Insulation requirements

Thermal insulation of pipes provides for a number of technical regulatory documents, the observance of which is mandatory in the design, installation and operation of engineering systems of residential and public buildings, and other facilities for various purposes.

More information can be found on the website:

https://www.ktto.com.ua/norm/teplo_pot

It should be noted that industrial thermal insulation refers to the thermal insulation of pipelines, tanks, as well as equipment and tanks.

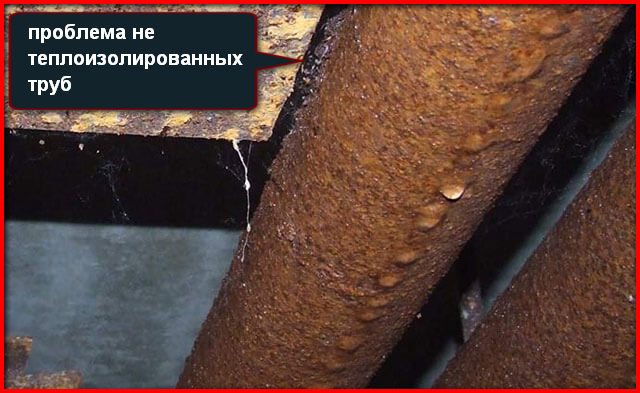

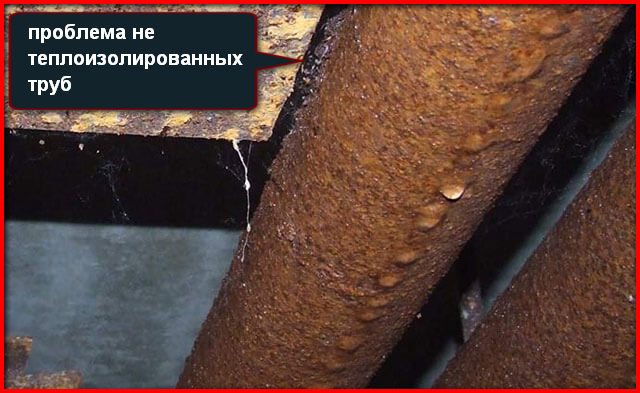

Thermal insulation is carried out to prevent cooling of the liquid present in the pipes or to avoid the formation of condensate on the equipment. If heat loss is not so important, then this technological process is necessary to comply with safety standards.

Different versions of insulators are considered for insulating pipes used to transport gas.

The thermal insulation of the gas pipeline is carried out by means of a special varnish or paint, but usually they resort to modern protective materials that meet all the requirements for this, namely:

- an insulator for a gas pipeline must be endowed with the potential of a monolithic, uniform device on the pipe;

- the material for the thermal insulation of the pipeline must be characterized by a low coefficient of water absorption and have high waterproofing qualities;

- protect the structure from destructive ultra-radiation.

Requirements for thermal insulation for heating pipes and its purpose

The main purpose of the materials:

- Reduced heat loss. With high-quality protection, the standard heating of the coolant in the pipes is maintained during the movement. The condition is necessary for uniform heating of heating devices in the house, apartment.

- Thermal insulation reduces the risk of liquid freezing and network failure.

- Reduced risk of condensation. When using insulation materials, it is permissible to lay pipes above the freezing point of the soil. This reduces the cost of forming the backbone.

On a note! Thermal insulation is used for the heating system, hot water distribution, cold water supply.

Indoors, you can do without insulating products. However, if the supply of heat is organized in remote outbuildings, the network is branched, the use of materials is necessary. In this case, thin sheets are used for installation on straight sections of the contours.

Before buying materials, you should decide on the type of insulation and the layer of layout. The thickness depends on the temperature indicators of the area.

Product requirements:

- the hydrophobicity index should be low;

- resistance to wind, mechanical stress and sunlight;

- extended operating temperature range;

- duration of operation.

Pay attention to ease of installation and docking. Some products are produced with tool joints of certain cross-sectional dimensions. Single-piece modules should be purchased only after measuring the diameter of the pipeline with a small margin.

Types of thermal insulation materials

Thermal insulation is subdivided into types with certain properties and is produced in the following forms:

- senments;

- cylinders;

- mats;

- half-cylinders;

- rolls.

Types of thermal insulation:

- mineral wool;

- shell;

- polyurethane sealant;

- tubular insulation;

- liquid ceramic composite;

- basalt insulation.

The list above is not limited to this, the market is regularly updated with new options in this area.

What is the basis of the choice of insulation material

To choose quality products, you should pay attention to the following nuances:

- Pipeline location area. If the highway is laid out indoors, you will not have to use protective sheets of galvanized or aluminum steel, mineral wool insulation is enough.

- Potential problems with biological life forms. Rodents do not damage glass wool and paint, but they can destroy foam and other insulating materials - this should be taken into account.

