Natural gas is one of the most efficient heat sources. In this regard, there are a large number of varieties of such equipment, as evidenced by various photos of gas boilers for heating a house.

Despite the increased requirements for such devices, their variety only increases, thereby increasing efficiency, energy efficiency and heat transfer.

Varieties of boilers

A gas boiler for heating a private house can be made in various versions. Their types include:

The number of contours. Equipment with one circuit involved in the heating process. A boiler with two circuits is considered more efficient, where water is heated in parallel, which can be used for washing dishes and so on.

Mounting method. Simple structures are located on the floor and do not require additional equipment. More modern options are wall-mounted and require additional electrical equipment.

Dependent and independent from electrical power supply.

These are the main criteria for dividing gas equipment. The choice of a suitable product takes place in each case separately, it all depends on the parameters of the premises and the needs of the customer.

Installation of gas equipment

Before proceeding with the installation of a gas boiler in a private house, you must adhere to the following sequence of actions. They include:

- Project creation. In this case, it is important to obtain a special permit from the gas service. Experts will help determine the place of fixing the heating equipment;

- Conclusion of a contract for the supply of gas;

- Installation of heating radiators and water supply distribution;

- Preparation of the place where the heating equipment will be located;

- Preparation of chimneys and ventilation;

- Installation of a gas boiler. It is fixed to a wall surface or installed on a floor covering. The mounting method depends on the selected model;

- Connection of a gas boiler with a chimney pipe;

- Connection of a fuel supply pipe with adjustable ends of the structure.

- Checking the performance of heating equipment.

The cost

The price of gas boilers for heating a house depends on many parameters. These include:

- The efficiency of the device and its efficiency;

- power, dimensions and the need for additional equipment;

- brand awareness of the manufacturer and the seasonality of the purchase.

Before purchasing a gas heater, monitor the market in advance and select the right product for which you can find the necessary spare parts if it fails.

What are hot water and steam boilers for?

The main purpose of the boiler lining is to protect environmental objects and workers from the effects of high temperatures generated during the operation of any high-performance boiler. It is also intended for:

- reduction of heat losses through the casing of the heat unit, which entails an increase in efficiency. Although part of the heat leaves through the body in the same volume, it is not dissipated throughout the boiler room, but remains within the lining structure;

- preventing combustion products and other fumes from entering the working environment, which can be displaced by high pressure in the system;

- preventing the ingress of external air masses into the system that can destabilize the working pressure.

This is what unfinished brickwork looks like.

Efficient devices

Double-circuit gas boilers for home heating are very popular. This is due to their features:

- one burner simultaneously heats up two circuits, which saves energy resources;

- they take up little space and there is no need to install a gas water heater;

- this is a fairly effective and reliable equipment.

Double-circuit boilers are very popular, they cost a little more than standard equipment with one circuit, but they allow you to save money without buying a gas water heater.

Which gas boiler is the best?

The best gas boiler for home heating must meet certain requirements. These include:

- economical consumption of energy resources;

- safety of equipment operation;

- production of a small amount of noise;

- simplicity of design and availability for repair;

- convenience in daily use.

Reviews about the main features of the KSG-7 AT model

If you want to purchase a gas boiler, then you should pay attention to KSG-7 AT from. The cost of the equipment is 10,600 rubles. This steel boiler is automatic and floor-standing. According to consumers, it is characterized by ease of use, provides maximum comfort and is easy to install.

The gas consumption during the operation of the device is quite economical. The efficiency is high. According to users, these features are among the main inherent in the described devices.

The gas boiler "Ochag KSG" has a modern unique design. The unit does not require external power sources and is non-volatile. Customers like the fact that even with a reduced gas pressure, the device works stably. It has a high efficiency, which is ensured by an increased heat exchange area.

Choosing the right gas boiler

Understanding the question: how to choose a gas boiler for heating a house - you will need to take into account some rules:

- initially it is necessary to determine the heated area of the room;

- it is important to foresee the local climate and possible heat losses;

- selection of equipment is based on 1 kW of boiler power per 10 m² of the area of the room;

- the boiler is selected with a power reserve of 25%, which allows it to be operated not at full capacity.

It is recommended to select equipment with the maximum possibility of smooth temperature control. It is better to purchase a two-stage boiler, which will allow using the equipment in two modes and significantly reduce energy costs.

