Water pressure

2 comments on the entry What is a check valve for a pumping station - how to choose how much it costs

One of the most important elements of an autonomous water supply system is a check valve.

Thanks to him, a constant pressure level is maintained in the water supply system, water leakage from the system and pump stop is excluded.

Some models of pumping stations are equipped with a built-in check valve, but for most of them, additional equipment with this element is required.

Check valve purpose ^

The purpose of the check valve is to allow the flow of water to the pump and prevent it from returning. Valves of this type are direct operated devices.

This means that no external control or power source is required for its operation. The check valve opens and closes under the influence of the movement of fluid flow through it.

When the pump is running, the valve opens and passes water through the pipeline, and in the event of a shutdown of the unit, it closes and does not let it flow in the opposite direction.

In this case, the pressure in the line before the check valve drops to zero, and after it it remains.

We also recommend that you familiarize yourself with the article of the pressure switch of the pumping station, it is necessary to automatically turn on and off the pump, working in tandem with a hydraulic accumulator, it maintains excess pressure in the network, compensates for hydraulic shocks.

Another interesting article about the principles of operation of domestic pumping stations is here, it contains prices, reviews, characteristics and advice on choosing such stations.

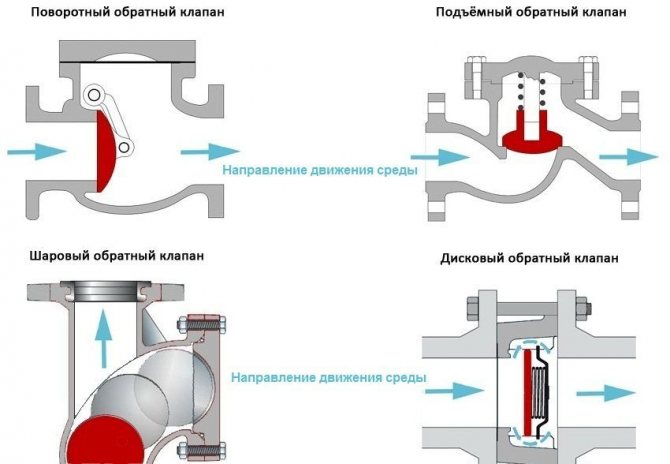

The main types of check valves for the water supply system

In the plumbing of a private house, a lift-type check valve is most often used. This element provides reliable retention of a column of water of several meters. It works great both with a borehole type of water intake, and when installed in a well. Under the action of the flow of water, the spring is compressed and the space for the passage of water is opened.

The ball check valve at the heart of the design has a cone-shaped chamber in which a ball is used as a shutter. The base of the cone is in the direction of the water flow. Under the action of the flow, the ball moves inside the cone and opens up a space for the liquid. When the flow of water stops, the ball moves in the opposite direction, blocking the neck of the cone.

A check valve that uses a swivel plate that swings back when fluid passes through the body and blocks the orifice when the direction of flow changes. Each of the designs of such a device is successfully used in practice, both in the plumbing systems of private houses and urban communications. The peculiarity of the installation of one or another type of equipment is due to the need for the project and technical parameters, starting from its mass, the material of the body, and ending with the use in specific conditions, for example, in hot water pipelines.

Classification ^

There are two types of check valves, which differ in the design of the overlapping element:

- valves - they look like a spool, are used in horizontal sections of pipelines;

- gates - are produced in the form of round discs, they can be mounted both on the horizontal and on the vertical section of the pipeline.

According to the design of the locking element, check valves are divided into several groups:

- lift-type valves: the shutter (locking element) in them is spring-loaded, can only move up or down.

- ball valves: the role of the shut-off element in this design is a ball made of polymer or cast iron.

- swing check valves: the shut-off element is in the form of a flap. It is fixed on an axis located outside the flow area.

- Flanged valves are large and heavy. Cast iron and steel are used for their manufacture. These are the most expensive products in the swing check valve group.

- Wafer valves are cheaper, but they "sin" with higher head losses compared to flanged ones.

- The cheapest rotary check valves are coupling valves.

- Disc check valves: a disc is used as a shut-off element, located perpendicular to the flow axis.

Under the influence of the water flow pressure at the supply, the spring is compressed and the valve opens. As soon as the water flow decreases, the spring returns the valve to the closed position.

Lift check valves are impressive in size; they are rarely used in the water supply system. Their main area of application is boiler houses and heat supply systems of industrial enterprises;

There are also rubber balls. The closure of the device is carried out only under the influence of gravity: springs are not used in ball valves.

Ball valves are most often used in sewerage systems, but they have also proven themselves in plumbing systems.

Structures of this kind have low hydraulic resistance. But, due to their size and weight, ball check valves are much more expensive than other types;

This valve design it is mainly used on pipelines with a diameter of more than 50 mm.

By the type of connection, rotary valves are divided into flanged, coupling and wafer type.

This category of valves is also made of cast iron and steel, and series made of anti-corrosion steel are also produced.

Brass and cast iron are used for their production. The head loss on the sleeve valves is less than on the flanged and wafer type.

It moves along the axis of the water supply system. Basically, butterfly valves are made in a sleeve design for pipelines of small diameters, but wafer-type ones can also be found.

The shut-off disc is most often spring-loaded, therefore, the disc valve is unpretentious in installation. It also wins in price, but its head losses are high. Nevertheless, such valves are widely used in utility systems.

Main varieties

Among the check valves used for a well or water well, several types of such devices should be distinguished, which have gained the most popularity among consumers due to their high efficiency.

Disk

Such devices can be single or double leaf. They are installed on an electric pump that supplies water to autonomous water supply systems. The locking elements of the disc devices are lamellar flaps fixed on a spring-loaded axis. Such check valves are subdivided into shock and shockless ones. The former are installed in systems for the equipment elements of which water hammer is not too critical a factor, the latter, more expensive ones, are used in cases where the consequences of water hammer arising in the pipeline (including as a result of the operation of such devices) must be minimized.

Ball

The closing element in these valves is a spring-loaded ball. It should be noted that this is the most common check valve for a pumping station due to its high efficiency and exceptional reliability.

Lifting

Devices of this type work due to a spring-loaded spool that moves freely along the vertical axis.If you decide to install a lift check valve on a pump that pumps out water from an underground source, keep in mind that such a device can only be mounted on horizontal pipelines.

Operating principle ^

At rest, that is, in the absence of water flow, the check valve locking element is in the "closed" position (lies in the seat of the body) either under its own weight or under the influence of a spring.

Under the influence of the pressure of the water flow, it rises and frees the passage through the valve. As soon as the head is zero, the valve is lowered into the seat, thereby preventing the reverse flow of the flow.

In other words, the check valve is automatically controlled by the medium itself and does not require any additional controls.

Sewerage check valve device and its installation

The non-return valve in the individual sewer network is designed to protect against the return flow of sewage water and fecal matter. An overflow of the toilet bowl threatens to spill around the apartment if there is no device that prevents the return movement of sewage water when the general sewer system is clogged. The device is extremely simple, despite the importance of the functions performed. It consists of a clamping movable round plate with a rubber gasket that tightly closes the outlet opening, which is attached to a springy lever attached to the body. By the pressure of water from the outlet, the plate rises horizontally, and after loosening it, it drops into place, preventing the return current.

The sewer check valve can be made of:

- bronze;

- cast iron;

- of stainless steel;

- polyvinyl chloride (PVC);

- polypropylene (PP);

The diameter of the outlet holes can be 100, 50 or 70 mm. The housing is equipped with a removable cover for cleaning the striker plate. By means of the handle brought out to the body, the outlet can be closed manually. The installation of this plumbing fixture allows for both vertical and horizontal inserts. The tie-in is made into the existing or newly installed sewerage system at the joints of pipes of the corresponding diameter. Docking of cast iron with plastic is done by means of adapters from cast iron to plastic or vice versa. With the tie-in, the possibility of maintenance must be foreseen and ensured.

Check valve installation rules ^

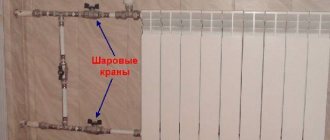

There are two options for installing a check valve on a water supply system, if a pumping station is involved in it:

- in front of the pumping station;

- immediately after the ratchet on the suction pipe.

The second option is considered the most optimal., because the installation of a check valve in front of the station may result in limited water volumerequired for discharge into the suction pipe and subsequent capture by the pump at the moment it is turned on.

Another disadvantage of this arrangement of the check valve is the filling of the suction pipe with air after the water is drained.

In this case, together with the working medium, the pump can capture a portion of air. This leads to the appearance of noise in the pipeline and the expulsion of the airlock when the water tap is opened.

Where are installed

The water check valve is installed in the following places:

- At the outlet of a submersible pump, lowered into a well or into a well. When the pump is turned off, the water will not return in the opposite direction; Installing a check valve on a submersible pump

- At the end of the suction pipe of a surface pump or pumping station, which is lowered into the water. After turning off the pump unit, water will always remain in the pipe; Check valve for a water supply system based on a pumping station

- At the inlet of the cold pipeline to the boiler. In this case, if there is no water in the pipeline, the backflow of liquid will not start from the boiler;

- For various types of water supply systems, especially if cold and hot pipelines are used at the same time. The pressure of the water in the pipelines is different, so hot water may be forced into the cold line or vice versa through the mixer. The back pressure valve of the water, installed in each separate line, will not allow its reverse flow;

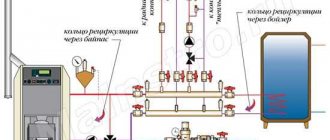

- In autonomous heating systems, when there are several separate circuits with different coolant pressures. In this case, each circuit has a separate pump. If the power of the pumps is different, then a more powerful unit can push the coolant into an adjacent circuit, where the pump has a lower power. This should not be allowed at all, therefore, a water return valve is an indispensable element in such a system;

- On water meters to prevent the movement of water in the opposite direction;

- In sewer systems to prevent backflow of drains.

It is quite easy to install a check valve on the water with your own hands correctly, because for this it is enough to have minimal plumbing skills, as well as to have the necessary tools. The basic rule during the installation process is screw the valve in the desired direction... On the body of the device there is an arrow showing the direction of movement of water through the valve.

We have analyzed why a water check valve is needed, and also considered the types and features of such valves. The use of these useful products can prevent emergencies in water supply and heating systems, as well as greatly facilitate the work with water pumps and pumping stations.

okanalizacii.ru

Popular check valve models ^

We have prepared for you a mini-rating of valves that are optimal in terms of price-quality ratio.

If your pumping station is installed in a country house, we recommend that you read the article How to choose and install a pumping station in a private house - prices, characteristics, owner reviews, it just contains a lot of useful information.

If you are pumping water from a well, you cannot do without a caisson, the most affordable option is a plastic one, read more about caissons here, drink only the purest water!

How to install a water check valve correctly?

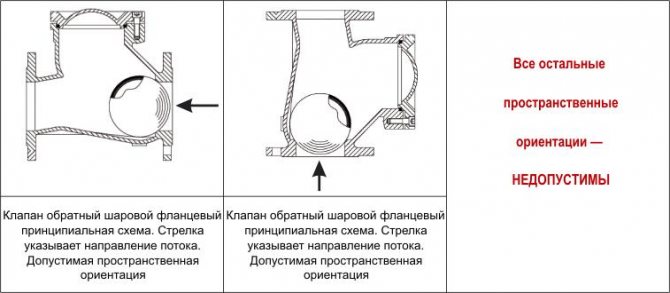

The device of check valves used in household plumbing with spring-loaded diaphragms installed in them makes it possible, it would seem, to install the valve with any orientation in space. After all, a check valve in any case, regardless of whether it is installed horizontally, vertically or otherwise, should work normally. In fact, the way it is, it is possible that you will never have such a problem. But it will not be superfluous to play it safe, because the devil is not joking, as they say ...

The spring installed in the check valve is so weak that it is not able to withstand various types of dirt and deposits. But during operation, they inevitably form on the walls of the check valve and the membrane! But if the spring of the check valve were more powerful, then the sense of using the check valve would disappear, because then it will with great difficulty let water pass in one direction, and not let it pass at all in the other.

So, if you are not a masochist and do not want the water supply system to bring additional problems and costs in the future, install the water check valve with the arrow pointing up, i.e. strictly vertical. And the more precisely you do this, the longer the check valve will last without any failures and complaints.

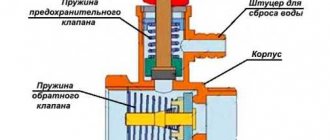

Not only the life of the equipment, but also the safety of residents depends on the correct piping of an electric storage-type water heater (boiler). This is how serious matters are. And its correct piping is a safety valve for a cold water heater.

Check valve 16h42r ^

This model is designed to work with pumping units. The design includes a mesh that acts as a primary filter that protects equipment from mechanical impurities.

In the manufacture of this model, cast iron and rubber are used. The installation location is at the end of the suction pipe. Such a valve is quite expensive: Du 50 - almost 2,000 rubles, Du 80 - about 3,600 rubles.

As for the quality of different brands of check valves, their design is so simple and has been worked out over the years that, in principle, when choosing, you can not bother too much: basically they all develop their resource flawlessly.

True, if plastic is involved in the product, then such a malfunction as a skew of the working body can be observed. In this case, it may be necessary to replace the check valve of the pumping station. BUT bronze, stainless steel, rubber does not cause much trouble to the user.

Initial installation and replacement of check valves

Check valves used in equipping pumping stations for a well or well are installed quite simply. The more difficult task is choosing the right place for installation. The choice of the device model depends on the type of pump with which it will work.

As mentioned above, check valves installed at pumping stations for a well or well are selected at the design stage of autonomous water supply systems. To equip the water supply system, you can purchase a pump model, in the design of which check valves are initially provided. They can be installed both on the input and output lines of pumping stations.

If vacuum-type pumps are used for a well or a well, then check valves are installed directly after the suction device - in front of the accumulator. The optimal choice for pumping stations of this type are ball and lift valves.

For surface-mounted borehole pumps, multiple check valves can be used at once. One of these valves is mounted on the lower part of the hose, which is lowered into the well, the second is installed in front of the accumulator.

Individual manufacturers indicate the appropriate type of check valve in the pump manual. However, as a rule, pumping units of various models can be equipped with any type of check valves. In most cases, the brand of the borehole pump, for which a check valve is used, does not matter either.

The downhole pump check valve is installed on the hose or pipe by means of couplings and fittings of the appropriate diameter. When installing such a device, it is necessary to ensure the tightness of the connections being made, for which a sealing FUM tape is used. In addition, during installation, it is necessary to ensure that the direction of opening of the device coincides with the direction in which the water moves in the pipeline. When choosing a check valve for installation in an autonomous water supply system, it is necessary to take into account the diameter of its nominal bore, as well as the working pressure for which it is designed.

met-all.org

Check valve spring coupling: types by material

Products can be made from different materials:

- Brass is the most popular material. It does not rust, is easy to maintain, and fits well with all types of pipes.

Brass valve body

- Cast iron cases are much less common. This material corrodes, various deposits accumulate on it quite quickly. Usually, cast iron products are used on pipes of large diameter, and they are not used in everyday life.

- Stainless steel. It is the most reliable, but also the most expensive material: its elements will last much longer than any others. They are not afraid of corrosion and the effects of various substances; deposits do not accumulate on the body.

Stainless steel body

- Combined: the body of such a product can be made of different materials, for example, combine brass and stainless steel. The shutter of any device is most often made of plastic.

Reverse type universal attachment with strainer

Differences in the method of fastening

Most devices are fastened with a sleeve. This requires two threaded transitions to match the size of the pipeline. Flanged mountings can also be used. Most often they have large diameter cast iron elements. These flanges are bolted together. This type of fixation is also relevant for small products, when there is no place for other fixing on the pipe.

Why do you need a check valve after the pump

On the discharge pipe I put a check valve as it should be, I give a task to the machine gunners on the pressure switch on the discharge pipe, and they say that the check valve must be moved from the discharge pipe to the suction pipeline, otherwise the pump will not work correctly. The drinking pump for the cottage is powered from the network.

Do I understand correctly that the pressure switch should be after the check valve? and what's wrong here.

it is necessary to add a hydraulic tank after the pump and, accordingly, after the check valve. then everything will work fine.

Group: Forum Members Posts: 23 Join Date: 03/10/2009 From: Big Derevnya User #: 30291

Group: Forum members Posts: 449 Registration: 1.5.2006 User #: 2777

But why is a check valve needed at the pressure head, because the impeller of a centrifugal pump can rotate in the opposite direction? there is no bad question, why is it impossible to put a check valve on the suction?

Post has been edited Fireman

— 12.11.2009, 9:12

Group: Forum members Posts: 95 Registration: 3.6.2008 User #: 19353

What are you installing the pump for? increase the pressure in the subscriber's system, right? and a check valve for what you put it, for what? )))))) For any pump, the impeller can rotate in the opposite direction, but why? ))))) You can put it on the suction, but is it needed there? ))))))

Group: Forum members Posts: 449 Registration: 1.5.2006 User #: 2777

I'm talking about this and ask what is the difference at the suction or the pressure head?

and the hydraulic tank is on the pressure head.

Post has been edited Fireman

— 12.11.2009, 9:37

I'm talking about this and ask what is the difference at the suction or the pressure head?

and the hydraulic tank is on the pressure head.

instrumentation and control devices are installed on those sections of the lines, the parameters of which you need to know and, or adjust. and are tied to those actuators (pumps, valves, etc.) that perform the functions of regulating the parameters of the sections of the network you need. Can you adjust the parameters at the pump suction? do you need it?

Group: Forum members Posts: 449 Registration: 1.5.2006 User #: 2777

personally, it would not have occurred to me to put a return flow at the suction, but right now they asked and I do not know what to answer - what is the fundamental difference, because if the return flow is put at the suction, it will also prevent the reverse flow of water as well as at the pressure head, so why pressured?

Group: Forum members Posts: 449 Registration: 1.5.2006 User #: 2777

The pressure switch is set to turn on the pump at 32 m, turn off 40 m, in the network 23 m. They wanted to lay a pump with a built-in pressure sensor. They say that the pump pumped 40 m into the network and turned off, the check valve closed there is no draw-off, respectively, the network keeps 40 m and at the suction at this time 23 m, the pump will turn on again, and then 40 m in the network, so it will be on. and off. constantly. I said to take a pump without a sensor and put a relay after the return flow, they agreed, but the return flow still says take it away.

Post has been edited Fireman

— 12.11.2009, 10:52