Requirement for sawdust as fuel

As far as we know, sawdust is a very finely chopped wood obtained during the impact of a cutting tool: saws, machine tools. As a rule, sawdust is referred to as woodworking waste from this, the cost of raw materials for fuel is minimal and in some cases even free.

The composition of sawdust is up to 70% carbohydrates (these are cellulose and hemicellulose), 27% lignin. The amount of carbon in sawdust reaches 50%, hydrogen 6% and oxygen 44%, nitrogen content - 0.1%.

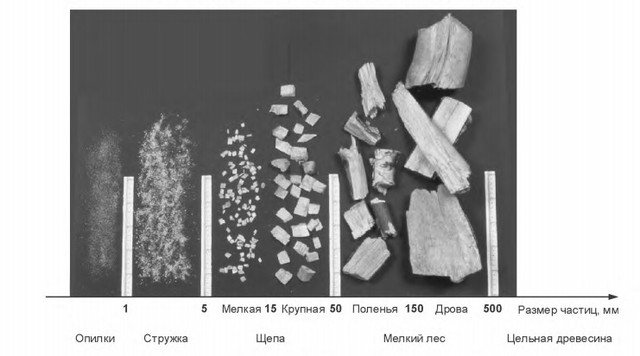

Fig. one Types of wood fuel, wood waste production

A - Obzol board processed into firewood; B - Croaker of conifers; B - Chips of various fractions; D - Sawdust of natural moisture up to 3 mm in size; D - Sawdust of street storage, raw; E - Needle-shaped sawdust of natural moisture; F - Sawdust with moisture W up to 30%; З - Rottened residue of sawdust and wood chips; I - Dry sawdust and shavings; K - Small shavings of street storage; L - Waste wood waste (former furniture, pallets, doors, building structures; M - Long shavings

To use sawdust as fuel, you need to know their technical characteristics. The main parameters that we are interested in are variables and constants. A variable but very important parameter of sawdust is W moisture. With an increase in humidity, the residual calorie content decreases, respectively, with the same volume of sawdust of different humidity, different amounts of heat can be obtained, and the amount of heat can differ significantly. The moisture content of the sawdust can not only be controlled but also brought to the desired value. The second important parameter is ash content - the higher the ash content of sawdust, the more impurities in them in the form of sand and bark. The presence of impurities in the fuel somewhat reduces its calorific value, affects the number of cleanings per unit of time. If sawdust is produced, it is obtained as a result of the work of machines on laminated chipboard, chipboard, MDF, etc. that is, from glued wood, then resins and adhesives will necessarily be present in the sawdust, the use of these sawdust is possible only with additional studies on the content of formaldehydes, and especially harmful substances. For the ash residue of harmful substances, disposal must also be provided.

The fraction of sawdust affects their density, the hanging of sawdust in automatic feeding systems. After adjusting the equipment, as was the rule, the sawdust is trying to withstand the same fraction or within certain limits, so as not to adjust the equipment again. So sawdust crushed into dust burns worse with a large flow of blast air than sawdust in structure closer to shavings.

Fig. 1 - B The classification of wood fuel according to GOST 33103.1 - 2014 is shown. GRV company has developed and manufactures universal boilers operating on all types of wood fuel

When buying sawdust under contracts and agreements, one should adhere to GOST 33103.1 - 2014, which details all the characteristics that should be paid attention to, GOST also regulates methods for determining the moisture content of the fuel and the heat of combustion, which is important since at the time of the conclusion of the agreement on the export of sawdust there may be only moisture and ash content, but in fact, after some time of export, the moisture content of sawdust can grow several times, for example, in the spring compared to autumn.

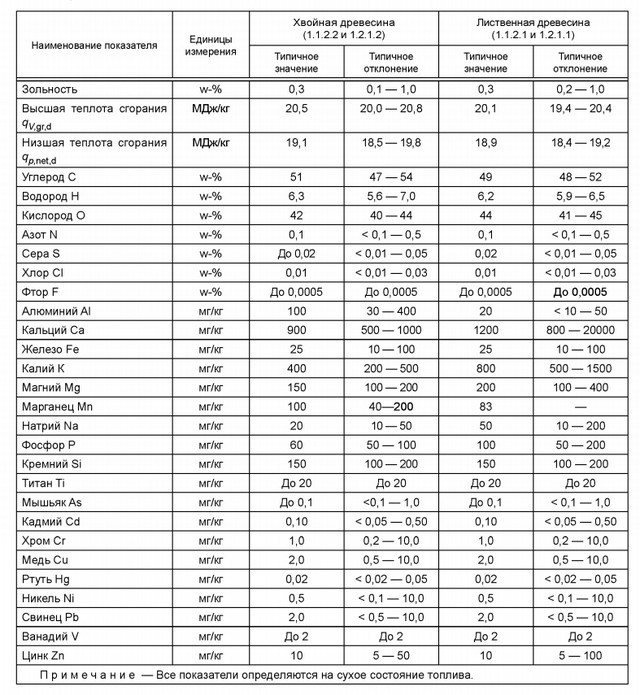

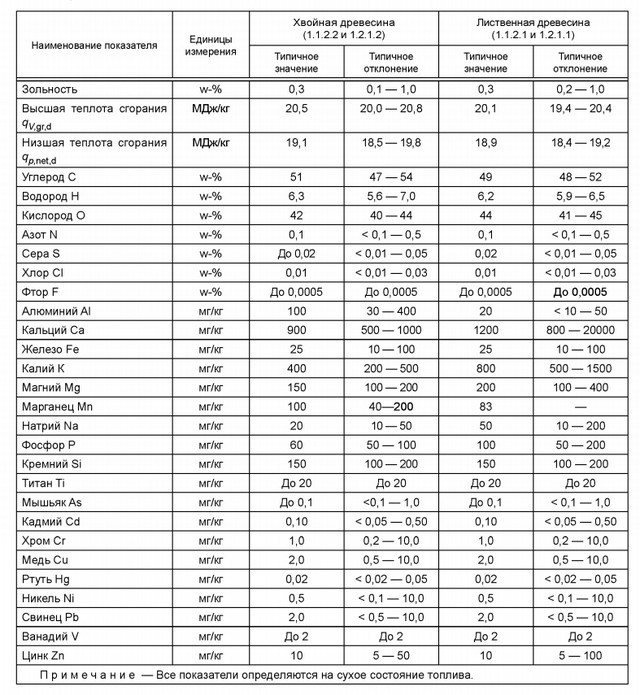

Table No. 1 - General composition and content of substances in wood fuel

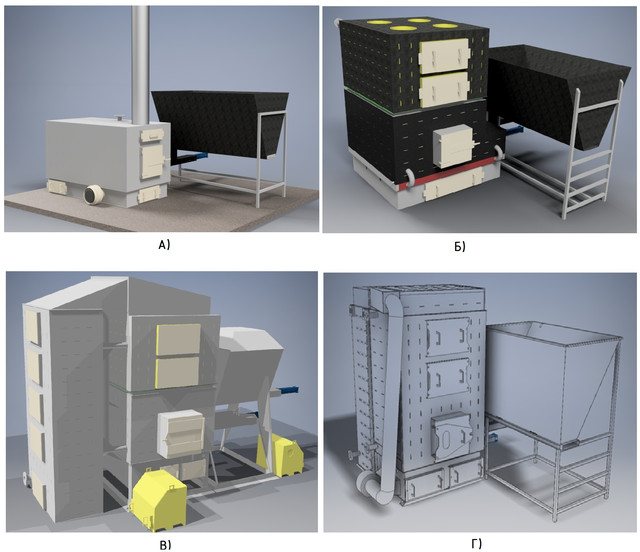

Sawdust storage

Basis for storage: the higher the humidity, the lower the calorific value of the sawdust.

Sawdust can contain a lot of moisture, sufficient for the process of decay and decomposition.Therefore, the storage of sawdust should not proceed for a long time under atmospheric precipitation. In the process of rotting sawdust, their structure changes (Fig. 1 - H) and the heat of combustion is lost. Before directly burning sawdust must be dried and stored under a canopy (Fig. 2).

Fig. 2 Sawdust storage under the canopy of a ventilated warehouse

Drying of sawdust is carried out in drying drums, on sites with protection from precipitation, always ventilated. To dry sawdust, wood chips, it should be turned over from the lower layers to the upper ones. Additionally, it is possible to organize a forced supply of air under pressure through the air ducts from the lower layers of sawdust. When storing sawdust, all fire safety rules and regulations should be observed. If sawdust is a secondary raw material after wood processing, then their moisture should be taken into account, and with a low humidity of 20-30%, it is advisable to send the sawdust for combustion to a boiler or heat generator as soon as possible.

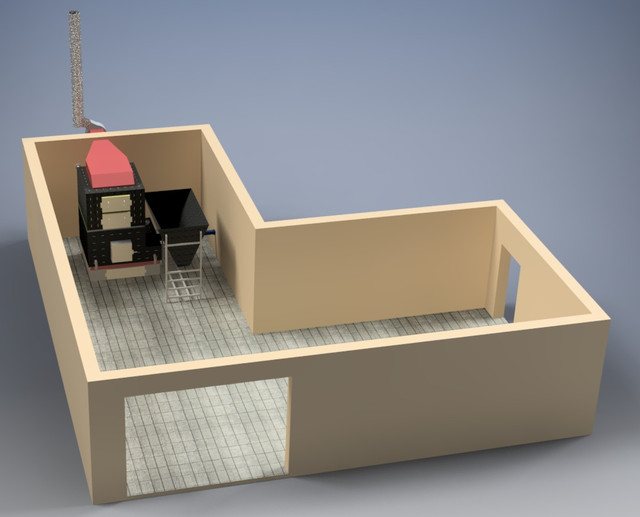

Boiler location, boiler room

The first rule of any boiler room is - non-combustible walls, roof. The requirements for the location of the main fuel storage are also added to the sawdust; it should not be located in the same room as the boiler or heat generator. On the equipment, the envisaged bunker is called operational, since its volume is only enough for a few hours of operation, this is primarily due to fire safety requirements. The boiler room must have supply and exhaust ventilation, or the possibility of airing the room. Since the air for the combustion process is taken from inside the boiler room, a supply should be provided.

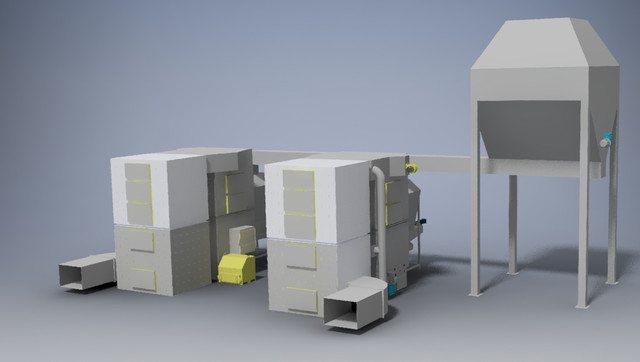

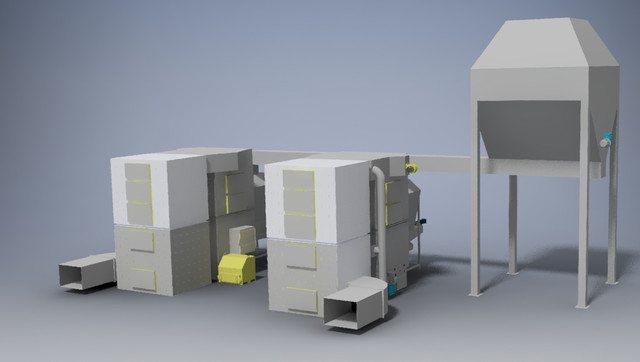

Fig. 3 GRV sawdust boilers and main sawdust storage bin

The dimensions of the boiler room also depend on the method of filling the operational bunker. When using a conveyor or auger, the dimensions of the boiler room are smaller than when special equipment for unloading sawdust arrives at it. It is possible to locate the boiler operational hopper in a separate room in order to reduce the size of the main boiler room

Closed storage bins are often used in furniture production, which is very convenient and as safe as possible (see Fig. 3).

Fig. four Sawdust boiler and low power boiler room GRV

For boilers on sawdust with a capacity of up to 50-400 kW, you can do with one bunker for fuel, while there is no need to organize a transport system from the main fuel storage to the operational bunker.

Homemade construction: materials and assembly order

So, when we figured out the device and the principle of functioning of the industrial design, we can begin to tinker with a similar household mini unit. First you need to stock up on the necessary tools and materials from which the stove will be assembled, namely, we need:

- welding machine;

- pipe of the available diameter (32 - 56 mm);

- gas outlet pipe (100 mm);

- a set of adjustable and gas wrenches;

- Bulgarian;

- roulette;

- clock relay;

- thermal sensor;

- anti-explosion valve;

- water pump;

- ball valves (3 pcs) and screw-thread couplings;

- feeding auger;

- ash removal screw (optional);

- metal corner 45 - 50 mm;

- hydraulic cylinder;

- 200 l barrels for ash pan and sawdust (2 pcs);

- electric fan;

- sheet metal (4 mm);

- tow or fum tape.

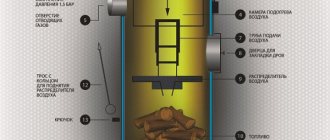

The working process

The assembly of homemade sawdust boilers begins with the manufacture of the body and the bottom of the unit. Everyone chooses the dimensions of the structure individually for himself. With the help of a welding machine, a boiler body without a bottom is formed and covered with a water jacket... Homemade boilers can consist of empty gas cylinders, however, we will focus on the welded version, which will allow you to vary the dimensions and power of the installation.

Next, it is necessary to make stiffeners between the water jacket, as well as provide technological holes through which air from the fan will be supplied to the combustion chamber. A "live" bottom is mounted from a metal corner, if it is provided, for which it is cut to a size of 50x25 mm and the stem is attached to the cylinder for output. When the furnace body on sawdust is ready, it is mounted on a seat, a screw is installed to remove ash and the container is fixed under it.... Now you can mount a fan, an auger that feeds chips, as well as a container for fuel, and we can say that the sawdust burner is assembled with our own hands.

How to light the stove

In order for homemade sawdust stoves to work as efficiently as possible, it is necessary to properly burn fuel. Initially, the crushed wood is placed in a barrel (or in a bunker of the "living" bottom) to 75% of its volume, after which the clock relay is triggered and the auger feeds sawdust into the furnace, where they are kindled with extreme caution with gasoline or diesel fuel. Next, you need to turn on the fan.

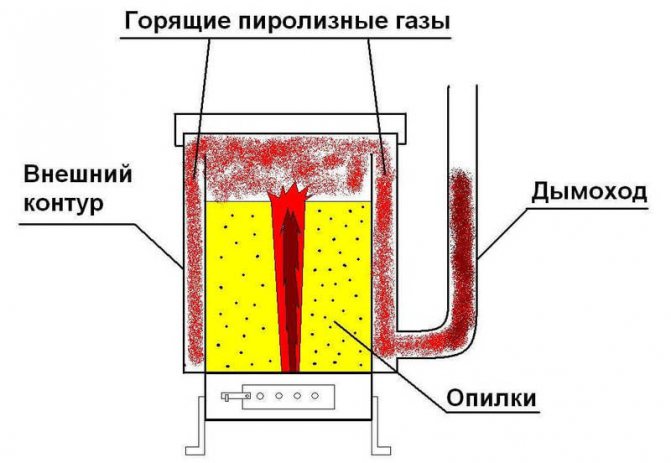

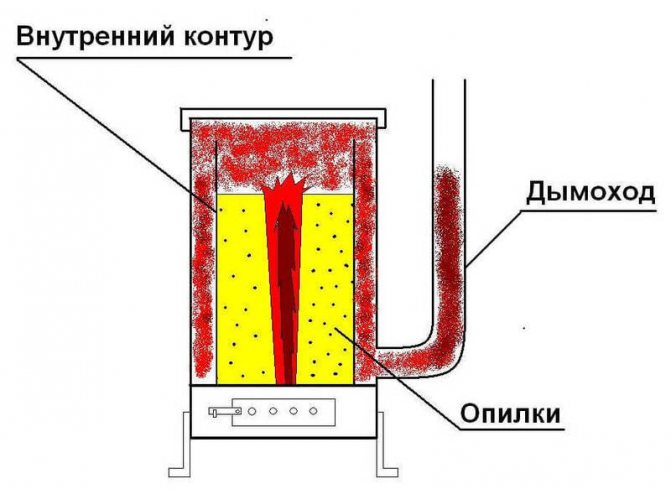

There is another scheme for heating with wood chips, which differs slightly from the previous version, since it is suitable for a simpler self-made sawdust boiler (see photo).

For its implementation, it is necessary to fill the fuel chamber with sawdust to three quarters of its volume, while the chopped wood is recommended to be pressed around the tapered pipe. After ramming, the pipe is removed, the sawdust heating boiler is closed with a lid and a damper on the chimney opens. Firewood is laid and kindled in the lower part of the furnace, from the heat of which the sawdust slowly smolders.

Now you know how to assemble a sawdust oven with your own hands, how it should work and how to heat it correctly. A well-made unit is able to provide economical heating of a small living space or any other outbuilding, and you can learn more about the functioning of a stove stove from the video below.

Fuel supply - sawdust to the boiler hopper

For equipment capacities over 1 MW, the main fuel warehouse with a “moving bottom” system should be used. This warehouse is filled using a front-end loader or dump trucks. From the main warehouse, sawdust is fed by conveyors to the operational hopper of the boiler. It should be noted that fuel in the form of chips (Fig. 1 - M) is practically impossible to supply with standard conveyors and augers, there is a very high degree of hovering of such chips, for this reason, at the initial stage, all characteristics of the fuel, including the geometric shape, should be selected. The following types are excellent for transportation: fig. 1 - B - K.

Models of boilers on GRV sawdust

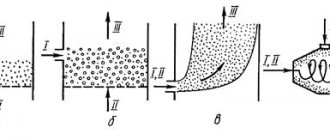

Generally, universal boilers for sawdust, wood, wood chips and coal prevail. Bulk fuels such as sawdust are automatically fed into the swirl burner. The torch from the burner then breaks out into the inside of the furnace, in which the fuel is completely burned out. The walls of the fuel perceive thermal energy and transfer it to the coolant, the combustion products in the form of a mixture of gases are red-hot and move to the boiler heat exchanger, due to the developed area of the heat exchanger, heat transfer from the combustion products to the coolant occurs.

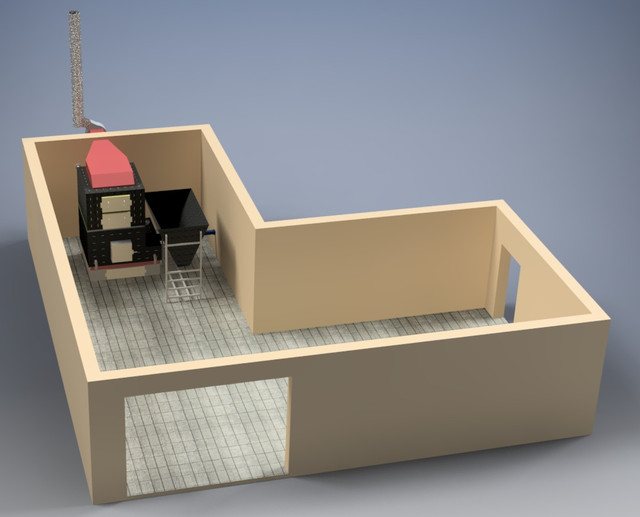

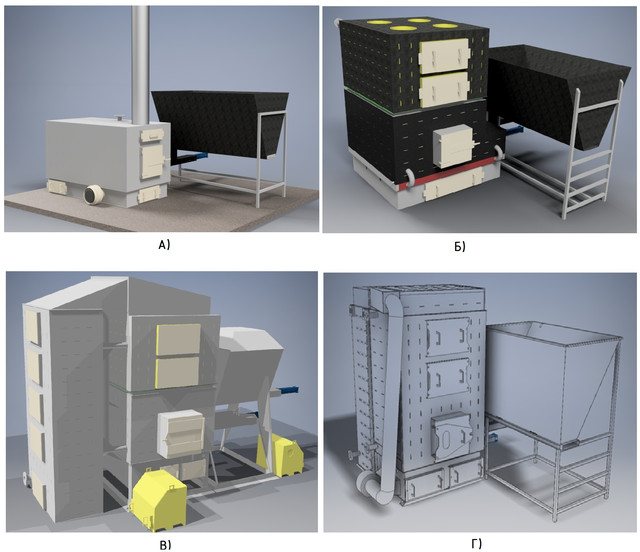

Fig. five GRV sawdust boiler models

A) - Universal boilers up to 300 kW using a vortex burner; B) - A universal boiler for sawdust with a movable grate, without air heating; B) - Universal boilers for sawdust, wood chips, pellets without a movable grate, with automatic ash discharge; D) - Universal boiler for sawdust, wood chips with cleaning the grate, heated blast air

A distinctive feature of universal boilers on sawdust:

The fuel hopper is used with a sawdust agitator to prevent hanging

All universal boilers GRV have a grate, which, like the walls of the furnace, is cooled by a heat carrier

Increased dimensions of the furnace of universal boilers

Spacious ash section of the boiler, the area of the ash section completely covers the area of the furnace

A heat exchanger only with the flow of combustion products outside the tubes, and not vice versa, which significantly increases the intervals between cleaning from carbon deposits, scale

· Universal boilers for sawdust, also operate at full capacity on manual loading, while the dimensions (length and width of the furnace) allow burning wane, pallets, dispose of large branches, etc.

· A separate blowing fan is installed for burning on wood, while the sawdust burner has its own blowing fan. This design is more reliable, you can always switch to reserve fuel without changing the settings and design of the sawdust boiler

The use of steel from 5 to 12 mm ensures a long service life of the equipment

Fig. 6 Sawdust boiler. Boiler hopper with agitator system and movable bottom

Fig. 7 GRV sawdust boiler during production

In fig. Figures 6 and 7 show GRV technology for sawdust boilers with a blast air heating system for the combustion process. Such systems are used in large CHP plants that use heating to generate electricity. The use of heat from the outgoing combustion products for heating the blast air in this case ensures the stable operation of the boiler on sawdust with a humidity of 50-55%, which significantly saves the cost of fuel preparation.

Fig. 8 Sawdust boiler without blast air heating system

The use of dry sawdust with a moisture content of W <20% allows the use of boilers of the GRV series (shown in Fig. 8 and Fig. 5 A, B, C) in which there is no preliminary air heating. These boilers have a 7-8% lower aerodynamic resistance and can be installed to operate on natural draft, the requirements for the chimney in this case are up to 10-12 meters, except for boilers with a capacity of over 400 kW.

Fig. nine GRV boiler on sawdust, you can consider the fuel supply drive

Features of boilers

The sawdust boilers available on the domestic market (most of which also operate on chips) have a capacity of 10 to 500 kW. Taking into account the use of 1 kW for heat supply of about 10 sq. m, this means the possibility of heating rooms with an area of up to 5000 "squares" with the help of such equipment. And for their work, it will take from 2 to 100 kg of raw materials per hour. Self-made devices can have almost any power, however, they are usually made on the basis of providing heat to 100-500 sq. m.

The advantages of such long-burning boilers over conventional systems are:

- the ability to work on wood chips, sawdust and pressed shavings (pellets);

- maximum efficiency;

- high speed of air heating;

- use not only for heating, but also for obtaining hot water, drying things and even for cooking and heating food.

Long-burning boilers operating on wood chips and sawdust are installed only on the floor. Wall mounting is not possible due to the heavy weight of the equipment. The maintenance of these devices is quite simple - ash is removed no more than 1-2 times a month for a boiler used in residential premises, and once a week for industrial equipment.

Sawdust stoves are not a new phenomenon, but they are still in demand today. Such units only increase their popularity among the population every year due to significant advantages.The design features of devices operating on wood waste contribute to long-term combustion of fuel with maximum heat transfer. Heating with sawdust, a cheap and environmentally friendly material, allows you to significantly save money by purchasing inexpensive raw materials for heating a private house.

Potbelly stoves on sawdust, as they are also called, do an excellent job of heating greenhouses, workshops, service stations, garages and not very large living quarters... The manufacture of such common boilers can be done without any special difficulties with your own hands, having previewed the drawings and studying the assembly process. As a starting material, you can use any improvised containers like old metal barrels, pipes, gas cylinders, of course, without contents, and other similar tanks. Before tinkering with a sawdust stove with your own hands, which you plan to heat in the cold season, we suggest that you familiarize yourself with the design and features of industrial equipment, and already on its basis draw conclusions about what a wood chip boiler should be, and how to cope with its assembly.

The difference between piston fuel supply and auger

The use of a piston feed from a pneumatic cylinder ensures fast filling with fuel, safety, since the piston that moves the fuel is also a gate to prevent backfiring. Pneumatics itself is used in many areas of automation, as the most reliable and not whimsical. If foreign objects enter, the controller that controls the boiler does not slowly turn on the warning siren and stops the blast air supply. This system, developed by GRV engineers, has been tested on such fuels as pellets, sawdust of different moisture content, wood chips, wood pulp, and coal.

Firefighting, risks, prevention

Before using sawdust as a fuel, the shavings must be fully aware of the fire hazard, and all measures must be taken initially to comply with fire safety.

Utilization of sawdust and wood pulp in boilers is ten times more environmentally friendly than storing sawdust at landfills, due to the fact that as a result this leads to a fire and sawdust burns with a large chemical underburning more related to the pyrolysis process, while not only the air is poisoned, but soil by pyrolysis products, including acids. In fig. 11 shows an example of sawdust burning in winter under a layer of snow.

Fig. ten Fires of slab and sawdust dumps

Fig. eleven Smoldering sawdust dumps in winter

Precautions and control measures provided on the boiler, heat generator:

1. Control over the position of the pistons, when the position of the piston deviates from the set one, an alarm is triggered and the sawdust boiler stops its work

2. Control of switching on of the smoke exhauster, when the exhauster is turned off, in order to avoid the possibility of backdraft and smoke in the room, the blowing fans of the GRV boiler and automatic fuel supply are stopped

3. Control of the temperature of the fuel supply tunnel, if the normally set temperature is exceeded, the boiler stops its operation, the tunnel may heat up due to the untimely cleaning of the heat exchanger

4. Closing the fuel hopper with an automatic shutter after fuel supply

5. Mandatory control over the temperature of the coolant, including on GRV heat generators

6. Of course, it is necessary to design a separate fuel storage from the boiler room, only an intermediate bunker is used on the boiler itself and the operational volume of the operational bunker is limited

7. The heat exchanger must be cleaned with the smoke exhauster turned on, and without the combustion process in the boiler.

8. All hatches for cleaning the heat exchanger are equipped with special reflective plates

Automatic boilers for coal and wood chips

The technical device and the basic principle of operation of such boilers are not much different from their pellet counterparts. A screw conveyor similarly carries out the automatic supply of coal to the furnace. The process of ignition and supply of air mass is carried out automatically, focusing on the information of a special sensor.

Some difference can be seen in the design of the auger. Coal-fired boilers operating in automatic mode have a more massive auger, which is driven by a sufficiently powerful electric drive.

Automatic wood chips boiler

Chip boilers contain an additional element in their design. This is a wood shredder. Indeed, the dimensions of the chips can be very diverse, and some elements of such fuel simply cannot accommodate the auger. A special chopping knife, which is driven simultaneously with the conveyor, helps to adjust the size of the chips to approximately a single standard.

There are also universal devices that can combine the functions of several devices. For example, an automatic coal boiler is equipped with an additional bunker with firewood supply. Of course, the efficiency from burning a non-main type of fuel will be lower, but the device will continue to work.

Economic efficiency of sawdust boilers

Boilers and heat generators are used to generate heat from fuel combustion, in this case BIO mass in the form of sawdust. Economic efficiency is influenced by transportation costs, the cost of raw materials, and equipment maintenance. You can influence all these factors, but the most basic indicator in this case is the calorific value of the fuel. Sawdust with a moisture content of 30% and a moisture content of 50% will differ twice in calorific value. In order to bring the moisture content of sawdust to 30%, space is needed, warehouses for storage, possibly additional drying plants, it all depends on the scale of processing sawdust into heat.

A promising direction on which the specialists of the GRV company are working is the production of pyrolysis gas from the mass of sawdust in retort installations, gas purification and its use in internal combustion engines. This technology has been known for a long time. We are working on combining gas production and heat production for the needs of production, heating systems. Due to the fact that the installation is located on the street, then in this case it is not required to solve a lot of issues on protection against carbon monoxide.

The use of a pyrolysis plant combined with a heat generator or boiler allows you to place a TPP at your timber processing plant, an agricultural enterprise, as well as at greenhouse complexes, etc.

Features of operation of boilers on sawdust, heat generators on sawdust

The use of sawdust in the form of fuel implies the presence of a minimum infrastructure for the storage of sawdust, the presence of a boiler room and a person responsible for the operation of boiler equipment.

Scope of work

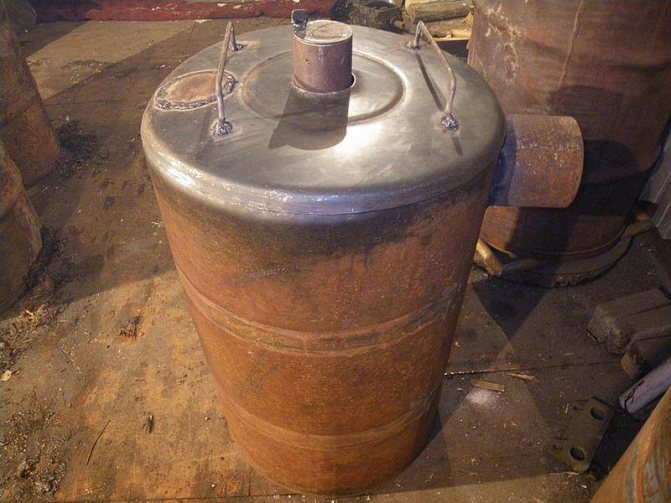

Homemade sawdust boilers

First, the furnace body is made from a gas cylinder. To do this, cut off its upper part along the existing weld seam, then carefully clean the seam residues from the outside. The resulting lid will have to fit tightly to the firebox, so you need to make an edging from a strip of thick metal around the circumference of the cylinder, protruding 15–20 mm above the edge. After that, you can attach to the body the latches for the lid of any design, and weld 2 comfortable handles from a metal bar to the lid itself. A hole should be made in it along the outer diameter of the air pipe.

A sawdust boiler must have a traditional flue gas outlet at the top, so a hole will need to be cut in the body for it.You can immediately weld the chimney pipe, but this can create inconvenience when installing a water jacket, here everyone chooses the sequence of work for himself.

The next stage is the manufacture of cargo that will press down on the fuel. The diameter of the part should be slightly less than the inner size of the cylinder. Having cut it out of thick sheet metal, ribs are welded to one plane of the product to diffuse air, and a hole is made in the center equal to the outer diameter of the air pipe. The latter is inserted into it and hermetically scalded in a circle.

It remains to make a water jacket. The cylinder body has a round shape, so here you have to tinker with sheet metal to repeat this shape. But first, you need to cut out from a thick sheet and weld stiffeners from the outside to the firebox body, which will not allow the metal of the water jacket to play due to thermal expansion. After that, the jacket metal should be welded to each stiffener. The last stage is cutting holes for coolant fittings and welding of threaded sleeves for connection to the heating system. Below is a video with recommendations for making a boiler.