Carefully study the technical characteristics of the gas boiler, this will make it possible to choose the right equipment and enjoy its trouble-free operation, while saving the family budget!

What are wall-mounted gas boilers

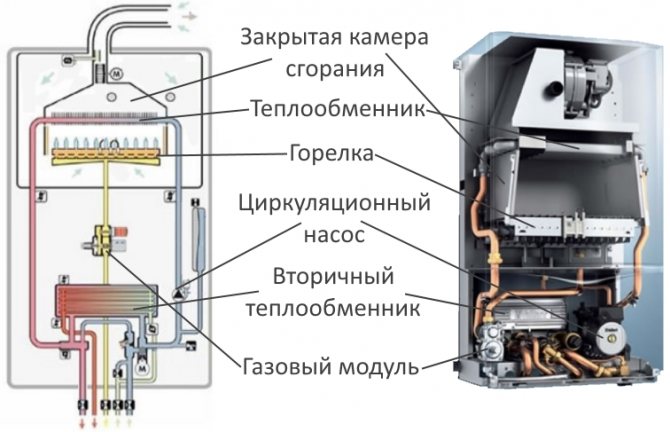

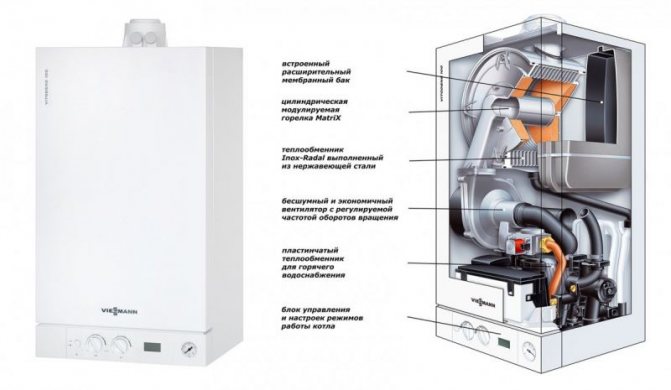

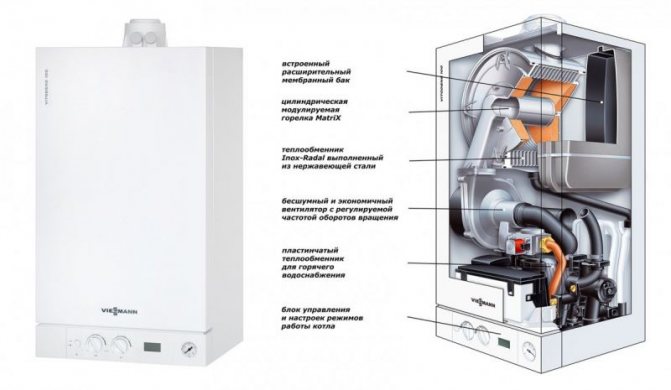

Gas mounted models are compact in size - from 55 to 90 cm in height and from 40 to 45 cm in width. They are less versatile, extremely volatile, but more efficient, compact and, in practice, according to the statistics of service calls, almost as reliable. In addition, already in the factory configuration of all wall-mounted boilers, all the units necessary for the heating system are provided: a circulation pump, a security group, a set of sensors, sometimes an expansion tank, etc. It remains only to connect the supply and return lines to the boiler, as well as the sanitary water supply circuit, if the boiler is double-circuit.

Compact dimensions, stylish design, a minimum of communications that can be hidden in walls and a coaxial chimney allow you to build wall-mounted gas boilers into a standard kitchen cabinet.

The absence of the need for a traditional chimney simplifies the installation of wall models even more. To get rid of gas combustion products, a coaxial pipe is installed, which is simply led out through the wall. The pipe consists of two parts. The inner one is used for the emission of combustion waste. Air enters the boiler through the outer part. For this, a fan is used, therefore such boilers are called turbocharged.

Device and principle of operation

The most typical interior design of a wall-mounted gas boiler, as exemplified by the Protherm Panther.

The technical device may vary from model to model, but the standard design used in more than 70% of wall panels is simple and straightforward: the burner, to which the gas is supplied, is ignited by the ignition electrodes and heats the heat exchanger above it → the primary heat exchanger gives off heat to the coolant circulating along the circuit heating, and the secondary heat exchanger, if any, sanitary water of the DHW circuit → the combustion products removal system naturally or forcibly removes gases from the combustion chamber through the chimney.