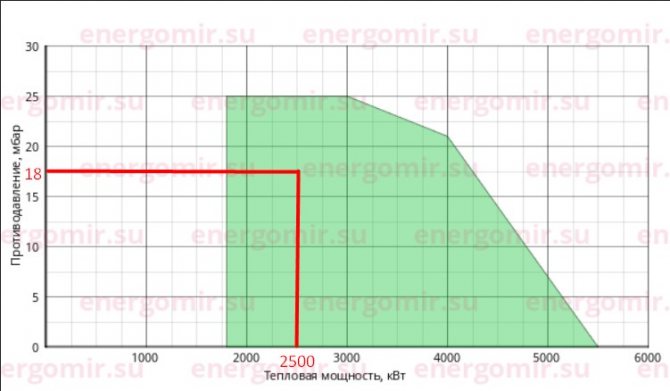

- What technical characteristics should the device have? Decide on the power, efficiency level and efficiency of the burner you need, focusing on the features of the heating system used.

- In what room is the oven used? For a small steam room, an inexpensive atmospheric burner is suitable, while for a larger room, it is better to choose a more expensive but efficient pressurized model.

- Are there power outages? If so, consider an additional power source for the forced draft burner.

- What fuel do you use to heat your sauna? Remember that there are devices that are only compatible with main gas, and there are universal burners that work with other types of fuel.

When heating a steam room, it is extremely important to ensure an even distribution of heat throughout the room. Therefore, it is better to choose burners that disperse the flame well, or supplement the selected device with a torch diffuser or distribution pipe.

Another important point to pay attention to is the correspondence of the threads on the burner and on the gas supply pipe. They should match perfectly without the slightest gaps and gaps.

And finally, the documentation. Quality burners always have an official passport confirming that the device complies with existing safety standards.

General classification of gas burners by fuel type

It is not always possible to provide country houses with natural gas supplied from a common highway. Therefore, the variability of the burners is provided in terms of the use of different types of fuel. If the fuel comes from the gas main, most likely propane-butane gas burners are used for heating boilers.

Main gas-methane is the most affordable natural fuel for boilers. However, there is currently no big benefit in the price of liquefied blue fuel (propane-butane mixture).The general heating provided by the main pipeline is also expensive.

Gas boilers operating on different types of fuel mixtures have approximately the same design. There is a slight difference in cost, but it is also insignificant (equipment for liquefied fuel will cost more). The burners themselves are slightly different, with different nozzles for liquid fuel and blue gas.

If natural gas is not supplied to the house, propane-butane gas burners are used.

Propane burners require adjustment for this type of fuel with the installation of a jet. When burning, the lights of the flame give off a yellowish color, soot accumulates more in the chimney. The jet is responsible for normalizing pressure.

Modern burners operate in a wide temperature range - from -50 to +50 ° C. Some of the equipment can be adapted for other types of energy sources:

- waste oil;

- diesel fuel;

- fuel oil;

- kerosene;

- propane butane base;

- arctic diesel fuel.

Modern devices often have both types of nozzles in the kit or universal equipment for fuel varieties, which makes it easy to reconfigure.

Attention! Some craftsmen offer do-it-yourself gas burners for boilers (for solid fuel equipment).

Homemade gas burners are most often used in solid fuel boilers

It is safer to purchase simple gas equipment adapted for gas in cylinders. Homemade equipment, although more affordable, is not safe! Usually carry out "alterations" based on old units.

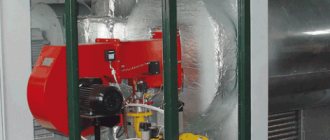

Turbocharged types of gas burners and their design differences

Among modern gas equipment, many specialists prefer closed-type burners for turbocharged boilers. They are self-sufficient in constructive terms, they assume the presence of a compact chimney, which can be diverted even into the general ventilation with autonomous heating.

A heating unit with a special closed-type combustion chamber receives oxygen from the outside - through a special supply pipe (coaxial chimney). The combustion products are discharged in approximately the same way. The heating equipment is controlled by a sufficiently powerful fan with automatic control.

It is interesting! A coaxial chimney is a pipe-in-pipe device. The turbocharged boiler can even work in a bunker or other sealed room without windows and a ventilation shaft.

Fan gas burners also have a drawback - this is the price due to the complex design of the product.

Such a device is much more expensive than atmospheric heating equipment. However, for an additional fee, the buyer receives a number of benefits, including autonomous operation in a residential area. This device, thanks to its automatic control, has a high level of security.

The turbocharged equipment has the highest efficiency and a flexible temperature scheme. The fuel burns almost completely, which is important for environmental performance. Disadvantages are also noted, including structural complexity, which causes difficulties in installation and repair.

Gas burners for combined equipment are most often used in solid fuel boilers. This is a rather complex unit, so all units must meet certain requirements for efficiency and safety. The automatic device is capable of switching from one type of fuel to another for an uninterrupted supply of heat. According to this principle, pellet and pyrolysis boilers are arranged, equipped with gas for the burners, which activates the ignition process.

Gas burners for the Teplodar furnace

The range of this domestic manufacturer includes heating systems for houses, summer cottages, garages, baths, saunas and many other buildings of any size and purpose. The company manufactures furnaces and boilers compatible with different types of fuel, as well as components for re-equipment of already operated devices.

So, you can purchase a branded gas burner "Teplodar", capable of operating on natural gas or liquefied gas. The device is intended for sauna stoves "Rus", "Domna", etc. Installation of such a burner is easy and quick, without additional metalwork and welding works.

If you are just planning to buy a heating system for a steam room, we suggest paying special attention to the compact but powerful heater "Rus 12 LNZP PROFI". The device provides rapid heating of stones and air, an even distribution of heat throughout the room and a large amount of wet steam to create the ideal atmosphere of a classic Russian bath. Such a stove is perfect for steam rooms with a volume of 6-12 m3.

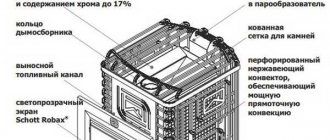

Another option - "Siberia 30 LK" - is intended for more spacious premises with a volume of up to 30 m3. Such a stove heats the air to very high temperatures (100–110 ° C) and produces dry steam, which is necessary to create a microclimate in a Finnish sauna. The manufacturer has provided a protective convector casing and stylish decorative inserts made of mirror steel.

Stove for baths and saunas Siberia 30 LK with AGG40P.

In the Teplodar catalog you will always find a high-quality and inexpensive sauna stove for a gas burner, and the company's consultants will be happy to help you choose the most suitable model and answer all your questions.

The main types and classification of gas burners

For a long period, there was no particular abundance of this type of product on sale. The simplest boilers, titans and gas water heaters were in short supply. The appearance of a gas burner for a boiler with automatic equipment was regarded as something fantastic. But these devices also required ventilation with a full-fledged chimney. Even mobile infrared gas-fired picnic burners are now being offered.

According to modern requirements, gas burners for heating boilers must be of low toxicity.

Modern fuel units are very diverse. Their advantage is the almost complete combustion of fuel and the absence of the release of toxic impurities during operation in closed conditions.

Traditional heating equipment is distinguished by its constructive variability:

- atmospheric boilers;

- universal;

- low temperature;

- turbocharged;

- fan;

- injection;

- gas burners with piezo ignition.

Hand-made devices are also far from uncommon. Homemade gas burners can be assembled using the drawings, diagrams and sketches of the masters, containing detailed descriptions, as well as watching the video.

Boilers have different types of flame ignition - with the help of a piezo lighter and with a spark when the electronics are triggered.

The advantage of modern gas burners is the almost complete combustion of fuel.

It is important! Piezo ignition is a single ignition, after which the flame is maintained in operating mode as long as there is a gas supply. This appliance should not be confused with gas stove burners (nozzle with diffuser) and grill.

Electronic ignition must be triggered when the supply valve is started: the gas is ignited by an electrostatic spark. This option is considered the most economical and reliable, but in case of power outages, the boiler is often idle (if there is no alternative way to ensure it is turned on).

Gas burner with piezo ignition and other methods of maintaining the flame

The variety of burners is determined by a number of features, including the method of air injection and the design features of the furnace itself, which can be:

- open (air comes from the heated room, supply ventilation is needed, combustion products are discharged into the chimney);

- closed type.

