Sauna stove with heat exchanger

It is possible to solve the issue of heating water for washing in a bath in various ways, including by installing an electric boiler. But when it is planned to put a good wood-burning stove in the bath, then no additional equipment is required for this purpose. It is enough to select and purchase a ready-made heater with a heat exchanger, or to make the latter yourself. This article is intended to help you understand why you need a heat exchanger for a bath and how to properly mount it.

What is a heat exchanger for?

The overwhelming majority of sauna stove designs are not conducive to saving wood fuel. This is due to the specific requirements for them, namely:

- the steam room should be heated as soon as possible to a high temperature;

- the stove cannot take up much space;

- the presence of a heater is required;

- the heater operation mode is periodic.

Based on the listed requirements, sauna stoves are designed in such a way as to quickly reach a high temperature in the firebox and maintain it for a certain period of time. At the same time, a lot of unused heat simply goes into the atmosphere through the chimney. It is a sin not to let this heat energy into heating water for washing or even heating rooms adjacent to the steam room.

Note. The exception is Kuznetsov's brick bell-type stoves, designed for baths. A well-thought-out design allows you to significantly save firewood, the stove keeps heat for a long time and, moreover, heats the neighboring rooms. There are also modifications using a water heat exchanger.

One of the simplest solutions is to use the heat generated by burning wood. There are many types of ovens with built-in coil available on the market today. If a heater without a water circuit is already installed and functioning, nothing prevents it from equipping it with a home-made or factory heat exchanger. Then you don't have to spend money on a boiler and then pay for electricity.

Experienced craftsmen's recommendations

When installing a heat exchanger for hot water in a bath, you need to remember that:

- A portable water tank should be selected in accordance with the capacity of the sauna stove - too large a container will heat up for a long time. In a small tank, the water will boil early and fill the washroom with unnecessary steam.

- The heat exchanger must also match the furnace - too large a design will reduce the furnace's efficiency. The best option is when the system takes 10 percent. from the power of the stove.

- The pipes of the system should not be rigidly fixed to the walls - their linear dimensions change when heated.

- For threaded connections of the system, only a seal is used that can withstand high temperatures.