- The size, configuration of the heating supply line. The more complex nodes, turns, the stronger and more flexible the heating pipe winding should be.

- The maximum indicator of heating the coolant.

If the pipeline is recessed in the wall, floor, covered with a cement screed, then polyethylene is used - the material can withstand the aggressive effects of cement mixtures. Dispersed polyurethane foam and paint allow you to cover any complex nodes with a protective layer, and polyurethane foam is sprayed in hard-to-reach areas. But to apply polyurethane foam, you will need a special device, and with thin pipes, difficulties can arise - most of the foam settles on the walls.

When protecting the mains in areas with unstable soils, when several objects are connected to one boiler, polyethylene or molded foam are considered the best insulating materials. Mineral wool basalt insulation is highly not recommended for moving soils - when creating excessive loads under the weight of the sheets, the pipes can deform and burst.

Thermal insulation with mineral wool

Mineral wool of all the types of insulation presented today is characterized by the lowest cost, and the advantage is the ease of installation of insulation. Thermal insulation of pipelines with mineral wool - process:

- a roll of cotton wool is cut into strips 200 mm thick (across) and they are then wrapped around the pipes, first with a layer of mineral wool (100 mm thick), on top - tightly with a layer of fiberglass;

- mineral wool should be laid evenly, it should not wrinkle.

Mineral wool is considered as thermal insulation of pipelines of significant diameter, applicable for heating routes of urban networks and for sewerage systems, for sewerage systems of small diameter and for water supply pipes - not practiced.

Thermal insulation of external pipelines

The choice of thermal insulation materials for external laying of heating pipes is quite large and are offered in the form of roll-type mats.

The pliability of the material allows you to give them a figured shape for ease of installation, heaters are offered, applied in a liquid form, their further qualities are manifested after solidification.

Removable thermal insulation in a galvanized casing is widely used in linear pipeline sections.

Foam rubber in the form of tubes or rolls, depending on the diameter of the pipes, is used as thermal insulation for pipes and parts of technological pipelines, installed in several layers, depending on the required thickness of thermal insulation.

An interesting method for thermal insulation is considered to be a cover layer, the types of which are really familiar on the site:

Materials for thermal insulation of heating pipelines

Products are produced in the form of rolls, sheets, cylinders or other units. There is also an assortment of liquid, dispersed compositions. Apply the mixture with a roller, spray gun.

Foamed polyethylene

Insulation for heating pipes with a thermal conductivity coefficient of up to 0.035 W / m * C. Roll material is easy to install and can withstand any level of humidity. Does not support combustion, self-extinguishes, but melts over an open fire.

The disadvantage in the fineness of the material - if you use polyethylene as a winding, the consumption will increase. It is more practical to take ready-made casings by laying them on open sections of the track. The inner diameter of the sleeves should be chosen according to the dimensions of the outer section of the pipeline. Installation with cutting the wall of the sleeve, fixing the cut with tape.

Types of plastic heating pipes and their characteristics

Penofol belongs to the type of polyethylene. The material has high strength, heat resistance. Penofol sheets are equipped with a foil-coated protective film.

Advice! It is permissible to use foamed polyethylene in circuits with heating of the coolant up to +85 C. At higher temperatures, the material melts. The area of use is the internal insulation of the autonomous heating network.

Mineral wool

This is a budget insulation for heating pipes of any type and length.

The advantages include:

- low cost;

- ease of installation;

- versatility of application;

- strength.

Minus one - cotton wool absorbs water. When forming insulation, additional protection with a film or roofing material will be required. Lay the sheets on top of the mineral wool, then fix it with tape.

Advice! When choosing a material, it is better to give preference to glass or stone wool (basalt). Slag raw materials absorb water too quickly, and residual acidity destroys pipelines.

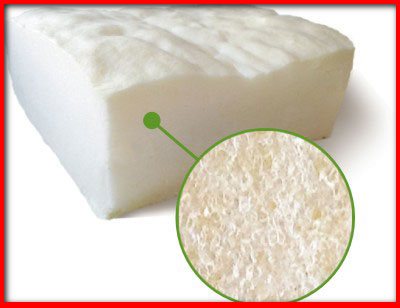

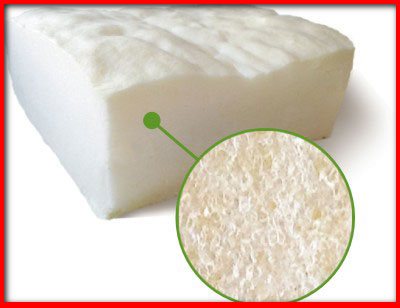

Expanded polystyrene

Inexpensive and effective thermal insulation of lightweight heating pipelines. Foam parts are sold in the form of piece finished forms. Installation is simple, but the parts are not flexible and durable.

