Gas boilers Lemax are a serious competitor to European counterparts.

They are assembled from spare parts manufactured by recognized leaders in the production of heating equipment - Vaillant, Sit and other well-known manufacturers.

With excellent quality, the cost of Lemax boilers is two or more times lower than that of the "Europeans".

Basically, this is achieved by excluding all additional devices and assemblies from the design, leaving only the most necessary elements.

This has a positive effect on the performance of the units, reduces the frequency of breakdowns or failures, but some malfunctions do occur.

The main malfunctions of gas boilers Lemax

The most common malfunctions include:

- Leak of gas. Open windows immediately, shut off the gas supply, turn off the boiler and call the gas service workers.

- The color of the flame is reddish, the tongues are elongated and smoky. Poor draft or burner clogging. Clean the chimney and burner, correct the position of the pipe.

- Spontaneous shutdown of the main burner. Chimney or thermostat problems.

- There is no water circulation. If there is a pump, the reason lies in it. If natural circulation is used, it is necessary to correct the configuration of the pipelines, giving them the correct slope.

- Shutdown of the boiler. Usually occurs due to a gas supply cutoff.

The list of possible malfunctions can be continued for a long time, but there is no point in this, since each situation requires separate consideration.

Boilers "Lemax": varieties and rules of use

To choose the right boiler, it is necessary, first of all, to be guided by the parameters, as many experts believe. And they will be partially correct, since brand reputation is also important, it provides at least some guarantee against deception.

began her journey in 1992 on the shores of the Sea of Azov, more precisely in Taganrog.

Against the background of a sharp change in the political situation in a real economic catastrophe, the founders of the organization managed to concentrate a close-knit group of executors capable of fulfilling any, even the most sophisticated, order.

Advice

As a result of many years of efforts, it was possible to ensure a stable position in the market, and in one of the most advantageous positions.

The Lemax boiler of any model from the Premium line is made of premium steel, the thickness of which is 0.2 cm.

The metal must be covered with a Certa anti-corrosion layer that can withstand heating up to +750 degrees. Additionally, treatment is carried out with a reagent that inhibits the development of corrosion.

The heat exchanger is designed in such a way that the risk of exposure to mineral oils and salts dissolved in water is minimized.

The features of this line are also the following:

- placement of the thermal regulator on the front panel;

- the ability to add room thermostats;

- compatibility with the Lemax turbine head, which facilitates the removal of combustion gases;

- readiness for a smooth start.

Any boiler model in this line has an efficiency of at least 90%. The digital index of the model allows you to determine its nominal thermal power. The 10N modification will be able to operate at a nominal gas pressure of 1.3 kPa, and having consumed 0.6 cubic meters.

m of gas in 60 minutes, it will heat the water up to +90 degrees. The 12.5 N and 16 N versions can be equipped with an additional hot water circuit based on a copper heat exchanger.

It is important to know that Lemax does not only manufacture systems that run on natural gas.

An example of solid fuel floor heating boilers is the Forward product line. These are three devices designed for 12.5, 20 and 16 kW of rated power, respectively. They cope well with heating both residential buildings and office buildings. The equipment is compatible with both gravity and pumped heating systems.

Any Forward model is equipped with a small and shock-resistant heat exchanger, securely covered with thermal insulation. In production, special grade steel with a thickness of 0.4 cm is used, supplied by special order from Magnitogorsk.

The grates are made on the basis of the highest quality gray cast iron. The addition of horizontal heat dissipation parts increases efficiency, and top loading is very convenient for people.

The developers have taken care of the use of a round 14 cm smoke duct, which can be connected very easily.

The underfloor heating devices of the company also include such a device as Clever.

It has the following advantages:

- formation of the boiler gas infrastructure from selected Italian components;

- power variation (for a number of models) from 20 to 55 kW;

- suitability for supplying heat to an indirect heating tank;

- compatibility with weather sensors, with a wide range of external pumps;

- automation providing flame modulation.

The permissible pressure of the gas flow is from 6 to 25 mbar, the device can be converted to the consumption of liquefied gas. The recommended pressure for all models in the line is 0.2 MPa, while testing at the factory implies twice as stiff bar.

Any version is capable of heating water up to +90 degrees and discharging it through connecting pipes with a diameter of 2 inches. But the problem may be that there is not enough space for the boiler of all the listed series.

Then it is worth choosing a parapet "Patriot" equipped with a closed firebox and not depending on the power supply.

Such versions are also advantageous with the exception of the classic smoke passages. To remove gaseous combustion products and to pump fresh air, use an outlet directly to the street through a coaxial channel.

note

Sealing the combustion chamber in this case is absolutely necessary, since it reduces the need for ventilation and completely blocks the penetration of toxic gases into the interior.

But it is important to consider that the wall must be completely fireproof, and not just covered with protective material.

In some cases, all of the above types do not suit users because they are placed on the floor. The solution is the wall-mounted boiler Prime. This selection is made strictly from foreign components, but when tested in Western test centers, it is tested according to the same program as all boilers adapted for Russia.

They have such features as:

- the possibility of using coaxial chimneys up to 450 cm long;

- total soundproofing of equipment;

- flawlessly thought out management;

- access to functions through services on modern mobile devices;

- suitability for high hydraulic head;

- enhanced protection of electronics from adverse factors.

If we return to the mounted heating boilers, then the Leader model fully justifies its name. The efficiency is even slightly higher than that of all the listed options, it reaches 91%.

The working gas pressure is 4 bar and the heat exchanger is protected against excessive heating. The designers also thought thoroughly about preventing the accumulation of soot, stopping traction, and blowing out by winds.

Reconfiguration for the consumption of liquefied gas is allowed.

There is no doubt that Lemax boilers can show their best side. But a lot also depends on the consumers themselves, because they comply with the provisions of the instructions or not.

And the most important thing begins even before the moment when the need arises to light the installed boiler. It is required to choose strictly such equipment that corresponds to the capacity of the heated room.

As it is very dangerous to exceed the working pressure, it is imperative to install a relief valve and adjust it properly.

The following actions are not allowed:

- introduction of water into the system when the combustion chamber is running, as well as after stopping it - until the coolant is cooled to less than +50 degrees;

- the use of a boiler with a circulation of a coolant cooled to +50 degrees or less;

- use of heating devices with automatic components without earthing;

- installation of gas boilers, their commissioning, prevention and any technical manipulations by persons who do not have an official permit;

- the use of devices in conjunction with inappropriate smoke ducts;

- overlapping ventilation duct grilles.

It is possible to turn on any boiler from the "Premium" selection or another series only after it is connected to the chimney; it is also imperative to exclude its blocking and disruption of normal draft. You should also check that the entire heating system is filled with water, so that nowhere it is blocked by valves, air plugs.

In the event of a serious failure of the automation, the boiler should be turned off immediately, and all attempts to start it should be abandoned until the defects are eliminated by professionals.

If the coolant warms up to more than +95 degrees, the boiler is also turned off and the cause of overheating is eliminated independently or with the help of involved specialists.

In advance, at the stage of selection and installation of equipment, it is required to prepare high-quality natural ventilation. It is recommended to install a steel sheet not only in front of the firebox, but also under the boiler itself, as well as around it around the perimeter.

If there was already some kind of boiler or stove before, then during installation without replacing pipes and radiators, they should be rinsed. Violation of this requirement means that all claims for the throughput of pipes, for heating the coolant and the room, for water circulation will not be accepted.

Important

When starting the gas boiler into operation, first turn the knob and only after that they begin to adjust and start. The time to initiate gas ignition is from 10 to 60 seconds, depending on a number of unpredictable parameters in a particular case.

After the end of the annual heating stage, water must not be drained from the boiler itself and from the heating mains - this threatens with rapid and powerful corrosion.

No matter how hard the engineers try to prevent possible problems, no matter how attentive the owners themselves are, sooner or later everyone will encounter failures. If Lemax Premium, for example, goes out (the main burner stops without permission), the following reasons can be assumed:

- weak vacuum in the smoke passage;

- overflow of the gas outlet;

- incorrect thermostat setting.

First, the channel through which the smoke is removed is inspected. If any contamination or blockage is found, remove it immediately. If this does not help or nothing interfering is found, adjust the regulator.

For your information: cleaning chimneys and burners can help with excessive elongation of flames that acquire an orange or even red tone.

If there is no water movement in the system, it must be topped up. When such a measure does not help, the entire heating circuit will have to be redone. In case of a sudden shutdown of the boiler due to a temporary interruption in the gas supply, the inlet valve must be closed.

Then very unpleasant consequences will be excluded. If the boiler fails to ignite, the problem may be with the igniter or thermocouple. It is required to clean the contacts and replace the thermocouple.

And also sometimes you need to work on the traction sensor, connecting it not "for crimping", but according to a more practical scheme.

Consumers for the most part rate Lemax boilers highly. They recommend taking devices with one circuit for non-volatile versions in summer cottages and in other similar places.

The second noticeably increases the payment for the equipment, while it is not always needed in practice. When selecting power, it is better to provide some margin than to focus on the exact value.

In houses with significant heat losses, it is necessary to increase the power by 25% compared to that calculated by the area.

An overview of the Lemax gas boiler is in the next video.

Why does the device go out?

There can be several reasons for burner fading.:

- Gas cut off. Switch off the boiler, wait for the supply to resume.

- Unstable or absent voltage in the power supply network (for volatile boilers Lemax).

- Failure or actuation of the draft sensor. It is necessary to check if it is there, if the chimney is not clogged. Sometimes cleaning the sensor contacts helps.

- The thermocouple contacts are oxidized and do not close. Should be cleaned with fine-grained emery paper.

- Reverse, insufficient or excessive thrust. The draft sensor reacts to all situations by switching off the burner.

Traction problems are most common in non-volatile installations, where the stability of the unit depends on it.

If the draft is too weak, the sensor turns off the burner due to the possibility of smoke in the room.

Excessive draft is dangerous due to the possibility of flame blowout on the burner, which will provoke gas supply into the room with unpredictable consequences. Therefore, an increase in draft against the set value is also an emergency case, leading to a stoppage of the boiler.

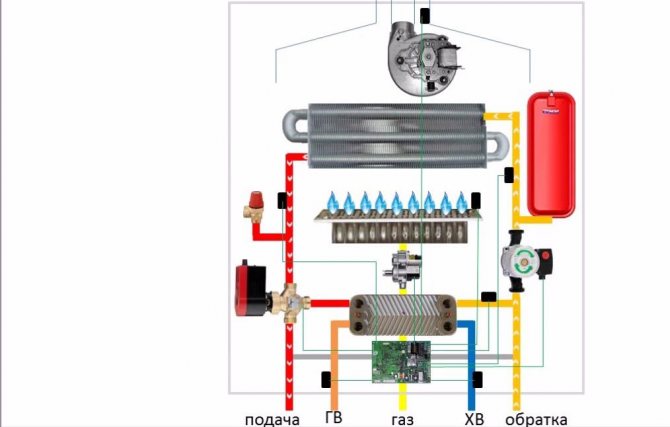

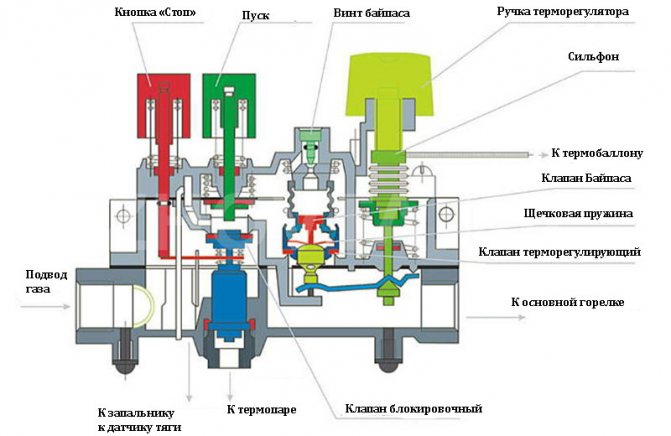

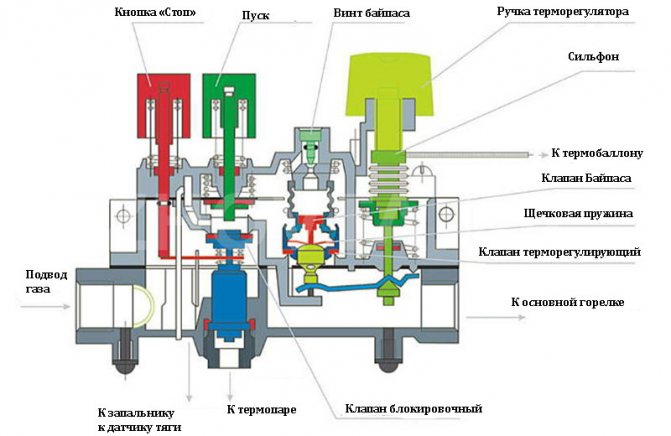

What is the principle of operation of automation

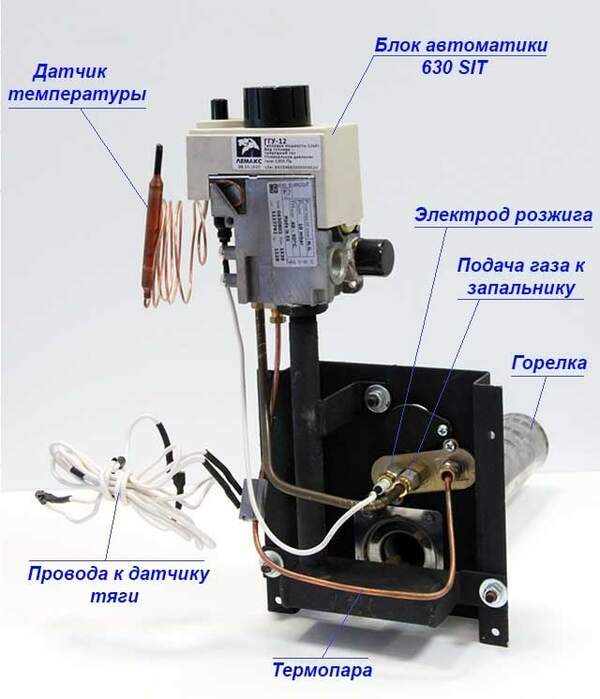

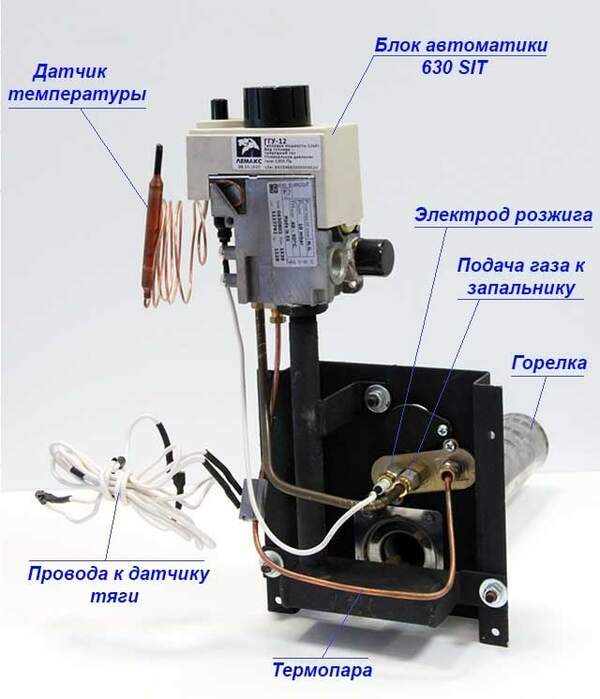

If we take into consideration the principle on which the safety system of the device works, then an unambiguous conclusion will be drawn from this - the main points of the entire structure device are:

- safety valve;

- main valve.

They are responsible for stopping the gas supply to the working chamber. They also open up access to fuel. All automatic equipment for gas boilers is built on this principle.

The difference is observed only in the fact that there are functions that go as additional devices in the operation, which are equipped with automatic adjustment.

That is, the device itself works due to the fact that both valves interact.

Basically, all systems operate according to the following scheme:

- The regulator is set to the position required for the temperature to begin to heat the room.

- A signal is sent to the sensor that the system is working.

- The shutoff and simulator valves begin to regulate the amount of fuel flow. As a result, the intensity with which the boiler is heated is set.

In order to understand how all these internal processes occur, it is necessary to consider the very design of the automation device for gas boilers.

It is better to dwell on this point in detail, because then the question of which boiler to choose for home gas heating will be more understandable. And it will also be possible to purchase the most efficient model with a high safety threshold.

How to turn on (light up)

The Lemax boiler is started up after filling the system with the required volume of water (12-14 liters for each kW of power) and connecting the gas pipeline.

Procedure:

- Open the lid, providing yourself with access to the regulator and the piezo ignition button.

- Turn the regulator counterclockwise, which will move the boiler to the “on” position.

- Sink the regulator all the way down and hold it in this position while pressing the piezo ignition button.

- After the flame appears on the pilot burner, the button can be released, but the regulator must be held for another minute.

IMPORTANT!

If the attempt to ignite the boiler was unsuccessful, it can be repeated only after 1 minute, not earlier.

How to turn on the Lemax boiler - operating rules

Content:

When choosing a suitable model of a gas boiler, it is recommended to pay attention to the quality, technical capabilities and cost of the device. Lemax boilers are especially popular with buyers, which have proven themselves well when used in private houses.

How the Lemax boiler works and how it works

The location of the enterprises of the Lemax company is the Russian city of Taganrog.

The supply of the main components for the boiler equipment assembled at our own facilities is carried out by both Western and domestic partners.

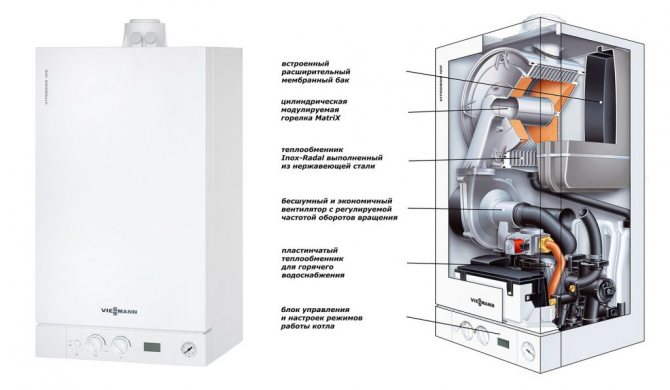

The manufacture of the heat exchanger and the housing is mainly carried out by Russian enterprises, but the control units, automation and burners come from abroad.

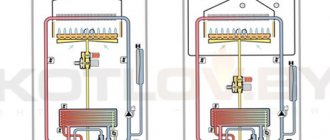

Boilers of this type can be equipped with both open and closed combustion chambers. There are always pressure and temperature regulators on the casing of the units.

note

As a rule, you can turn on the Lemax boiler not only from the network: some models do not depend on electrical energy at all. As stated by the safety precautions, the Lemax device must always be connected to the chimney.

Only rooms with good ventilation are suitable for installing the equipment.

The characteristic features of the Taganrog devices are the simplicity of the procedure, how to light the Lemax boiler.

Regardless of how many circuits this equipment serves, and what kind of material was used for its manufacture, switching it to the mains usually does not cause any particular difficulties.

A prerequisite is the use of a voltage stabilizer in the circuit, how to turn on the Lemax gas boiler (any jump can provoke a breakdown of the device).

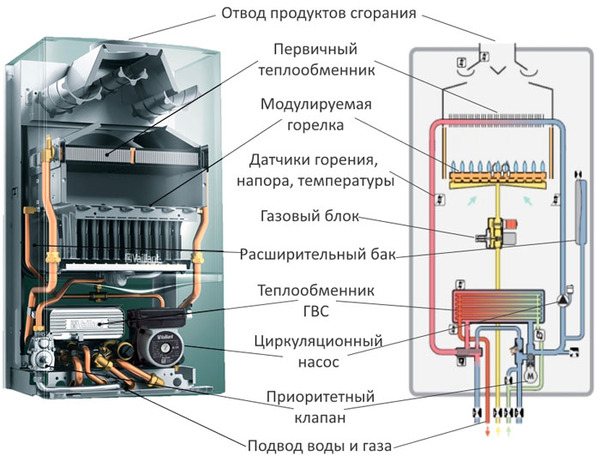

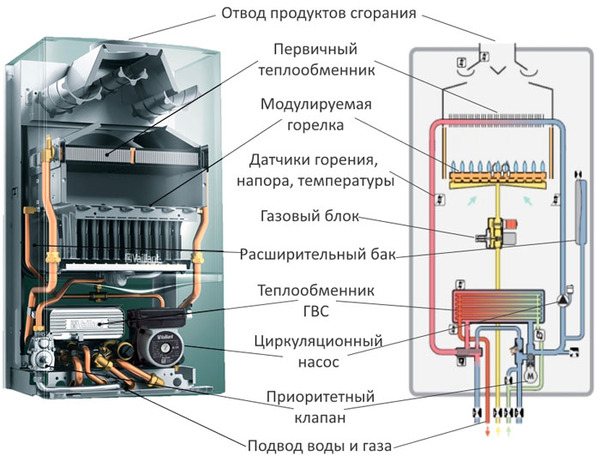

Lemax boiler consists of the following components:

- Gas burner.

- Valve.

- Control boards.

- Expansion tank.

- Circulation pump.

Advantages and disadvantages

Every year, Lemax specialists develop and release new types of gas boilers and other heating devices.

At the same time, there is a consistent increase in their quality and improvement in technical characteristics. For the assembly of boiler equipment, the best components of German, Austrian and Italian production are used.

This is the reason for a noticeable increase in the quality of these products.

Like any other appliances, Lemax gas boilers have strengths and weaknesses. They are characterized by energy independence, wear resistance, overheating protection, good power and high efficiency. The products are guaranteed for 3 years. Heating devices of this manufacturer are presented in several models, differing in their technical characteristics.

The list of positive characteristics of the Lemax boiler:

- Energy independence.

- Durability.

- Reliability.

- Easy to operate.

- Affordable price.

- Convenience of the procedure, how to start the Lemax boiler.

Gas boilers of this company are wall-mounted and floor-standing. Only one series of this equipment is included in the wall models. The range of floor models is more extensive - there are six of them. Each of the varieties is characterized by good durability, reliability, simplicity of the device and low cost.

Operating recommendations - how to turn on the gas boiler correctly

Before igniting the Lemax boiler, you need to make sure that there is water inside it and other elements of the heating system. Next, the traction level is checked and the most optimal action algorithm is selected.

Its formation is influenced by the power of the equipment and the presence of automatic units. The Lemax boiler belongs to the category of non-volatile, therefore, the task of how to ignite a Lemax gas boiler is solved using a conventional piezo ignition.

In some models, there is a special draft sensor, which ensures the safety of the device.

To connect such a boiler to a heating system, special skills are not required. In addition, during operation, special care is not required, and small malfunctions can be eliminated by hand. In order to avoid surprises during start-up, it is imperative to check all your actions with the manual on how to ignite the Lemax gas boiler.

The list of actions how to turn on the Lemax boiler with automation:

- The gas cock was opened.

- Set the control knob to the ignition position.

- Press the knob all the way for 10 - 60 seconds until the burner lights up.

- The temperature regime is adjusted.

- Floor standing models with steel or cast iron heat exchanger.

- Wall mounted solid fuel.

What are the models

The main types of gas boilers Lemax are:

Solid fuel type of equipment is presented in two models:

- Wood stoves.

- Coal boilers.

Wall-mounted boilers are produced only in double-circuit: they are capable of operating at pressures up to 3 bar. In all cases, Italian automation and circulation pumps are used.

The set of wall-mounted models includes an expansion tank with a volume of 6 liters. This equipment is guaranteed for 2 years. Floor-standing modifications equipped with steel heat exchangers are also in high demand.

High-strength metal with a thickness of 2 mm is used for their manufacture.

There are 5 models of steel boilers with different capacities:

The most advanced model to date is considered the Premium nova model. Thanks to automatic settings, the device can independently start the Lemax gas boiler and set the optimal operating parameters in the system.

For devices of the Patriot series, the presence of a closed combustion chamber is characteristic. They are produced exclusively in single-circuit, without the need for electrical power and a chimney. The presence of a cast-iron heat exchanger with a thickness of 4 mm for Leader and Wise units extends the service life by about 2 years.

They are not afraid of various pollution and corrosion.

Conclusion

Considering options for a heating boiler for your home, it is recommended to pay special attention to the equipment of the Lemax company.

The products of this domestic manufacturer are presented in a fairly wide range of various modifications that can satisfy any customer's needs. The existing models are characterized by good power and high performance.

Many of them are equipped with automation that ensures the safety of the procedure on how to connect the Lemax boiler.

Does not start (lights up)

The unit is fired up according to a certain scheme. It does not always start the first time, and this is quite normal. But, if after repeated attempts the boiler does not ignite, it is necessary to check the condition of the nodes responsible for ignition.

Possible reasons could be:

- Failure of the electronic or mechanical ignition system. It is necessary to replace the system, or clean the thermocouple contacts.

- The voltage in the power supply network has disappeared (for volatile units).

- The valve on the gas supply pipe is closed.

- The gas pressure in the system does not correspond to the nominal values.

- Main burner nozzles clogged. It is necessary to clean them and start the boiler.

All of these reasons are the most common, but far from the only possible ones. Any malfunction in the system can adversely affect the ignition of the boiler..

NOTE!

If you have tried all the options, but the problem is not resolved, you need to call the wizard from the service organization.

Why is the pressure growing

Pressure build-up is a serious and dangerous situation. An increase in pressure in the system can only mean an increase in the amount of water.

This is due to the expansion of the coolant during heating.Any liquid is incompressible, so an increase in its volume can lead to rupture of the heat exchanger, or, in the most serious case, provoke an explosion.

To exclude such a possibility, an expansion tank is used in the design of boilers. It takes in excess water, compensating for its increase when heated.

An increase in pressure most often indicates a malfunction in the condition of the expansion tank. Its design consists of a container and an elastic membrane installed approximately in the middle.

When liquid begins to arrive, the membrane flexes and makes room for excess water..

When the volume decreases, it returns to its previous position. If the membrane is torn or not firmly attached to the expansion tank stacks, the coolant will fill the entire volume of the tank.

When expanding, the water will have nowhere to go, which will provoke a constant increase in pressure. The solution to the problem is to restore the condition of the membrane or replace the expansion tank with another, serviceable copy.

What causes the pressure to drop

A drop in pressure (the boiler goes out) indicates leaks. It is necessary to check the condition of pipelines, threaded connections, gaskets and other external elements of the heating system... If there is no visible damage, you should look for faults in the boiler.

The main problematic element can be the heat exchanger. Welded joints sometimes crack or break due to frequent temperature changes. Cast iron sectional heat exchangers used on heavy-duty floor-standing models are risk factors at section connections.

In addition, the pressure relief valve may be triggered or stuck open..

Threaded connections of branch pipes can also lose tightness due to drying out or destruction of gaskets, connection not by thread, etc. All detected problems are eliminated in accordance with their specifics.

Possible malfunctions in the operation of the boiler and how to eliminate them

Common faults and solutions:

- Spontaneous burner shutdown. The reason for this malfunction may lie in a clogged chimney or an incorrectly configured thermostat. The solution is to check and clean the chimney or adjust the temperature sensor.

- Gas leakage at the joints. The most common cause of a malfunction is worn gaskets or loose threaded connections. In no case should you try to fix the problem yourself. It is necessary to close the gas valve, call the specialists of the gas company for extraordinary maintenance.

- The flame on the burner has an elongated shape and is colored in an unusual red-orange color. This happens in two cases: with insufficient draft and clogged burners. To eliminate the problem, it is necessary to clean the chimney, thereby increasing the draft, or burners.

- The boiler is working, but the pipes are not heating. Hot water in the boiler is cold or barely warm, in pipes this happens when there is a shortage of it in the heating system or in the absence of slopes at its pipes. To solve the problem, it is necessary to add water to the system or install it in accordance with the requirements of the manual for the use of the unit.

- The unit has shut down spontaneously. This only happens if the gas supply is turned off. It is necessary to close the gas valve before resuming its supply. Under no circumstances should you try to re-ignite the burner.

- The device does not work. When you try to ignite it, nothing happens. The cause of the malfunction may be oxidation of the contacts or burnout of the thermocouple. The solution lies in cleaning the contacts or completely replacing it.

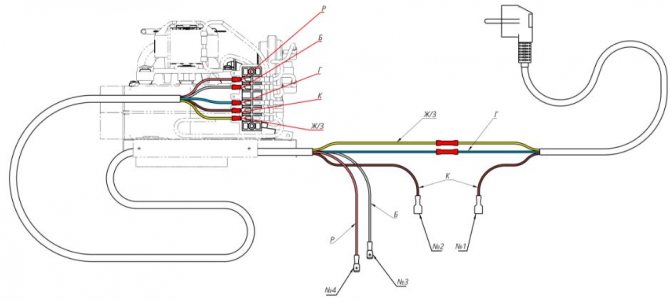

Room thermostat connection

A room thermostat is a convenient and useful device that allows you to regulate the temperature of the air, not the coolant in the heating system. The default sensor monitors the outlet temperature of the extract air.

This does not give a correct picture of the state of the indoor microclimate. For example, when the outside temperature rises, the room gets hot.

But the sensor cannot track this, and the extract air temperature is within the limits set by the mode, therefore, from the point of view of the system, everything is going well, in accordance with the boiler settings.

If a room thermostat is used, the burner will shut off much earlier, which will improve the room climate and significantly reduce gas consumption.

To connect a room thermostat, set the boiler's own element to the maximum temperature.

It will only work as a limiter when overheating.... The external unit is connected at one end to the automation unit, and at the other end to the boiler thermostat. By default, a jumper is installed between the contacts, which must be removed and the thermostat connected.

IMPORTANT!

Appropriate grades must be used, eg CEWAL RQ10. Installation of a thermostat is only possible on boilers marked with N (with SIT 820 NOVA control unit).

Heating boilers Lemax

___________________________________________________________________________________________

- Repair of boilers Danko

- Malfunctions and repair of boilers Aton

- Boiler adjustments Zhytomyr Atem

- Operation of boilers Mimax

- Recommendations for the repair of boilers Conord

Tell me if it is possible to install a Lemax Premium 10 heating boiler in an unheated room size 2.5 × 2.5. How this will affect gas consumption. You can install, the gas consumption will naturally increase. I do not recommend installing a model with the Italian automatic 710 minisit, since there the adjustment to the main burner is made by a rubber membrane, which can stick to the body in the cold. We want to buy a floor-standing gas boiler Lemax Leader 50. I am interested in its work on warm water floors. Underfloor heating area 200 sq. m. House 500 sq.m. We then think to transfer the batteries of the whole house to it. It is necessary to know the maximum volume of coolant in warm floors in order to understand whether this unit will warm them up. The maximum volume of the coolant for Leader-50 is 750 liters. The Lemax Premium 12.5 model was installed for me. The organization has permits, everything is fine. I was surprised by one moment: when adjusting the automatics, they used a hose with water, such as a hydraulic level. I am satisfied with the operation of the device, there are no pops when the burner ignites, but I am worried about the accuracy of the setting. I read that you need to use a pressure gauge. Maybe I should contact another organization to reconfigure? If no pops are observed when switching on / off, it means that the ratio of gas pressure on the main and pilot burners is within acceptable limits. No additional adjustment is required. How will the Lemax Patriot 16 gas parapet boiler behave if it is connected to a circuit without a tilt, but with a pump, in case of a power outage. Will the automatics work in this case, since overheating is possible? If the thermostat is working properly, the unit will turn off the main burner when the set temperature is reached. When it cools down, the thermostat supplies gas to the main burner and the device turns on. I want to buy Lemax Premium 30 NB. Please tell me if it is possible to install the turbo nozzle at a distance of one meter from the boiler. After the turbo nozzle, I plan to bring a horizontal pipe through a 1 meter long wall with a slight slope (3 degrees from top to bottom). Will it be right? Yes, you can, that's right. A distance of up to 1.5 meters is allowed. The angle of inclination towards the street must be at least 5 degrees. The fifth year of operation of the floor-standing boiler Lemax Leader 25. Last winter, I noticed that if to reach a temperature of 80 gr. used to be set at 5 on the thermostat, but this year we have to raise it still. Is it possible to flush the system with a 10% hydrochloric acid solution, I think, maybe because of scale. After starting, after 15 minutes, the boiler goes out. If you open the door, then it works. You need to clean the heat exchanger and the gas burner, because turning off the device when the door is closed indicates an insufficient amount of oxygen supplied for the operation of the main burner.Only specialized substances must be used to flush the heating system. Floor-standing gas boiler Lemax Premium series KSG-30. Interested in the pros and cons of this model for a house of 280 sq.m. This manufacturer has long established itself in the market, customer reviews are only positive. The only thing that I recommend in terms of power is the Premium KSG - 35 model, tk. 20% is usually reserved for less wear and tear and in case of extreme cold. I have a Lemax Patriot 10 kW parapet boiler. When the temperature on the street rises, the pressure goes off scale, I'm afraid it will squeeze out somewhere, and when it drops, it drops to zero. How do I adjust the pressure? You can adjust the expansion tank. How to heat a house with a Lemax Forward 16 solid fuel boiler in cold weather and why does it need to be heated all day? By using the correct settings, you can increase the burning time in the following ways: Try to reduce the air supply to the firebox (bottom front). Using a gate (chimney damper). The more air enters, the faster the fuel combustion occurs. Another important role is played by the type of fuel itself, for example, coal is enough for 8 hours, which is considered high-calorie, and firewood burns faster, pressed paper even faster. Is it possible to connect a turbo nozzle to Lemax Premium 16 instead of a natural chimney? The turbo nozzle can only be connected to models with automatic 820 NOVA SIT (units with the suffix N in the name). Help me figure out why the Lemax wise 35 boiler has a gas consumption almost two times less than that of similar proterm bear klom 35 and baxi slim? Consumption indicated is average. The models you are comparing have the maximum indicated. The maximum gas consumption for the Wise series is 40 kW. is 4.5 m3. Installed steel floor boiler Lemax Premium 12.5. Do I need to install a safety valve when connecting? The expansion tank is open and there is a circulating pump. If the heating system is closed, then yes, you need to install a safety valve. Gas wall-mounted boiler model Lemax Prime V24. After 10-15 minutes of work, there is a strong drop in temperature for heating the water supply system. For example, there is a temperature of 43 degrees, the unit honestly produces it for a while, and then the water temperature drops to about 25-30 degrees, after a minute it rises again to 43. But after another minute, again 25-30. Moreover, the device does not seem to notice this on the display exposed 43 are lit. And in fact, a bathroom with 30 degrees of water. You need to check the functionality of the DHW flow sensor (the so-called flowmeter). He is responsible for giving the command to open the gas valve according to the amount of water passed through. Most likely, the sensor is out of order and the board does not understand how much gas needs to be supplied to the burner. The installation and installation of a Lemax gas boiler with SIT 820 NOVA mv automation and the ability to connect an external room thermostat was recently carried out. Only the boiler itself and the coolant were replaced, the rest of the system remained unchanged. The chimney has temporarily remained the same from the old boiler, but installed with an adapter 130 to 120mm. When heated and cooled, the device begins to click and creak. The sound is loud and comparable in level to the built-in thermostat when turned on and off. Clicking starts after 15-20 seconds. after turning on the burner. It is usually repeated with a frequency of about once every 5-10 seconds, depending on the temperature in the system and continues until the burner is turned off. Then the opposite process takes place, but with much less intensity. In some periods, there are no clicks at all, or it can accidentally click only 2-3 times, while only the operation of the burner is audible. It is very difficult to understand the source of the noise, but I still assume that the noise comes from the heat exchanger. What I tried to do. Increased the circulation rate of the coolant by switching the speeds on the pump. He turned off the pump completely.By the way, this situation also often happens on an old boiler, if the power supply was turned off for up to 6-8 hours. At the same time, the room of course cooled down, the boiler continued to heat up, but it turned on very rarely. Increase and decrease the gas pressure on the burner using the gas inlet valve. He turned off the burner completely and allowed it to cool. I checked the air in the system. It completely blocked all heating radiators, while naturally the device turned on very rarely. I removed the chimney, while after a minute the draft sensor was triggered, and the gas was completely turned off. Clicks occur during heating and shutdown, at the points of contact (connection) of metal parts, one part heats up more than the other, mutual displacement occurs, the parts are tightened with bolts and there is no smooth movement, from here and clicks. This situation can arise when using extremely concentrated antifreeze (the manufacturer does not recommend the use of antifreeze containing liquids). With regard to ethylene glycol containing antifreeze, any leakage from the heating system can be detrimental to health. Such problems are addressed by consumers who did not flush the heating system when replacing the unit with a new one. Why did I ask for the circuit, there are situations when it is not properly fixed (models with a circuit o in the description, i.e. Premium-16 V), when the temperature of the coolant rises, the circuit (copper coil) starts to emit sounds, these devices are the manufacturer changes to new ones. In operation Lemax Patriot 12.5 (parapet, gas). I put it at 70 degrees, and it goes out at 60, then it burns - only ignition. The pipes are cooled, falls below 40 and that's it. You regulate to 90 degrees, then rises to 60 again and turns off, what to do? Look at the system - there is no circulation or it is airy, maybe the tap is closed somewhere. The temperature sensor may not work. I want to buy a gas floor boiler Premium KSG-16 or Premium Nova. There was a question about the burners. They use three burners - Eurosit 630, Minisit 710, Sit 820 Nova. The first two support smooth throttle control, and the Nova sit 820 works only in the on / off mode. It seems that everyone is trying to avoid cycling when setting up the boiler, then why does the newest burner work in this mode? What's the point? It is clear, however, that it is better to keep the temperature a little with low fire than to wear out the burner and heat exchanger with ragged fires. Who can advise on this issue and the choice of the unit? First, not burners, but automatics. Secondly, modulating automation does not provide for the connection of a room thermostat. A floor-standing boiler Lemax KSG-20 is installed and connected - square (old model). Automation Eurosit 630. There are 2 problems. When Eurosit 630 extinguishes the main burner (it is hot and overheats even at 40 degrees), the pilot burns, but somewhat unusual - there is a periodic noise phenomenon. Here, as it were, the main tongue of the pilot burner flame - by 1 -2 millimeters at the base, detaches from the burner itself for 0.5-1 seconds, then everything falls into place. Is it possible to supply nozzles from smaller boilers of the same series. Will there be anything wrong with the burners or will you try to lower the boiler with a gas valve? The igniter can go out for various reasons. Better a specialist will figure it out on the spot. Traction elongation problem, perhaps if there are to be traction choppers. The pilot pressure is adjustable. Your nozzles are 2.6, replacing them with 2.5 will reduce to 19 kW. It is also necessary to adjust the main and low flame so that the unit does not go into low flame earlier than it should, and warms up the heating. The Lemax Leader 16 gas boiler is in operation. I put a power of 1 or 2 on the regulator, and the boiler works normally for 4-5 hours. But then the house warms up to +25, and it first switches to a low flame, then to a large one, then again to a low flame, and the main burner turns off.On the settings of the boiler operation - I would not like to increase the small flame, but to reduce it and thereby achieve constant operation of the device. That is, they warmed up to the required temperature, switched to a low flame, but it must be adjusted so that it maintains combustion and a smooth decrease in temperature until the moment when the main burner turns on again at full power. Is it possible to regulate low and high flame only on a cold unit with the burner off? By low and main flame of the burner. Is it possible to slightly reduce the power by reducing the gas flow rate on a large flame with the main burner adjustment screw without changing the nozzles (how to understand the range as far as possible). How to properly adjust to the required gas flow rate? Try to see if the thermocouple will move further or try positioning the thermocouple without the nut until it stops. See, if possible, how it is washed by the flame of the igniter. All thermocouple contacts must be secured. It is impossible to clamp the thermocouple tightly in the socket, the tin on (+) may begin to come into contact with the mass. It is necessary to regulate the flame on the working boiler, in general, only to specialists. From the position of the full recession of the adjustment screw to its maximum unscrewing, it is impossible to make more than 4 turns. The Eurosit 630 automatics also have a gas regulator at the inlet, but I have never been able to reduce or increase the gas pressure with it. Perhaps it only decreases from very high pressure to less. For all that, of course, the igniter tube and nozzle must be clean. We installed a floor-standing gas boiler KSG Lemax 10 kW. After ignition, it switches off automatically after a few minutes. Tell me, what is the reason, and can it be eliminated? The reasons for the described problem may be as follows: when the main burner is turned on, the igniter is knocked down, the gas pressure on the igniter is not set, poor draft or insufficient supply ventilation. First of all, check the thrust in the system. In the overwhelming majority of cases, it is the problems with the chimney that cause the unit to shut down. This model has a high efficiency, so the temperature of the flue gases is quite low (up to 120C). Because of this, draft may disappear in non-insulated chimneys. In this case, the sensor is triggered and the gas supply is interrupted. This automation ensures the safe operation of the equipment. In addition, we recommend checking the gas pressure settings on the igniter and the ventilation valves in the room (the grilles must be open). The parapet boiler Patriot 10 kW constantly goes out. We cleaned the pipe, the draft is good. After that, problems began, it was constantly going out, it was very inconvenient to kindle it. They called the gasman several times, he said that it was not a pipe. I think it can replace? Maybe it's a thermocouple. The Lemax Wise 16 boiler is in operation. When the lights are turned off, the unit heats up and the batteries cool down. They are heated only when the external pump is turned on. Us, have it been connected incorrectly? Non-volatile was specially chosen. The unit is non-volatile, but when the light is turned off, the idle pump becomes a barrier with natural circulation, you need to make a bypass loop. Wall-mounted boiler Lemax Prime V24. Heats up the batteries well. The second circuit does not heat well. Impossible to wash. You just have time to wash your hair. Then comes cold water. It is impossible to get a bath. Even half. What is the reason? How to fix it? The point is in the clogged hot water supply circuit. You need to flush the circuit using a flush station and a solution that will not harm the copper tubing. As a rule, service centers are engaged in this flushing. Gas boiler Lemax KSG-10 with UGG-9 (Danko-26). Worked perfectly for 6 years. The house was stuffy and hot even in -35 frost. But this winter, apparently the resource of some spare part has ended. It smelled of gas, the burner went out and the wick itself too. When trying to turn it on, a flame flared up from under the burner in solid blue fire.Tell me, please, what could have broken down? Most likely, the liquor spring has failed - the resource has ended. Separately, this part cannot be replaced, because they are no longer produced. You can purchase and replace the entire gas valve assembly. Boiler Lemax Premium 20 kW, installed yesterday, tried to start today. The nozzles are turned on, after a minute or two, the nozzles and the wick are turned off. Someone tell me what is the reason? The problem with starting the boiler described by you may be associated with the following reasons: when the main burner is turned on, the igniter is knocked out, the gas pressure on the igniter is not set, insufficient supply ventilation or poor draft. With a weak draft, a sensor is triggered and gas does not flow to the main burners. Check the ignition gas pressure settings and system draft. Please note that due to the relatively low temperature of the flue gases (110–120 C), in models with high efficiency in chimneys without insulation, the draft may disappear. We installed a Lemax Leader-35 boiler (cast iron), began to click, you can hear it throughout the heating system. What to do with him? Problems not with the boiler, most likely they did not clean the old heating system. The comfort automation stopped working, the flame does not fall on the wick, what could be? Who knows? Installed about 6 years ago, everything worked. Flat burners 3 pieces. Model KSG-16. The whole problem is in the traction sensor, or rather in the connectors. Take it off or move it and it will earn. The boiler KSG-12.5 is in operation. The intensity of combustion, and therefore the quality of heating, directly depends on the ambient temperature. Yes, yes, not on the temperature of the coolant (water), but on the weather outside. That is, if it is warm outside, but at this time it is still cold at home, the unit stops working. Even with increasing gas flow, the main burner does not burn, only the wick burns. But when it's cold outside, the battery gets hotter than ever, even with reduced gas consumption. Who can explain what is the cause and how to eliminate it? Most likely, there are surges in gas pressure in the pipeline, and because of this, the device is unstable. In order to confirm this assumption, it is necessary to measure the pressure under various conditions. In such a situation, the solution to the problem can be a gas pump and a stabilizer. However, we cannot say that the reasons for the interruptions in the operation of the unit are related precisely to pressure surges in the system. Model of a gas boiler Premium KSG-16. Why does it often go out even with a weak wind? Your problem has nothing to do with the design or performance of the machine. Attenuation may be due to the following reasons: when the main burner is turned on, the igniter is knocked off, the gas pressure on the igniter is not set, poor draft or insufficient supply ventilation. In the absence of draft, the sensor is triggered, the gas supply stops and the boiler goes out. In addition, attenuation occurs in light winds. Most likely the chimney is below 5 meters. Please check that its design meets the requirements stated in the passport. This is essential for the stable and safe operation of the equipment. We also recommend checking the gas pressure settings at the igniter and the draft in the system. Please note that due to the relatively low temperature of flue gases (110–120 C), draft may disappear in non-insulated chimneys. In many cases, this is precisely why problems with gas equipment of this type are associated. Also check if there are any problems with the supply ventilation. Open the grilles of the ventilation ducts if they are closed. It became cold at home, I wanted to turn on the boiler, but it does not burn. You hold the wick for a certain time (according to the instructions) - it goes out. The main burners are not supplied with gas. What to do? Such a malfunction may be associated with the following reasons: the gas pressure at the igniter is not set, when the main burner is turned on, the igniter is knocked off, insufficient supply ventilation or poor draft.In the latter case, the draft sensor is triggered and gas does not flow to the main burners. Check the ignition gas pressure settings and system draft. Steel heating boiler Premium 25 c GGU-30 floor standing with turbo extension. The first season is in operation, that is, 3 months. The main burner began to go out while the extension continues to work, after which the temperature drops accordingly. You cannot leave him unattended. I start it up again, it doesn't light up. As far as I know, in these turbo nozzles, the email changed. scheme of work, that is, initially the pressure switch of the turbo nozzle worked in a low voltage circuit with mil. generator, after one or another period of time this voltage was not enough and the plant changed the circuit by installing an additional relay, which made it possible to transfer the pressure switch to a high voltage circuit, and a relay worked in the circuit with the generator, ensuring the stability of turning on and off the main burner. Check your availability for this relay. Tell me, which arrow in the thermomanometer shows the pressure? I have a Leader 25 series boiler with a cast iron heat exchanger. Red bottom arrow or black? If black, then I have it almost at zero. How to raise the pressure? And what if it falls? Is it too bad? The red arrow on the thermomanometer shows the temperature, the black arrow shows the pressure. Most likely a leak in the system. A drop in pressure will result in no water circulation. In your case, you need to find and repair the leak. We installed a floor-standing gas boiler Lemax KSG-12.5 Premium. After turning off the main burner, a click occurs after a couple of minutes, what is the reason, tell me? There are holes inside, there are flaps in them. If they sit tightly, this is where the metal clicks occur. Also look at the level of the unit. Technical characteristics The modern series of economical gas boilers have a total output of 16 to 50 kW. The line of these products is presented in 5 different capacities, produced in one- and two-circuit design. All units are produced by joint production, irrelevant parts, the brand and the body are made in Taganrog, and most of the components are made in Italy and the Czech Republic, for example, automation from SIT, and the heat exchanger from Viadrus. High-quality cast iron СЧ - thickness 4 mm with a possible pressure during burner operation of 4 bar. The heat exchanger is covered with thermal insulation. An inhibiting composition is used as an anti-corrosion coating, which slows down the destruction process. All models are equipped with a system of protection against soot formation, interruption of traction, flame combustion and overheating. Heating devices are divided into two groups with a cast iron and steel heat exchanger. If you choose the right model, you can significantly save on heating the whole house. There are several types of heating equipment according to the following characteristics. Number of circuits - Single-circuit steel models operate practically without failures, non-volatile, provides maximum performance. Has a low consumption of natural gas, a good option for heating a home heating system. A double-circuit floor-standing household gas boiler operates in two modes - heating the coolant and water for hot water supply, and has high efficiency. They are the best and most economical option for large private houses. Heat exchanger device - There are two modifications - they are distinguished by the material used in the production process. Models with a cast iron heat exchanger perform better than other models from the entire range. Cast iron reacts well to an aggressive environment, is resistant to overheating, and has anti-corrosion properties. Models with steel heat exchangers are sensitive to the quality of the heating medium. The steel heat exchanger is 2 mm thick and requires a water treatment system.Ignition of the Lemax Premium boiler with SIT 820 NOVA automation The control knob is set to the required position by lightly pressing and turning to the desired position. In the initial (off) position, the control handle is in the "point" position. Pilot and main burners are off (gas supply to them is blocked). To ignite the pilot burner, the control knob is moved to the “spark” position. In this position, the control knob is held down until it stops, while the piezo igniter button is pressed (several times if necessary) until the pilot burner lights up (see the viewing window). After the pilot burner lights up, the knob is held down for at least 30 seconds, after which the knob is released and moved to the “torch” position. By moving the control knob to the “torch” position, the gas supply to the main burner is unlocked. The device is turned off by turning the knob to the “point” position. In this case, the pilot and main burners (if lit) will go out. If the control knob, after moving to the "dot" position, is immediately set to the "spark" position, the burner will not light up until the so-called internal automatic lock is unlocked. The blocking is removed automatically after the thermocouple has cooled down (after about 60 seconds) after the knob is moved to the “point” position. The temperature of the coolant is controlled by the temperature regulator knob on the unit body. Installation, installation and maintenance of Lemax Leader boilers The volume of the room in which the boiler is installed must be at least 8 m3, the height is at least 2 m.The distance between the lining of the unit and the walls must be convenient for installation, repair and operation, but at least 10 cm There must be a passage in front of it, at least 1 m wide. There must be natural ventilation in the room where the unit is installed. When installing the Lemax Leader gas boiler on a wooden floor, the floor is insulated with a non-combustible material. The insulation should protrude 10 cm beyond the dimensions of the device. The connections between the boiler and the heating system and the gas main should be threaded, allowing the unit to be disconnected if necessary. If it is installed instead of the old one, then it is imperative to flush the pipelines and radiators of the heating system from rust, scale and sediment deposits. If these requirements are not met, the products of deposits (rust, sediment) are transferred to the unit, which significantly complicates the circulation of the coolant and reduces its heat transfer. With increased heat consumption of the room (the thickness of the outer walls of the house, the integrity of windows and doors, the routing of pipes of the heating system in attics, attics that are not insulated, its area is exceeded or the capacity of the coolant is significantly exceeded - the number of radiators, pipes) from the established standards, the temperature of the coolant may not reach 80C, which does not mean a factory defect. Operation of a solid fuel boiler Forward 20; 12.5; 16 kW Check draft. Check the amount of water in the heating system. Place paper and wood through the loading doors on a clean wire rack. Close the top door. Light the paper through the open ash door. Open the combustion air door slightly. Place a small layer of the main fuel on top of the burning wood. After the main fuel has ignited well, add the main volume of fuel to the bottom of the chamber. After reaching the heating water temperature, adjust the amount of combustion air. Combustion regulation is carried out using the air supply door, which regulates the amount of air under the grate - manually or using a combustion regulator. The combustion regulator must be adjusted so that the air supply door is almost closed when the required heating water temperature is reached. Depending on the need for heat and the intensity of combustion, it is necessary to replenish it with fuel during operation of the Lemax Forward solid fuel boiler.It is necessary to add so that the layer of fuel is uniform over the entire area of the grate. When using coke, coal, brown coal, the air supply door must be partially opened. The combustion controller must be set so that the air supply door always remains slightly ajar. If necessary, adjust the traction with the gate. The loading door must always be closed during operation. Remove ash from the igniter and, if necessary, from the combustion chamber several times a day. When burning coke, coal, brown coal, it is necessary to regularly, at least once a month, clean the walls of the boiler inside the combustion chamber and the chimney. Installation Requirements All the basic requirements for the installation and operation of Lemax heating equipment are exactly the same as those of many other manufacturers. The technical characteristics of all products are high, but subject to the observance of all the rules of installation and operation. The device has a draft sensor; if the intensity is insufficient, the burner turns off. The main task during installation is to create all the conditions for good traction. The company's manufacturers recommend using a chimney when connecting, which is better made from sandwich pipes. The models need some modifications, for example, floor-standing gas models can often not heat water enough to be used for domestic needs. Experts advise choosing a single-circuit unit in order to connect an indirect heating boiler to it, in this form it will be able to heat up a large amount of water at the required temperature. Boiler piping - The circulation pump is installed on the return line of the heating system right in front of the unit.

___________________________________________________________________________________________

___________________________________________________________________________________________

Repair of gas boilers AOGV Borino, ZhMZ, Siberia, Alpha Calor, Thermotechnik. Adjustment of gas automatics Eurosit 630. Replacement of the thermocouple and maintenance of the ignition burner.

Malfunctions and repairs of Baxi boilers Models Luna, Luna 3 Comfort, Luna Duo Tec (F / Fi). Double-circuit, turbocharged. Recommendations for eliminating errors and malfunctions. Settings and adjustment of operating modes.

Gas heating boilers Bosch Models ZWC, ZSA, ZSC, ZWR, Gaz 5000, Gaz 3000 W ZW, WBN 6000. Wall-mounted, double-circuit. Repairs, adjustments and malfunctions. Options for setting functions and modes.

Repair recommendation Navien Models Deluxe Coaxial, Deluxe Plus, GA. Errors and malfunctions. Work with remote control Ksital. System control. Setting work on temperature and pressure.

Floor standing boilers Buderus Repair of Logano G124, G125, G215, G234, G334 models. Breakdowns and malfunctions. Operation with Logomatic control system and indirect heating boiler. Modes and functions.

Operation of Vilant boilers Turbotec Atmotec pro / plus VU / VUW INT models. Components and work functions. Adjustment programs. Gas system. Installation and assembly. Maintenance and prevention.

Floor standing boilers Protherm Repair of the Bear models KLOM, KLZ, TLO, PLO with a capacity of 20 to 50 kW. Breakdowns and malfunctions. Operation, maintenance. Recommendations for setting operating parameters.

Lemax - repair and settings Models of gas floor boilers Premium, Leader, Patriot. Performance characteristics. Prime, Wise models. Adjustment of automatic equipment Eurosit, Minisit, Sit Nova. Solid fuel boilers Forward.

Wall-mounted coppers of Protherm Repair of the Panther, Cheetah, Jaguar, Lynx, Leopard models. Breakdowns and malfunctions. Operation and service. Recommendations for adjusting operating modes.

Beretta - repair and adjustment Repair and operation of boilers Ciao, City, Novella, Exclusive. Wall and floor models. Malfunctions and error codes. Working functions and setting of service modes. Maintenance.

Boilers Teplodar Kupper PRO Operation and adjustment of solid fuel boilers with a capacity of 22, 28, 36 kW. Installation of an automatic pellet burner APG-25, 36, 42. Settings of operating modes.

Repair of gas boilers Oasis Models of wall-mounted boilers ZRT, ZRN, BM. Malfunctions and error codes.Troubleshooting tips. Operating modes and setting of service parameters. Maintenance.

Heating boilers Alfatherm Description of Beta floor standing boilers and Sigma wall mounted gas boilers. Malfunctions and error codes. Repair and troubleshooting questions. Basic maintenance work.

Wolf - malfunctions and repairs A Wolf boiler is installed. I noticed that over time, the pressure in it gradually decreases (by about 1 in 2 days). I checked all the pipes for leaks but found nothing. What else to check?

Gas boilers Junkers After 7 years of operation, the gas boiler Junkers ZW-23-KE has the following problems. When DHW starts working, it either turns off or stops working ...

Repair of boilers Neva Lux Neva Lux 8224 (Baltgaz), discovered the following problem: the post-circulation pump does not turn off, no matter what the temperature is. To make sure that this is so, he raised the temperature in ...