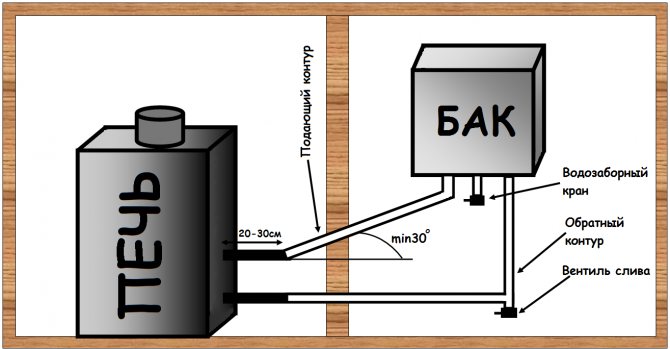

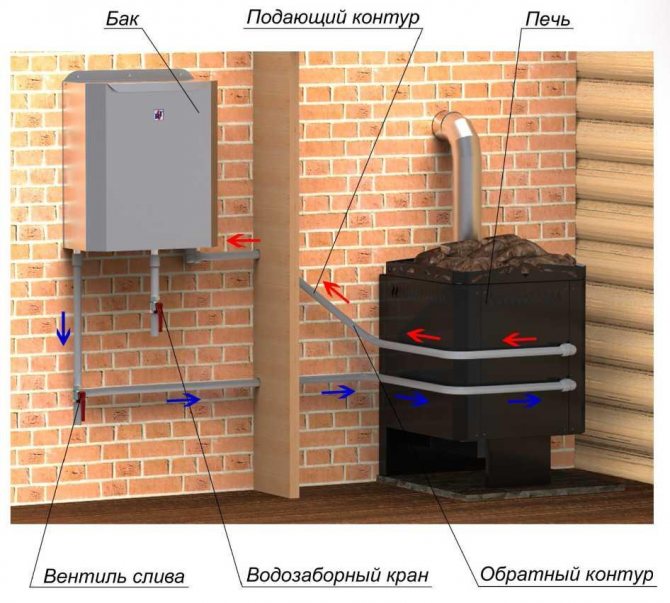

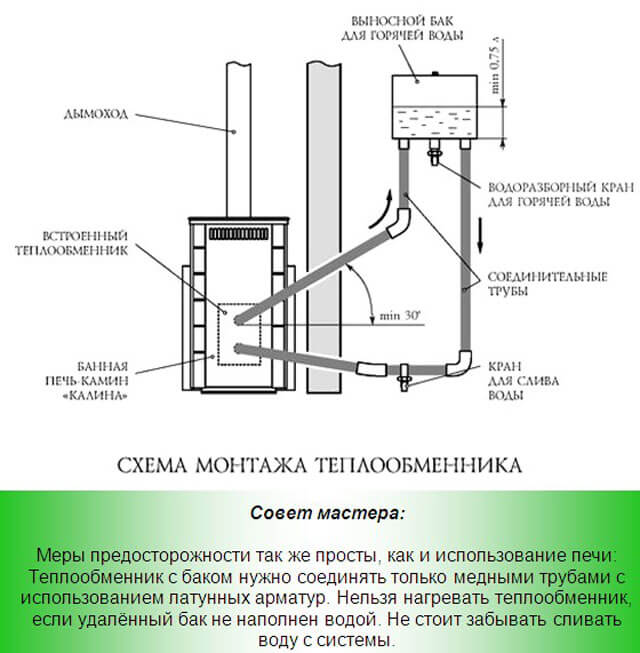

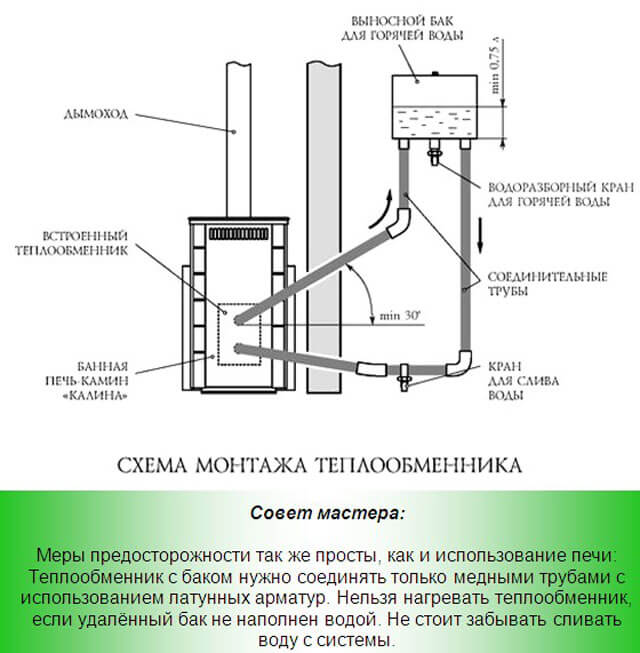

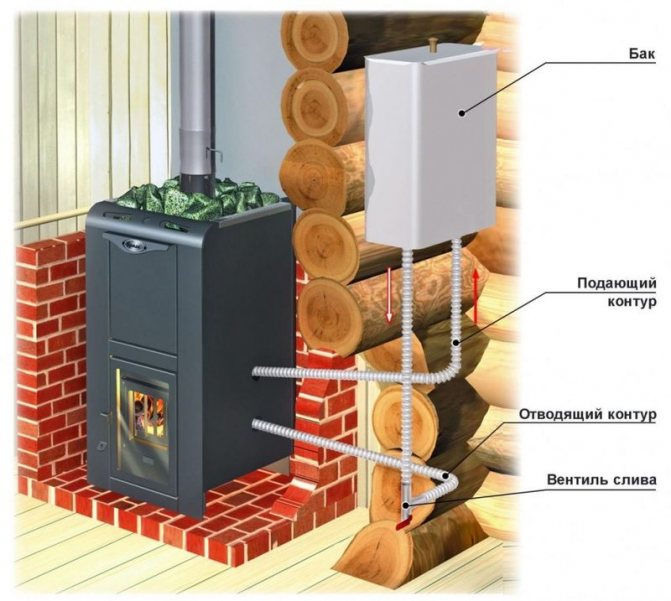

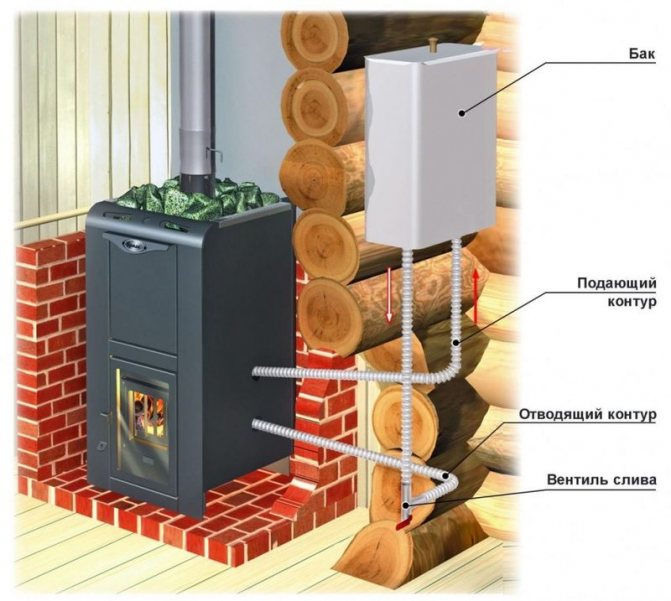

- In a system with natural heat exchange (without using a pump), a slope of 2 - 5 degrees of the upper and lower pipe contours must be observed.

- The bath tank with a heat exchanger must not be empty during the heating of the stove.

After warming up the system to high temperatures, it is undesirable to add cold water - a sharp drop will negatively affect the service life

A sauna stove with a heat exchanger will allow you to get maximum comfort and, at the same time, preserve the charm of this beloved traditional procedure.

