Manual Bypasses

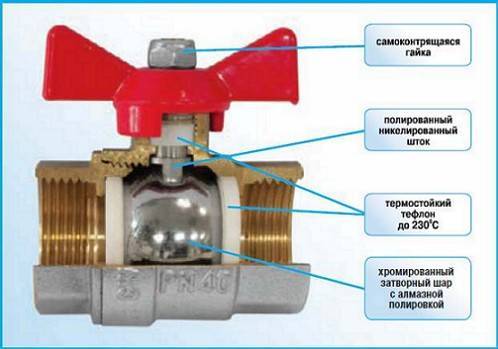

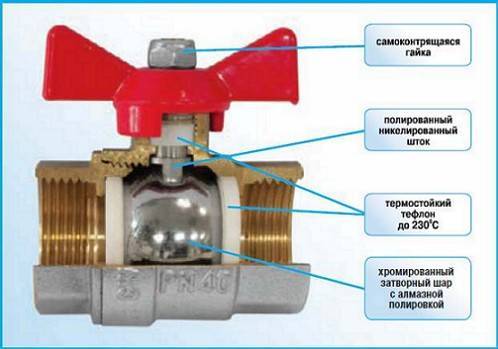

Bypasses that are manually set (manual bypasses) are equipped with ball valves. The use of ball valves is due to the fact that they do not completely change the throughput of the pipeline when switching, since the hydraulic resistance in the system does not change. This quality makes the ball valve the best choice for bypass applications.

This type of shut-off valve makes it possible to regulate the volume of liquid that passes through the bypass section. When the tap is closed, the coolant moves in full along the main line. The operation of ball valves has one important nuance - they need to be turned regularly, even if there is no need to adjust the system. This is due to the fact that with prolonged stagnation, the taps can stick tightly, and they will have to be changed. Sometimes a recharge valve for the heating system is also installed, which plays a significant role.

Bypass design

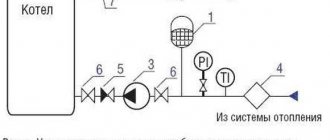

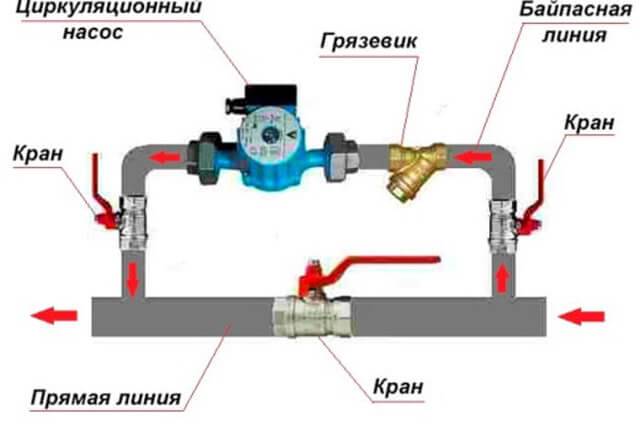

The bypass device is simple. Structurally, the bypass device consists of the following elements: • circulation pump • coarse filter • shut-off valves.

The bypass in the heating system can work continuously or during the start-up of the radiators. The following elements can be used as shut-off valves in the system: • ball valve • check valve. Therefore, it is considered necessary to have a check valve in the heating system. In a heating system, a non-return valve can be installed instead of a tap.

In this case, when the circulation pump is turned on, the check valve is in the closed mode. In the event of a power outage, the valve opens automatically, allowing the system to return to natural circulation. Therefore, the issue of choosing shut-off valves in the bypass design is fundamental. In the absence of a valve, the circulation pump is switched on along the small heating circuit, which is formed by the main line and the bypass.

The check valve design must include a spring-loaded plate and a ball to close the lumen. The advantages of having a check valve in the system are that it functions without the presence or participation of a person. Turning on the circulation pump under the pressure of the coolant mixture "closes" the valve. But in terms of reliability of functioning, the valve is inferior to the valve, because the presence of abrasive impurities in the coolant mixture takes place.

According to specialists involved in the installation of valves, the best option is to purchase a valve from the best manufacturers, because a leaked ball valve cannot be repaired.

