Insulation of the attic of a private house can be partial, that is, one overlap, and complete. Also, such work can be done independently or by hiring craftsmen, but in any case, the owner will have to decide the issue of choosing a heater himself.

Each roof model has its own best insulation, the main thing is to choose it correctly

And then we will analyze in detail what kind of insulation to choose for the attic in different situations and outline the general nuances of installing different types of material.

Wadded insulation

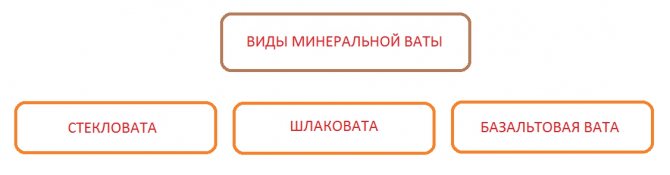

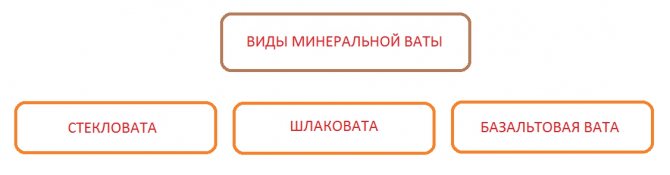

If initially only glass wool was present on the domestic market, now the range of such materials has grown to a whole area

Cotton wool for roof insulation began to be used about 50 years ago. It can be used as insulation for floors and as insulation for roofs, and at the same time.

Glass wool

The material is a special kind of fiberglass. Most models are available in soft mats of various thicknesses, but dense glass wool boards have recently appeared on the market.

The cheapest models are not worth taking, they are a source of harmful glass dust, and the mats themselves quickly deteriorate.

The trade mark "Isover" produces high-quality insulation based on fiberglass

Now there is environmentally friendly thermal insulation with excellent performance characteristics, for example, Isover has released a good fiberglass line.

The price of these models is slightly higher, but they are absolutely harmless and nothing comes from them.

Slag

The material is made from blast furnace waste, specifically from slag.

Slag wool has pros and cons:

- Low material cost you will be pleased, in addition, the density of the boards and mats is quite high, which is also good.

- Low environmental friendliness - the entire periodic table is in the blast-furnace slag, although the manufacturers assure that the material is harmless.

Perhaps the slag from the promoted brand really does not pose a danger, but personally I do not recommend installing this insulation in a living room. But for baths, boiler rooms and other technical rooms, this is a great option.

It is not advisable to insulate the living space with slagging

Basalt or stone wool

Stone wool is made from basalt and similar minerals and is considered the queen of all cotton wool.

Insulation of the attic roof with stone wool is considered one of the best options.

In terms of characteristics, it significantly surpasses the above options:

- Environmental friendliness- 100% natural material.

- Fire resistance - the melting temperature of this heat-insulating material fluctuates around 1000 ºС, which makes it possible to use it for arranging chimneys and other fire-hazardous places.

- Holds volume - dense slabs of stone wool do not lose volume when wet and are completely restored after drying.

Basalt wool is suitable for insulating the entire attic room, regardless of the sector. The only drawback here is the price, this material is somewhat more expensive than competitors.

How to properly insulate an attic floor with mineral wool

Mineral wool is a widespread and modern heat insulator. Available in rolls or slabs (mats). It does not rot and does not burn, rodents and various kinds of microorganisms are also not afraid of it.

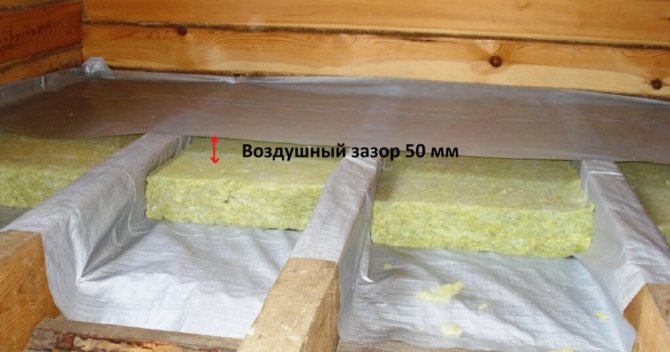

Thermal insulation of the ceiling of a cold attic with mineral wool begins with laying the lining material on the floor.For a budget option, glassine is laid on the floor, but a more expensive and high-quality option is a flooring made of a vapor barrier film. The film is laid with an overlap, and the joints are glued with tape or fixed with wooden slats, which are fixed with a construction stapler.

The width of the insulation is selected based on the requirements of thermal engineering standards for each region. Mineral wool is placed between the lags tightly and without cracks. The joints are glued with tape. After the insulation is laid, flat boards are simply placed on the logs, thus forming the floor in the attic. Such a simple solution for creating a floor allows the mineral wool to "breathe" and ventilate normally if moisture gets on it. To prevent moisture from entering the mineral wool, waterproofing material is laid under the roof.

Mineral wool is laid in personal protective equipment: tight clothing, glasses, gloves, respirator.

Ecowool

Cellulose based insulation - make it from woodworking industry waste or waste paper. Ecowool is a cross between loose and wadded insulation.

In the video, the author of the video tells how he insulated an attic with an area of 100 sq. blow molding machine:

- Ecowool is well sprayed on walls and between rafters, but this requires special equipment.

- But if we are talking about warming the floor over the beams, you can fill the ecowool between the beams with your own hands.

The material is harmless and vapor-permeable, but in contact with an open fire, ecowool burns.

Loose heaters

In bulk insulation, it is attracted by the affordable cost and relatively light installation instructions. Plus, all bulk materials are harmless.

But bulk options have 2 common drawbacks:

- Suitable only for horizontal slabs... More precisely, there are technologies for filling the same expanded clay into inclined rafter systems, but it is very problematic to do this with your own hands.

- Thickness any dump at least 2 times more compared to cotton wool boards or polystyrene.

Bulk insulation has the richest history - people do not know how many thousands of years they have been used. Nevertheless, it is difficult to say which insulation is better, it all depends on the specific conditions.

Let's consider the 3 most popular options:

- Expanded clay - this is fired clay, it looks like round granules of different sizes. The material is strong, durable and non-flammable. Quickly absorbs moisture, but also dries quickly.

Among bulk heaters, expanded clay is considered the golden mean.

- Perlite - a porous volcanic rock, the price of perlite is slightly higher than that of expanded clay, but this material absorbs moisture less.

- Sawdust - the cheapest, almost free option, but the sawdust must be cooked for a long time before use (dried and impregnated with different compositions), according to the technology it takes at least six months, and most importantly the sawdust burns perfectly.

When choosing insulation for backfill, you should not rely solely on the price. The difference between the cost of sawdust and expanded clay is small, but the latter will last longer than the house itself.

Polystyrene boards

This niche is represented by EPS and extruded EPS.

They have excellent thermal insulation, but the problem is different - Styrofoam and especially EPSP do not allow steam to pass at all.

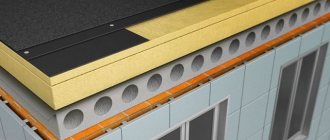

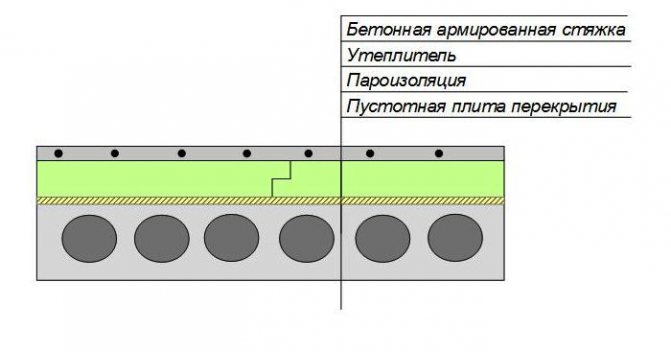

EPPS on floor slabs is able to withstand even a concrete screed

They are suitable for insulating reinforced concrete floor slabs, but if you lay polystyrene between the rafters or wooden beams, they will rot in a few years, and even forced ventilation does not help here.

Further in the video in this article, the specialist shows what happens when, when choosing a heater for wooden structures, polystyrene is preferred.

A little from the history of roofing

Since ancient times, people have erected private households with such high quality that they could stand for 100 years. At the same time, living in them was not cold, and the roof frame made of natural wood was always dry. As for the shape of the roofs on such buildings, they were most often erected with two slopes, and had a slight slope.

This choice was explained by the fact that the snow that fell in winter had to linger on the roof and serve as a natural insulation. In the attic of the building, one, less often two, windows were made. They were closed for the winter and then the air in the under-roof space played the role of a heat insulator.

In the summer, the windows were slightly opened at night so that the temperature in the attic would drop. In the heat they were closed, and the air did not heat up. This was how the temperature was regulated in the attic.

In winter, when snow fell, it covered the roof with a solid carpet and thus was a natural roofing heat insulator. Even in severe frosts, the temperature in the under-roof space did not drop below zero. As a result, the house was warm in cold weather.

At the same time, the roof slopes were not insulated so that the snow on them would not melt. The rafter system was left open, thus allowing for inspection and maintenance. Therefore, in such attics, only ceilings were insulated.

If the roof slopes are insulated, then the attic becomes a heated attic, which has a different functional purpose.

General installation principles

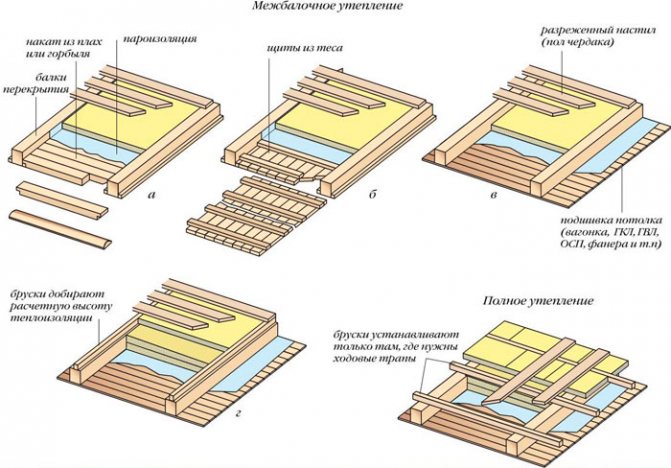

Thermal insulation of the rafter system and overlapping beams are similar. We proceed from the fact that the rafter system is assembled and covered with roofing material, and the attic floor beams are hemmed from below with a rough floor.

Step-by-step installation:

- Vapor barrier. First, a vapor barrier is attached to the base. Keep in mind that the canvas is laid so that the steam escapes from the room towards the street, and moisture is blocked on the back side.

- Insulation. Further, between the rafters or beams, insulation is laid or filled up.

- 2 layer of vapor barrier. On top of the insulation, another 1 layer of vapor barrier is mounted, it is located in the same way as the previous one.

- Overlapping on beams. Further, if the overlap is arranged along the beams, then the floor is laid, and when the attic roof is insulated, the interior decoration is attached.

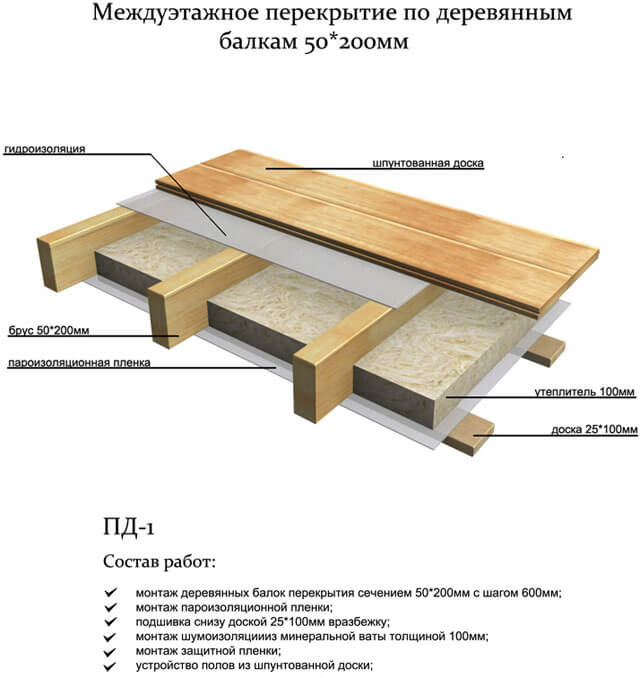

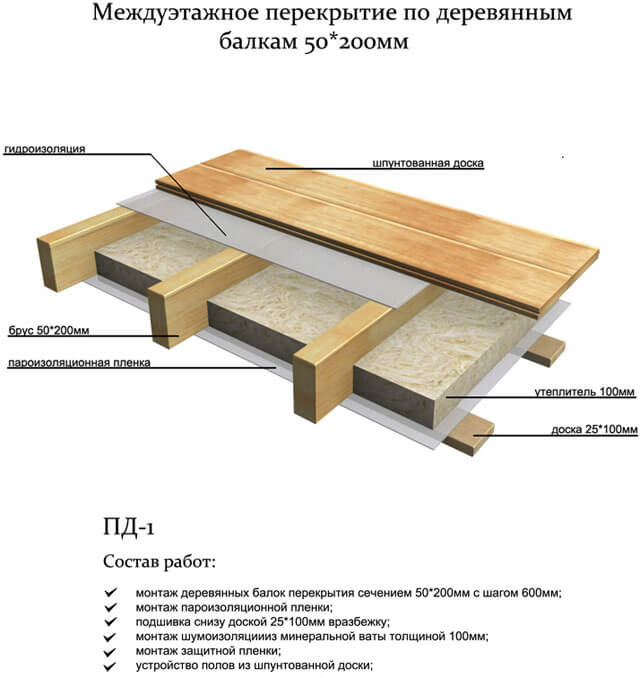

Types of floors under the roof of the house

In private houses, two types of floors are mainly used:

- wooden floor;

- reinforced concrete slabs.

Attic floors over hardwood floors

The slab consists of wooden beams. With a span of 6 to 12 m long, beams are laid from pine logs with a section of 200 x 200 mm. On wooden beams, a flooring of boards with a thickness of 40-50 mm is arranged.

Logs from a bar are placed on the wooden flooring with a pitch of 400 - 500 mm. The overlap is insulated.

Warming and soundproofing of the floor

First of all, the floor space is covered with a layer of vapor barrier made of a thick polyethylene film. Insulation is laid between the lags. These can be mineral wool mats, polyurethane boards or other similar material.

Mineral wool is very often used in the form of floor insulation due to its cheapness. However, you should know that at the slightest penetration of moisture into the subfloor, the cotton wool will turn into useless dust.

If there is heating in the house and the use of the structure in the winter, there is no need for additional thermal insulation of the attic floor. Of great importance is the soundproofing device of the floor.

Some experts advise filling the vapor barrier with a small layer of sand, explaining this by the noiseless effect of hitting the sandbag.

The sand layer is made with a reliable bearing capacity of the subfloor.

Finishing floor covering

You can use any material to cover the floor, in particular, wooden floors look good in a wooden house

On the joists it is best to lay a 20 mm thick boardwalk with tongue-and-groove joints.The rough flooring is attached to the logs with nails or screws.

The sockets of the mountings must be sunk into the wood. Chipboard flooring will not require additional leveling of the surface.

The flooring is sanded by hand with an emery or a grinder. Then they must be impregnated with an antiseptic or drying oil. The floor is painted or varnished.

Plywood is a cheap and practical covering

The treated attic floor is also used as a sub-floor for a topcoat.

What will be the floor covering of the attic room depends on the taste and financial capabilities of the owners of the house.

You can lay laminate parquet, lay linoleum, carpet. It is also perfectly acceptable to arrange a vinyl flooring.

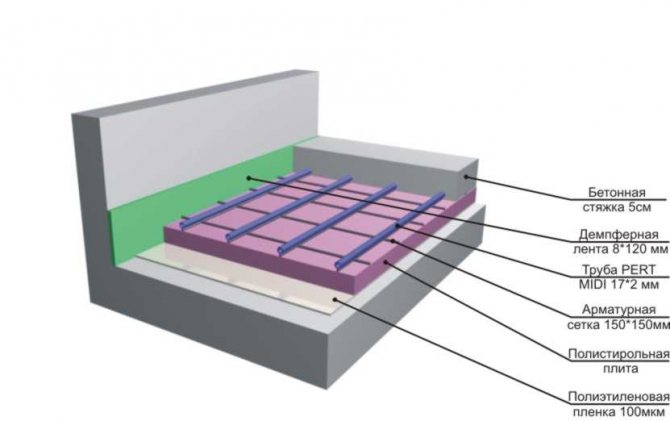

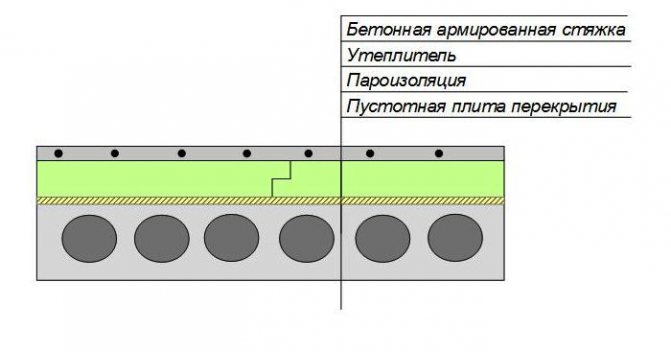

Installation of a floor in the attic on a reinforced concrete floor

The floor in the attic on a concrete base is no different from the usual covering on interfloor floors made of reinforced concrete slabs. Floor installation consists of several stages:

- The concrete base is cleaned of dust and dirt. Cracks and chips are filled with cement mortar.

- The entire area is covered with a vapor barrier made of polyethylene film.

- Insulation made of mineral wool, polyurethane plates or expanded clay backfill is placed on the film. In general, the insulation material can be of different materials.

- The expanded clay backfill is covered with a layer of cement mortar. The screed is made with a horizontal and flat surface.

- The laid insulation is covered with fiberboard sheets or chipboard plates.

- For the device of wooden floors, logs from a wooden bar are installed on the vapor barrier. Insulation is placed between the logs.

- A plank covering is laid on the logs.

- On a cement screed, they arrange a finishing floor covering from any type of floor coverings. The screed is treated with a primer. On such a base, it is convenient to lay self-adhesive linoleum or vinyl parquet with an adhesive base.

Today, the device of underfloor heating in the attic is relevant. Of course, there is no question of installing a water heating system.

It is expensive and not advisable to do this.

However, options such as cable electric heating on dry backfill or infrared heating are quite possible. For more information on how to make floors on the second floor, see this video:

Least of all labor costs arise when installing infrared heating. The IR elements are placed directly under the laminate flooring substrate.

All the "pros and cons" of the device of one or another type of underfloor heating depend on the totality of financial capabilities, technical availability and other circumstances.

Hello, my name is Valentin Viktorovich, and my question is as follows: how to make the floor in the attic with your own hands. Now, this is a classic cold attic, with the usual clay mound across the beams, but I would like to cultivate and adapt the attic for storing various household items. How and from what would you advise to make the floor?