Thermal insulation of a balcony with a brick parapet

Insulating material will help to effectively insulate the balcony of their bricks.

Most of the facades of new houses make up a single architectural composition. Violation of its integrity by piling up additional materials for insulation is unacceptable or is associated with multiple bureaucratic coordination delays. The best way to insulate cold-glazed balconies is to use insulating materials from the inside of the room.

A balcony or loggia often has a brick parapet. Installation of aluminum windows with this design takes place directly on the top row of bricks. Insulation of such a room will be effective due to the fact that an insulating material with low thermal conductivity can be laid against the parapet wall.

About the application of cold glazing for balconies

In modern construction, there are two technologies for arranging balconies and loggias for the required conditions when using:

- Cold glazing is used to protect the premises from the external environment;

- Warm glazing is used to use the premises at any time of the year as a living space.

Cold and warm glazing of balconies provides for the implementation of a number of different measures for the redevelopment and improvement of the additional balcony room for the purpose of its further use.

Cold glazing of a balcony using a frame structure allows for large panoramic windows of various sizes, which creates a beautiful interior view for the entire room and building.

Cold glazing of balconies has its own specific advantages:

- The constructions used during installation are considered to be strong and reliable;

- Corrosion-resistant and wear-resistant;

- They are not flammable and flammable;

- Easy to assemble and maintain;

- They have different opening methods and allow you to save space.

Cold glazing of balconies provides for the protection of the room of the balcony or loggia from external precipitation, wind, dust, to a small extent from the cold. It can also protect from sunlight when shading windows with different types of curtains or blinds.

The material used as a supporting structure is an environmentally friendly aluminum profile, which, during operation, does not change its properties even at different temperatures, is not demanding in maintenance and is durable.

Also read: Glazing of the loggia p44t: architectural features, options and types

Due to its strength and lightness, as well as the absence of corrosion, the profile is widely used in the manufacture of especially panoramic window structures. Unfortunately, the cost of an aluminum profile exceeds the cost of metal and other materials for window profiles.

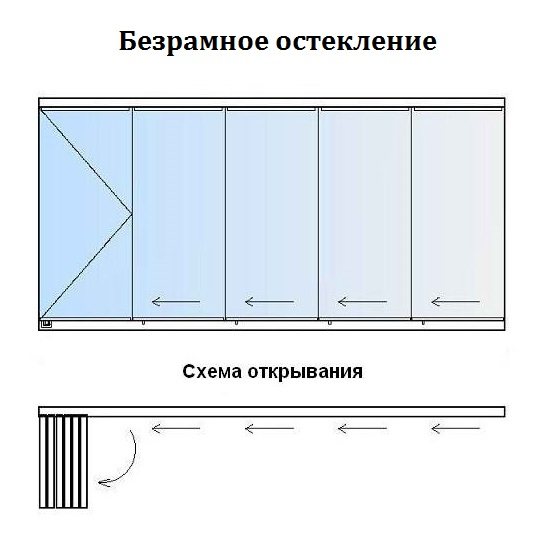

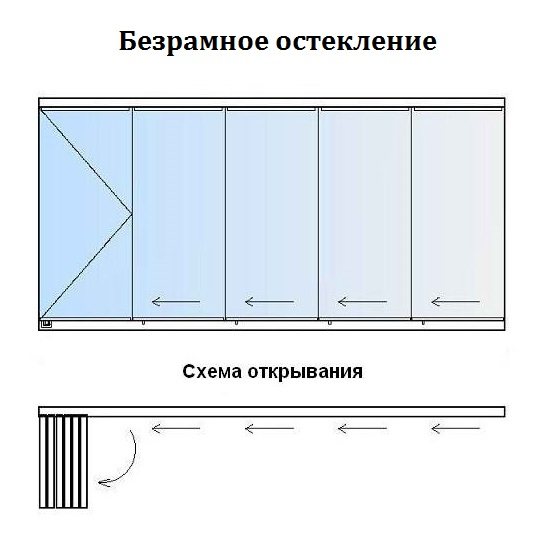

There is also a cold glazing option using frameless technology. With this design, the glass is installed in special seals and fastened through hinged sliding fittings.

Due to the horizontal displacement on the hinges, the glass is fitted at the joints tightly to each other, forming a whole glass zone. In terms of cost, such structures are more expensive than frame structures and in frosty conditions of use have certain limitations.

Insulation of glass

Most of the heat will go through the glass

In the case when plastic double-glazed windows are installed, the window will not require additional insulation.To isolate the leaky joint between the glass and the frame, a special polyurethane sealant is applied to the joints to prevent air penetration.

The greatest heat loss will occur through the glazing.

Complete replacement of windows

From the point of view of heat preservation and aesthetic appearance, this option is the best, but also the most expensive. But you need to understand that the old structure will be completely removed to the concrete or brickwork. In addition, it will not be possible to dismantle and install new structures on your own. We'll have to seek the services of industrial climbers.

Helpful! To calculate how much load a balcony slab will withstand, it is enough to use the standard rule. It lies in the fact that 8 kg of weight that falls on each m2 of the slab is an acceptable rate. But you need to take into account the wear factor of the balcony. It is believed that for each year of operation, it decreases by 1%. Accordingly, the older the building, the less loads the balcony slab can withstand.

Before starting work, we decide on the type of future structure. It is worth starting from which windows have already been installed in the building and choosing a similar one (if we are talking about a new building). In order to get a warm balcony, it is worth choosing PVC windows or aluminum structures. In the first case, you will gain in the weight of new windows. Aluminum is lightweight and durable. In addition, such windows do not deform due to sudden changes in temperature conditions and have anti-corrosion properties. Since they are lightweight, the load on the base plate will be minimal.

But these windows are quite expensive. If there is no money to buy them, then it is worth buying plastic windows. They are easy to install and maintain. Moreover, such windows reliably protect against the formation of condensation, and therefore from mold and mildew. But the weight of such structures is greater, so they are only suitable for a concrete or brick base.

Helpful! If possible, you can purchase wood-aluminum windows. They are the best protection against negative factors.

You will also need to choose the color of the windows, they should be the same color as the rest of the window structures.

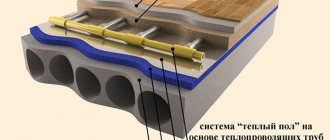

Floor insulation

Penofol can be used as insulation

An important component in obtaining a warm room is floor insulation. For better thermal insulation, you can use the following materials:

- Penofol.

- Electrical floor insulation.

- The bar is wooden.

- Styrofoam or mineral wool.

- Polyurethane foam.

- Floor board.

Foil-clad penofol is laid on the surface of the concrete floor. This material has excellent insulating properties. It will prevent condensation from accumulating in the floor, providing oxygen access to prevent moisture and mildew. The next step is to install an electric underfloor heating.

Warm floor - one of the options for insulating a balcony

The thickness of the lag sets the size of the insulation layer. The larger its layer, the better the thermal insulation. When installing, it is necessary to take into account the height from the future floor to the parapet. In the standard version, it ranges from 95 to 105 cm. The safety of finding a person on the balcony is always in the foreground, so you need to choose the thickness of the log, taking into account the height of the floor construction cake.

Parallel to each other in one plane, wooden blocks are installed with a step of 30-40 cm. Mineral wool or foam is placed between them. All the cracks formed during the installation process can be sealed with polyurethane foam. In the winter season, a special polyurethane foam is used, which has the properties of hardening at low air temperatures.

On the laid logs, a floorboard is laid for painting and varnishing.You can use rough wood and then lay some finishing material on it.

Features of designs and installation of cold glazing

Since the main purpose of windows is considered to be protection from external precipitation, dust, moisture, wind and slight cold, respectively, they can be made of a single-sheet glass unit tucked into a narrow aluminum or plastic profile.

With this technology, the weight of the window is not high due to one sheet of glass and an aluminum profile, which allows them to be installed in runners and used as sliding structures in a horizontal plane.

For areas with frosty conditions in winter, it is better to use the technology of hinged windows with plastic profiles or sliding frames with an offset. This method ensures easy opening of windows even in winter.

Reliable protection of the loggia from the environment is ensured by tightly closing the windows and docking technology. Therefore, all technologies of sliding structures refer to cold methods of protecting premises.

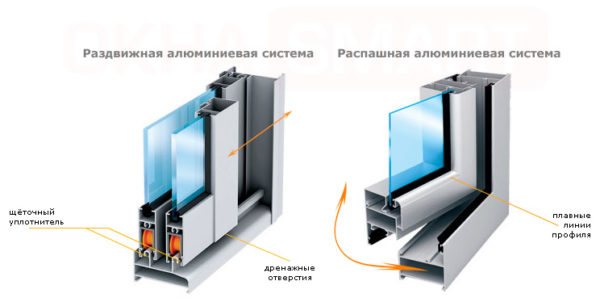

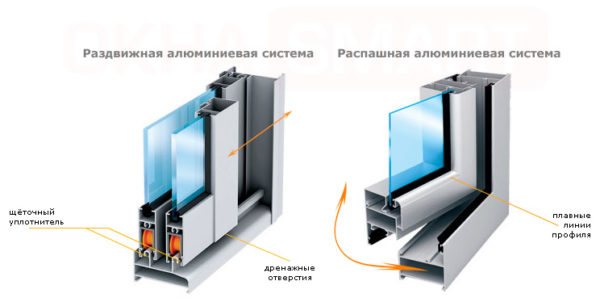

The use of an aluminum profile as a frame structure in cold glazing works provides:

- ease of design and the ability to manufacture different shapes and sizes;

- installation of a single-chamber or two-chamber double-glazed window in a window case;

- use an opening design with sliding doors;

- external aesthetic appearance and structural reliability.

Also read: Glazing a balcony with plastic windows: views, tips - how to glaze

These parameters are especially important for balconies with a small internal area and where it is problematic to open the window sashes inside the room.

To carry out work on the installation of frame structures of cold glazing, a number of preparatory measures should be performed:

- before the installation of window frames, all construction work must be completed to strengthen the balcony frame;

- the place for the installation of window frames must be even in size and not have deviations in the vertical and horizontal plane;

- the places of fastening of windows must be strong, reliable and provide a rigid connecting connection with the frame structure;

- construction measures must be taken to ensure protection from direct exposure to rain during installation work.

When deciding to independently perform cold glazing of balconies, you must:

- Prepare the frame structure for the installation of the window frame;

- To remove the dimensions of window spans to fulfill an order for the manufacture of a balcony window;

- Upon receipt of the window frame, check the compliance of the order with the specified dimensions and check separately the dimensions of the joining of individual or common frames with the perimeter of the window space;

- Fasten fastening plates on the common frame in the upper part and on the sides intended for alignment and fastening of the frame to the building surfaces of the balcony in the axes;

- Fasten the frames or the common frame through anchor bolts to the surfaces of the building structures of the balcony on all sides, checking for deviations along the axes and tight joints in the corners or when bending the surfaces of the docking frames;

- Mount window frames in the installed frame with opening fittings and check the freedom of opening and closing of the frames and their tightness of the docking;

- The window sill is checked and adjusted to the installation location with the frame;

- At the end of the installation, the place of installation of window frames, the window sill with the building parts of the balcony must be sealed with mounting foam and all cracks.

Also read: Sliding windows to the balcony - the main advantages

The final stage of work on cold glazing of the loggia will be external and internal finishing with various building materials.

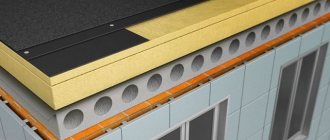

Insulation of walls and ceilings

For wall insulation, you can use the following components:

- Penofol.

- Wooden bars.

- High density foam.

- Polyurethane foam.

For strengthening the balcony, see the video:

Walls requiring insulation are sheathed with penofol. The lathing is usually made from a 50x50 mm bar. For convenience, the step between the bars can be made in accordance with the width of the filler. Styrofoam is placed between the bars and attached to the wall using plastic "fungi". The slots formed during installation are also sealed with polyurethane foam. As a cladding, you can use eurolining or imitation of a bar. Plastic panels are also suitable for wall cladding.

Technology for insulating joints between the wall and the frame

If, before insulating the balcony, the replacement of the glazing with a warm one is not provided, then you need to start with the seams. It is through them that most of the heat goes to the street, and frosty air comes back.

Moisture can enter through the seams, which contributes to the destruction of the balcony structure. Also, with high humidity, the risks of encountering fungus and mold increase. Items stored on a wet balcony gradually deteriorate.

The cracks are eliminated using the following technology:

- Seams are cleaned of plaster, old paint, and residues of polyurethane foam. The job can be done with a spatula.

- It checks for empty spaces and gaps, which can be done when the weather is sunny.

- The empty spaces between the window and the wall are filled with polyurethane foam. A cement mortar can also be used, but this is more difficult and not always justified.

- When the foam dries, the remains of it are removed. This can be done with an ordinary knife. Then the joints are sealed with a special tape that is resistant to moisture.

- The seams can be closed with putty, and plastic strips will also help.

This prevents further heat escape from the room through the cracks. After sealing the gaps, you can proceed to floor insulation.

Thermal insulation of panoramic balconies

Panoramic balconies have an excellent appearance, have a number of advantages over partially glazed balconies in terms of aesthetics. But the insulation of such a balcony with cold glazing will result in large financial costs. Insulation of the floor, ceiling and walls, except for the facade, can be done in the same way as in the case of parapet balconies, but a glazed wall will require a different method of insulation.

For information on how to insulate panoramic balconies, see this video:

The frame of the cold glazing window system consists of an aluminum profile, which has excellent thermal conductivity.

The supply of heat to such a room at a negative air temperature outside will lead to the formation of ice on the glass, and heating will be insignificant due to serious heat losses.

As mentioned above, unauthorized changes to the facade of a residential apartment building may cause a conflict with local authorities and with the rest of the residents of the building.

Warming methods from "craftsmen"

The simplest way that they are trying to solve the problem of insulating the cold aluminum profile of a window on a balcony is pasting over its frame with thermal insulating material - penoizol or penofol. The efficiency of such "insulation" tends to 0. This is understandable. Even using the thickest foam foam of 10 mm, it is impossible to provide sufficient thermal insulation. Such "insulated" aluminum windows lose heat not so much due to freezing of the metal frame, but due to heat loss through a single window glass.

Pasting a single window glass with a high-quality heat-insulating (energy-saving) film can reduce heat loss in winter by up to 30%.But, of course, it cannot completely replace the second or third glazing circuit with the help of a film. Some craftsmen completely remove the window frames from the aluminum profile, leaving only the crossbars-guides, and in their place they mount the PVC-profile windows with double or triple glazing. In this case, the appearance of the facade of the building immediately suffers. Since the PVC profile is thick and visually very different from the aluminum window profile. Such a replacement is not acceptable if the balcony is semicircular.

Another trick to insulate the balcony is to install a secondary glazing system made of PVC profile with double glazing behind the existing glazing. This significantly reduces the area of the balcony and makes it impossible to wash window panes between adjacent window units.

All these "partisan" methods of insulating the cold aluminum profile of balcony windows are either ineffective and still do not allow using it in the cold season, or lead to a critical loss of appearance and functionality.

Installation of an additional glazing contour

When installing an additional glazing contour, the usable space will not decrease much

Installation of the second row of double-glazed windows will not damage the overall appearance of the building. The resulting air chamber will provide heat retention on the balcony or loggia. The disadvantage of this method of insulation will be the inconvenience of washing the glasses inside the chamber. The useful space of the room will be reduced by the indent and the thickness of the inner wall, which can be a significant disadvantage in a limited area.

What is cold glazing: features and differences from warm

By the type of sash opening: sliding and hinged

Cold glazing is a structure of profiles (usually aluminum) and glass. Its construction will protect the balcony or loggia from atmospheric precipitation, street dust and dirt, but will not be able to create a warm space. Therefore, this type is chosen in the case if the balcony is not planned to be attached to the room - such a room can be used as a storage area, drying clothes or as a resting place only in the warm season.

Characteristics and features:

- Unlike warm glazing, the cold version does not require complex preparatory work to strengthen and insulate walls, floors and ceilings.

- Windows are installed directly on the balcony parapet or pre-fixed beams.

- Instead of expensive plastic or wooden double-glazed windows, aluminum profiles and single glass are used.

- The sash opening design, as a rule, is sliding - an additional advantage when the size of the balcony space is small.

Replacing a profile

To insulate the frame of the structure, you can replace the existing aluminum profile with the same analog, but with a special insert made of polyamide. This method is quite expensive, since you will have to completely replace the entire frame of the glazing wall.

Thermal insulation of the balcony, which was originally thought out by the designer as a cold room, is a rather costly and time-consuming task. It is advisable to obtain competent advice from specialists in the field of construction before making a decision on insulation.