Despite the ubiquity of gas pipelines, many settlements use solid fuel in winter to heat apartments and private houses. The traditional rustic stoves found in every home have been replaced by new boilers that provide good heat transfer and fuel economy.

For proper use, it is recommended to study the instructions for solid fuel boilers, learn about the nuances of installation, operation and subsequent maintenance.

Preparation for operation

Solid fuel boiler (TTK) is a type of heating equipment that runs on wood, coal or pellets, providing room heating. Regardless of the model chosen and the principles of its operation, there are certain installation rules necessary for compliance.

How to protect the premises and where is it better to put

To date, there are no specific requirements for the placement of a structure in a private or apartment building. Some experts recommend that during installation, take into account the rules set forth in SNiP in the section "Boiler Installations". However, the information in the document rather refers to powerful units.

It is highly recommended to consider the following requirements when choosing a location:

- all pipes of the heating system should freely exit from the selected room and be distributed throughout the house or apartment;

- the room should be well ventilated and isolated;

- it is forbidden to install models in bedrooms, especially in children's bedrooms;

- installation in the corridor, kitchen is allowed;

- the device must be freely accessible from any side;

- the ideal option is the construction of a separate extension from foam blocks;

- it is allowed to install boilers in an outbuilding or in a separate boiler room;

- the structure is mounted closer to the outer wall;

- there must be at least 100 cm of free space in front of the unit, at least 60 cm at the back and sides.

If the recommendations are followed, the operation of the device becomes easier and safer.

Preparing the premises is equally important. It is necessary to fill in the concrete base in advance for the installation of the TT, punch a hole for the chimney and ventilation. The walls in the room must be protected from fire. You can trim them with thin leaves of metal, asbestos cement or other non-combustible material.

If the room is decorated with wooden plates, it is allowed not to remove them, but simply to protect them with metal sheets. On all sides of the boiler, it is also required to put a metal protruding by 80 cm. This will prevent the floor from igniting when particles of burning fuel fly out of the boiler. If additional electrical equipment will be installed in the room, it is necessary to make a common concrete screed on the floor to protect it from accidental fire.

How to make ventilation

After preparing the room and choosing the place for installing the heater, you can proceed to the ventilation equipment. The use of wood or coal involves the formation of a large amount of dust and smoke, so this stage cannot be ruled out.

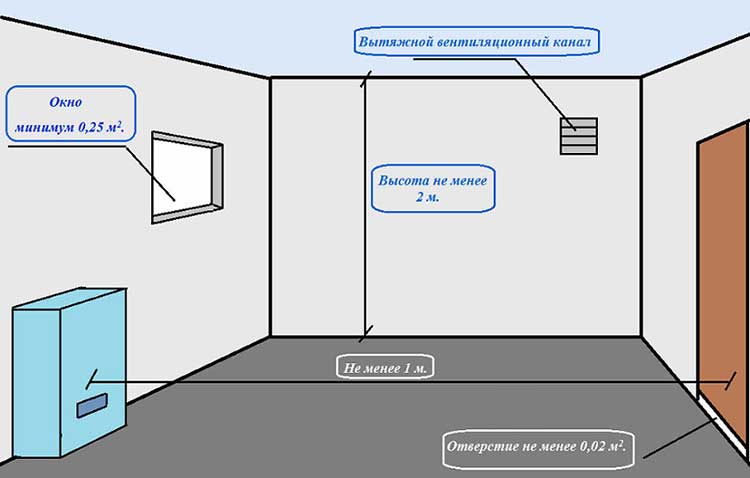

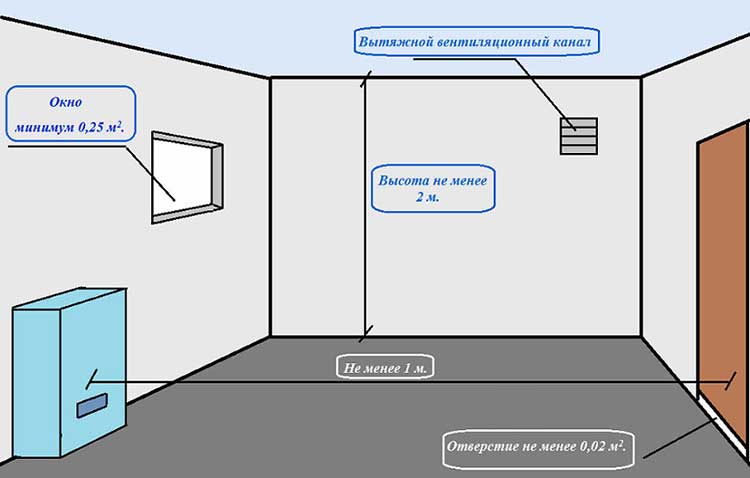

For unhindered access of cold air and outflow of hot air, it is necessary to make two windows with gratings. The exhaust is located in the upper part of one of the walls of the room and is small in size. The supply window is slightly larger, located at the bottom of an adjacent or opposite wall.

Sometimes the ventilation window is mounted above the boiler, which is not recommended.A gap under the door leading to the living rooms can act as an inlet.

Fire safety and environmental regulations

The boiler room is organized in accordance with the following standards:

- The boiler is mounted on a cover that is resistant to open flames. Sometimes a concrete base is made. Installation on a wooden floor is possible, but a preliminary implementation of a cushion of cement and sand, as well as ceramic tiles, is required.

- According to safety rules, it is forbidden to place tanks in a residential area that are larger than a certain norm, as well as store items that are easily flammable (oil products and rags are no exception).

- In industrial boiler rooms, the installation of an alarm system and a fire extinguishing system is mandatory. It is required to install a gas concentration sensor, which notifies a person about the presence of accumulated vapors in the room at a critical level, which can lead to an explosion.

2-circuit units not only heat the room, but also heat water for domestic needs.

Before starting the installation of the boiler room, it is necessary to consult with the employees of the Ministry of Emergencies.

Now, with regard to environmental standards. According to GOST, emission standards should not be higher than certain values. The document calculates the maximum possible emissions. In order to avoid violations, experts recommend "feeding" the boiler only with the fuel that is allowed by the documents for the boiler equipment.

The distance from an industrial-type diesel boiler house to the building should be 50-100 m. The security zone is essential, it should be fenced off with an iron fence. To reduce the distance between the boiler room and houses, it is necessary to increase the height of the chimney.

The norms for diesel heating of a country house are much lower. By and large, when used for domestic purposes, it is possible to use diesel fuel of any quality.

The efficiency of the diesel fuel boiler, depending on the brand and design features of the modification, ranges from 75 to 85%.

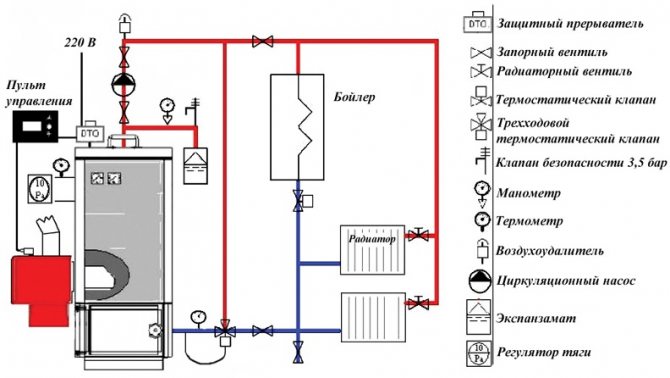

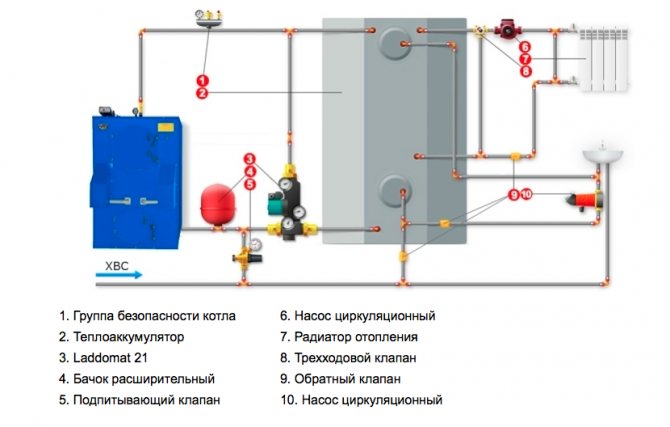

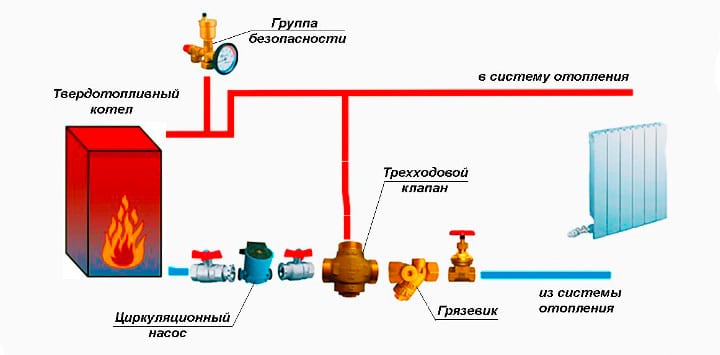

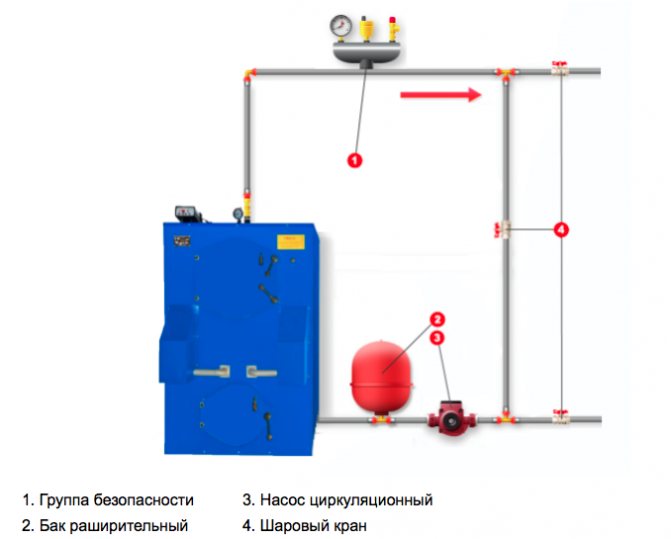

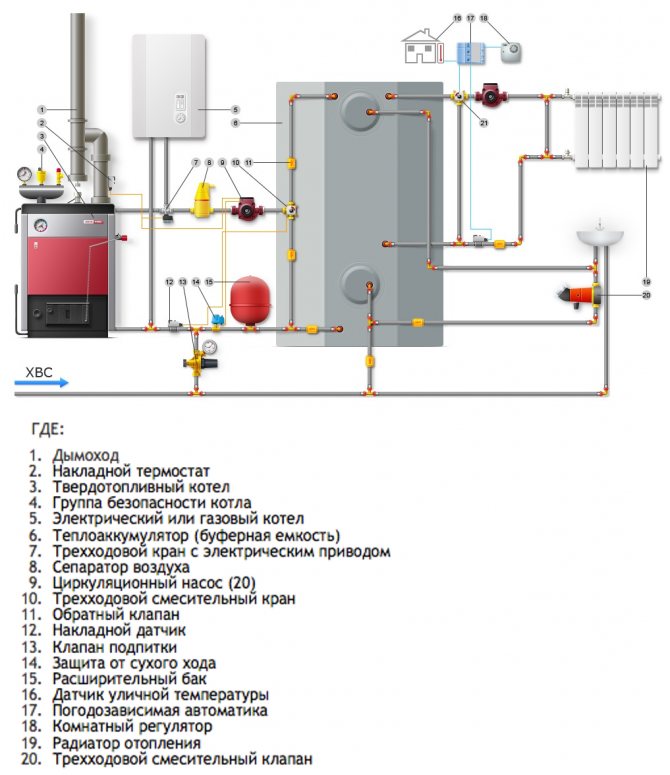

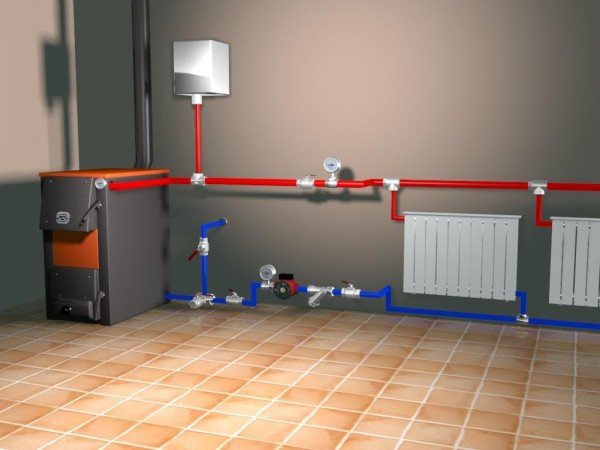

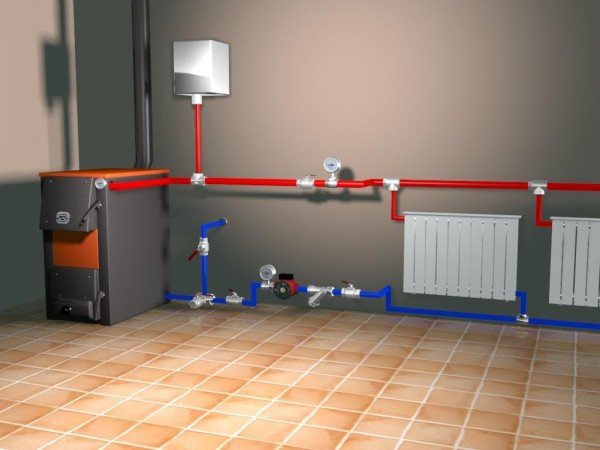

Boiler connection diagrams

After the preparatory work, the device is installed. It is better to entrust the work to professionals in this matter or consult with a specialist before doing it yourself.

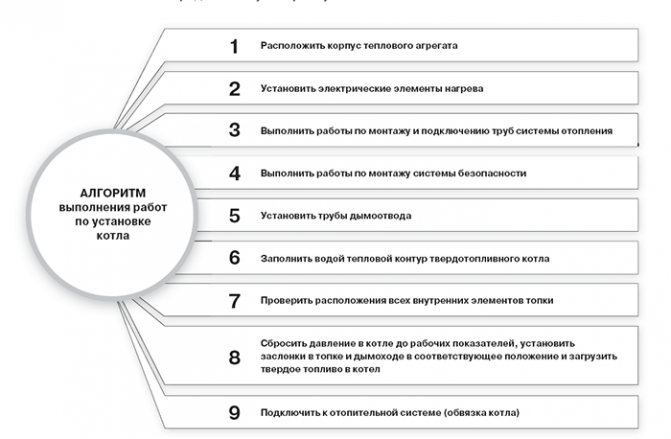

Stages of connecting the boiler to the system

Installation of heating equipment is carried out in several stages. Experts strongly recommend that you follow the sequence to get a good result.

The algorithm of actions is as follows:

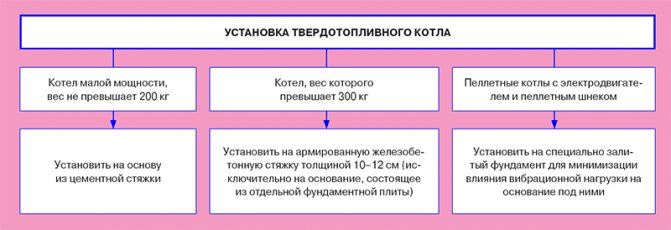

- Preparing the base on which the device will stand.

- Protection of walls and ceilings, installation of ventilation windows to ensure gas exchange.

- Connecting safety elements and inserting pipes to radiators. The connection diagram is individual for each room, it is developed by specialists.

- Installation of a chimney and a generator if the boiler requires connection to the power supply system.

- Pumping water into the system, identifying leaks and malfunctions.

- Checking the position of all dampers on the device and chimney.

Then you can start laying fuel and kindling.

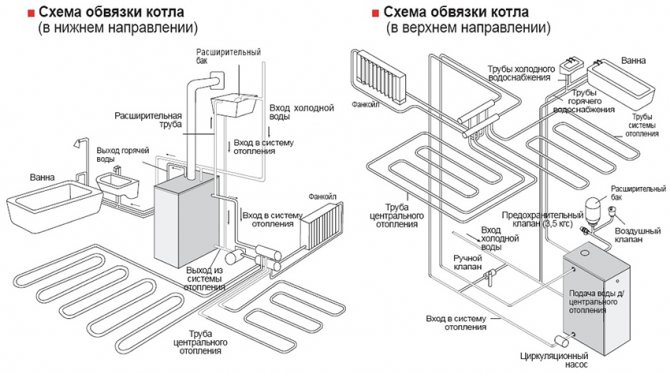

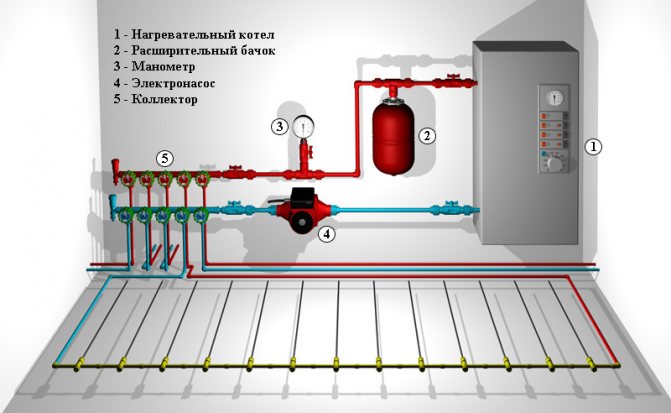

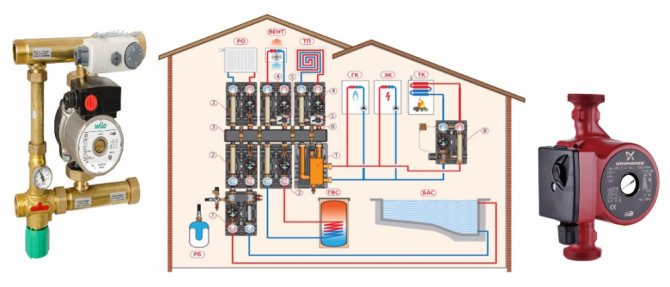

Gravity

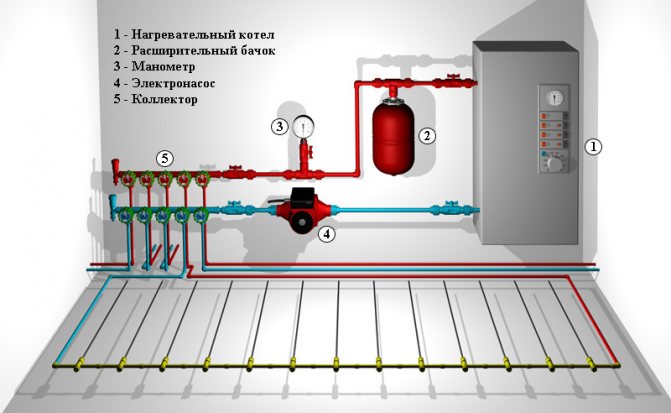

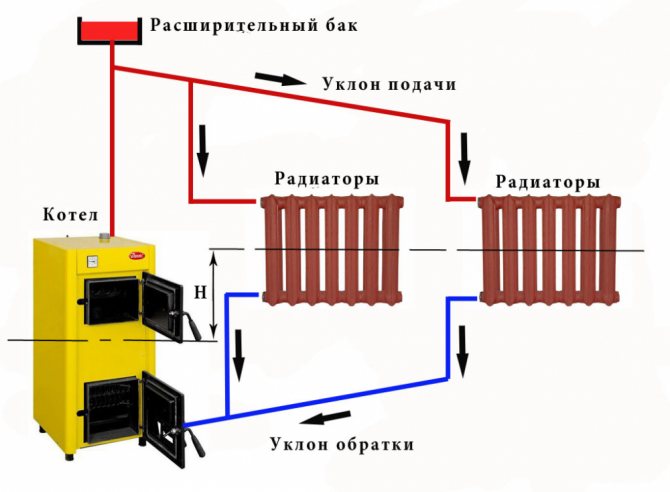

A gravity heating system is considered the most preferred option for solid fuel models, especially in a private house. It is easy to install and does not require any special devices. Does not depend on the source of electricity, which is important when installing in settlements remote from the metropolis.

Typically, such a system is installed in an open way, when the expansion tank is much higher than the heating device and all the radiators in the rooms, which allows the coolant to propagate through the pipes under the influence of gravity without an additional pump.

It is important to ensure that all pipes from the radiators are tilted normally so that water can drain freely.

The system has several disadvantages:

- the need for regular pumping of water into the expansion tank due to its rapid evaporation;

- the ingress of air into the system, which causes corrosion of the inner layer of the pipes;

- uneven distribution of the coolant over all radiators.

Despite its drawbacks, the system is popular and often used.

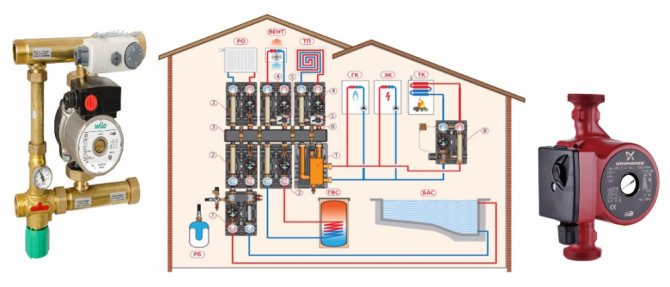

Forced

The forced system is much more convenient and easier to use, it provides an even distribution of the coolant and the same temperature in all radiators thanks to a special pump.

It is installed near the expansion tank or cuts into another place in the system, constantly distills water through the pipes, it evaporates more slowly and does not boil, which is important if the heating device is not equipped with a thermostat.

Requirements for the installation site of the tank when using a forced system are minimal. The slope of the pipes coming from the radiator also does not matter.

Basic requirements for diesel boilers.

To organize a boiler room based on a diesel boiler, it is not required to obtain a special permit, but it is necessary to strictly observe all the general rules applicable to the premises of the boiler room.

In addition to general requirements, it is important to take into account such a feature of a diesel boiler as an increased noise level produced by a forced draft burner. It is also necessary to provide a place for the safe storage of a stock of flammable fuel.

At the same time, one should not forget about the convenience of further refilling of fuel tanks.

The list of requirements for the boiler room:

The diesel boiler must be installed in a separate room. If the boiler is located in one of the rooms inside the house or in an annex directly adjacent to it, it is necessary to provide additional soundproofing of the room. If the boiler capacity does not exceed 60 kW, then the diesel boiler can be placed inside the house. For diesel boilers up to 350 kW, a separate standing room or an extension is required. The extension can be placed only near a blank part of the wall at a distance of at least 1 m from door and window openings.It is necessary to provide a separate room for the installation of a fuel tank

It is important that the room is well ventilated and the temperature inside it does not drop below 5 ° C. Also, a container for storing diesel fuel can be placed in the ground so that the distance from the burner to the bottom of the tank is no more than 3m

When choosing a place for fuel tanks, one should not forget about the convenience of transporting fuel for further replenishment of stocks. The maximum allowable volume of fuel stored in the tank, according to fire safety rules, should not exceed 900 liters. Diesel boilers cannot be installed in rooms with a small area, since such equipment has significant dimensions. The dimensions of the boiler room are determined by the dimensions of the boiler itself, while a number of requirements must be met: The height of the boiler room must not be less than 2.5 m. The distance from the wall to the front surface of the boiler is at least 1 m.

The dimensions of the boiler room must ensure a constant supply of fresh air. If the door from the boiler room leads to the interior of the house, then such a door must necessarily be fireproof with class 3 protection. The boiler must be installed on a leveled concrete podium or metal frame 150-200 mm high. The walls of the boiler room must be made of non-combustible materials such as concrete or bricks. Surfaces must be covered with tiles or mineral plaster.

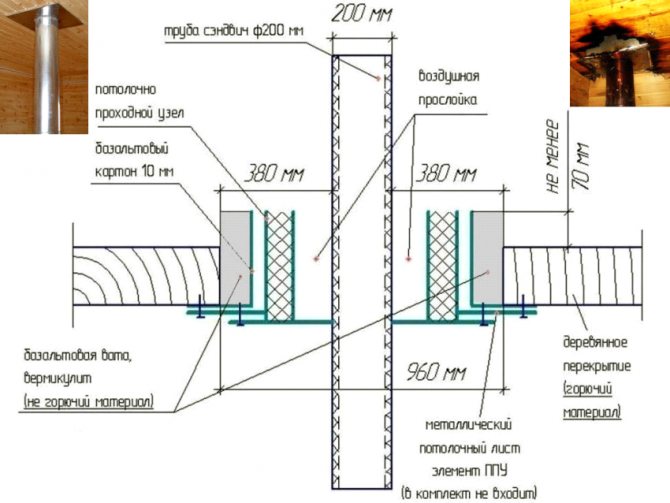

Step-by-step installation of the heat generator and chimney

Do-it-yourself installation of heating system elements is not difficult, especially with proper preparation of the room and directly the place where the structure will be installed.

The step-by-step installation instructions consist of several stages:

- Installing the device and leveling it vertically using metal pads or special feet. It is necessary to take into account the ratio of the branch pipe and the hole prepared for the installation of the chimney.

- Prepare several insulated pipes or take ordinary ones, wrapping them with basalt fiber.

- Make a hole in the wall that will be 35-38 cm wider than the chimney.

- Install a passage box made of metal, pass a pipe through it, fill the remaining space with basalt wool.

- Outside, the chimney is installed vertically, parallel to the wall. A kind of umbrella is attached to the top, preventing the ingress of a large amount of water, from the bottom - a collector for condensate.

- The part of the chimney coming from the heat generator is mounted at a slight angle towards it.

After completing the work, it is worth making sure that the chimney is not under the ridge of the roof and water will not drain into it during rain or melting snow.

How does a diesel boiler work and features

The principle of operation of a modern liquid fuel boiler is the same as that of a gas boiler: fuel is supplied to the nozzle under a certain pressure. The only difference lies in the design of the nozzle itself. Standardized and unified boiler unit

Special attention is paid to the burner and firebox. A modern diesel boiler house is a fully automated system

Types of nozzles:

- Fan

- the fan is used to build up the burner pressure. Fan built into the system. Nozzles of this type have high productivity, but they are quite noisy. - Inflatable.

A turbine is installed in the system as a fan. It helps to increase productivity, improve fuel combustion efficiency.

The boiler heating system is based on the reduction of fuel and air flows. This leads to the ignition of the first in the combustion chamber. Regularly adding the right amount of hot heat keeps the combustion process uninterrupted.

Fig. 2 Nozzle

Diesel heating units have many features and benefits. Their work is carried out autonomously, temperature parameters are regulated automatically. Built-in elements, which function in the equipped system for the benefit of comfort and safety, are responsible for fuel supply and heating.

The operation of a diesel boiler room is quite simple. Starting the main unit of the system, two devices work: an inflatable pump and a fuel pump that supplies diesel to the nozzle (Fig. 1). This creates the ideal pressure that is measured by the manufacturer. This ensures that the diesel is supplied evenly (10-16 bar). The next stage is spraying the combustible mixture through the nozzle and supplying voltage to the heat electrodes. The combustible mixture lends itself to setting fire - the diesel boiler starts its work in normal mode.

In the operation of such a boiler plant, it is important not to forget about seasonal changes in fuel. It can be summer and winter

In case of ill-considered operation of summer fuel, there is a possibility of its freezing in the pipeline.

First heating of the boiler

After checking the heat generator and all valves for leaks, it is allowed to start using the unit for its intended purpose.

The first heating is recommended to be carried out with an open door or window in the room where the TTK is located. During operation, an unpleasant odor may be emitted due to the combustion of a small layer of industrial oil or other components remaining on the device.

The minimum burning time for the first time is 60 minutes, the furnace must be fully loaded. Before setting fire it is worth checking the chimney.

Instruction No.

for boiler room service personnel

hot water boilers working with solid fuels.

- General Provisions.

- This instruction contains requirements for ensuring the safe operation of hot water boilers and is compiled on the basis of the standard instruction of the Gosgortekhnadzor R.F.

- Persons at least 18 years of age who have undergone special training, a medical commission, who have a certificate with a photo for the right to service boilers operating on natural gas are allowed to service boilers.

- A repeated check of the boiler room personnel is carried out at least once every 12 months.

1.4. When entering on duty, the staff must familiarize themselves with the entries in the log, check the serviceability of the equipment and all boilers, gas equipment installed in the boiler room, the serviceability of the lighting and the telephone.

Acceptance and handover of duty should be formalized by the senior operator by an entry in the shift log indicating the results of checking the boilers and related equipment (pressure gauges, safety valves, feeding devices, automation equipment and gas equipment).

1.5. It is not allowed to accept and hand over the shift during the liquidation of the accident.

- Access to the boiler room for unauthorized persons is permitted by the head of the enterprise.

- The boiler room, boilers and all equipment, passages must be kept in good condition and proper cleanliness.

- Doors for leaving the boiler room must open easily outward.

- Repair of boiler elements may only be carried out in a complete absence of pressure. Before opening hatches and hatches located within the water space, the water from the boiler elements must be drained.

- Work inside the furnaces and gas ducts of the boiler may only be carried out at a temperature not exceeding 50 ° C with the written permission of the person responsible for the good condition and safe operation of the boilers.

- Before starting repair work, the furnace and gas ducts must be well ventilated, illuminated and reliably protected from possible penetration of gases and dust from the gas ducts of operating boilers.

1.12. Before closing hatches and manholes, it is necessary to check whether there are people or foreign objects inside the boiler.

- Preparing the boiler for kindling.

- Before starting up the boiler, check:

A) Serviceability of the furnace and gas ducts, shut-off and regulating devices.

B) Serviceability of K.I.P., fittings, feeding devices, smoke exhausters and fans.

C) Filling the boiler with water by starting the feed and circulation pumps.

E) The absence of plugs on the feed lines, purge lines.

E) The absence of people and foreign objects in the firebox.

Adjust the draft in the upper part of the firebox by setting the vacuum in the firebox to 2-3 mm of water column.

- Boiler firing up and switching on.

- The boiler should be fired up only if there is a written order in the shift log of the person responsible for the good condition and safe operation of the boilers. The order must indicate the duration of the kindling, the time, who should carry out the kindling.

- The boiler must be fired up during the time set by the head of the boiler room, at low fire, reduced draft.

When firing up the boiler, ensure uniform heating of its parts.

When firing up, it is necessary to control the movement of the boiler elements during thermal expansion.

- Monitor the temperature of the water leaving the boiler, it should not exceed 115оС.

Keep the outlet water temperature according to the schedule, i.e. depending on the outside air temperature.

- Boiler operation.

- While on duty, the boiler room personnel must monitor the health of the boiler (boilers) and all boiler room equipment, strictly observe the established operating mode of the boiler. Malfunctions revealed during the operation of the equipment should be recorded in a shift log. Personnel must take corrective action.If the malfunctions cannot be eliminated on their own, then it is necessary to inform the head of the boiler room or the person responsible for the gas facilities of the boiler room.

- Particular attention should be paid to:

A) The temperature of the water in the heating network.

- Checking the serviceability of the pressure gauge using three-code taps, checking the serviceability of the blowdown safety valve should be carried out by the operator on a monthly basis with an entry in the shift log.

- During the operation of the boiler, it is forbidden to mark the seams, to weld the boiler elements.

- All devices and devices for automatic control and safety of the boiler must be maintained in good condition and regularly checked, within the established time frame by the administration.

- Clean the furnace from slag at least 2 times per shift

- Emergency shutdowns of the boiler.

- If the safety valve is found to be defective.

- When all circulation pumps stop working.

- When the torch goes out, one of the burners.

- When the vacuum is reduced to less than 0.5 mm of water. Art.

- If detected, cracks, bulges, gaps in welds will be found in the main elements of the boiler.

- When there is a power outage.

- In the event of a fire endangering the operating personnel and the boiler.

- When the water temperature behind the boiler rises above 115 ° C.

The reasons for the emergency shutdown of the boiler must be recorded in the shift log.

In case of emergency shutdown of the boiler, it is necessary:

BUT

Stop fuel supply, pour slag and unburned coal with water.

AT)

Cut off the water to and from the boiler, go to work on another boiler.

In the event of a fire in the boiler room, the personnel must call the fire brigade and take all measures to extinguish it, without stopping the supervision of the boilers.

- Stopping the boiler.

- It is carried out only but by a written order of the boiler room responsible for the gas facilities.

- Ventilate the firebox and gas pipelines.

- Close the valve at the water inlet and outlet of the boiler.

- If there is no other boiler in operation, stop the circulating pump.

- Make an entry in the removable logbook for stopping the boiler.

- Final provisions.

- The administration of the enterprise should not give instructions to personnel that contradict the instructions and may lead to an accident or accident.

- Workers are liable for violation of instructions related to the work they perform in the manner prescribed by the internal labor regulations and the criminal code of R.F.

The instruction was developed by

Boiler house manager

Agreed

OT Engineer

Name of company

Safety measures during operation

To prevent accidents and other problems, you should carefully study the instructions for use of the solid fuel boiler.

The basic rules are as follows:

- avoid close contact with a functioning device;

- do not leave plastic buckets, wood or other flammable objects near the heat generator;

- do not leave the device unattended;

- prevent complete evaporation of the coolant during combustion in order to avoid corrosion and rupture of pipes, as well as radiators;

- regulate the air supply to the fuel using the blower door;

- do not put various objects on the boiler;

- when water boils in the system, close the chimney and blower flaps to prevent complete evaporation of water in the expansion tank and pipes;

- fill the tank with water in a timely manner.

If you have a choice, it is worth installing a closed-type forced system, which will facilitate the operation of the equipment.

LABOR PROTECTION REQUIREMENTS DURING WORK

3.1. When preparing the boiler for firing up, a boiler-house employee must check: - serviceability of the furnace and gas ducts, shut-off and regulating devices; - serviceability of instrumentation, fittings, feeding devices, fans, as well as the presence of natural draft; - serviceability of equipment for fuel combustion; - filling the boiler with water; - whether the water level in the boiler is kept and there is no water leakage through connections, flanges, hatches and fittings; - are there any plugs in front of the safety valves and after them, on the steam, fuel oil and gas pipelines, on the feed drain and blowdown lines; Before firing up the boiler, ventilate the furnace for 10-15 minutes. 3.2.In preparation for firing up a gas-fired boiler, in addition: - check the serviceability of the gas pipeline and the valves and valves installed on it (all shut-off valves on gas pipelines must be closed, and valves on purge gas pipelines must be open); - blow the gas pipeline through the purge plug, gradually opening the valve on the branch of the gas pipeline to the boiler, make sure that there is no explosive mixture in the gas pipeline (gas analyzer), and then close the plug; - make sure that there is no gas leakage from the gas pipeline and gas equipment and fittings by soaping them. It is prohibited to use open fire for this purpose; - check the gas pressure on the manometer; - adjust the draft of the boiler to be fired, setting the vacuum in the furnace to 2-3 mm of water column. 3.3. Igniting the gas in the burner with an igniter, slowly opening the valve, start the air supply, then increase the gas and air supply. If the igniter goes out before igniting the burner, then it is necessary to immediately shut off the gas supply, remove the igniter, ventilate the furnace and gas ducts for 10-15 minutes and only then proceed to re-ignite the burner. If the lit burner goes out during ignition, it is also necessary to shut off the gas supply, ventilate the furnace and gas ducts for 10-15 minutes, and then proceed to re-ignite the burner. 3.4. Before firing up the oil-fired boiler, the fuel temperature must be brought up to the value specified in the instructions. 3.5. It is prohibited for a boiler room employee to light extinguished gas in the firebox without preliminary ventilation of the firebox and gas ducts. 3.6. When firing up a boiler operating on liquid fuel, a boiler-house employee must: - when spraying liquid fuel with steam, insert a lighted ignition torch into the furnace, then supply steam to the nozzle, and then fuel; - when mechanically spraying fuel oil, introduce a lighted ignition torch, turn on the automatic ignition, slowly opening the valve, supply fuel oil to the furnace; - after the fuel oil has ignited, adjust the combustion; the ignition torch should be removed from the furnace only when the combustion becomes stable; - close the safety valve or air valve and open the purge valve if steam comes out of the open safety valve or valve. 3.7. Before putting the boiler into operation, the boiler room employee must: - check the serviceability of the safety valves, water indicating devices, pressure gauge and feeding devices; - checking the readings of the lowered water level indicators according to the direct action water level indicators; - checking and switching on of safety automatics, signaling devices and equipment for automatic control of the boiler; - boiler blowdown. 3.8. During the operation of the boiler, the employee must: - maintain a normal water level in the boiler, while the water level must not be allowed to fall below the permissible lower level or rise above the permissible upper level; - maintain normal steam pressure; - maintain the normal temperature of the superheated steam and feed water; - maintain the normal operation of the burners (nozzles); - at least once a shift, check the serviceability of the pressure gauge by purging it with a three-way valve; - check the serviceability of water indicating devices and safety valves by purging within the time specified in the boiler operating instructions; - keep the boiler doors closed; - stop blowing the boiler, if during the blowing of gases through the hatches occurs. 3.9. The employee is prohibited from: - jamming or additionally loading the safety valves; - continue to operate the boiler with faulty or unregulated safety valves; - to blow off the boiler in case of detecting malfunctions of the blowing fittings and the boiler; - open and close fittings with hammer blows or other objects; - use flammable liquids for kindling a solid fuel boiler; - when the boiler is in operation, mark the seams, weld the boiler elements, etc .; - be near the slag gates when they are opened; - stand against the boiler door when it is blown off; - leave the boiler running, even for a short time,without supervision and allow unauthorized persons into the boiler room; - clutter up the boiler room with foreign materials and objects. 3.10. The stopping of the boiler in all cases, except for an emergency stop, should be carried out only after receiving an order from the administration of the enterprise. 3.11. When stopping the boiler, the employee is obliged to: - maintain the water level in the boiler above the average working position; - stop supplying fuel to the furnace; - disconnect the boiler from the steam lines after the complete cessation of combustion in the furnace, if there is a superheater, open the purge; if after switching off the boiler the pressure in the boiler rises, the blowdown should be increased; - to cool the boiler elements to +25 0С or lower and drain the water. 3.12. When stopping a solid fuel boiler, the employee must: - burn out the remaining fuel with reduced blowing and draft; - stop blowing and reduce thrust; - clean the furnace and the bunker; - stop the draft by closing the smoke damper, furnace and blower doors. 3.13. When stopping a gas-fired boiler, the employee must: - reduce and then completely stop the gas supply to the burners, and then air (with injection burners, first air and then gas); - open the purge plug at the branch and ventilate the furnace and flue gas ducts. 3.14. When stopping the boiler operating on liquid fuel, the employee must: - close the fuel supply to the nozzle; - stop the supply of steam or air; - ventilate the furnace, gas ducts, and then close the blast and draft. 3.15. Work related to the presence of people inside the boiler can only be carried out with the written permission (according to the permit) of the head of the boiler house or the person who is responsible for the safe operation of the boilers, with the adoption of the necessary safety measures and an entry in the duty-handover log.

Boiler and chimney cleaning and maintenance rules

When the heat transfer of the TTC decreases, its condition should be checked. It may have been caused by soot contamination. For cleaning, it is necessary to wait until the entire structure has cooled completely, open the grates and blower, and use a metal poker to clean the accumulations from the walls.

The soot settles on the remaining fuel, which must also be removed in order to reload the chamber. It is difficult to clean the chimney on your own, especially if there are several bends. Soot and condensate accumulate on its walls, as a result, draft deteriorates, and the risk of fire increases.

Depending on the operating mode and the fuel used, cleaning is carried out 1 or 2 times a year. It is better to entrust the work to professionals, which will avoid injuries and other problems. A cleaned boiler and chimney will ensure high heat transfer and a long service life of the entire system. Study liquid thermal insulation by the link.

liquid thermal insulation

GENERAL LABOR PROTECTION REQUIREMENTS

1.1. This instruction regulates the basic safety requirements when working in boiler rooms. 1.2. Individuals over 18 years of age who have no contraindications for health reasons, who have undergone introductory and initial briefing at the workplace, briefings on labor protection, trained in safe working methods and having an appropriate certificate, have passed the examination of knowledge of labor protection requirements, are allowed to work independently in the boiler room. 1.3. The boiler room personnel (driver, fireman, operator) must undergo repeated instruction on labor protection at least once every 6 months, at least once a year - a regular test of knowledge of labor protection requirements and a periodic medical examination. 1.4. The boiler room personnel is obliged to comply with the internal labor regulations adopted at the enterprise. 1.5. The duration of the working time of the boiler-house driver should not exceed 40 hours per week.The duration of daily work (shift) is determined by the internal labor regulations or the shift schedule approved by the employer. 1.6. In the process of work, the boiler room personnel may be affected by the following dangerous and harmful factors: - steam - can cause burns; - equipment (boilers) - if used improperly, pressure may rise and an explosion may occur, as a result of which injuries (burns) are possible; - harmful gases and dust - emitted during the combustion of fuel in boilers (especially coal and peat). The main harmful gases are: carbon monoxide, nitrogen oxides, hydrocarbons, sulfur oxides, etc., as well as coal dust. Once inhaled into the human body, gases can lead to poisoning, and dust particles can damage the upper respiratory tract. 1.7. The boiler room personnel must use the tools and devices, the handling of which is trained and instructed. 1.8. Boiler room personnel must work in special clothing and use other personal protective equipment. 1.9. In accordance with the Standard Industry Norms for the free distribution of special clothing, special footwear and other personal protective equipment, the boiler house workers are issued: when the boiler house is running on solid mineral fuel: when mechanically loaded: - cotton suit; - combined mittens; - goggles; for manual loading: - cotton suit with flame retardant impregnation; - leather boots; - combined mittens; - goggles; when working on wood and other types of fuel: - cotton suit; - combined mittens. 1.10. The boiler room personnel must comply with fire safety rules, be able to use fire extinguishing equipment. Smoking is allowed only in specially designated and equipped places. 1.11. Boiler house employees are prohibited from leaving the operating boiler unattended during operation. 1.12. The boiler house employee must immediately inform his immediate supervisor about malfunctions of equipment, devices and tools, as well as personal protective equipment and other violations of safety requirements and not start work until they are eliminated. 1.13. Boiler room personnel must follow the rules of personal hygiene. Wash hands with soap and water before eating, smoking and after finishing work. 1.14. For non-observance of the requirements of the instructions, the boiler room personnel is responsible in accordance with the current legislation of the Russian Federation.

General installation requirements

From year to year, climatic conditions around the world undergo significant changes that do not go unnoticed. And for the most part, these temperature shifts lead to an increase in cold days per year, which means it's time to think about installing a complete, convenient and durable heating system. First of all, it should be understood that solid fuel heating boilers are a specific technique, working with which requires certain knowledge and skills. However, even if you are not going to install such a boiler yourself, it is recommended to study the principle of operation and all sorts of nuances of operation in as much detail as possible in order to perform maintenance yourself in the future, and not spend money on calling the master.

Seat selection

The choice of a place for installing a solid fuel boiler depends on its design and operational features. Traditionally, for this, it is necessary to equip a special room - a furnace, but it also happens that there is not enough space in it due to the existing gas, electric or other boiler. In this case, the unit can be installed in a frame extension, sheathed with sandwich panels or profiled sheets with fire-resistant insulation, for example, stone wool. This option is extremely convenient for coal-fired boilers, the maintenance of which is not complete without dirt.

Any inexpensive low-power solid fuel boiler for the home can be installed directly on the floor or screed. Due to its low weight, such a technique cannot give serious vibration loads to the base. For boilers, the power of which goes beyond the 50 kW mark, a foundation of concrete or rubble concrete is already required. The same goes for long-burning boilers with heavy-load feeding mechanisms. A hole should be dug and a drainage pad made of sand and gravel. The foundation should rise above the level of the rough screed by 8-10 cm, but in no case should it be connected to the foundation of the house itself.

House projects in most cases provide for the arrangement of a chimney for a solid fuel boiler. This is usually a shaft inside a wall that is piped out through the roof. If there is no shaft or it is occupied by a previously installed gas heating system, it is necessary to mount a separate chimney from metal double-walled insulated pipes. They are lightweight, and the entire system can be easily assembled independently from separate sections, just like a designer. The assembled chimney is eventually attached to the outer wall of the house.

Requirements and Regulations

As for the requirements and standards for the installation of a solid fuel boiler and the entire heating system, then how strictly you adhere to them depends not only on the safety and ease of use, but also on the durability of the equipment itself.

What conditions need to be created in order for the boiler to work as efficiently and for a long time as possible:

- The area of the room where the boiler will be located must be at least 7m².

- In the room, it is necessary to equip a powerful ventilation system of the supply and exhaust type with a channel section at the rate of 80 mm / 1 kW. More details about the ventilation system in the boiler room are described in the article "Ventilation of the boiler room in the house."

- Between the outer walls of the boiler and the walls of the room, there should be at least half a meter, while the walls should be made of fire-resistant material (it is advisable to upholster the corner in which the boiler will stand with metal sheets or panels, drywall is also suitable).

- The floor must also be faced with fire-resistant material, and around the boiler itself, 30-50 cm in all directions, it is better to make a flooring of metal or stone.

It is worth noting that most of the indicators are not axioms and are calculated in accordance with the technical characteristics of the boiler, which can be viewed in the documentation attached to it.