Principle of operation

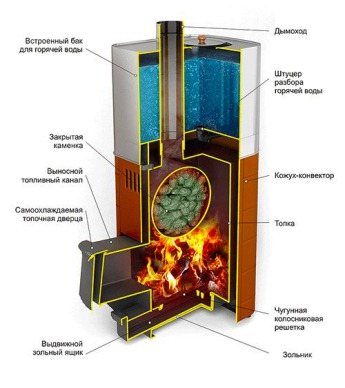

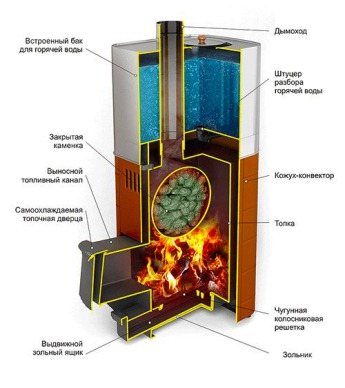

According to the principle of operation, devices for heating water are divided into 3 types:

- coil built into the heater;

- an external heat exchanger in a bath in the form of a rectangular tank heated directly from the furnace wall;

- external water circuit that extracts heat from flue gases.

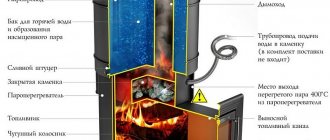

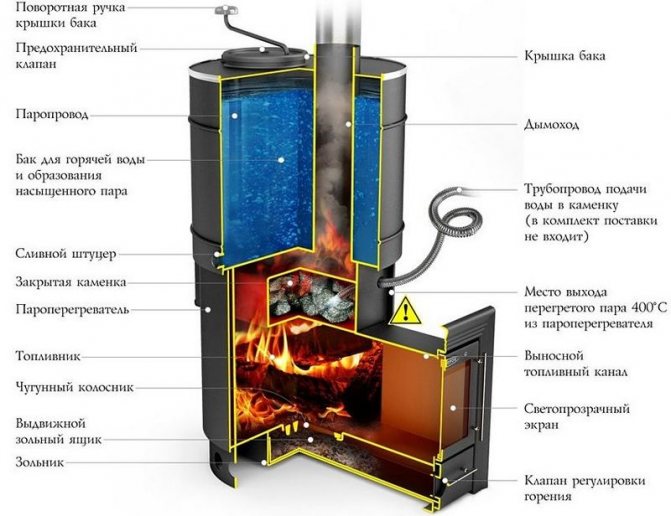

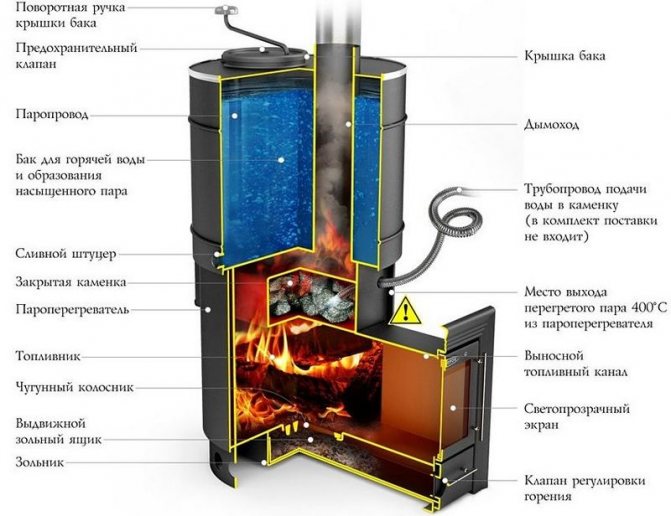

Note. There are models where not a coil is built into the body of the stove, but a stainless steel water tank. Their principles of operation are similar.

In the first case, the heat exchanger is a steel pipe coil built directly into the firebox. It is positioned so that the pipe is not directly exposed to the flame, that is, it is outside the zone of the highest temperature. It is desirable that the element stands in the way of the waste products of fuel combustion, then it will not burn out and will last long enough. The built-in coil for heating the water at the outlet has connections for connecting pipes leading to a remote storage tank.

In such heat exchangers, water heats up quite quickly, but at the same time, the process cannot be called effective. After all, the heater takes heat directly from the firebox, thereby reducing the power of the heater. The steam room takes longer to warm up, therefore, more firewood is consumed. The incandescent flue gases both flew into the chimney and continue to fly out unhindered, the efficiency of the unit remains very low (no more than 50%).

Note. An exception to this rule is considered to be brick sauna stoves with a heat exchanger and several strokes of flue gases, heating the dressing room and the washing room.

An external hinged stainless steel tank is another option for transferring furnace heat to water. Usually it is suspended from one of the side walls of the firebox and is heated by infrared radiation from it. The method attracts with its availability in implementation, but it is not very convenient in operation. In addition to the drawback with rectilinear heat removal described above, the hanging tank also requires constant addition of cold water.

Types of heat exchangers

A heat exchanger is a special part in equipment that is required to heat the heat carrier, in the case of a sauna stove, water. There are 2 main types of such components:

- Internal - a coil or "jacket" built into the furnace system, which heats up when the fuel burns, transferring heat to the water.

- External - attachments. It is attached to the chimney of a wood-burning stove, the water is heated by the high temperature of the exhaust gases.

For the heat exchanger to work, it must be filled with liquid. In sauna stoves, it communicates with a separate container: a water tank. The liquid circulates through the system in a natural way, due to temperature changes.

Devices for taking heat from flue gases

It should be noted that even the simplest water heat exchanger per tube dramatically increases the efficiency of fuel combustion up to 60%. The trick is that this device does not in any way affect the functioning of the stove itself, does not increase the heating time of the steam room and the consumption of firewood. The main advantage of such heat exchangers is that they take away the thermal energy of the combustion products, lowering their temperature.

This principle of operation of the heat exchanger is used by many manufacturers of metal bath stoves, installing an open-type water tank directly on the chimney. This option is popular due to its availability, but not very convenient. The reason is the same adding water as it is used or evaporated due to boiling.

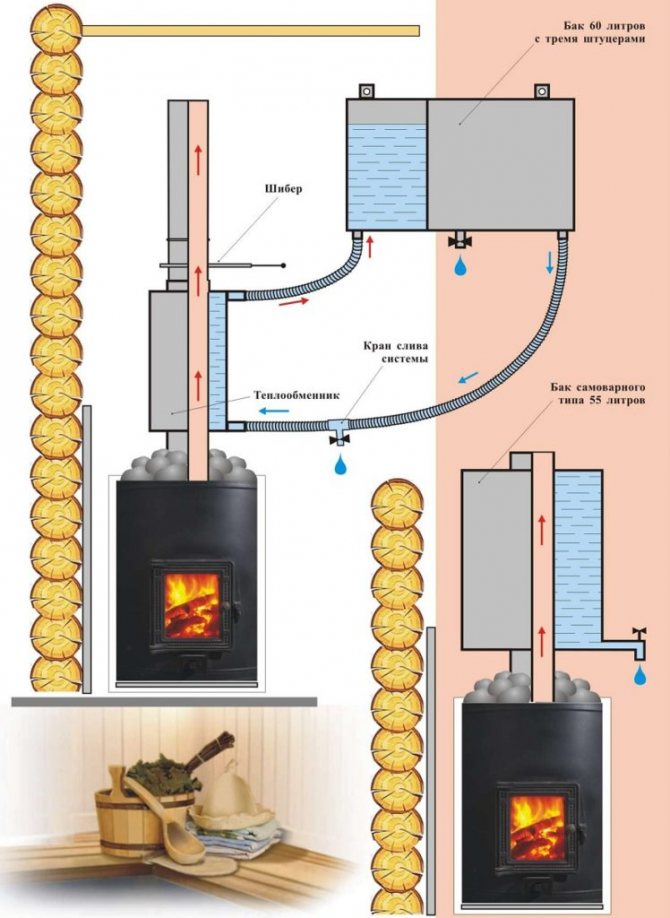

Finally, the best option from all points of view is a sauna stove with a heat exchanger on the chimney in the form of a flow-through heater of small capacity (from 5 to 10 liters). To it, as well as to the coil built into the furnace, a system with a remote storage tank is connected through the branch pipes. The volume of the remote tank is 60-120 liters, depending on the capacity of the heating unit. During heating, the water in the tank reaches the required temperature for washing.

In addition to those listed, there are also combined models, where a sauna stove with a heat exchanger built into the firebox also has a tank on the chimney.Moreover, these elements are interconnected by pipelines, that is, not one heater is involved in the heating circuit, but two. Accordingly, this option has incorporated all the advantages and disadvantages of various modifications. Again, this stove will still need a separate storage tank, since the water in the tank will boil quickly enough.

Making a heat exchanger with your own hands

Heat exchanger made of flexible pipes, which are mounted on a stainless steel pipe

If necessary, a heat exchanger for a chimney pipe is made by hand according to simple step-by-step instructions. In the process, it is important to comply with all safety conditions and rules, as well as to create a structure with a maximum margin of safety.

Required materials and tools

To create a standard coil-type heat exchanger, you will need a set of standard pipes, metal sheets for the tank, as well as pipes for supplying and removing water to the tank. The list of tools that should be prepared includes a vise, pliers, wrench, metal shears, a flaring tool, and a welder to ensure seams are sealed.

Calculations

It is quite difficult to carry out the correct calculations for a hand-made device due to the lack of the ability to regulate the air supply. Also, the reason is the uneven quality of the fuel, even if the stove is heated with only one type of wood, and a sharp decrease in the heat transfer of the wood at the end of the heating process. For this reason, all heat exchangers are manufactured with an additional margin of strength conditions. If we are talking about self-assembly, steel pipes with a diameter of no more than 3/4 are used for the furnace, for coils their copper counterparts, the diameter of which is 10 mm. The approximate length of the element is 1 meter, for steel pipes, a distance of 10-15 cm is allocated, for copper options it should be much less.