Having found that the ignition does not work, first of all you need to check its connection to the mains

Low temperature gas burners (atmospheric) are mainly used in open furnaces. They are distinguished by a simple device and a streamlined operating principle. The gas is supplied to the wick by means of an ejector. In this case, the air comes directly from the boiler room, where the heating equipment is installed. When firing up, small low-temperature flames are visible.

This type of gas burners for furnaces and boilers is characterized by low noise level, availability and versatility. A similar device can be adapted for combined fuel furnaces, modern specialized equipment and primitive old-style boilers.

The principle of operation of a gas burner with piezo ignition is quite simple, especially if the operating parameters of the heating circuit are set. The sensor detects a decrease in temperature, the stop valve and ignition are triggered. The blue fuel entering the burner ignites, generating heat.

The control of the flame in gas equipment takes place in different ways. In some units, everything looks very primitive, others are equipped with electronics. Sometimes complex schemes are used even when modernizing old equipment using a do-it-yourself gas burner for a boiler.

Gas burners for heating boilers can be of different capacities and sizes

Attention! If this is an inexpensive burner, then, in all likelihood, it includes the simplest thermoelement that will need to be replaced as soon as possible.

Advanced boilers with smart options are equipped with an ionisation controller that is sensitive to changes. This ensures that the gas is shut off in the event that the flame goes out and there is not enough oxygen for the combustion process (fuel runs out).

Electronics also react to increased levels of impurities in the bluest fuel and combustion byproduct. The gas will be shut off (this is thought out in the SABK gas burner), and the ventilation will start working at full capacity.

Useful advice! Before cleaning the burner of a gas boiler, it is important to understand its structure by studying the technical documentation containing a description of the operation. Each type of product has its own design differences.

An unstable flame in a gas burner is an indication that a specialist must be called in.

Burners for atmospheric boilers and manual gas burners

Work due to the flow of oxygen in a natural way gives a full combustion of fuel, the removal of combustion products is carried out through a conventional chimney. The operation of the equipment was simplified with the use of atmospheric-type devices and special nozzles for gas burners.

Attention! The only condition for the operation of the device on oxygen taken from the heated room is excellent supply ventilation.

Important advantages of boilers with atmospheric gas burners:

- independence from power sources, which is important when working in rooms without electricity;

- high reliability (no complex assemblies requiring frequent repairs);

- low noise threshold;

- constructive simplicity;

- affordable price.

Important! Information for those who are interested in how much a gas burner of the simplest sample costs - its price starts at 250 rubles. And the cost of the gas burner ugop-P-16 "Ugolyok", for example, is approximately 1000 rubles.

Cylinder manual gas burner is popular with people doing renovations

The disadvantages of atmospheric units include:

- the need for a full-fledged chimney that removes smoke and fuel suspension outside;

- relatively low efficiency (in comparison with modernized samples);

- the likelihood of incomplete combustion of fuel with a lack of oxygen;

- the difficulty of adapting to other heat sources;

- the need to install supply ventilation or a small window.

Helpful information! Electronic ignition burners require a mains-operated high-voltage converter. In this they differ from such simple devices as manual gas burners.

Use of ejector burners in finished and converted boilers

The ceramic gas burner combi boiler justifies the cost with its versatility, although it is considered an expensive option. Far from budget equipment has a lot of advantages, including autonomous furnaces:

Related article:

Gas boilers for heating a private house: how to choose and install

Types of boilers. Varieties of gas boilers, their features, replacement and installation. Top 10 gas boilers.

- for solid fuel;

- with a gas burner.

The ceramic gas burner has a number of advantages over the ejector

With this equipment, you can easily switch to coal and firewood, usefully dispose of any organic matter. This is a good opportunity to save on gas, especially in a private house, where there is always an opportunity to find something for recycling.

To supply gas for burners, additionally equipping them with automation, wood-burning boilers are often equipped with special nozzles or wicks. For these purposes, a simple atmospheric or ejector burner (with air suction) is suitable. At the same time, the entire boiler does not need to be altered, since the rest of it functions according to the same principle: fuel is burned in order to obtain thermal energy for heating the coolant.

Useful advice! For old domestic equipment, atmospheric-type gas burners are more suitable, since complete tightness cannot be achieved in them due to their design specifics.

Equipment for automatic support of the combustion process in combi boilers can be purchased additionally if you need to convert a wood-burning furnace into a gas boiler. Some models of solid fuel boilers, including pyrolysis ones, are equipped with a gas burner, the flame of which is necessary for ignition.

Ejector burners are being replaced by ceramic

Fan or inflatable forced air burner

The firebox of some devices has a built-in fan (air blower). Its function is to force the supply of oxygen to the ignition chamber. In this case, the oxygen supply is forced, the volume is controlled automatically.

This is the need for closed-type chambers, where there is no free access of the air mixture, which creates conditions for a higher temperature of the gas burner. The lack of natural access is compensated by a simple fan-type device.

Such burners have their own pros and cons. But they are not so versatile, since artificial injection has to be used, which requires additional energy consumption. An important advantage is that the fan devices are fully adapted to automate the operation of the boiler. In such models, a mixture of fuel and oxygen is obtained directly at the outlet.

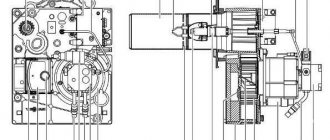

Multiblocks of gas burners for space heating with air conveying by means of a fan have the following structure:

A turbocharged gas burner has a number of advantages over atmospheric

- fan relay that turns off the burner when the blade engine stops;

- pressure regulator;

- block filter;

- burner off / on valve (when pressure changes);

- fuel consumption option;

- reducer;

- uninterruptible power supply (needed in case of a sudden power outage, but not all devices have it).

Note! Inflatable or fan burners are often part of boiler room equipment with a fairly high automation threshold, which is necessary to avoid serious accidents.

The servo drive controls the position of the damper, so there is no need to adjust the burner and additionally monitor the operation of the boiler. The regulation of the portions of the supplied oxygen required for full combustion occurs automatically.

A significant disadvantage of this type of gas burner is the price due to the complex design of the product.

If the gas burner fan breaks down, it can be replaced or repaired

Gas burners are not suitable for "homemade", especially in the case when they want to remake a solid fuel boiler for a universal unit, and its heat exchanger requires good insulation. The burners are volatile, most often they are equipped with a backup power source.

Types of stoves for gas heating

Gas stoves are often used to heat residential premises, but they are mainly used in the construction of baths. As a rule, these are ready-made factory models in metal cases, designed for certain operating conditions, taking into account design calculations. Brick analogs for gas are also being assembled.

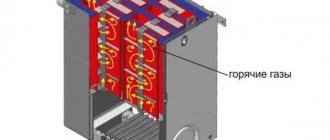

By way of generating heat

According to the method of generating heat, furnaces are divided into two main types:

- with a combustion chamber,

- with a heat exchanger.

In the first case, gaseous fuel enters the refractory chamber, where, burning, heats its walls. The temperature of the air rises as it passes through the openings in the casing and comes into contact with the outside of the chamber. The second option is gas heating stoves for the home, which are often also called "heaters". In such structures, the burning gas is also fed into a bent heat-resistant steel pipe, which is also a heat exchanger.

By heat capacity

Like solid fuel heating devices, gas units may differ in heat capacity. It all depends on the stove's ability to store thermal energy. On this basis, gas ovens for the home are classified into ovens:

- constant burning,

- periodic heating.

Furnace equipment of constant combustion does not have strong walls, it cools down quickly. But at the same time, it quickly heats up the room, since the air takes energy from the heated thin walls without any obstacles. To ensure a stable temperature regime, the stove must always be “on”. This is a suitable gas stove for a summer residence, where people come from time to time, and you need to quickly heat the house to a comfortable temperature.

Intermittent furnace systems have a heat-absorbing mass, which, when heated, then (after the gas supply is stopped) gives off heat for some time. To create an accumulation mass, clay brick is usually used, with which channels can be laid, a combustion chamber is lined, and simple heating shields are also made. By the way, because of the high calorific value, gas-fired bath stoves can heat a large mass of stones and "work" for heating for several hours - this is a classic example. Heat-consuming stoves for home use are more relevant.

Note! Many heating gas stoves for home and summer cottages can operate both when connected to a common system and from liquefied bottled gas, including biofuel obtained by decomposing organic waste. You only need to make the necessary reconfigurations of the equipment.