Stages of installation of the bypass valve (for radiators and with a circular pump)

DIY bypass valve installation

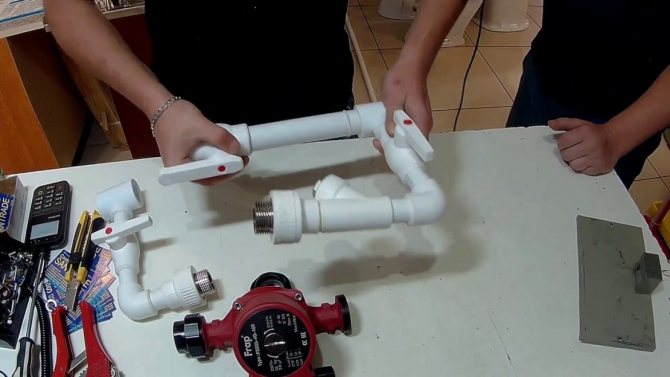

The installation of a bypass in a heating system equipped with a circular pump is done as follows:

- excess liquid is drained from the common pipe;

- a 40 cm section of the pipe is dismantled from the coolant;

- holes of the required diameter are cut at the ends of the pipe for joining the bypass;

- a filter is installed on the cropped areas;

- then the bypass valve is mounted;

- the hydraulic pump crashes.

Important! Installation of screws for distribution of incoming water is carried out in the direction of the general flow of the pipeline.

Installation of a bypass in the heating system

For radiators, the following installation scheme applies:

- the diameters of the bypass and main pipe are checked;

- at the docking ends are mounted: single-pipe jumpers and a control valve;

- then the valve is installed as close as possible to the heating radiator.

Important! Before tapping the bypass, the pipe must be checked for an air lock.

Required tool

You can do the installation of the bypass line with your own hands using tools for installation work, the list of which consists of the following items:

- tape measures for measuring the length and volume of the pipe;

- level for adjusting heating devices and the slope of the water supply;

- pliers for removing and maintaining individual parts of the heating system;

- adjustable wrenches for joining the structure;

- a set of keys for installation (conventional);

- cutter for metal;

- screwdrivers: cross and flat;

- pipe cutter (for large diameter pipes);

- welding machine;

- grinder for aligning the corners of pipes and pipes;

- puncher;

- gas burner.

For one-time work, it is not necessary to purchase all the tools, but you can rent them.

Recommendations and typical mistakes

The insert of the bypass valve should be done according to the rules of SNIP and the recommendations below:

- It is advisable to put filters (mesh type) before installation.

- Installing monomers will help control water pressure.

- Do not twist, squeeze or stretch the spigots during installation.

- The average size of the pipe joint must not exceed 5 DN before and 10 DN after the bypass.

The relief valve can be mounted on horizontal and vertical pipe runs according to the installation instructions.

Tips & Tricks

Before proceeding with the installation of the bypass in the heating system of an apartment building, first of all, representatives of the local housing and communal services should be notified of their decision in writing in order to coordinate the issue of temporarily shutting off the coolant supply from the boiler room. After that, adhere to the following recommendations:

In order for water to normally enter the heating device, it is necessary that the diameter of the pipe of the bypass section be one size smaller than in the general circuit. When purchasing a ready-made bypass unit, you must require a quality certificate, which will serve as a guarantee of durable and normal operation of the device. When buying elements of the bypass section, you should check the threaded connections - they should be easily unscrewed and not twisted when tightened. When deciding to install a bypass, use only ball valves, since they not only have low hydraulic resistance, but also open and close easily. It does not matter whether the bypass is working or not, it is necessary from time to time to open and close all the valves in order to avoid the ball sticking and will significantly increase the service life of all elements of the unit. Before putting the heating into operation after a long shutdown period, it is imperative to vent the area with the circulation pump. Throughout the heating season, preventative cleaning of the filters installed in the bypass system should be performed. In order to avoid mistakes, and for the heating to work efficiently, it is advisable to entrust all the work to an experienced specialist.

Bypass Installation Examples

Varieties

Bypasses are used in a wide variety of heating systems. Two main types can be distinguished - with or without a check valve:

- The former are used with circulation pumps. Engage them as needed. When the pump is running, the valve turns on and opens, and then, under the pressure created by the pump, the coolant passes through.

- Valveless bypasses make it possible to repair one part of the system without turning off the entire heating.

This device can perform several functions and be used in different ways.Below we will consider what the bypass valve is responsible for in different schemes of heating systems.

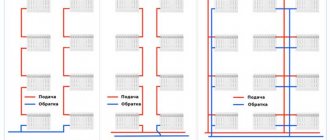

Radiator bypass in one-pipe heating main

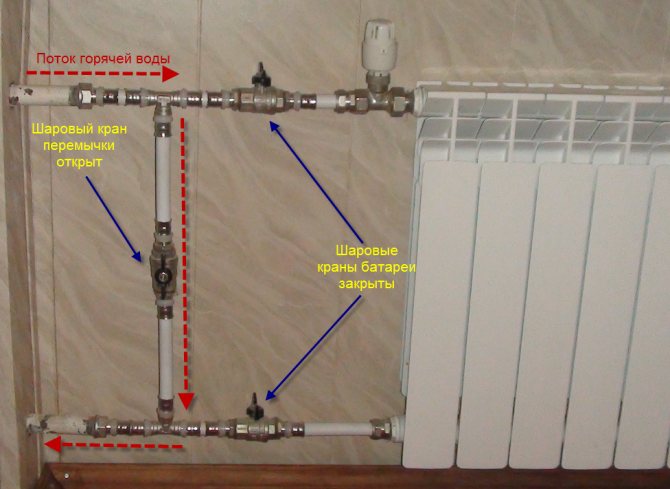

Installing a bypass in the heating system in parallel to the battery makes it possible to regulate the flow of liquid through it and, accordingly, the temperature regime, and also provides the possibility of replacing or repairing the heating device without stopping the functioning of the heating, which is especially important in apartment buildings. How to install the bypass correctly?

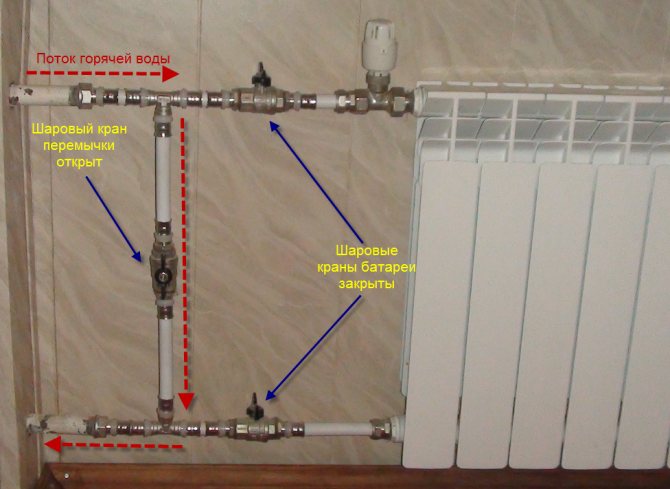

We look at the picture, similar systems look something like this ...

The bypass photo of which you see on the left is just an ordinary jumper connecting the supply (hot) and return (cold) pipes directly near the battery.

Ball valves are installed between the bulkhead and the radiator. It is they that allow you to turn off a separate device, and the coolant will calmly circulate along a parallel bypass path.

The third valve can be installed on the jumper itself and allows you to adjust the bypass mode - the balance of the fluid flow through the heating battery and the bypass pipe. The closed position of this valve ensures the circulation of the entire flow of the coolant through this heater. Optionally, instead of a tap on the supply pipe in front of the radiator, a thermostat can be installed that maintains the temperature set on the radiator.

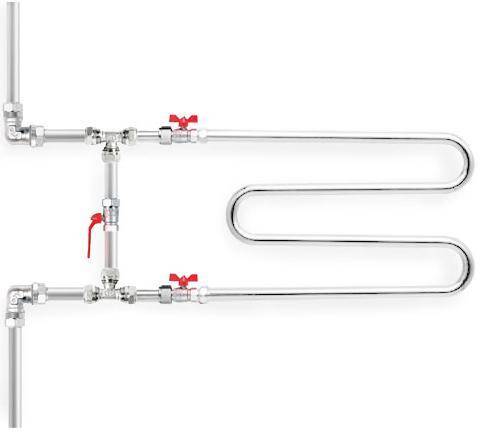

In houses with central heating, it is advisable to install a bypass for a heated towel rail, since many models of this heating device may not be designed for the parameters of our boiler rooms. In this case, the diameter of the bypass is chosen less than the diameter of the main pipes - usually it is a half-inch pipe.

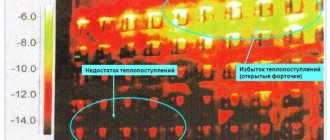

What is a bypass for? It allows you to reduce energy costs by limiting the amount of coolant entering the radiator. Thus, the heat transfer of the radiator is reduced and energy is saved. The lack of the ability to adjust simply leads to overheating of the room, followed by the opening of the vents and the heat dissipation. A heat exchanger with a bypass used in boilers allows you to regulate the required flow rate of the heat carrier through it.

By installing a bypass with your own hands (if you have plumbing skills), you will leave a significant amount of money in your pocket.

How does a relief valve work in a cooling system?

Bypass working principle:

- The cooling liquid at the time of starting the engine that has not yet been warmed up begins to circulate in the so-called small circle. That is, without the participation of the radiator itself. When the engine warms up to the desired level, everything falls into place and the cooling works normally.

- At the beginning of work, when the liquid cannot enter the radiator, it is the bypass valve that does not allow it to do so. It opens by closing the main valve.

- When the temperature exceeds 80 degrees, the main valve begins to open gradually, and the bypass valve, on the contrary, closes.

- At this moment, partial circulation occurs, that is, simultaneously in a small and large (with the participation of a radiator) circle.

- At 90 degrees, the bypass valve closes completely, and the liquid is directed exclusively through the radiator.

How the bypass valve works

If an abnormal situation occurs, a power outage or a pump breakdown, the pressure stops, and the valve automatically closes the jumper, letting water flow naturally. This allows you to fully automate the heating system. The disadvantage of an automatic bypass is sensitivity to water pollution and fine dirt. Before installation, it is recommended to clean the AED water supply system to eliminate deposits and rust in pipes and radiators.

Before starting work, you need to decide on the material of the water supply system.For polypropylene pipes, collapsible joints are used, and first the pump unit is assembled together with the bypass. The branch is connected using tees mounted in the main pipe. In the case of a steel version, the pipes are first soldered, then the valve on the bypass. The bypass system is installed in the direction of the coolant and must be assembled in a certain sequence.

Assembly diagram:

- Filter;

- Check valve;

- Compulsory pump.

The diameter of the passage of the bypass line must be equal to the diameter of the return. Experts recommend that all cranes be equipped with collapsible fittings during installation. In this case, various situations will be eliminated during the repair.

How the bypass valve works

Before starting the installation work on installing the pump, it is necessary to drain the coolant from the system. The entire structure is oriented so that the outlet pipelines are vertical or horizontal, depending on the pipe stroke.

How the bypass line works:

- A section of the bypass is assembled, which will be located parallel to the highway;

- A section equal to the length of the bypass is cut off from the return;

- Tees are installed at the ends of the line;

- A section with shut-off valves or a valve is mounted between them;

- The assembled section of the bypass is connected to the main with pipes equal in length.

During installation, it is necessary to leave space for the possibility of subsequent dismantling of the pump and other elements. It is necessary to do the installation correctly, following the coincidence of the arrow on the body with the coolant current.

Types and designs

According to the principles of operation, a distinction is made between overflow valves with spring and diaphragm designs. Spring mechanisms prevail in systems where the cross-section of the pipeline is no more than 200 mm; in other water supply and heating networks, a lever-load principle is used.

Membrane aggregates are used more and more when working with fluid media in which there are solid particles.

Depending on the pipeline environment, bypass devices are intended for:

- gas;

- couple;

- liquids.

According to the purpose of the system, they are used for pipelines:

- cold water supply,

- hot water supply,

- heating,

- cooling,

- air conditioning.

In heating and water supply systems, bypass valves are distinguished according to their purpose:

- for radiators;

- for boiler and bypass;

- for automatic feeding;

- for low or high pressures.

This photo shows an overflow valve with a setting scale. Made of bronze and brass, it is designed for installation in central heating systems.

Along with bypass regulators, the following are installed in the heating design:

- air vent to prevent air congestion in pipes;

- three-way valve for mixing or dividing streams of hot and cold water;

- backward, preventing backflow in the pipeline.

For industrial and utility networks, constructions with a nominal diameter of DN up to 500 mm and a flange connection are used.

In the car, access devices are for:

- turbines;

- fuel supply mechanism;

- engine cooling systems.

The turbine bypass unit relieves the exhaust gases, reducing the head force in the manifold. Thus, it protects the motor from overheating.

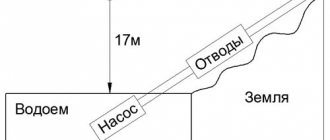

Pump connection via bypass

It is advisable to connect the circulation pump through the bypass only in those systems that were originally intended for natural circulation, i.e. they must have a booster manifold, the slopes of the pipes are observed and their diameters are correctly selected. The pump in such systems is not designed to keep them running, but to improve efficiency.

For systems that were designed for forced circulation at the design stage, the bypass is simply irrelevant.Such systems work only at the expense of the pump, therefore, when it is turned off, the circulation of the coolant simply stops. Bypass in this case will not be able to solve the problem.

When the pump is connected via a bypass line, there is a possibility of backflow in the bypass. In addition, a closed circulation loop is formed between the pump and the bypass itself. In order for such a scheme to function normally, the bypass device must be equipped with a ball valve or check valve.

Installing a bypass: the subtleties of DIY installation

By and large, the bypass jumper has a fairly simple design, and it can be assembled even with minimal plumbing experience. Once again, I repeat that the principle of operation of this device and its understanding are important here - knowing this, it is not so difficult to independently make a bypass for a circulation pump or something else. Let's take a closer look at this process.

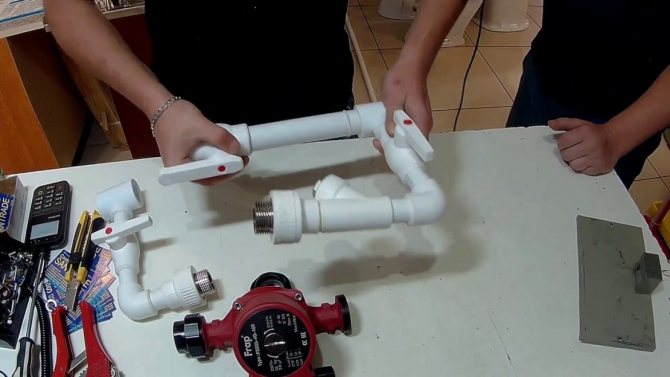

- What we have? For example, a heating line on which a circulation pump is mounted. The first thing to do to install the bypass is to remove it and slightly alter the line - in particular, you will need to slightly increase the distance between the threaded ends on which the pump was screwed. It is best to determine this distance in place - in the sense, to assemble the pump and the assembly around it as expected.

- To do this, immediately behind the pump, on one side and on the other, we wind up ball valves - this can be done immediately overhauled. We have detachable connections on the pump, so it will not be a problem to quickly disassemble the unit and mount it on the pipeline.

- After the taps (also on both sides of the meter), tees are installed with exactly the same diameter as the pipeline itself. A reservation should be made here - the type of tee depends on the pipeline itself. In most cases, tees made of the same material as pipes are used - if polypropylene or metal-plastic, then first threaded ends are screwed into the taps and then tees are soldered or screwed to them.

- In principle, everything, the size is set, and now we try on the assembled unit in place, cut the pipeline according to the marked marks and insert the assembled unit. For ease of use, it can be disassembled on American women - simply put, remove the pump, after which you will have two parts of the pipelines, which will need to be connected to the main line. After this section of the bypass is assembled, the pump is installed in place (overhaul) - only after that it will be possible to focus on the bypass pipe itself.

- Here, too, everything is simple - to begin with, we raise the pipeline from the tees upwards so that it does not interfere with the pump. Then, by turning, we bring the two pipes coming from the two tees to each other - at least we set them the right direction to each other. And then there is a jumper and a crane, for the installation of which, again, you will need a detachable connection and a pair of threaded ends.

In principle, this is the entire bypass for the circulation pump - exactly the same principle is used to mount the bypass for other plumbing fixtures. The bypass pipeline can be positioned both vertically and horizontally - from this moment its functional purpose and quality of work does not change.

That's all. Now you know what a bypass is and how it works. Moreover, an attentive and scrupulous reader will now have no difficulty in making this unit on their own, without the help of qualified specialists. I'm not afraid to repeat myself - if you understand the principle of its operation and understand the device and the purpose of each element, then it will not be difficult to assemble the bypass with your own hands.

The author of the article is Alexander Kulikov

Step-by-step do-it-yourself bypass installation technology

The recommendations of experts will help you install a bypass valve for water, taking into account all the nuances:

- There must be a much greater distance from the riser to the bypass than from the valve to the radiator.

- If there is no factory product at hand, a homemade one from a piece of pipe with two tees will do. Docking by welding or threading. Threaded connections are on ready-made tees, and the ends of the pipe are to be threaded independently.

- Adjustment or temperature control equipment must be embedded in the area between the bypass valve and the battery. Additional equipment is useful for adjusting the heating temperature, helping to make the system more efficient.

- To make it easier to remove the pump, the bypass pipeline should be supplemented with shut-off valves. To turn off the water supply, turn off the taps, remove the pump, repair, install, then you can restart the circulation of water through the pipes.

- To start the old and long-term non-working heating system, a bypass device with a circulation pump, a check valve and ball valves is cut in. The pumping equipment will run water through the pipes, the check valve will not allow the coolant to return, it is convenient to adjust the intensity of the water supply to the system with ball valves.

- To circulate the coolant at a given rate and enter the batteries without delay, the bypass is constructed from a pipe with a section 1 size smaller than the section of the central pipeline.

- When connecting the pump to the branch pipe of the bypass device, you need to equip the system with a ball valve or check valve.

- When laying out the contours of a warm floor, the bypass is equipped without fail. The bypass bypass pipeline will provide the coolant supply from the mixer after mixing hot and chilled water (return). Three-way valves pass a small portion of hot water, most of the coolant of the desired heating mode circulates through the bypass pipe, is transported along the circuit and directed to the heating device (boiler).

- In the process of arranging a small circuit of a solid fuel boiler, the bypass device must be installed so that one pipe is connected to the supply pipe with the most heated coolant, the second pipe is connected to a three-way valve installed on the water return pipe.

On a note! Installation of a bypass does not require replacement of system elements. It is most convenient to work with a device equipped with ball valves. In this case, only the section of the pipeline into which the bypass valve, taps and tees are cut will have to be changed.

Step-by-step device installation:

- increase the distance of the threaded ends in the area where the pump was previously wound;

- assemble the pumping equipment, the assembly around the pump, tighten the ball valves;

- all pump connections are detachable, you do not have to use welding, you need to monitor the twisting strength and tightness of the joints;

- behind the ball valves, install a tee with a cross-sectional size that is equal to the diameter of the pipeline;

- remove the pump, cut off the line pipe, install the unit by connecting both parts of the pipeline to the main line;

- as soon as this section of the bypass is assembled, reinstall the pump;

- raise the pipeline in relation to the tees so that it does not interfere with the operation of the pump;

- reduce two pipes by rotation, screw on a jumper, ball valves - all parts are equipped with threads and detachable connections, there will be no difficulties with tightening.

The bypass valve pipe can be positioned vertically or horizontally, the position does not affect the functionality of the bypass.

There are nuances in the case of a tie-in device when installing a bypass pipe:

- The section of the bypass pipe must be selected 1 size smaller than the section of the inner tunnel of the main pipeline.

- Install the jumper as close to the radiator as possible.

- In an apartment of a multi-storey building, a bypass tap is not installed.

Important! After assembling the bypass valve, the heating system must be checked for leaks. The easiest way is to pressurize with water, if there are no violations and leaks, you can start the line in constant operation.

The bypass valve is part of the residential heating system. The bypass bridge ensures continuous water supply where a complete stop of the pumping station is not possible (for example, in a cooling station). Let's take a closer look at what it is.

Bypass device

The use of a bypass for the installation of an additional pressure unit is often accompanied by the inclusion of an element such as a check valve in the main part of the pipeline.

It is a small device with a two-piece body. A ball or spring-loaded baffle is located inside the bypass housing. The main task of the valve is to ensure the operation of the heating system in the absence of additional pressure generated by the pump. The operation of the valve in the heating system is automated and does not require human intervention. This is very convenient for emergency shutdown of the pump in the absence of residents of the house.

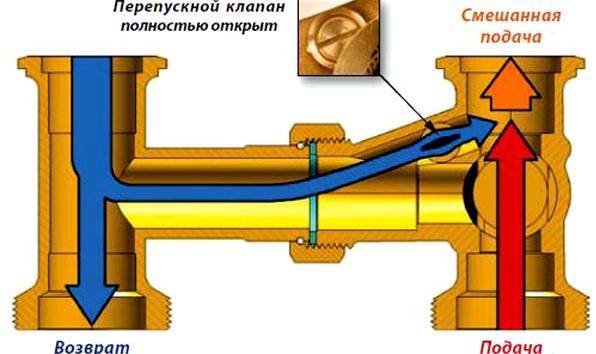

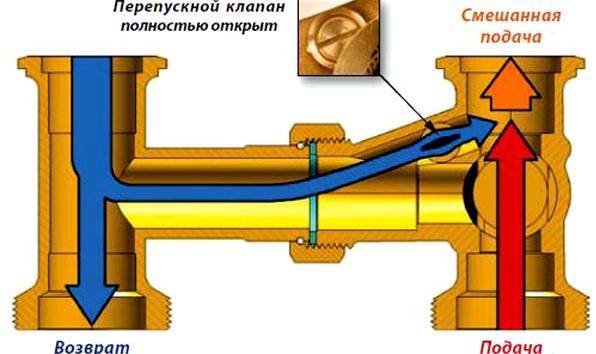

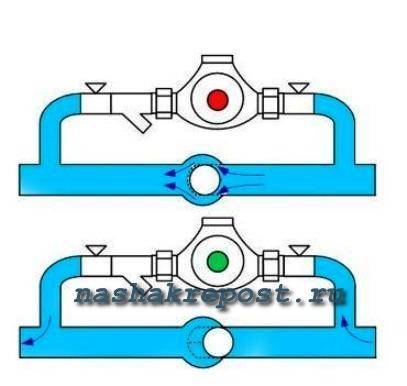

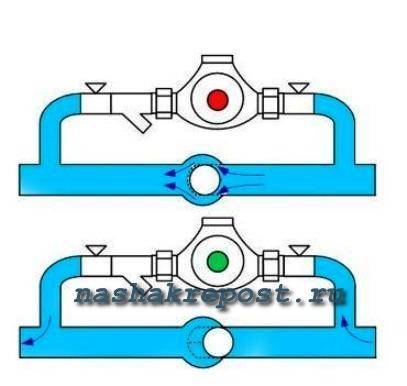

The principle of operation of the check valve is as follows. When the pump is turned on and in good working order, additional pressure is created at the outlet of the valve, which locks it and prevents the movement of liquid (lower part of the figure).

In the event of an emergency shutdown of the pump (upper part of the figure), there is no additional pressure in the system, which “unlocks” the bypass check valve and opens the main pipeline for the movement of the heated coolant. In this case, the device functions independently of the presence of an operator, using only the laws of physics. This allows you to protect the entire heating system of the house from destruction.

One of the fasteners that have appeared and are actively used in recent years when installing elements of heating systems is the so-called American nut.

It consists of two parts, equipped with threads and screwed onto each other. Available in two versions - straight and angular. When fixing one or another element of the system, one part of the nut is screwed onto the threaded part of the branch pipe of the installed device, and the movable part of the connection is driven onto a threaded pipe or fitting. The use of such parts makes it relatively easy to fix certain elements not only in the bypass, but also in any other place of the heating system. The main advantage of the American connection is the ability to remove the installed device - pump, radiator and others without disassembling the system itself.

Dear readers, comment on the article, ask questions, subscribe to new publications - we are interested in your opinion