Manufacturing

Copper pipes are more suitable for making a heat exchanger

You can make a heat exchanger for a sauna stove on a 115 mm chimney using step-by-step instructions, which include the following steps:

- Creation of a coil from a copper tube with a diameter of up to 10 mm.

- Flaring the element at the ends to form a transition to the diameter of the selected tube.

- Cutting out the outlet holes in the section of the smoke piece.

- Installation of bends and coil.

- Installation of the tube and other parts to the chimney.

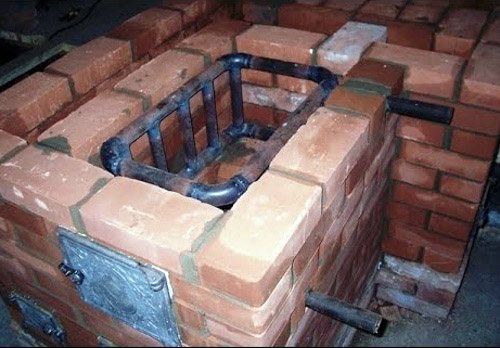

If it is necessary to make an internal heat exchanger, steel pipes are installed in the furnace, for which direct bends are suitable. To prevent the water from heating up in them, an indent is made between each turn. Additionally, it is recommended to install the circulation pump during the installation of the coil. In the firebox, the device is held by brickwork, in the chimney - with the help of taps, which must have an extremely minimal length.

Before connecting, the system must be tested with cold water, filling it completely and inspecting each element. Even a minimal hole can turn into an impressive leak, so such problems should be eliminated at the installation stage.

Heat exchanger installation

The easiest way is to install a heat exchanger in a bath when it comes with the purchased metal stove. You just need to carefully study the operating instructions and perform the assembly in accordance with the diagram. All that remains is to connect to the system, this will be discussed below. Another thing is the installation of a water circuit in a gas duct or firebox of a brick oven. Then the register must be made in advance from a black thick-walled pipe or stainless steel, and then built in in accordance with the furnace design.

On the Internet, you can often read the recommendation that the area of the heat exchanger, that is, its surface, should be 1 m2.The statement is not entirely correct, because stoves are different, and it is rather difficult to calculate this indicator. In this case, it is better to make the coil by analogy. That is, you need to find the technical characteristics for a product of any manufacturer with the same power as yours, and take the specified heat exchange surface area.

Important. If you make a circuit with a small exchange surface, then the water in it will constantly boil, which is unacceptable. "Overkill" with the size, on the contrary, is fraught with long heating, as a result, by the time of washing the water in the tank will remain cool.

As for chimney heat exchangers, operating on the principle of a water economizer, such an element can either be purchased ready-made or welded from two pipes of different diameters. Remember, the longer the circuit is, the more efficiently it will exchange heat with the chimney.

Calculation of the area of the heat exchanger

A stove for a bath with a heat exchanger for heating should provide 5 kW of heat with a standard area for an ordinary family. Calculating the dimensions of the system elements independently, it is assumed that 1 m 2 of the heat exchanger area gives about 9 kW.

It is recommended to make dimensions with a large margin, since the location and shape of the boiler and the quality of the fuel affect the efficiency of the system.

When designing a system for obtaining hot water (with a remote tank), it should be borne in mind that the tank itself will additionally heat the room.

The connection diagram of the heat exchanger in the bath is simple for factory-made stoves in the corresponding models. However, for people with welding skills, it is quite possible to assemble the system on their own and for a brick oven. For a system with natural circulation, you will need pipes, fittings, fittings (2 taps), and a water tank.

Metal sheets are needed if the water tank or heat exchanger is intended to be welded independently (in the form of a cube or parallelepiped).

A little about connection

When installing a heat exchanger in a stove, one must understand that it is primarily intended for heating a steam room, and heating water is a secondary function. It is impossible to control two processes at the same time, the steam room is in priority, so the water in the tank or coil does not cost anything to boil. This means that it is necessary to ensure good heat extraction or sufficient storage capacity. For the same reason, it is not recommended to use circulating pumps in such systems, the flow of a hot medium should be natural.

Manufacturing and connection of a furnace for a bath with a heat exchanger for water

Having made a stove for a bath with a heat exchanger for water with your own hands, you can save on buying ready-made factory heaters, without losing the pleasure of visiting the steam room. This work is not particularly difficult, so you can easily do it yourself. It is only necessary to select a high-quality stove project and make it in full accordance with the documentation on hand.

If in the past the most popular were classic heaters, which only allowed heating the steam room, but today universal stoves with heat exchangers are in demand on the market. Such installations allow you to simultaneously heat the steam room and solve the problem with heating the water. Thanks to their use, the comfort of taking bath procedures increases, and the cost of purchasing the appropriate heating equipment is reduced.

Stoves with a heat exchanger for water will be a convenient solution when the steam room and the washing room are located separately. Universal heaters are easy to use, they are extremely convenient, they quickly heat up the room, completely solving the problem with warm water. The choice of stoves with heat exchangers available today allows you to purchase or make them yourself both for a small steam room and for a spacious public bath. Advantages of heaters with a thermal circuit:

- long service life;

- compactness of heaters;

- efficiency and high speed of heating the room;

- the possibility of making it yourself.

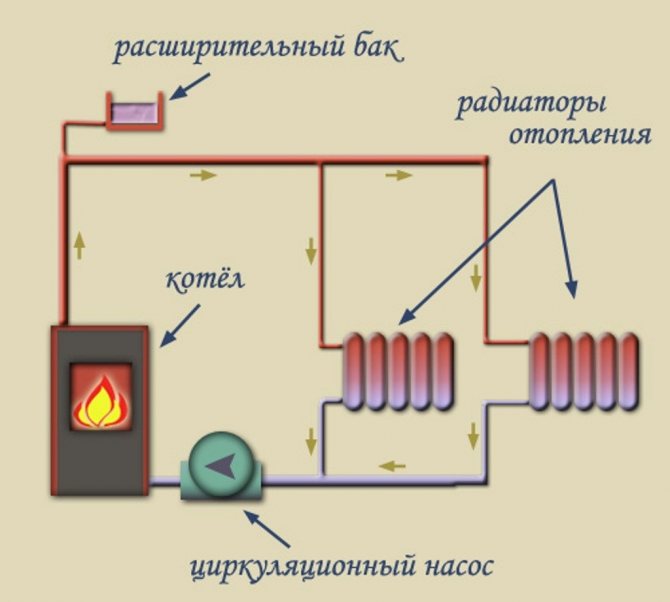

Certain types of heaters can be used as an autonomous boiler to heat nearby rooms in the house. It is only necessary to connect a closed circuit with radiators to the existing heat exchanger, inside which the coolant will circulate.

Depending on its design, the heat exchanger for the sauna stove can be made in the form of an iron water tank with two nozzles or a metal coil. In each case, the size of the tank is selected depending on the power of the stove and the desired volume of heated water. Heat exchangers can be of two types:

- 1. Outside ones are fixed on the chimney or on the wall near the stove.

- 2. Internal ones are made in the form of a water jacket, which is located at the bottom of the stove or mounted on one of the side walls.

The most widespread are internal-type heat exchangers, which is explained by their improved heat saving performance. Water heating in such a metal circuit is carried out until the stove cools completely.

If you choose a stove with a heat exchanger, which will be responsible for heating the water in the bath, then you can choose a compact version with an external tank of 5-6 liters. If it is planned to use heated water to heat adjacent rooms, then the total volume of the system can be 15–20 liters. In the latter case, it is additionally recommended to install circulation pumps and expansion tanks, which will protect the pipe circuit from damage when the pressure increases from the heated coolant.

A prerequisite for the correct functioning of sauna stoves with a heat exchanger is filling the pipeline with liquid, which will prevent the failure of the entire heating system. If the heat from the stove in the bath is planned to be used to heat adjacent rooms, then water and antifreeze can be used as heat carriers.

The liquid heated in the water jacket will be supplied independently or with the help of circulation pumps to the external tank. A small tap can be cut into it to take off heated water, or a circulation pump can be installed to supply the coolant to the circuit with heating radiators. Hot water, having given up its heat to the radiators, returns to the boiler heat exchanger, where it heats up again, after which it is fed back into the pipes for heating the room.

There are various schemes for the execution of a stove in a bath with a heat exchanger, which will differ in their design, depending on the purpose of the heater. The easiest way make a heater yourself with an additional water tank and coil, which will significantly simplify the reception of hygiene procedures after visiting the steam room. If it is planned to carry out a stove for heating adjacent rooms, then it is necessary to correctly calculate the total length of the pipeline and the number of radiators used.

To ensure the highest possible efficiency of self-made equipment in the bath, it is recommended to install a stove with a heat exchanger, which has an open water heating system. The coolant in the pipes will move by gravity without pressure, which eliminates the need to purchase expensive circulation pumps.

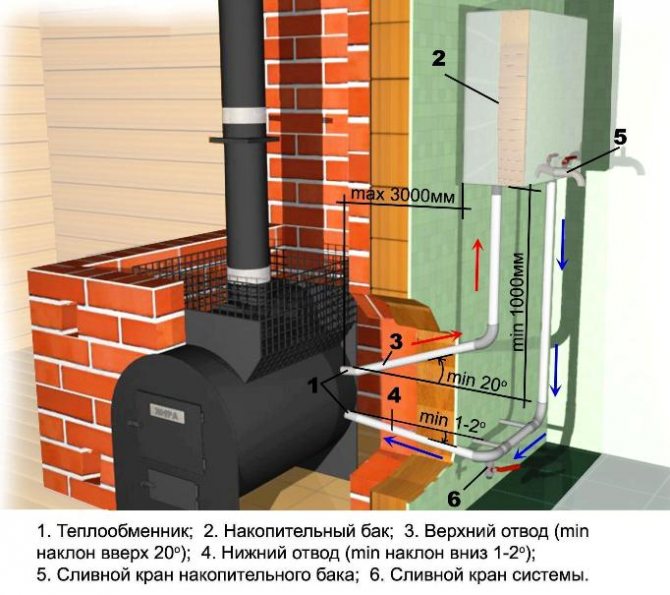

The most efficient will be the heating system, in which the length of the pipes does not exceed 3 meters. With this length of the pipeline, the hot water tank can be installed directly behind the wall of the steam room. Depending on the location of the container, water can be supplied into it by gravity or under pressure due to special pumps.

In open systems where circulation pumps are not used, the inside diameter of the heat exchanger tubes must be greater than 1 inch.This will allow the heated liquid to easily cope with resistance, move by gravity, quickly running through the system, and the tank will always have the required volume of hot water.

It is necessary not only to choose the correct model of the stove for a bath with a heat exchanger, but also to correctly perform the installation of the heating unit. It is on how correctly the installation of the heater is carried out that the efficiency and complete safety of its use will subsequently depend.

It is necessary to install a stove for a bath with a heat exchanger for heating on a properly prepared foundation. The minimum base depth should be 400 millimeters. The height of the pedestal is chosen depending on the type of firebox and the overall dimensions of the stove. The foundation is poured from cement with a strength of at least M300, additionally waterproofed and covered with fireproof materials. It is forbidden to install the stove in the bath directly on a plank or log floor.

The sauna stove must be fenced off from the wooden walls using brickwork. Ceramic or fireclay material can be used for it. Laying is done with high temperature clay mortar. This improves the thermal efficiency, making the heaters completely safe to use.

Pipes leading directly from the heat exchanger must be insulated. For their insulation, mineral wool or other material with improved fire resistance can be used.

Calculation of the area of the heat exchanger

A stove for a bath with a heat exchanger for heating should provide 5 kW of heat with a standard area for an ordinary family. Calculating the dimensions of the system elements independently, it is assumed that 1 m 2 of the heat exchanger area gives about 9 kW.

It is recommended to make dimensions with a large margin, since the location and shape of the boiler and the quality of the fuel affect the efficiency of the system.

When designing a system for obtaining hot water (with a remote tank), it should be borne in mind that the tank itself will additionally heat the room.

The connection diagram of the heat exchanger in the bath is simple for factory-made stoves in the corresponding models. However, for people with welding skills, it is quite possible to assemble the system on their own and for a brick oven. For a system with natural circulation, you will need pipes, fittings, fittings (2 taps), and a water tank.

Metal sheets are needed if the water tank or heat exchanger is intended to be welded independently (in the form of a cube or parallelepiped).

Wood-fired sauna stoves with heat exchanger

In this category, you can choose and buy wood-burning sauna stoves with a heat exchanger inexpensively with delivery throughout Russia.

- New Year 2020

- Steam room volume: 8-18 m 3

- Kamenka: open (mesh)

- New Year 2020

- Steam room volume: 35 m 3

- Kamenka: open (mesh)

- New Year 2020

- Steam room volume: 6-12 m 3

- Kamenka: closed

- New Year 2020

- Steam room volume: 15-30 m 3

- Kamenka: open

- New Year 2020

- Steam room volume: 8-18 m 3

- Kamenka open

- New Year 2020

- Steam room volume: 8-16 m 3

- Kamenka: open

- New

- New Year 2020

- Steam room volume: 6-12 m 3

- Kamenka: open

- New

- New Year 2020

- Steam room volume: 6-12 m 3

- Kamenka: open

- New Year 2020

- Steam room volume: 12-24 m 3

- Kamenka: open

- New Year 2020

- Steam room volume: 12-24 m 3

- Kamenka: open

- New Year 2020

- Steam room volume: 12-24 m 3

- Kamenka: open

- New Year 2020

- Steam room volume: 12-24 m 3

- Kamenka: open

- New Year 2020

- Steam room volume: 12-24 m 3

- Kamenka: open

- New Year 2020

- Steam room volume: 12-24 m 3

- Kamenka: open

- New Year 2020

- Steam room volume: 12 m 3

- Kamenka: open

- New Year 2020

- Steam room volume: 12 m 3

- Kamenka: open

- New Year 2020

- Steam room volume: 12 m 3

- Kamenka: open

- New Year 2020

- Steam room volume: 12 m 3

- Kamenka: open

- New Year 2020

- Steam room volume: 12 m 3

- Kamenka: open

- New Year 2020

- Steam room volume: 12 m 3

- Kamenka: open

- New Year 2020

- Steam room volume: 8-18 m 3

- Kamenka: open (mesh)

- New Year 2020

- Steam room volume: 12-24 m 3

- Kamenka: open (mesh)

- New Year 2020

- Steam room volume: 12-24 m 3

- Kamenka: open (mesh)

We accept for payment:

Our main customers: Moscow Region (MO), St. Petersburg, Yekaterinburg, Nizhny Novgorod, Krasnoyarsk, Omsk, Samara, Crimea, Rostov-on-Don, Volgograd, Ufa, Perm, Voronezh, Kazan, Novosibirsk, Chelyabinsk, Yakutsk, Surgut , Arkhangelsk, Krasnodar, Astrakhan, Vladimir, Izhevsk, Ulan-Ude, Saransk, Irkutsk, Orenburg, Murmansk, Penza, Ryazan, Penza, Tula, Vladivostok, Ussuriisk, Petropavlovsk-Kamchatsky. © 2020 KaminDom.ru Inexpensive online store of fireplaces and stoves for a private house and summer cottage. Here you can buy heating systems in Moscow, St. Petersburg with delivery across Russia inexpensively.

You can pay for your purchase in the following ways:

| 1. Cash payment to the courier upon delivery or at the pickup point (only for residents of Moscow and the Moscow region). |

| 2. Cashless bank transfer to the settlement account of the individual entrepreneur according to the previously issued invoice. |

| 3. Payment by credit card from the site. Before paying, check with the manager in advance. |

| 4. Transfer to a bank card. You can pay either through the Internet bank by transferring to our card (Sberbank), or at any branch of the bank. |

| 5. Payment via terminals. |

If you have chosen to pay in cash to the courier or by credit card upon delivery of the goods, then you can pay for the purchase directly with the courier of our store at the time of delivery of the order. Payment is accepted only in Russian rubles upon delivery of goods and transfer of all necessary documents. This payment method is available only for individuals.

For individuals residing outside the Moscow region and receiving goods through a transport company and for legal entities - payment is made in a non-cash form to the current account of the store or to a bank card. In this case, payment for the order is made according to the issued invoice, which you can receive by e-mail.

The invoice must be paid within 3 banking days. If during this time you have not sent funds to pay the invoice, it is considered invalid. After paying for the order, be sure to inform us about the fact of payment.

In the message, indicate: date, amount of payment, order number, full name. and the number of the payment order.

Which heat exchanger to choose for a stove in a bath

When choosing a heat exchanger design, the advantages and disadvantages of each type are taken into account. The selection of a suitable device is influenced by the intended purpose and the required performance:

- Sauna stove with built-in heat exchanger - used for simultaneous heating and hot water supply. Long-burning furnaces operating in gas generation mode cannot provide the necessary heat transfer when installing a hinged tank. The reason for this is that the flue gases have a lower heating temperature. If you plan to install a long-burning stove, there is no alternative to the built-in coil or plate structure. Effective heating in a bath is possible only from a stove with a built-in heat exchanger.

A stove for a bath with a samovar-type water heater is distinguished by high performance of hot water, but for heating, a tank worn on the chimney is not very suitable in terms of technical characteristics.

When choosing what to install, a built-in heat exchanger or a samovar type, take into account the peculiarities of their operation. For simultaneous heating and hot water supply, a coil, plate heat sink or water jacket is better suited. Exclusively for hot water supply, it is better to install a samovar-type water heating tank.

How to install a heat exchanger in an oven

Built-in heat exchanger - mounted at the factory, drum type - installed on the chimney. Tanks are made of different internal diameters, therefore, installation does not require much effort and is carried out simultaneously with the output of the chimney. Factory containers are supplied with a capacity of 20 to 80 liters.

The difficulty lies in connecting the batteries from the oven. On the body there are special outlets for the supply and return of the coolant, to which the pipes of the heating system are connected.

The work is performed in compliance with the following recommendations:

- Pipes for connection to the heat exchanger. The coolant temperature often exceeds 85-100 ° C. Plastic, with such heating, can deform, so it is not used. For the heat exchanger, you must use steel pipes, copper is suitable.

- Connecting batteries - with natural circulation, the length of the pipe from the furnace body should not exceed 10 m.

- Installation of circulation equipment - forced circulation heating systems are installed for large heated rooms, often used in industrial baths.

- Heat exchanger pipe diameter - manufacturers clearly prescribe in the technical documentation the size and pitch of the thread, which facilitates the selection of the pipe for installation. The diameter of the pipeline in the heating system, if necessary, can be increased, but not reduced.

Experienced craftsmen's recommendations

When installing a heat exchanger for hot water in a bath, you need to remember that:

- A portable water tank should be selected in accordance with the capacity of the sauna stove - too large a container will heat up for a long time. In a small tank, the water will boil early and fill the washroom with unnecessary steam.

- The heat exchanger must also match the furnace - too large a design will reduce the furnace's efficiency. The best option is when the system takes 10 percent. from the power of the stove.

- The pipes of the system should not be rigidly fixed to the walls - their linear dimensions change when heated.

- For threaded connections of the system, only a seal is used that can withstand high temperatures.

- In a system with natural heat exchange (without using a pump), a slope of 2 - 5 degrees of the upper and lower pipe contours must be observed.

- The bath tank with a heat exchanger must not be empty during the heating of the stove.

After warming up the system to high temperatures, it is undesirable to add cold water - a sharp drop will negatively affect the service life

A sauna stove with a heat exchanger will allow you to get maximum comfort and, at the same time, preserve the charm of this beloved traditional procedure.