Additional disadvantages are flammability, emission of harmful substances, short service life and deformation under mechanical stress.

Pros:

- low coefficient of thermal conductivity;

- non-susceptibility to biological life forms;

- ease of installation, processing;

- chemical inertness.

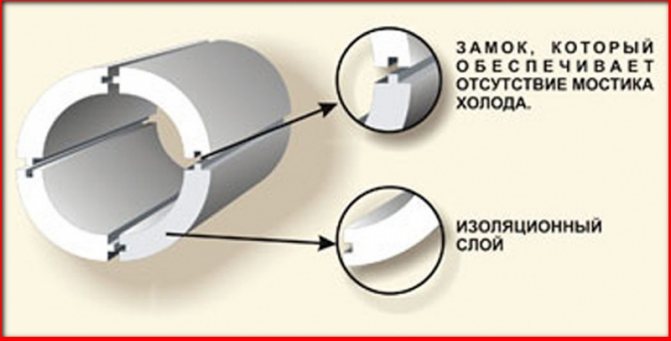

Foam modules are inexpensive, equipped with a lock connection, and are easy to transport.

Important! When the modules are heated above +75 C, linear deformation is possible. The material should be protected with galvanized metal sheets. This condition increases the cost of arranging the network.

Polyurethane foam

Modified material with high strength and durability.

Heating pipe diameters and installation options

Thermal insulation products are produced in different forms:

- Dispersed mixture. Apply by spray. After drying, a flexible layer is formed on the line, which transfers thermal, mechanical stress. The mixture is expensive, it should be used in areas of complex shapes, nodes.

- PPU modules or shells. The goods are supplemented with a foil layer, tongue-and-groove connection. The size is selected depending on the section of the pipe. On the inside, the modules are covered with an adhesive layer, which facilitates installation.

On a note! The dispersed mixture fits well on the surface of the highway, resists water. Protection is required only from sunlight. It is better to take sheets of galvanized steel, fasten metal belts in the areas of joint of the sheets.

Foamed rubber

A new type of product that has a wide range of advantages:

- extremely high tensile strength;

- minimum density (40-80 kg / m3);

- incombustibility;

- no shrinkage;

- inertness to biological life forms, chemicals;

- zero permeability.

Rubber pipes with a diameter of 60-160 mm, a wall thickness of 6-32 mm or sheet products do not shrink throughout the entire service life. The products are equipped with an adhesive inner layer (the sheets are coated on one side), so installation is not difficult.

Important! Rubber is vapor permeable, so the risk of condensation is reduced to zero.

Heat insulating paint for heating pipes

If the standard winding of heating pipes does not suit you, you can choose a ceramic liquid insulation.A thin layer of the composition has extremely high insulation values, protects pipes from any external influences. The mixture should be applied with a brush, roller or spray.

The composition contains ceramic, silicone vacuum capsules, dissolved in a mixture of acrylic, rubber components. Fillers explain the high thermal insulation properties. After painting, pipes do not need additional protection with sheet materials.

On a note! The number of paint layers depends on the climatic conditions of the region, the temperature of the standard coolant, and the operating conditions of the network.

Polyurethane foam

Polyurethane foam as a pipeline insulation is an environmentally friendly and efficient insulation. It is characterized by a neutral odor, is not susceptible to fungus, endowed with increased resistance to harmful environments, does not deteriorate, and is completely harmless to humans and the environment.

Directly for large-diameter pipes, a spraying method is applied, as a result of which a seamless continuous insulation is formed, a peak reduction in heat loss is guaranteed. Spraying is carried out at the place of work, using special equipment for thermal insulation of pipelines, the simplicity and speed of the procedure is a clear advantage. For work on pipes of small diameter, shells based on polyurethane foam are considered, which provide a high level of thermal insulation, this method is affordable at its cost.

Helpful hints

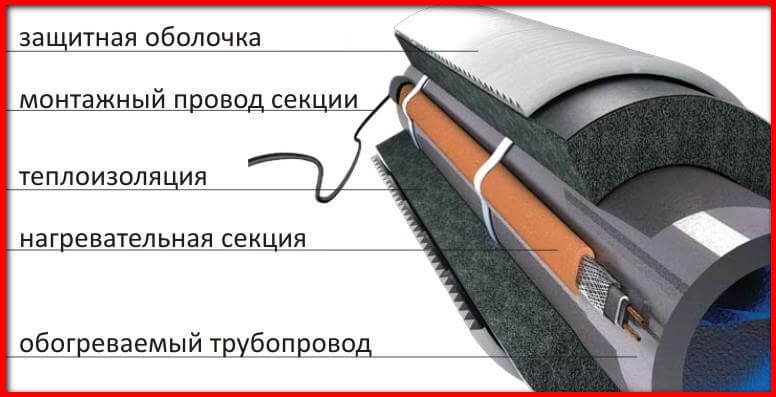

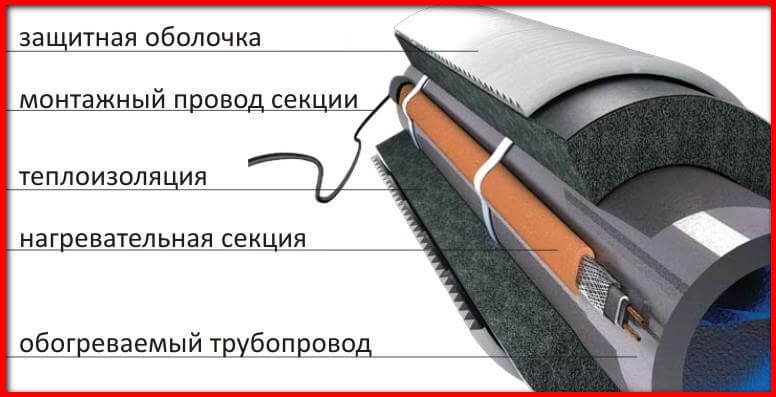

Pipeline heating system

The pipes on which the heater will be installed for them in the future do not have to be placed below the depth of soil freezing. To eliminate heat loss, it will be enough to cover the structure with an insulating layer.

It is imperative to make marks not only directly on the pipeline itself, but also near the trench. Decals will indicate that heating cables are installed here.

Do not install the wire if the ambient temperature has reached –15 degrees. Indeed, during installation, you need to bend the cable, the diameter of which should be at least 6 diameters of the electrical wire itself.

If the heating system is mounted on an object to protect it from freezing, be sure to equip it with a special residual current device. It is selected according to the rules for the installation of electrical installations.

How is the work on the insulation of pipelines carried out

Thermal insulation must be carried out in accordance with applicable rules and regulations, which guarantees effective energy savings and an increase in the duration of the useful life

.

The installation of thermal insulation of pipelines, based on the article, can really be done using various materials, but taking into account certain factors and, above all, from the direct purpose of the future laid system.

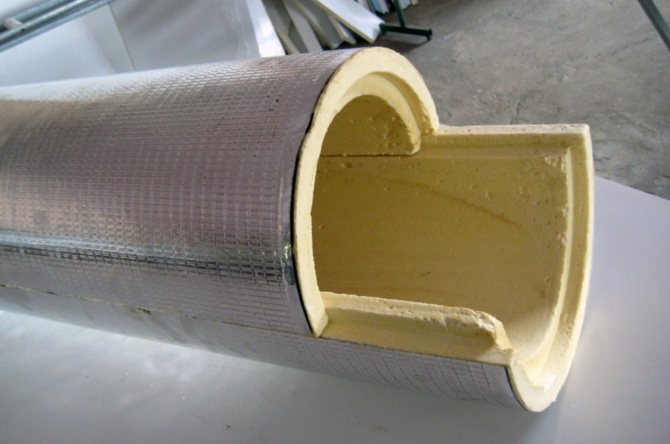

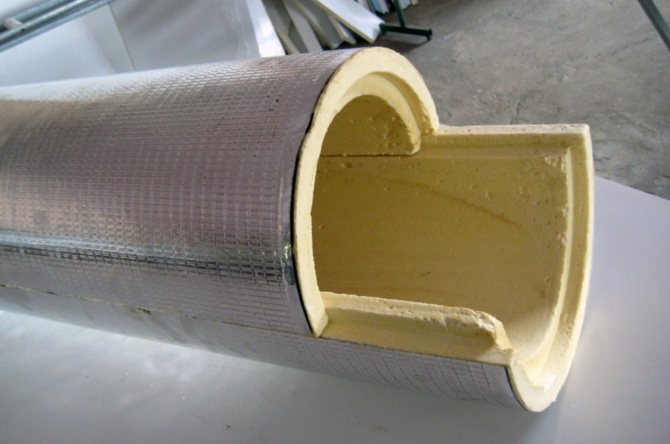

For example, thermal insulation of pipelines with a high temperature of the medium transported through it is best done using cylinder insulation (polyurethane foam shell), additionally lined with foil cardboard or foil.

Brief device for thermal insulation of pipelines

Preliminary stage:

- complete completion of installation work (locksmith, welding);

- cleaning with steel shields (manually) or using sandblasting machines of the surface and joints of the pipeline, degreasing;

- testing the strength and tightness of welded seams (visual inspection, pressure testing, control (if necessary) using special equipment));

- application of special compositions - epoxy primers (as an example).

It is interesting to get acquainted visually with the installation process: