The construction of new private houses is distinguished by a rational approach to the issue of energy conservation. But what to do with buildings that have stood for more than 30-40 years. Not everyone will be able to start a complete reconstruction, but it is quite possible to increase thermal protection. You need to start by examining the surfaces of walls, roofs and foundations.

Maintenance should be done if necessary. It makes no sense to install insulation material on dilapidated buildings. There will be little benefit from such isolation. But to make the sealing of small cracks, holes and potholes, which do not pose a threat of reducing the bearing capacity of the structure, is within the power of everyone. As a rule, cement mortar is used for these purposes. Window and doorways require special attention, because through the cracks in them the lion's share of heat leaves the room. When preparing a house for winter, do not forget about floor insulation. First, you need to figure out which base is under the boardwalk.

Option number 1: floor insulation in a house standing on the ground

This method of arranging the floor has as a base a concrete screed or slab, laid without reference to the foundation. When erecting a structure, this method saves time and money, so builders often use it. According to the technology, it is impossible to lay slabs on loose sagging soil. Due to shrinkage, the concrete base sinks above the level of the subfloor, which forms a flow of cold air into the dwelling. Heating the room in winter is problematic. But the situation can be remedied.

Insulation stages

1. Dismantle the plank covering.

2. Level and compact the soil (if it appears on the concrete surface due to cracking).

3. Make a bed of expanded clay or crushed stone (at least 10 cm).

4. Lay coarse sand (at least 10 cm) on top of the backfill layer.

5. Tamp the surface.

6. Pour the concrete screed.

7. After complete solidification of the solution, cover the waterproofing layer (use a special film or roofing material).

8. Install the extruded polystyrene foam boards. The joints between the insulation should be kept to a minimum.

9. Line the reinforcing metal mesh.

10. Pour the surface with a finishing screed, using a cement-sand or self-leveling mixture.

11. Next, a floor covering is laid on the surface or a "warm floor" system is installed.

After such installation, it will be comfortable to walk on the floor even in severe frost.

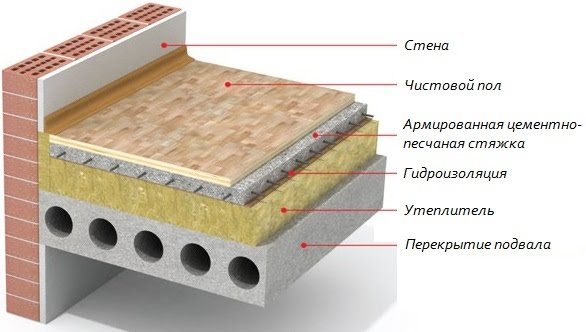

Option number 2: floor insulation above the basement

Before proceeding with the thermal insulation of the floor, you need to explore the basement. For the normal functioning of the air and creating optimal humidity in the basement, it is necessary to carry out ventilation. If the foundation is the walls of the basement, the base of the house should be insulated. For this, it is better to use the outdoor installation method.

If the floor is unpaved in the basement, it must be carefully tamped and covered with coarse sand with a layer up to 20 cm thick.

nastroike.com

Insulation of the basement of the house from the inside

If the foundation was not insulated during construction, then external insulation becomes very time consuming. Therefore, insulation is most often made from the inside. In an insulated and unheated basement, the temperature remains within +10 degrees, even during frost periods. Accordingly, the house itself is better kept warm. There is also a minus - interior decoration with heat-insulating materials reduces the useful area of the room.

Insulation of the basement walls from the inside

Basement insulation from the inside in a private house or apartment building can fully provide adequate protection against humidity and cold. But it must be remembered that the use of a waterproofing material is mandatory, otherwise the condensate will penetrate into the insulation and not only worsen its thermal insulation characteristics, but also completely destroy it.

The order of work is as follows:

- existing damage on the walls is covered with sealant or blown out with polyurethane foam;

- the surface of the walls is leveled as much as possible so that the insulation plates lie flat;

- walls are treated with waterproofing material (mastic or liquid rubber);

- insulating slabs are laid using an adhesive mixture;

- laying begins from the bottom, tightly joining the plates;

- all cracks are filled with polyurethane foam;

- the plates are fixed for reliability with dowels (5 pieces for each plate);

- after the glue has dried, a screed is made using a mesh and a cement mixture;

- in the end, the wall is covered with a finishing material.

Correct insulation of an unheated basement from the inside will provide protection from moisture and cold

Basement ceiling insulation from the inside

The ceiling in the basement is a concrete ceiling that conducts both heat and cold well. The insulated ceiling of the basement will always provide a warm floor in the house.

Stages of work on insulation of the ceiling in the basement:

- the concrete ceiling is covered with a water-repellent layer (mastic, rubber), which at the same time closes all cracks in the concrete;

- after the waterproofing has dried, the insulation boards are glued and fixed with dowels;

- a special mesh is applied to the fixed insulation using a cement mixture;

- finishing decorative finishing is performed.

It is important! The ceiling is most susceptible to condensation. Therefore, it is necessary to carry out a very high quality waterproofing.

How to insulate the ceiling in the basement and what material is better for this will be discussed below.

It is not recommended to insulate the ceiling without waterproofing

How to properly insulate the floor in the basement of the house

The process of insulating a basement floor is easier than insulating walls or ceilings. If it is not yet equipped, then the basement floor is insulated directly on the ground in the following order:

- the ground surface is leveled;

- a layer of sand is poured and compacted;

- a layer of crushed stone is poured and also compacted;

- poured with liquid concrete;

- after drying, the waterproofing layer is laid overlapping;

- insulation plates are being laid;

- a layer of foam foam (thin roll material) can be laid on the insulation with the foil surface upwards so that this film reflects heat;

- a reinforcing mesh is laid and everything is poured with concrete;

- after drying, you can install the floor covering.

Useful advice! After laying penofol and a mesh, if you want to make a warm floor, a heating circuit is laid and then everything is poured with concrete.

If the floor has already been concreted before, then the task becomes easier, and the work begins with laying the waterproofing.

A waterproofing layer is laid on top of the screed

In cases where the floor is equipped with logs, the first step is to remove the upper finishing coating. Considering that the waterproofing should already be laid under the logs, you can pour expanded clay or lay out insulation plates between them. Then the entire structure is covered with another layer of vapor barrier (a simple film, for example) and a final floor covering is installed.

Related article:

Soundproofing walls in an apartment from neighbors

Materials that provide the best effect. Characteristics, description, reviews, installation methods.

If there is a utility room in the basement, then floor insulation is not required. In the case when the basement is insulated in order to equip a functional room in it, then the question of how to insulate the floor in the basement suggests a positive answer.

Building with a basement

Owners of private buildings intended for permanent residence often think about how to cheaply insulate the floor and not spend a lot of money on work. You don't need to save too much. Inexpensive insulation made from low-quality materials will only lead to one loss. But you should not carry out complex work, where you can really do without them. In buildings with a plinth, alas, this cannot be done.

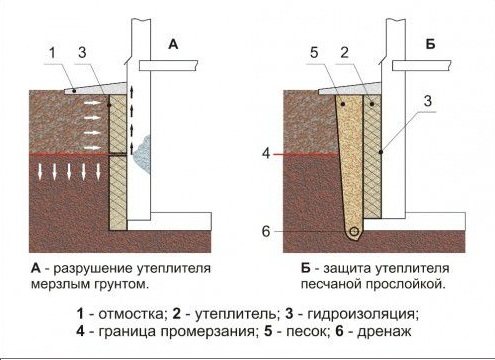

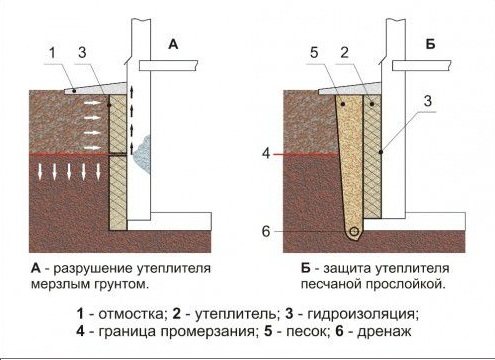

Since the ground masses usually freeze to a significant depth, insulators should be installed in areas where the maximum exposure to cold occurs. The best option is external insulation of the basement walls. Due to this, the soil will be deprived of the opportunity to contact the wall surface.

A good option for insulation is extruded polystyrene foam. This is not to say that it is very expensive, but you cannot call it cheap either, since a large number of products have to be used at the facility. Expanded polystyrene plates have all the necessary properties to reliably protect the base from freezing. It is advisable to carry out the insulation itself along the entire height of the supporting structure.

The correct calculation of the thickness of the insulation material is calculated on the basis of many characteristics, from the variety of soil masses to the depth to which the soil freezes. When the underground areas of the foundation are covered with expanded polystyrene, they are subsequently covered with earth. The basement area is allowed to be finished with any suitable material. It serves as the final decorative and protective layer of the insulation system.

When insulation is required from below

When thermal insulation of the floor in the house is required

- the need to reduce the height of the room;

- protection of the floor and the entire coating from freezing;

- moving the dew point, due to which the decay process can be avoided.

Insulation of floors protects the house from freezing

During repair work in a private house, some difficulties often arise that are directly related to the insulation of the bottom. Let's consider the most common ones:

- a more reliable fixation of the heat-insulating material is required;

- the presence of a low subfloor greatly complicates the work;

- floor insulation from below contributes to the rapid fatigue of workers, which greatly delays the process;

- the variety of types of insulation is not very large.

How and what can you insulate the floor in a private house

Floor insulation is a rather complex process that requires preparation. First of all, before starting repair work, you need to decide on the choice of insulation.

How can you insulate the floor in a private house and what materials should you use?

The floor is right above the basement

It is not always possible to properly isolate the foundation and basement. In this case, the work is carried out inside. Before proceeding with the necessary activities, the underground space is thoroughly dried. If it is already dry, you can start creating ventilation holes. Is there ventilation already? Let's assume you're in luck. Therefore, it remains to tamp the soil, after which sand is poured 15-20 cm.

Next, you need to put lags and nail the cranial bars to them. The latter are mounted along the entire length of the beams. Then a special board roll is installed. There should not be any gaps or cracks in it. An alternative to boards is special boards with good moisture resistance.

The roll is covered with a film that is unable to pass water. Instead of a film, wax-type paper is sometimes used. Both the film and the paper take over the tasks of the waterproofing layer.

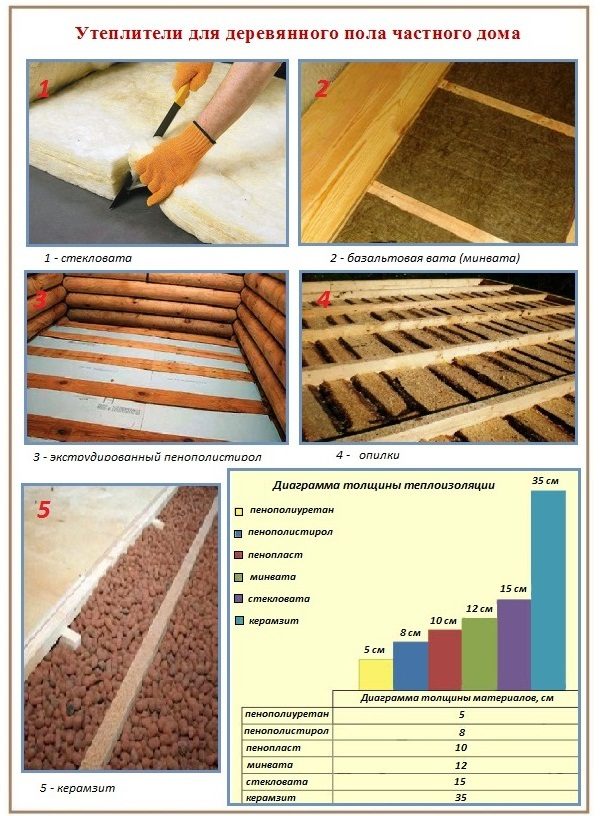

Warming

Insulation material is placed on top of the waterproofing. The optimal solution is either a product made of basalt or staple glass fiber. The listed products are able to "breathe".

Following the laying of insulators, it is the turn of the subfloor. Everything is simple here. Wood blocks, chipboards, unedged boards or other material are nailed to the previously installed beams. A gap of about 1 cm is left between the floor and the wall structures.Purpose - ventilation. The gap will not spoil the appearance of the room, since it is subsequently necessarily masked with baseboards.

How to inexpensively insulate the floor in compliance with the technology, which involves the use of logs, ventilation holes, nailing boards and other elements? Honestly, no way. BUT do not think that the described works cost prohibitive sums. The price is quite adequate when compared with various measures for the construction of a residential building.

Of course, very cheap materials can be used. Such a floor will quickly deteriorate. We'll have to do it all over again. You end up paying one and a half or even double the cost. So it is better to immediately warm up normally so that the system will serve for decades.

Floor insulation

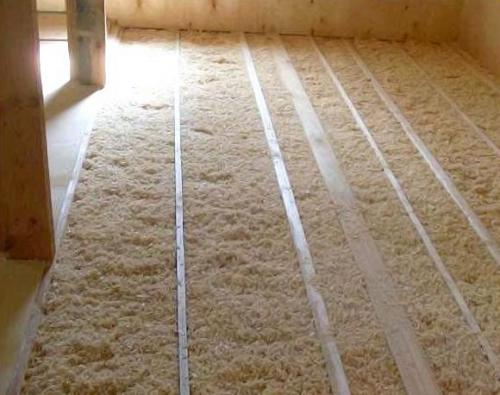

The energy efficiency of building structures, both external and internal, is of great importance for keeping the home warm. One of the processes requiring special attention is the insulation of ceilings and floors. Uninsulated floors can cause 15% of total heat loss. In multi-storey residential buildings, ceilings are not insulated, because they separate rooms with the same temperature regime of operation. In individual dwellings, however, this does not always happen. Some of the premises can be located above an unheated garage or a cold basement. In such cases, the floor of the first floor or interfloor overlap should be insulated. In cottage construction, floors are most often used from prefabricated reinforced concrete panels or load-bearing wooden beams. Depending on where they are located, the floors are divided into attic, interfloor, basement and basement. Attic wooden floors Thermal protection of attic floors should be given due attention: in a cottage with a cold attic, up to 10-15% of the energy spent on heating is lost through the attic. And this is not surprising, because the attic floors separate the non-residential under-roof space and the roof. If it is not insulated, in order to avoid heat loss, the overlap on the side of the under-roof space should be insulated. As a heater, you can use basalt or fiberglass slabs, as well as heat-insulating materials, on one side covered with foil, which should face a warm room. The insulation is placed on a board roll made between the floor beams along the cranial bars. To protect the material from getting wet, it is covered with waterproofing.

On top of the waterproofing, a continuous running floor is arranged from a board with a thickness of 30-40 mm (this parameter depends on the step with which the floor beams are laid). Since water vapor from the lower rooms penetrates into the attic through the attic floor, the insulation from the "warm" side must be protected with a vapor-proof material. It is attached from below to the floorboards with a stapler, and then the ceiling is made from hemmed boards or drywall slabs. In the case of using foil insulation, vapor barrier is not needed. Good thermal insulation of the attic floor is also important because it prevents the temperature of the lower floor ceiling from decreasing. As a result, wet spots do not form on it - harbingers of fungus and mold, which are difficult to get rid of.

Interfloor wooden floors As for interfloor floors, they have not been insulated for a long time, but today new energy-saving canons and requirements for living space have emerged, more technological materials have appeared. Nowadays, interfloor ceilings are insulated also because they are equipped with warm floors, which give comfort and economy. There is another reason why heat-insulating materials are placed in the inter-floor ceilings - they have good sound insulation properties and can reduce the noise level in the rooms of adjacent floors. In addition, the design of the floor slabs must prevent heat from escaping to the outside.This happens in the places where the ceilings rest on the walls, because due to the design features in these areas, they are thinner. In interfloor ceilings, beams simultaneously serve as load-bearing elements of the lower floor ceiling and floor joists. An option is possible when logs are additionally laid on top of the beams with a pitch of 600-800 mm, on which a rough and then a finishing floor is arranged. Thermal insulation materials are placed between the beams in one or more layers. From the side of the lower floor, the insulation is protected from wet vapors with a vapor barrier material, which is attached to the flooring made of boards. The ceiling of the lower floor, as in the case of the attic floor, is made of planks or gypsum plasterboards.

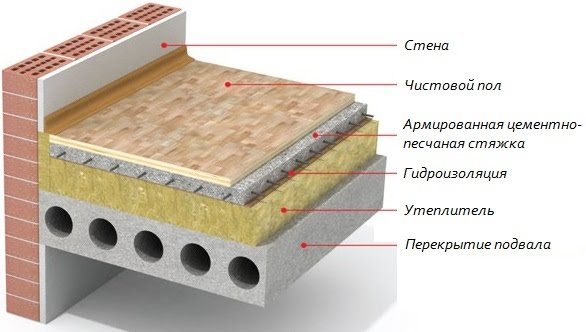

Ceilings made of reinforced concrete slabs If the floor is made of precast concrete slabs, then regardless of whether it is between floors, attic or basement, it is insulated. The first thing to do is to stamp (fill) the joint seams and unevenness of the floor slabs, since when laying them they are aligned along the lower surface that serves as the ceiling. This is done with a cement-sand mortar. A vapor barrier film with glued overlapping joints is placed on the leveled surface, and on top of it is a heater, the thickness of which is determined by thermal engineering calculation. I must say that vapor barrier is needed when using mineral insulation. If a polymer material is laid, for example, extruded polystyrene foam (EPS), then a vapor barrier, like waterproofing, is not needed. Indeed, thanks to the closed cellular structure, this material is not afraid of water. EPS is not the cheapest insulation, but its presence in the underfloor heating allows you to save on steam and waterproofing.

If the thickness of the selected insulation plates is not enough, they are placed in two layers with a gap between the joints. On top of the insulation, a cement-sand floor screed is made, reinforced with a metal mesh with a cell size of 100 x 100 mm. In this case, the mesh should not lie on the insulation, but be "torn" from it by 20 mm and be in the thickness of the screed, otherwise the latter will not work. For this, small pieces of brick or crushed stone are placed under the mesh, after which they are poured with a cement-sand mortar. The screed is leveled with a leveling compound. If wet processes will be carried out in the room, then a waterproofing layer must be applied over the screed. After that, any floor covering can be glued to this base (if it is not located on the attic floor): linoleum, carpet, ceramic tiles or parquet. The materials used for thermal insulation of floors are subjected to increased loads, therefore, they must have high strength and low deformation during compression. Best of all, such loads withstand hard mineral wool slabs, designed specifically for floors, and EPS.

Basement hardwood floors In hardwood floors installed above basements and basements, beams also serve as floor joists. Of course, the floor above a cold underground or unheated room must be insulated. What is the best way to do this? First of all, you need to decide what to insulate: the floor itself or the underground? It is more effective to insulate such an overlap from the floor side. However, using this or that material for this purpose, you need to understand what function it performs. Consider an example that relates to the construction and insulation of floors both above a cold underground (if there is no basement in the house) and above unheated rooms.

Wooden floor beams are supported on the walls of the house, leading them into specially made holes. The height of the basement base determines the depth of the underground, which must be dry so that the logs and the floor structure as a whole do not rot.To do this, ventilation openings should be provided in the underground, which will ensure the inflow and outflow of air, and all wooden elements - floor beams, cranial bars and subfloor boards - must be treated with antiseptics. The underground soil must be carefully tamped with crushed stone and covered with a layer of sand 150-200 mm thick. It will help keep the room dry as it absorbs moisture. To lay the insulation, cranial bars are nailed to the logs along the entire length, on which a roll of boards (subfloor) 20 mm thick or a moisture-resistant OSB-3 board is supported. Boards must be nailed without gaps so that the insulation is not blown out through the cracks.

For insulation, it is better to use a material based on basalt or staple fiberglass, which allows the floor structure to breathe. On top of it, wooden blocks of 50 x 50 mm are nailed or a board 0SB-3 is placed, which serve as the basis for the finished floor. A ventilation gap of about 10 mm should be left between the wall and the floor, which will be covered with a skirting board after the floor has been laid. If the floor on a wooden floor is arranged above an underground with moisture-saturated soils and closely located pound waters, then a cement screed with a thickness of 20-30 mm should be arranged on the leveled surface of the underground. Then, on top, you need to lay a waterproofing made of a fused roofing material and bring it to the walls to the level of the finished floors.

When insulating the floor from the basement side, polystyrene foam plates with a thickness of at least 60 mm are used. They must first be glued to the ceiling with mastic, and then secured with special pegs (4 pcs / m). The finishing of insulated ceilings depends on the way the basements are used and the aesthetic requirements arising from it: you can lay a leveling layer of mastic on the slabs, and then paint the prepared surfaces or glue a fiberglass mesh to the slabs, and then plaster them. So that there are no cold bridges left in the insulation, you need to carefully seal the places in which pipes pass through the ceiling. Polyurethane foam is best suited for this purpose. It is also necessary to seal the door leading to the basement by gluing rubber gaskets, and if there is a garage on the basement floor, insulate its gates as well. This will increase the temperature in the basement, which means less heat loss.

Ground Floors Warming pound floors is more difficult and time consuming than warming a basement floor. Care must be taken especially if the concrete floor is laid on a layer of slag or other material with poor thermal insulation capacity. To effectively insulate such a floor, use polystyrene foam or EPS boards with a minimum thickness of 100 mm. However, this will significantly reduce the height of the room, as the floor level rises. In addition, the area of the door leaves will have to be reduced. It is much better to dismantle the old floor and replace it with EPS plates with a thickness of 150-200 mm. EPS floor insulation is effective when used in the most extreme conditions: under the influence of moisture, low temperatures and mechanical stress, as well as in the presence of aquifers and groundwater in the construction areas.

It is much easier to insulate a plank floor on logs installed on brick posts, because such a floor is easier to disassemble. And after dismantling, there is usually enough space for laying insulation, concrete lining and leveling layers for any finish. Do not forget that it is better to lay "floating" floors on the thermal insulation, that is, to mount them so that they do not come into contact with the walls of the building, and the resulting gaps should be forgotten with elastic material.

Thermal insulation from the basement side

Don't want to take apart your existing floor? Perhaps you will be satisfied with a solution based on complex thermal insulation of the basement ceiling located in the basement. This is done as follows:

- take thin wood slats, mount a vapor barrier type film with them to the ceiling filing (the size of the linen overlap is 10 cm);

- to nail the blocks made of wood, with a step that is equal to the dimensions of the insulation materials;

- lay insulators between the bars (mineral or glass wool, polystyrene and analogs);

- strengthen the heat protection with a wire mesh or wood slats;

- fill the boards.

The technology allows both to reliably insulate the home floor and to save oneself from a lot of indoor work. The advantage is as follows - the footage is taken away from the basements, not living quarters. Considering that basements are rarely fully used, weaning of 10 cm or more is really neglected.

Floor on the ground

The floors of the premises are based on a concrete slab that lies underneath. A monolithic product is assembled using different technologies. In some cases, it is associated with wall structures, in others it is not. We will not go into construction nuances. The main point is that the floor located on the ground must be insulated. How? According to the following time-tested technology:

- leveling and tamping of soil masses;

- backfilling of crushed stone or expanded clay (thickness - 10 cm, purpose - to protect the slab and insulation from low temperatures and water penetrating from the outside of the building);

- creating a layer of coarse sand;

- installation of a finished slab or production of a screed;

- waterproofing flooring;

- laying of thermal insulators;

- end screed;

- floor covering.

Now you roughly know how to insulate a floor in a house on the ground in accordance with classical technology. Here, the most subtle moment lies in the slab. Its installation or creation from scratch will require a lot of money, time and effort. By the way, if you are going to make a warm floor, heating elements are mounted between the gasket of the insulators and the final screed.

Finally, a few words about thickness. Although there are strictly set indicators, it is not always possible to comply with them. The thickness and height of the ceiling surface imposes its own limitations. In rooms with high ceilings, the thickness of the insulation is neglected. For greater reliability, sometimes they even use two-layer thermal protection. Low ceilings cause a lot of problems and sometimes do not make it possible to fully carry out the insulation process.

x-teplo.ru

Thermal protection of a wooden floor from the basement side

If the height of the basement allows, then from its side it is possible to perform thermal insulation of a wooden floor in a private house.

The technology of floor insulation in the house from the basement side consists of:

- Preparation of wooden beams. They are examined, if necessary, they are repaired and impregnated with fire retardants and antiseptic compounds for wood.

- Waterproofing devices. Cloths of polyethylene or foil film are attached with a construction stapler to the overlapping beams.

- Insulation installation. Mineral or basalt wool mats are laid flat against existing beams and secured with wooden slats or wire. It can be insulated with a cheaper synthetic material - foam. It is lightweight and easy to use.

- Vapor barrier devices. The vapor barrier membrane is attached to the beams with a stapler, sealing all joints with reinforced adhesive tape. As a vapor barrier material, glassine, isospan, foil or polyethylene film are used.

- Installation of rough flooring. A subfloor is arranged with an edged board from below, nailing it across the beams with nails.

It is not difficult to insulate a wooden floor in a private house from the basement side. All work can be done by hand.

Why insulate the floor above the basement?

- The floor above the basement is cold

- Mold and mildew will gradually grow on its surface and walls.

The appearance of such troubles leads to:

- Damage to the completed repair

- Accelerated structural failure

- Decreases the health of people living in the house

When an unheated basement is planned in a residential building, thermal insulation of the floor above the basement is always necessary. Since, firstly, the walls are not insulated in a cold basement, and the temperature in the basement is negative in winter. A cold floor means uncomfortable indoor conditions and a significant waste of energy resources for heating. And, secondly, the moist soil in the underground throughout the year continuously gives off moisture in the form of water vapor, which is saturated with wooden logs. The surface of the basement ceiling that is not insulated and not protected from moisture will easily transfer cold and dampness to the room, which is located above. The basement microclimate promotes the development of mold and mildew on the walls.

Therefore, the insulation of floors should be taken seriously: layers of steam, hydro and thermal insulation should be included in the construction of the floors.

As a rule, wooden beams with a width of 150 mm are used for flooring. When installing insulation between the beams, the heat-insulating layer turns out to be heterogeneous, because every 60-100 cm, instead of the insulation, a load-bearing wooden beam will be located. Depending on the pitch of the beams, the share of insulation in such a "pseudo-thermal insulation" layer accounts for 70 to 85%. And the rest of the floor surface is nothing more than heat-conducting inclusions, called cold bridges. In order for a wooden beam not to be a cold bridge, but to perform heat-saving functions, its thickness must be at least 60 cm (for example, a house in the Moscow region). It becomes obvious that even when using a wooden beam with a section of 20x20cm, that is, three times less than the required height, the heat loss through the cold bridges will be three times higher than the normalized ones!

3 conclusions can be drawn from this:

- cold bridges do not provide full insulation

- installation of insulation between wooden beams should be done only in houses of seasonal residence (for example, summer cottages)

- insulation between beams should be considered only as additional to the main continuous layer, in order to increase the heat-shielding properties of the floor structure.

pirrogroup.ru

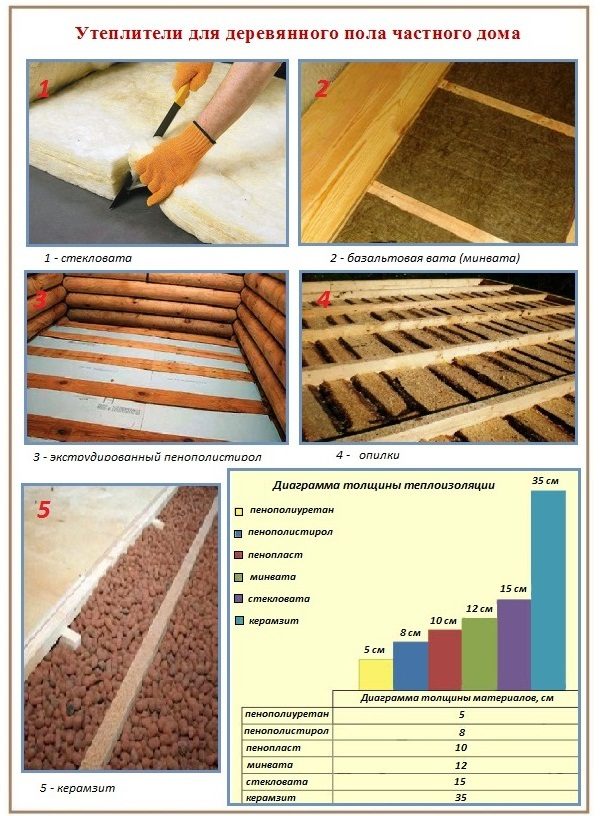

Insulation of the floor above the basement without heating. What material can be used to insulate the floor

Here is a list of materials that can be used to insulate the floor over an unheated basement from the side of the house:

1. Expanded polystyrene with a density of 35 kg per cubic meter, including extruded. Excellent thermal insulation properties, water resistance, vapor permeability, ease of installation, low price.

Special profile mats are made of PPP for laying underfloor heating.

Cons of the material: flammability and toxicity when burning.

2. Mineral wool (usually basalt). Also high-quality insulation, non-combustible, environmentally friendly, easy to process and inexpensive. Minus: hygroscopicity. When wet, most of the heat-shielding properties are lost. When installing mineral wool insulation, it is necessary to lay a vapor barrier membrane on top, because cotton wool is a vapor-permeable material.

3. Expanded clay. Loose material, fired clay granules. Non-flammable, environmentally friendly, cheap. Low weight, can be used to insulate wooden bases. It is used both separately and as part of a concrete screed.

Minus: hygroscopicity. When wet, the weight increases and the load on the floor increases.

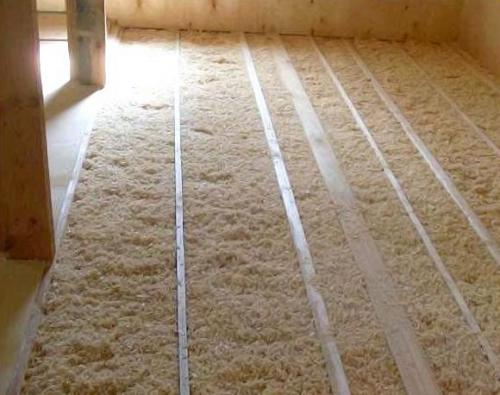

4. Ecowool - fluffed cellulose. Ease of processing, environmental friendliness, non-susceptibility to damage by rodents and fungus. Does not shrink, does not lose heat-shielding properties when wet. Does not support combustion, but smolders. It is used dry and in solution. Negative: special injection equipment is required for styling.

5. Sawdust. Environmentally friendly, cheap and warm material. Cons: flammability, hygroscopicity. In its pure form, it is prone to decay, damage by rodents, insects, fungus. It is used as a mixture with lime and gypsum or clay.

6. Liquid polyurethane foam.It is applied from a spray gun in an even layer over the entire surface of the base, it forms a hermetically sealed even coating without voids.

It can be applied on a reinforced concrete slab, on a rough floor or between logs. Cons: flammability (G1, G2), susceptibility to destruction by UV rays, spray gun is required for application, not too low price.

Most insulation can be installed both under a concrete screed or without it. In this case, the choice depends on the base material: you cannot put a screed on a wooden floor, it will not support the weight of the concrete. The screed is a common structural element of underfloor heating if they are installed on top of a concrete slab.

Note!

The minus of the screed is that it greatly reduces the height of the room (for example, the total thickness of the water heated floor in this case can reach 10 centimeters).

Insulation of the floor over the heated basement

If the basement is heated, all its walls are insulated, and the temperature difference between the rooms located one above the other does not exceed a couple of degrees, then the basement ceiling is insulated in the same way as the interfloor floors are insulated. And since it is easier and cheaper to lay insulation on the floor than on the basement ceiling, the work is done in this way.

If mineral wool of low density or polystyrene with a density of no more than 15% is chosen as insulation, then it is better to equip wooden logs, place insulation between them, send a rough floor. And then lay the final flooring.

Floor insulation instructions

When planning to insulate the basement, it must be remembered that the work is carried out in three directions: insulation of ceilings, floors and walls. It is recommended to insulate basement floors only when the temperature in the cellar is lower than in the entire building. Basement insulation in this case begins with the careful sealing of all cracks, crevices and joints.

Basement insulation outside.

If metal nails and pins are used for fastening, they must be covered from the side of the basement with heat-insulating material, because this kind of metal elements are capable of creating so-called. cold bridges, through which a lot of heat escapes from the heated room to the basement.

Attach thermal insulation material to the basement ceiling. Of course, such manipulations will somewhat lower the height of the basement, but the floor in the living quarters will become warm. After warming the basement floors, additional care must be taken to prevent condensation from falling out. Do not forget that water vapor is moving through the coating. This is precisely what needs to be prevented.

For this, a vapor barrier is installed on both sides of the insulating material. A high-quality vapor barrier will protect the insulation from getting wet, mold and rotting. On the basement side, insulation materials are usually protected by exterior trim. To do this, you can use paints and varnishes, plaster or panels.

Insulation of the floor over the unheated basement

It is quite another matter if the basement is not heated. Maybe this contributes to a longer preservation of products, but it also affects the efficiency of heating. After all, some of the heat goes through the basement. To optimize heating costs, it is necessary to insulate the floor above the basement.

The order of work is presented in the figures of the diagrams.

As can be seen from the figure, the basement ceiling is insulated both from the side of the house (outside) and from the side of the basement (from the inside). That is, the ceiling of the room is insulated.

- For the first case, the order of work is similar to the insulation of interfloor ceilings. Only the recommended insulation thickness should be at least 10 cm.(depending on the type and density). For floor insulation, you can use polystyrene, expanded polystyrene, basalt wool (mineral wool) or loose insulation (expanded clay). Thus, the basement is insulated during the construction process or when it is possible to remove the floor covering.

- In the second case, when it is not possible to insulate the floor, the basement is insulated along the ceiling. And before proceeding with the work, you need to find out what constitutes the basis of the ceiling - wooden beams or a concrete floor slab. The approach to insulation will be different for each case.

Insulation of the floor above the unheated basement. Types of heaters

Several types of materials can be used to insulate a floor placed above a cold basement. They can be in the form of blocks, bulk materials and rolls, in some cases even liquid insulation is present. They are suitable for cold floors that are located on the ground floor above the basement. The most commonly used mats and board materials are lightweight and have the same thermal conductivity.

Finishing with such materials can be carried out both on the floor and from the basement side, placing them on the ceiling. They are made from polystyrene, and also created on the basis of mineral wool, basalt fiber and expanded polystyrene. In private houses, organic insulation is widely used, for example, straw, but they decompose over time and need to be updated.

Plates and mats can be used in parallel with roll insulation, this will increase the thickness of the layer and improve the heat saving of the room.

Loose heaters are less popular, but at the same time effective, because they can fill the space between the crate. This minimizes the chance that some spaces will remain uncovered and cold will pass through them. Expanded clay and similar materials can be used both on the ground under the floor of an individual house, and in apartments, under which an unheated room is located.

Building materials for insulating roll-type basements can be thick and thin, their range is very large:

- expanded polystyrene;

- mineral wool;

- cork mats;

- insulation with foil.

In the case of mineral wool and polystyrene, a crate is required, because the material usually has a large thickness, but foil options that do not have a thick layer are best used as additional ones.

They will not allow cold air to pass through the base material.

The most optimal material for insulating an apartment above a cold basement will be rolled mineral wool, it is inexpensive and very easy to install.

Liquid insulation materials can be very simple, the most popular is cement mortar with a mass of impurities.

To improve the structure and heat-saving properties, foam plastic, wood chips and expanded clay can be added to the mixture. There is also a modern version based on polymers, which has a foamed structure.

It is called penoizol, and to work with it, you should purchase additional equipment that allows you to tightly fill the voids between the crate.

Thermal insulation on wooden beams (lags)

Wooden joists or floor joists are commonly used in low-rise construction and cover a small basement area. In addition, wood has a lower heat transfer rate. This means less heat passes through the wood.

Basement insulation technology for wooden floors:

- beams or logs are installed on the ceiling in increments of 60 cm. or 1 m. Depending on the type of insulation. So, the width of the strip of basalt wool is 60 cm, of foam and polystyrene foam - 1 m;

- a superdiffusion membrane or vapor barrier film is fixed on the ceiling. At the same time, in order to avoid the appearance of cold bridges, the film must be brought onto the wall, at least 10 cm.In addition, the film must be overlapped, and the joints are glued with special tape. Its feature is the ability to reliably protect the film and insulation from moisture ingress. The film is fixed with wooden slats.

- when closing the beams (logs) with a film, you need to leave 10-15 cm free from each end of the log. This is necessary so that the moisture content of the wood can be regulated in a natural way;

- have a heat-insulating material, the thickness of which depends on the type and density (as a rule, it should be 10-12 cm). The material is fixed using mesh or wire. To avoid the appearance of cold bridges at the junction of the wall and ceiling, you need to put a 5 cm insulation on the wall;

- carry out the finishing of the ceiling. The insulation is closed with an osb slab, drywall. And in the case of rigid insulation, you can fix the mesh and putty.

moydomik.net

Insulation on a concrete floor

In this case, it is advisable to use a hard insulation. It is fixed to the concrete floor of the basement with glue and dowels. Then it is closed with a net and plastered.

If you prefer a soft insulation, then you need to fill the ceiling with wooden slats or a galvanized profile for drywall (the thickness of the profile should be equal to the thickness of the insulation), cover it with a vapor barrier film, install thermal insulation and decorate the ceiling.

Related article: Wine bottle holder

We hope this information will help you decide how to insulate the floor over the basement and reduce heat loss in the house.

Insulation

Types of heaters

As a heater, both bulk and roll or plate materials are used. Bulk insulation is expanded clay, vermiculite, slag, mineral fibers, shavings.

Slabs are prefabricated slabs or blocks of materials with low thermal conductivity. Recently, polyurethane foam insulation has gained great popularity, which is blown into the space of the insulated structure.

Mineral wool insulation

But the most popular, especially in private construction, are flexible, soft materials. Such insulation is good because it is easy for them to give the necessary shape, they are convenient when laying. The most common insulation is the so-called mineral wool in the form of mats or rolls.

Advantages of mineral wool insulation:

- good indicators of thermal conductivity;

- not flammable and does not support combustion;

- lightweight, saving on supporting structures;

- convenience and speed of installation.

Disadvantages:

- hygroscopicity;

- you need a base for laying.

Thermal protection of the floor located above the ground

How to properly insulate the floor in rooms that do not have a basement underneath, and at the same time not reduce the height of the ceiling?

If a subfloor is not provided under the floor, then it should be insulated from the outside during the construction stage. Under the part of the house area located above the ground, the bottom of the pit is leveled and compacted. A crushed stone base 25-30 cm thick is arranged on top, on the top of which a sand cushion (5-10 cm) is poured.

The made layer of sand is covered with overlapping sheets of polyethylene film, the seams are glued with reinforced tape. The device of a sealed waterproofing layer is necessary to prevent groundwater seepage to the thermal protection. Then, a bulk insulation is laid - expanded clay or slab - extruded polystyrene foam (penoplex).

The thickness of the thermal insulation layer should be at least 15 cm. The foam panels are laid as tightly as possible to each other, the seams are filled with sealant, expanded clay is tamped. If we insulate with penoplex, then a waterproofing layer must be laid on top of the thermal insulation layer. Then the insulating layer is covered with a reinforced mesh and the screed is poured with cement mortar or concrete M200.After the rough rolling of the floors has dried, you can proceed to the device of the finishing coating.

Vapor barrier - why is it needed

The insulation must be protected from moisture. Any insulation, if it gets wet, very much loses its heat-shielding properties. And since mineral wool is a hygroscopic material, you need to take care that moisture does not get on it.

But protection is required not only from water. Protection is required against steam penetration. Vapor barrier plays an important role in creating optimal operating conditions for the insulation.

Without going into the concept of partial pressure, we note the importance of understanding two points:

- it is the vapor barrier that is the barrier that does not allow moisture (in the form of steam) to penetrate into the insulation;

-It is important to correctly determine in what place of the "pie" the vapor barrier should be placed.

Vapor barrier placement principle

In order to briefly, but at the same time unambiguously understand where the vapor barrier should be placed, you need to remember: steam always spreads from a place with a higher pressure to a zone of lower pressure. Simply put, warm steam always (practically) spreads from the room to the outside. This must be remembered and then it is easier not to get confused with where it should be placed.

It follows from the above that the vapor barrier is not placed "above" or "under" the insulation. It is placed "between" a warm room that is a source of steam (usually heated indoor rooms) and a cold room (outdoor space) where this steam moves. Therefore, in the case of insulation of the attic floor, the vapor barrier will be under the insulation, and in the case of insulation of the wooden floor above the basement - above the insulation.

Concepts vapor barrier, waterproofing, membrane

In order for the vapor barrier to be effective, i.e. worked correctly and did not harm, the film must be laid on the right side. To do this, you need to study the manufacturer's instructions and consult the seller. A wide variety of materials are now available for protection against steam and water. But there is a difference between them. The scope of their application depends on the type of premises, their humidity and temperature conditions, ambient air temperature, for which structure they are used - roofs, ceilings or walls. Often the confusion comes from the concepts themselves: vapor barrier and membrane, instead of waterproofing, vapor barrier is used.

Vapor barrier designed to protect against water vapor that is in the air of the room. In fact, steam is a water-saturated gas, or you can say the gaseous state of water. The vapor barrier must have a low vapor permeability, i.e. she must not let steam through. It is approximately equal to 10 grm2 days.

Basically, a vapor barrier is a film. They can be conditionally divided into:

- vapor permeable or "breathable" (membranes);

- vapor-tight, practically impermeable to neither steam, nor water, nor air.

Waterproofing designed to protect structures from water. Water molecules are larger than gas molecules.

Membrane... Now the word membrane has become very popular. Membranes are already more high-tech films. With regard to the topic of vapor barrier, we can say that this is a material capable of permeating or, on the contrary, capturing certain substances. The most common expression is a vapor-permeable moisture-proof membrane. This means that this material does not allow water to pass through, but at the same time it allows steam to pass through and allows moisture to evaporate. It is these properties that are required during construction to protect thermal insulation.

The direction from where the membrane passes steam and from where it does not let water pass from different membranes can be different, depending on the place of its destination. Therefore, you need to be very careful when choosing and ask the seller for all the necessary characteristics.

Do-it-yourself insulation of the wooden floor of the first floor above the basement

The main distinguishing feature of the construction of the floor of the 1st floor, located above the unheated underground, is that there is a heater in the construction. And where there is a heater, the question of its protection from adverse factors automatically arises in order to preserve its heat-shielding qualities. And one of the most important issues in protecting a heater is the issue of protecting it from moisture, that is, a vapor barrier device. This article will focus on warming the wooden floor of the first floor above the basement, and with your own hands.

Creation of temperature and humidity conditions

The main task of all structures using insulation is to create the correct mode of operation, i.e. to make sure that moisture does not penetrate into the insulation, and the one that can form in it has the opportunity to evaporate outward without hindrance. The first remedy is vapor barrier. The second is ventilation, as adequate ventilation helps the moisture evaporate. These principles should be used when constructing the floor of the 1st floor.

The first is ensured by the correct use of vapor barrier means. Ventilation is provided by air gaps and the space under the floor (underground). The underground (technical underground, basement) must be dry and well ventilated. Incorrect temperature and humidity conditions of the underground can lead to the formation of condensation inside the insulation. Whatever this happens, the underground must have air vents for its ventilation. At very low air temperatures in winter, they can even be closed so that the temperature in the underground is not very low and this does not lead to a large temperature difference, which contributes to the formation of condensation in the insulation or on its surface.

Insulation

Types of heaters

As a heater, both bulk and roll or plate materials are used. Bulk insulation is expanded clay, vermiculite, slag, mineral fibers, shavings.

Backfilling with expanded clay

Slabs are prefabricated slabs or blocks of materials with low thermal conductivity. Recently, polyurethane foam insulation has gained great popularity, which is blown into the space of the insulated structure.

Mineral wool insulation

But the most popular, especially in private construction, are flexible, soft materials. Such insulation is good because it is easy for them to give the necessary shape, they are convenient when laying. The most common insulation is the so-called mineral wool in the form of mats or rolls.

Advantages of mineral wool insulation:

- good indicators of thermal conductivity;

- not flammable and does not support combustion;

- lightweight, saving on supporting structures;

- convenience and speed of installation.

Disadvantages:

- hygroscopicity;

- you need a base for laying.

Vapor barrier - why is it needed

The insulation must be protected from moisture. Any insulation, if it gets wet, very much loses its heat-shielding properties. And since mineral wool is a hygroscopic material, you need to take care that moisture does not get on it.

But protection is required not only from water. Protection is required against steam penetration. Vapor barrier plays an important role in creating optimal operating conditions for the insulation.

Without going into the concept of partial pressure, we note the importance of understanding two points:

- it is the vapor barrier that is the barrier that does not allow moisture (in the form of steam) to penetrate into the insulation;

-It is important to correctly determine in what place of the "pie" the vapor barrier should be placed.

Vapor barrier

Vapor barrier placement principle

In order to briefly, but at the same time unambiguously understand where the vapor barrier should be placed, you need to remember: steam always spreads from a place with a higher pressure to a zone of lower pressure. Simply put, warm steam always (practically) spreads from the room to the outside.This must be remembered and then it is easier not to get confused with where it should be placed.

It follows from the above that the vapor barrier is not placed "above" or "under" the insulation. It is placed "between" a warm room that is a source of steam (usually heated indoor rooms) and a cold room (outdoor space) where this steam moves. Therefore, in the case of insulation of the attic floor, the vapor barrier will be under the insulation, and in the case of insulation of the wooden floor above the basement - above the insulation.

Concepts vapor barrier, waterproofing, membrane

In order for the vapor barrier to be effective, i.e. worked correctly and did not harm, the film must be laid on the right side. To do this, you need to study the manufacturer's instructions and consult the seller. A wide variety of materials are now available for protection against steam and water. But there is a difference between them. The scope of their application depends on the type of premises, their humidity and temperature conditions, ambient air temperature, for which structure they are used - roofs, ceilings or walls. Often the confusion comes from the concepts themselves: vapor barrier and membrane, instead of waterproofing, vapor barrier is used.

The vapor barrier is designed to protect against water vapor that is in the room air. In fact, steam is a water-saturated gas, or you can say the gaseous state of water. The vapor barrier must have a low vapor permeability, i.e. she must not let steam through. It is approximately equal to 10 g / m2 / day.

Basically, a vapor barrier is a film. They can be conditionally divided into:

- vapor permeable or "breathable" (membranes);

- vapor-tight, practically impermeable to neither steam, nor water, nor air.

Waterproofing is designed to protect structures from water. Water molecules are larger than gas molecules.

Membrane. Now the word membrane has become very popular. Membranes are already more high-tech films. With regard to the topic of vapor barrier, we can say that this is a material capable of permeating or, on the contrary, capturing certain substances. The most common expression is a vapor-permeable moisture-proof membrane. This means that this material does not allow water to pass through, but at the same time it allows steam to pass through and allows moisture to evaporate. It is these properties that are required during construction to protect thermal insulation.

The direction from where the membrane passes steam and from where it does not let water pass from different membranes can be different, depending on the place of its destination. Therefore, you need to be very careful when choosing and ask the seller for all the necessary characteristics.

Basic structural schemes of the floor of the 1st floor

Consider the construction of the floor of the 1st floor above an underground or unheated basement.

The scheme of the wooden floor of the first floor without waterproofing

The basic layout of the ground floor is as follows. The subfloor is laid along the load-bearing beams, which rest on the foundation. A rough floor is necessary in order to lay out insulation on it. Insulation fits into the space between the beams. A vapor barrier is lined on top of the insulation. It is imperative to arrange an air gap between the vapor barrier and the boardwalk to evaporate condensate that may form on the vapor barrier from the side of the room. It can be organized by nailing bars 2-3 cm high. A boardwalk is arranged on top of which the finishing floor is laid.

Scheme of the floor structure of the 1st floor above the sub-floor

The supporting structure of the floor is beams. The pitch of the beams is usually 60-80 cm. You can choose the step so that it would be convenient to lay insulation between the beams. Then the step will be equal to the width of the insulation plus the thickness of the timber.

In the places where the beams are attached to the stone structures between them, there must be a waterproofing gasket made of, for example, roofing material or bitumen mastic.Between the timber and the foundation wall, it is necessary to make a gap for ventilation, the timber should not adjoin the wall closely.

There must be a ventilation gap between the vapor barrier and the deck.

Rough floor. To attach the subfloor to the beams, smaller blocks, "cranial bars", are attached. Subfloor boards are laid on them. Here you can use a low grade 15-50 mm thick board.

floor construction with insulation

Wooden floor of the 1st floor with waterproofing

Sometimes waterproofing is provided in the floor structure. It is appropriate if the basement is very damp and there is a high level of groundwater. Then it becomes necessary to protect the insulation from below. For this, waterproofing is arranged under the insulation. This waterproofing must be made of a water-repellent but vapor-permeable membrane. In order to avoid annoying mistakes, it is better to call the upper film simply vapor barrier (even if the manufacturer calls the film itself a membrane), and the lower one - waterproofing. And here, ideally, a membrane should really be used - a vapor-permeable waterproof one.

An example of the use of improper waterproofing

This video is a very clear example of the fact that water can form in the insulation. This video is very common on YouTube under various names. It is often called "incorrect vapor barrier". The vapor barrier itself is not visible in the video. Perhaps the authors of this design used the lower film as some kind of vapor barrier.

But the point is that the bottom film was supposed to be waterproofing, waterproof on one side, but vapor-permeable on the other.

Useful videos

Basic structural schemes of the floor of the 1st floor

Consider the construction of the floor of the 1st floor above an underground or unheated basement.

The scheme of the wooden floor of the first floor without waterproofing

The basic layout of the ground floor is as follows. The subfloor is laid along the load-bearing beams, which rest on the foundation. A rough floor is necessary in order to lay out insulation on it. Insulation fits into the space between the beams. A vapor barrier is lined on top of the insulation. It is imperative to arrange an air gap between the vapor barrier and the boardwalk to evaporate condensate that may form on the vapor barrier from the side of the room. It can be organized by nailing bars 2-3 cm high. A boardwalk is arranged on top of which the finishing floor is laid.

The supporting structure of the floor is beams. The pitch of the beams is usually 60-80 cm. You can choose the step so that it would be convenient to lay insulation between the beams. Then the step will be equal to the width of the insulation plus the thickness of the timber.

In the places where the beams are attached to the stone structures between them, there must be a waterproofing gasket made of, for example, roofing material or bitumen mastic. Between the timber and the foundation wall, it is necessary to make a gap for ventilation, the timber should not adjoin the wall closely.

Rough floor. To attach the subfloor to the beams, smaller blocks, "cranial bars", are attached. Subfloor boards are laid on them. Here you can use a low grade 15-50 mm thick board.

Wooden floor of the 1st floor with waterproofing

Sometimes waterproofing is provided in the floor structure. It is appropriate if the basement is very damp and there is a high level of groundwater. Then it becomes necessary to protect the insulation from below. For this, waterproofing is arranged under the insulation. This waterproofing must be made of a water-repellent but vapor-permeable membrane. In order to avoid annoying mistakes, it is better to call the upper film simply a vapor barrier (even if the manufacturer calls the film itself a membrane), and the lower one - waterproofing. And here, ideally, a membrane should really be used - a vapor-permeable waterproof one.

An example of the use of improper waterproofing

This video is a very clear example of the fact that water can form in the insulation. This video is very common on YouTube under various names. It is often called "incorrect vapor barrier". The vapor barrier itself is not visible in the video. Perhaps the authors of this design used the lower film as some kind of vapor barrier.

But the point is that the bottom film was supposed to be waterproofing, waterproof on one side, but vapor-permeable on the other.

Insulation of ceilings over cold rooms with heat-insulating materials from basalt

Heat and sound insulation of ceilings above cold rooms

In homes, basements and underground spaces are often designed, which are used to store various things that do not require room temperature. In this case, to ensure low temperatures in the basement and the required temperatures on the floor surface, it is necessary to insulate the ceiling.

The temperature on the floor surface should be no more than 2–2.5 ° C lower than the room temperature. For insulation of ceilings above cold basements and undergrounds, soft rock wool slabs ROCKWOOL Rockmin or Superrock are used, which are placed in the space between beams or joists. When insulating slabs, rigid ROCKWOOL Stroprock slabs of the required thickness are placed under the base of the floor.

To ensure a normal humidity regime and to prevent the appearance of mold in the basement, ventilation must be provided through special vents.

Ventilation device for underground ventilation: 1 - waterproofing; 2 - load-bearing floor beam; 3 - ROCKWOOL Rockmin or Superrock slabs; 4 - ROCKWOOL Superrock or Rockton 5 - floor; 6 - ventilation duct; 7 - filing of the basement ceiling.

Air vents measuring (10x10) - (15x15) cm are arranged in the basement part of the wall after 4–5 m on each side of the house at a height not lower than 15–20 cm from the level of the blind area.

Insulation of floors on beams

Insulation of the floor over wooden beams over a cold underground or basement with ROCKWOOL Rockmin or Superrock slabs.

Insulation of the floor over wooden beams above the cold basement: 1 - floor covering from boards or parquet boards; 2 - vapor barrier; 3 - wooden beams resting on the basement or basement walls; 4 - ROCKWOOL Rockmin or Superrock boards of the required thickness; 5 - sheathing made of boards or wire mesh.

The load-bearing timber floor beams are supported by the plinth. The lower part of the nest for laying beams is leveled with a solution and a waterproofing material is laid - 2-3 layers of roofing material or other waterproofing material.

Floor beams are installed in 0.6 or 1 m increments. Rockwool Rockmin or Superrock stone wool slabs are usually placed on boards or shields reinforced with cranial bars, on planks or steel wire, hemmed to the bottom of the beams.

The insulation is protected from humidification by water vapor of the internal air, which diffuses from the internal room into the cold basement. For this, a layer of vapor barrier is laid on top of the insulation from the warm side. To ensure better vapor tightness, an overlap of the vapor barrier panels is made by 10-15 cm. The edges of the vapor barrier panels are brought up to a height of 10 cm above the insulation surface and attached with a plinth to the wall. Floorboards and flooring are laid on wooden logs.

Often the floors above the underground are arranged along wooden logs laid on brick posts. In this case, logs are laid on a column along a layer of roofing material on a wooden gasket. ROCKWOOL Rockmin or Superrock slabs are placed in the space between the logs.

Overlapping over the cold underground by brick posts: 1 - floor covering from boards or parquet boards; 2 - vapor barrier (polyethylene film); 3 - wooden beams; 4 - ROCKWOOL Rockmin or Superrock boards of the required thickness; 5 - boardwalk; 6 - plank sheathing; 7 - wood antiseptic lining

Insulation of floors on concrete slabs

The load-bearing part of the ceiling above the ventilated underground or basement can be a reinforced concrete slab. In this case, the floor above the ceiling can be arranged along the joists, and its insulation is carried out with ROCKWOOL Rockmin or Superrock slabs, laid along the slab between the logs.

Insulation of slabs over a cold basement with logs: 1 - floor covering from boards or parquet boards; 2 - vapor barrier; 3 - lag; 4 - ROCKWOOL Rockmin or Superrock slabs; 5 - floor slab; 6 - ventilation duct; 7 - ROCKWOOL Rockton slabs.

The logs are laid on a reinforced concrete slab on a wooden lining over roofing material. Sometimes beams are laid on brick posts. It is recommended to make a lag step of 600 or 1000 mm so that ROCKWOOL Rockmin or Superrock insulation boards can be tightly installed between them with a small gap. Insulation plates are placed in the space between the lags. Floorboards or slabs are laid on the beams.

Insulation of slabs with lags by columns: 1 - floor covering; 2 - vapor barrier; 3 - lag; 4 - ROCKWOOL Rockmin or Superrock boards of the required thickness; 5 - floor slab; 6 - roofing felt gaskets; 7 - a brick post or a lightweight concrete block.

It is imperative to lay a gasket made of roofing material or other waterproofing material under the logs on brick posts.

A slab over a cold basement can be insulated using ROCKWOOL Stroprock hard stone wool slabs. To do this, ROCKWOOL Stroprock slabs of the required thickness are laid on the reinforced concrete floor along the leveling screed. A layer of waterproofing material is laid on top of the slabs, followed by a 3–5 cm cement screed and a floor covering made of ceramic tiles, linoleum, etc.

If the ceiling height in the room is small, then the basement floor can be insulated by installing a thin ROCKWOOL Stroprock insulation material over the floor slab, and from the bottom side, fix the ROCKWOOL Wentirock insulation boards with dowels or strips.

ROCKWOOL Wentirock rigid slabs can be attached to the floor slab with dowels.

Additional insulation of the ceiling above the basement: 1 - floor covering; 2 - ROCKWOOL Stroprock slabs; 3 - floor slab; 4 - additional insulation with ROCKWOOL Wentirock plates; 5 - ventilation duct; 6 - cold basement floor.

The essence of the first floor floor insulation

Basically, the floors between the first floor and the basement are made of concrete. The same picture is observed in the variant with the base of the house, if there are no basements at all. In some cases, reinforced concrete was used, in others - conventional with the use of crushed stone.

Concrete is a specific material. It absorbs heat quickly, but it is difficult to heat it up. Without a constant heating source, it instantly cools down. Therefore, concrete floors will be an inexhaustible source of cold in a house or apartment. Hence the recommendations of builders regarding the separation of concrete from the floor using thermal insulation materials.

In the context of thermal insulation resembles puff pastry: there are many balls and each has its own purpose. The sequence of these balls looks like this:

- concrete slab or foundation-fill;

- insulating film (protection against steam);

- insulating material;

- waterproofing;

- foam concrete (finishing screed).

Their combination and combination of positive qualities will not allow cold air to penetrate from below through the floor into the apartment.

Each of the layers has a specific purpose:

- The insulating film will protect the insulation from moisture. The basement is an unheated room with a high level of humidity. This dampness rises and destroys the thermal insulation. The vapor barrier prevents the process.

- Thermal insulation is responsible for keeping warm air in the room.

- Waterproofing film will protect against excess moisture inside the room.

- The finishing screed is only needed for laying planks or other flooring.

Building secret. Having decided to insulate the floor, it will require a thorough inspection of the basement. Look for cracks or other structural damage. This is especially important when there is an unheated basement under the apartment.

The same inspection should be carried out in the room where the insulation is carried out. If cracks and breaks are found, they are removed with polyurethane foam. From above, the sealed cracks are covered with cement.

Independent floor insulation

For the production of work on insulation, it will be necessary to prepare certain tools that will be universal for all cases:

- Building level, which will be used to check the slope.

- A special mixer for construction, which will mix the adhesive composition.

- Container for adhesive mass.

- Spatula for applying adhesive and filler solutions.

- Emery.

- A hacksaw used for cutting slabs or rolls of insulation.

Insulation of concrete slabs

The thermal insulation process is the same for any material. Finishing the concrete floor in a private household without a well-equipped basement will be done by combining materials. Therefore, the thickness of the insulating layer must be calculated in advance.

When carrying out work in an already inhabited room, you will have to prepare the base:

- Dismantle the decorative coating.

- Check the concrete base for defects (chips or cracks).

- Clean the slab and seal up any imperfections with cement mortar.

- To enhance the effect, you can use sealing - a specialized compound that strengthens the concrete surface.

- Roll out the waterproofing material.

- Lay the polystyrene plates in a checkerboard pattern.

- Set up beacons and pour a layer of finishing screed over them.

What is the best way to insulate a concrete floor?

The construction market is full of various insulation materials. Some are widespread and in demand. The most popular and versatile material is mineral wool. It is suitable for insulation under a concrete screed or immediately under a wooden floor covering.

If there are logs under the floor covering, then use bulk insulation. Lags can be located on top of the poured concrete or act as the base of the floor. In this case, you can still resort to insulation in the form of foam. It fills all the space between the beams.

For this type of insulation, use:

- polyurethane foam;

- expanded clay;

- vermiculite;

- perlite.

The first is foam insulation, the rest are loose.

In the case of laying the floor immediately along the screed, there is no need for logs. Then they use another type of insulation - sheet. A ball of polystyrene or mineral wool is placed between the boards and the concrete.

Sometimes it is allowed to immediately lay the laminate on top of the waterproofing film. The only condition is a high density of insulation. But according to the rules, the reinforced screed should be poured. So the work will be of better quality, and its reliability will increase several times.

The listed methods of floor insulation are suitable for unfinished premises. Otherwise, they will require significant construction work. To make insulation, you first have to dismantle the floor covering, and then update it.

It is possible to insulate the floor without significant reconstruction. Thermal insulation is laid on top of the tile or linoleum, under which they give a protective film against moisture. Then you can cover the insulation with a laminate immediately or make a pre-screed.

Increasing the reliability of floor insulation

The secret of high quality work is hidden not only in the material, but in the technique of its execution. You should not neglect the rules and advice regarding insulation work. The result of the procedure will depend on this.

For example, choosing mineral wool as a heater and preparing to lay it on a concrete floor, you will need:

- A mixture of sand and cement to serve as a rough finish. It must be leveled and tamped.

- Waterproofing layer. There is a special film for this. But it can be replaced with a more affordable material, for example, roofing material.

- A layer of mineral wool. Plates are located tightly so that there are no gaps between them. There is no need to glue the seams. Resting against the walls with their edges, the plates will mutually compact.

- Another layer of film (can be replaced with roofing felt). These are protective measures against the accumulation of moisture in insulation, since most materials have a tendency to this.

- Filling the screed. Its thickness is only a few centimeters.While the concrete is still fresh and liquid on top of the poured layer, it is necessary to stretch the galvanized metal mesh. It will strengthen the screed. On top of the mesh, you will need to pour another concrete ball, the optimal height of which is 2 cm. It is recommended to use foamed concrete for the screed. It is lighter than usual and easier to work with. In addition, it has thermal insulation characteristics. Concrete with mesh provides a reinforced screed - insurance against cracks.

- Laying the floor covering. It can be anything, at the discretion of the owners. But new floors are laid only after the concrete has completely hardened.

uteplenievdome.ru

Hello Alexandra!

You write: "cold damp basement", "blowing from the front door, ventilation is bad" - "advise us what to do?"

In our opinion, the answer is obvious. To make an apartment warm and dry above a cold and damp basement, you need to do the following:

- Insulate floors. If possible - external walls too.

- Eliminate the penetration of moisture from the basement.

- Close the gaps in the front door. Install seals, put platbands, upholstery the door with vinyl leather, placing a soft insulation under it. It happens that cold air penetrates through the keyholes, lining helps. It would be nice to install a second wooden door if the entrance is metal.

- Restore ventilation. Only normal ventilation coupled with sufficient insulation will solve the problem with mold. Do not keep windows tightly closed all the time. We recommend that you ventilate the premises from time to time; for this in winter, it is enough to periodically open the micro-ventilation if you have modern windows installed.

Better yet, install ventilation valves in the frames.

Installing an exhaust fan in the bathroom and in the kitchen will also be beneficial. Check if the exhaust ventilation is working. If the craving is not enough - actively complain to the housing department, it is their job to find out which of the neighbors from above has arranged a cozy niche for the refrigerator, depriving you of fresh air. The ideal solution is the installation of forced supply and exhaust ventilation with heat recovery, however, this is expensive.

- Make a warm floor in the bathroom. But in the rooms it is better not to rush, first take measures to insulate floors, walls, and reduce humidity. Maybe, installation of additional heating is not needed.

- It may be worth increasing the heat transfer of the radiators by installing a couple of additional sections for each of the radiators. However, this is not always justified and technically feasible, you should first consult with a specialist.

Read more about points 1 and 2: insulation and dampness control. We strongly recommend upgrading the floor structure. Alas, for this you have to carefully disassemble it first. You don't have to throw anything away, all materials can be reused. Next, we do the following:

- Roll out a vapor barrier film over the floor slabs. It must be brought to the walls just above the level of the finished floor, and the joints between the rolls must be glued with construction tape.

- We install the logs, leveling them with shims. You should try to fix them securely and strictly horizontally.

- We fill the space between the lags with insulation, it is better to use non-combustible mineral wool. If the thickness of the insulation is less than 10 cm and it is possible to raise the floor level, it is worth filling a block on the logs in order to increase the thickness of the heat-insulating layer.

- We spread a vapor barrier film on top of the insulation, connect it to the bottom layer, glue all the joints. Thus, we will protect the fibrous material not only from dampness from the basement, but also from damp air from the apartment.

- We lay boards.

- If additional floor heating is required, infrared film heating elements with a minimum thickness and maximum heating area are suitable for these purposes.An additional layer of foil-clad insulation should first be laid on the boards, for example, foamed polyethylene with a thickness of 3-4 mm.

- We roll out the heating elements, connect them to the thermostat and the sensor, test them, fix them with tape to the floor.

- We install the final floor covering. It can be a laminate with a backing, it is better to choose the thinnest and most inexpensive. Or linoleum, carpet, under which it is recommended to lay solid sheet material: plywood, OSB, chipboard. In our opinion, it is easier and even a little cheaper (plywood costs money) to lay the laminate.

A useful video that shows you step by step how to properly lay a warm floor under the laminate. Also shown is the installation of an infrared floor under linoleum and carpet. Pay particular attention to removing the bottom backing underneath the electrical terminals and wires. Often they do not do this, which leads to the fact that the laminate "wiggles" when walking, and the wires fray over time.

- If the boards of the old floor are bent "hump" or "boat", the laminate is laid perpendicular to them.

- A heating cable should be used to heat the bathroom floors, it can be placed in the screed or adhesive layer on which the tiles will be laid. The main problem is whether there is insulation under the existing floor. If, as usual in old panels, there are five centimeters of expanded clay - no wonder that "in the bathroom ... like in the refrigerator." In an amicable way, the floor also needs to be opened. Replace the waterproofing, if it is leaky, instead of bulk insulation, put 10 cm of extruded polystyrene foam. Above - reinforced cement-sand screed 4 cm, tiles and underfloor heating cable. If this “correct” option is not available to you, you can glue a relatively thin (4-5 mm) foil insulation on the existing floor, and lay a new ceramic tile on it, placing a heating cable in a layer of glue. However, you need to understand that in the absence of serious insulation, a significant part of the heat will go down into the concrete. Electricity consumption for heating in this case will be quite high.

As for the insulation of the outer walls: