This article will describe the concept of pellets, their varieties, the scope of these products, and, of course, the step-by-step technological process of their production.

Pellet - This is a solid fuel material that is used in heat power engineering, heating of residential and industrial premises, and has recently been gaining popularity among residents of private houses. The raw materials for its production are: woodworking industry waste (sawdust, chips, branches, tree bark, slabs).

Agricultural waste (husk of sunflower, corn and buckwheat) is also used. Peat and straw are also raw materials. It is a pressed cylindrical granules (length 10-30 mm, width 6-10 mm).

They are pressed under pressure and high temperature (250-300 ° C). Pieces of wood and other raw materials are glued together under pressure and temperature using the natural substance lingine, which is contained in the raw material itself.

However, the use of pellets is not limited only as a combustible fuel for boilers.

They also apply:

- In animal husbandry (pellets are used to sprinkle the floors in animal rooms, they serve as a bedding, absorb moisture well, warm and retain heat).

- When cleaning fuels, lubricants and technical fluids in auto repair shops, gas stations.

- As a mulch (protective covering) soil for your vegetable garden or garden.

- As fuel for grilling instead of charcoal.

- As cat litter.

- As an absorbent for cleaning gas from sulfur.

Main types

Wood pellets

They are made in the form of cylindrical granules from wood waste (sawdust, chips, bark, slabs, low-quality wood). They are divided into household and industrial. Household pellets are made from fresh sawdust and wood chips. Other impurities are present in industrial granules. They are light, brownish, or gray.

A lighter color indicates a high quality of the pellets (a light color is a sign of using exceptionally good wood without bark and clean sawdust). They are the most popular for heating private houses, as this type of pellets has the lowest ash content, since they do not contain dust and wood bark (up to 0.5%) and good heat transfer.

Vegetable pellets

They are also produced in granular form from agricultural waste (straw, sunflower husks, corn and buckwheat waste). The final product is generally dark in color. In terms of heat transfer, these granules are in no way inferior if we talk about pellets from sunflower husks, corn and buckwheat, since straw pellets are inferior in this indicator to wood pellets.

But at the same time, straw pellets have their advantages: a large amount of raw materials and a low cost. Vegetable pellets have a higher ash content (up to 3%) than wood pellets, so the boiler will need to be cleaned more often. This type is intended for industrial use, since more ash is released during combustion.

Peat pellets

They are made in the form of peat granules, the color is dark. They are also popular among industrial enterprises, as they have good caloric, economic and environmental qualities. They did not become widespread among private consumers due to their increased ash content, since the boiler will need to be cleaned very often after using peat pellets.

Advantages of pellets over wood

In the previous section, we outlined some of the advantages of pellets. Now we propose to highlight all their advantages in comparison with inexpensive solid fuel - firewood:

- due to the high density and low moisture content, the specific heat of combustion of pellets reaches 5 kW / kg, while dried wood will give a maximum of 4.5 kW;

- for the same reasons, the efficiency of pellet heating boilers is 80-85% versus 75% for traditional wood-fired boilers;

- fine structure and strength of granules allow automating the process of fuel supply and combustion control;

- since manufacturers do not use chemical additives for the manufacture of granules, fuel is not inferior to wood in terms of environmental friendliness;

- low ash content (for wood products - 0.5-1%, for agro-pellets - up to 4%) makes it possible to increase the interval between cleaning heat generators up to 7 days.

An important point. The wood dries to a moisture content of 15% within 2 years, so homeowners rarely dry and heat with freshly cut wood. The real heat transfer in this case is 2-2.5 kW / kg, adjusted for the boiler efficiency. How much ash and soot is generated in this process can be easily determined by daily cleaning of the unit.

Pellets also have disadvantages. Fuel costs 2.5—3 times more expensive than freshly cut firewood, and the price of automated heat generators is the same as compared to conventional TT-boilers. The lion's share of this cost falls on the pellet burner and the electronic control unit.

You need to buy pellets in sealed bags or organize a dry storage space at home, for example, a closed container. Unlike wood, granules saturated with moisture simply crumble into dust and are not suitable for further use.

https://youtu.be/ado5JDtfoSw

Quality requirements

The main requirements for the quality of fuel pellets are:

- The pellet should be flat and smooth.

- Absence of cracks in granules, their warping and shedding.

- The pellet must be tightly compressed.

- The finished product must have the correct percentage of moisture (it must not exceed 15%).

- It is desirable that the pellets be of the same size (mainly manufacturers produce fuel pellets with a length of 5 mm to 70 mm, and a diameter of 6 mm to 10 mm), regardless of the type of fuel pellet.

- The absence or the smallest content of impurities (dust, sand) in the finished product, which degrade the quality of the pellets.

- Colour. For wood fuel pellets, it should be light (lighter - higher quality), since the fewer dark or brown inclusions in the pellet, the less bark and impurities it contains. In peat and plant granules, it is dark gray or black.

- The pellets should be free of mold or mildew.

- There should be no chemicals.

Requirements for raw materials for manufacturing

These criteria are few, but they must be observed in full:

- The raw materials should not have any impurities (stones, dust, sand, metal debris, foliage).

- It should contain as much natural adhesives as possible (lingin, resins and other adhesives), which speeds up the manufacturing process and the quality of the finished product.

- Raw materials should not be very wet, although this is corrected during drying, but still slows down the production process.

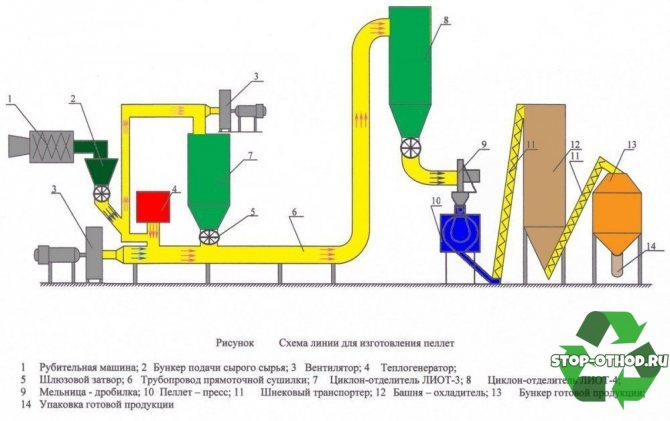

Equipment for the production of

The most basic equipment for the production of fuel pellets are:

- scales for large packages (500, 1000 kg);

- packing machine;

- bunker for finished pellets;

- belt or scraper conveyor;

- smoke exhauster;

- a fan to remove the dropout;

- cooler;

- pellet press;

- dryer drum;

- mechanism for loading processed raw materials into the dryer;

- boiler (gas or sawdust);

- mixer;

- hammer mill;

- crusher (drum or disk);

- container for raw materials with a conveyor;

- cyclones;

- air sleeves;

- screw conveyors;

- air conveyors;

Production technology

The main technological stages of the production of fuel pellets are:

Coarse crushing of raw materials

At this stage, large raw materials are crushed to the required size (length up to 25 mm, diameter up to 2-4 mm). This is necessary in order to simplify the work of the pellet press, since the smaller the material, the better and faster the pellets are formed.

This process is carried out using a crusher. Crushing can be performed several times, if the first time it was not possible to achieve the required fraction of the material. Further on the scraper conveyor, the crushed raw material enters the mixer, and then into the drying drum.

Drying of processed raw materials

This stage is one of the main and takes place in a drying drum. Hot air is fed into it from the boiler through the sleeves, which dries the moisture from the processed chips. The dried chips should have a moisture content of at least 8%, since very dry raw materials will stick together worse in the granulator, but not more than 12%, since the finished pellets will burn worse in the boiler.

During drying, the exhaust air under the action of the vacuum of the exhaust fan is captured together with small fractions, which are deposited down into the cyclone for further fine crushing, and the exhaust air is removed to the atmosphere. In this case, part of the smallest fractions through air conveyors enter the boiler.

Fine crushing

This stage is necessary for even greater crushing of chips and sawdust (length up to 4 mm, diameter up to 1.5 mm) to ensure more efficient operation of the pellet mill. Fine crushing is carried out using a crushing mill. The raw material is fed into it from a cyclone.

In the crusher, the raw material is crushed to the state of flour, and then this flour through air conveyors enters the cyclones (the 1st cyclone for the primary separation of wood flour from the air, the 2nd cyclone for the secondary, final separation). Further, after air separation, the wood flour is fed to a straight screw conveyor. Then from the direct to the inclined screw conveyor to the bunker of the pellet press, in which the mixer is installed.

Humidity correction

This process will take place in a special device - a mixer. Correction of moisture content is very important, because if the raw material is very dry (moisture less than 8%), then the gluing of the raw material in the pellet press will be of poor quality. A mixer is required for the adjustment. If necessary, it will supply steam or water through its channels and the output will be wood dust with the correct moisture content.

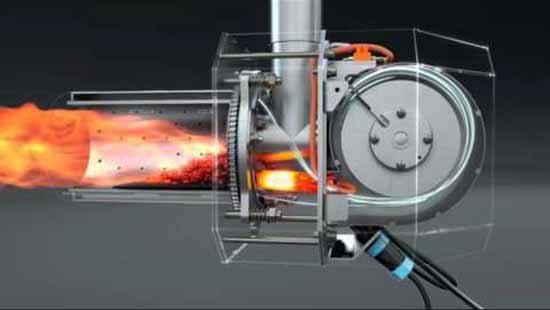

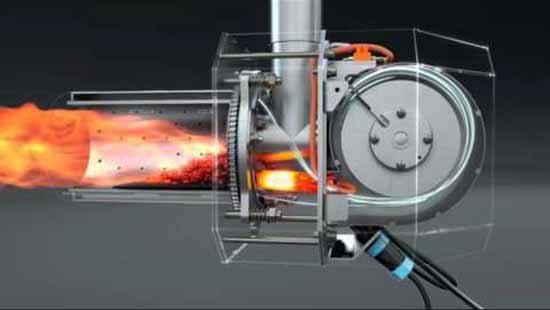

Granulation and pressing

This process takes place in a special pellet press. After the moisture content of the raw materials has been adjusted in the mixer, they go to the granulator. In it, under high press pressure and high temperature (250-300 ° C), the raw material is pressed through a special matrix, passing through which, wood dust is glued into cylindrical granules.

Resins and lingin contained in shredded wood are natural bonding materials. This glue under high pressure and temperature glues the particles of raw materials into granules with high quality. A fixed knife is installed in the granulator, which cuts the finished material squeezed out of the matrix into granules of the required size (length 10 ... 30 mm, width 6 ... 10 mm). Then the granules are fed to the cooler.

Pellet cooling

The finished pellets that have just come out of the pellet mill are very hot, so they need to be cooled. This operation is carried out using a cooler. The pellets entering the cooling column are blown with air from the fan, which "sucks" hot air from the pellets and captures non-granulated wood flour.

Hot air is removed to the atmosphere, and flour is removed to a cyclone. The physical and chemical properties of fuel pellets change during cooling, and due to this they acquire the correct level of moisture content, hardness and temperature (70-90 ° C). Next, the granules are sent for packaging.

Packaging of finished products

The final stage of the production of fuel pellets. From the cooling column through a belt or scraper conveyor, the finished granules are fed to the hopper for finished products. The hopper is equipped with scales to know exactly the weight of the bag packed with pellets. Here, granulated pellets are packed into bags (10 kg, 25 kg, 50 kg). Also pellets are packed in large bags (250 kg, 500 kg, 1000 kg).

This is actually the whole production process.

The final waste from the combustion of fuel pellets is ash. Its disposal consists in cleaning the ash drawer in the boiler. Ash can be used to fertilize the soil in your vegetable garden, in your garden, in flower beds, as it is an excellent fertilizer.

Hence, it should be concluded that both the production and use of fuel pellets are environmentally friendly and waste-free (waste can be used for useful purposes).

How to make a granulator for the production of fuel pellets with your own hands

In order to make pellets on your own, you need to assemble a special machine. In appearance, and technically, it is somewhat reminiscent of a powerful meat grinder. That is, the sawdust is poured into the bunker, then a powerful drill squeezes them under high pressure and granules are obtained at the exit. Subsequently, they are dried and packed in bags or other containers. No additional materials and ingredients are used for the production of pellets, only pressure and moisture are needed, the necessary binders are already in the wood. Materials and tools for assembling the granulator:

- powerful engine; - reducer (chain transmission is used); - matrix; - worm wheels; - two cylinders (made from pipes); - corner to create a frame; - grinder; - welding; - drill and other tools.

Comparison of pellet production technologies

From wood

Stages of wood pellet production:

- Coarse crushing of wood waste in a hammer mill.

- Drying chopped wood in a tumble dryer.

- Fine crushing (bringing to the state of wood dust).

- Control of humidity in the mixer (if necessary, supply of steam or water).

- Compression and granulation of fuel pellets in a pellet press.

- Cooling of finished cylindrical granules in a cooler (temperature 70-90 ° C).

- Packaging and packaging of finished products in bags.

From sawdust

The production of granules from sawdust is as follows:

- Dry the sawdust so that its moisture content does not exceed 12%.

- Take a sieve and sift the sawdust so that no debris (small stones, leaves, etc.) gets into the granulator.

- Grinding sawdust in a hammer mill.

- If the humidity is below 8%, the crushed sawdust must be fed into the mixer (increase the humidity to 8-10%).

- Granulation of sawdust pellets.

- Cooling and drying of granules in a cooler.

- Packing sawdust pellets in paper bags.

From straw

Straw pellet production:

- Straw chopping (length up to 4 mm).

- Re-crushing in a mill crusher.

- Drying in a tumble dryer.

- Moisture control of chopped straw in the mixer (water or steam supply).

- Straw flour pressing and granulation.

- Cooling of straw pellets in a cooler.

- Straw pellet packaging.

From the slab

Slab pellets are produced as follows:

- Processing of slabs in a chipper (chip length up to 50 mm).

- Crushing wood chips in a hammer mill.

- Drying slab chips in a drying drum (moisture content from 8% to 12%).

- Fine crushing in a mill grinder (to the state of wood dust).

- Control of humidity in the mixer (if the humidity is below 8% steam or water is supplied).

- Granulation of wood flour slab in a pellet mill.

- Cooling of cylindrical slab granules.

- Packing slab pellets into bags.

From peat

The technology for the manufacture of peat fuel pellets is as follows:

- It is necessary to lay out the peat so that it dries naturally.

- It must be cleaned of debris (plant roots, foliage, stones).

- Peat crushing in a crushing machine.

- Dry the peat mass in a dryer to a moisture content of no more than 12%.

- Re-grind (fine crushing) in a crushing mill.

- Feed the crushed peat mass into a pellet press with a built-in mixer for peat granulation and steam treatment.

- Cool peat pellets in a cooling column.

- Pack the finished fuel pellets into bags.

What can be made from sawdust

First, let's figure out why wood pellets gained their popularity so quickly. So:

- Among all types of solid fuels, they are the most practical and convenient to store, move and load into the boiler plant.

- Pellet boilers do not require intervention more often than 1 time per week and are fully automated. The duration of combustion is determined only by the volume of the hopper, where the fuel pellets are poured.

- Sawdust is very common as waste from various woodworking sites and entire enterprises, and after pressing into pellets, they have excellent calorific value and low ash content.

- In the manufacture of pellets, there are no various chemical additives, the fuel is absolutely environmentally friendly.

- Wood pellets can be produced independently, providing yourself with a cheap energy source.

When stored, wood pellets take up less space than wood or coal and can be packed in bags and stacked neatly.

Important! Places where pellets are stored must be equipped in accordance with fire safety rules.

Sawdust and shavings as raw materials for the production of pellets are the most convenient and affordable for many owners of private estates. Nevertheless, in order to obtain high-quality granules, some requirements are imposed on raw materials:

- Soft wood, the best fuel comes from it. If you have hardwood or a lot of bark, mix them to achieve good pellet strength and low ash content.

- Large chips or debris should not be caught in the shavings; pellets are made from small sawdust.

- Humidity. Its indicator should be within 12%, otherwise the cylinders may crumble during manufacture, and during combustion, wet biomass will reduce the efficiency of your boiler.

Sawdust that is too wet, which is very difficult to dry or requires more heat than it can generate on its own during subsequent combustion, is useful for another purpose. For example, the production of briquettes with drying in the open air, as shown in the video.

That is, before starting the technological cycle, chips and sawdust must be properly prepared. Remember that low-quality raw materials will produce the same handmade pellets that you will load into your home boiler.