Varieties of solid fuel boilers

As you know, one of the main properties of a heating boiler for a summer residence, which must be taken into account when choosing a particular model, is the efficiency of work (in more detail: "How and which solid fuel boiler to choose: selection and comparison"). This parameter directly depends on what type of solid fuel boiler is planned to be operated, since the fuel burns out in completely different ways in different designs. Therefore, it is necessary to dwell in more detail on the types of TTK.

Choosing a boiler for a summer residence

Main varieties

Pellet model

As a rule, solid fuel heating boilers for summer cottages are classified according to the type of fuel used. To make it easier for you to analyze the options, basic information has been collected in the form of a table:

| Variety | Features of the |

| Coal |

|

| Wood and pellet |

|

| Pyrolysis |

|

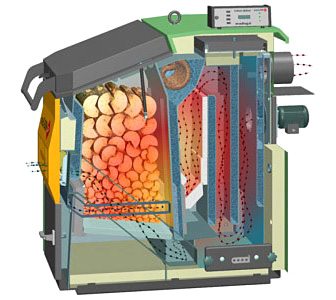

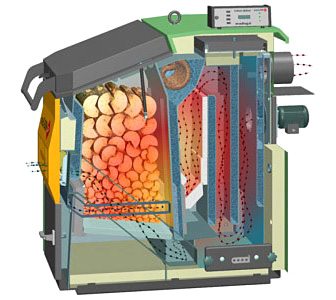

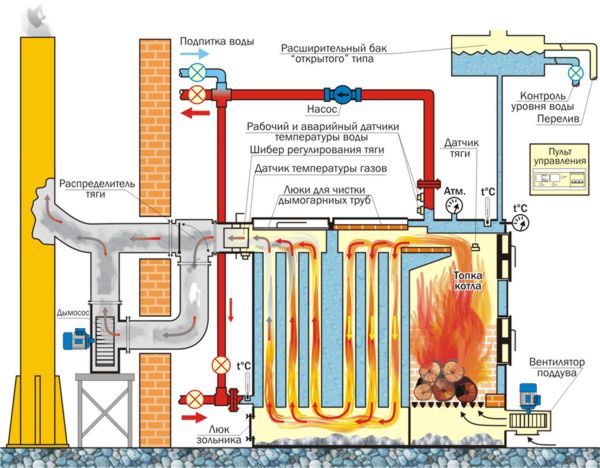

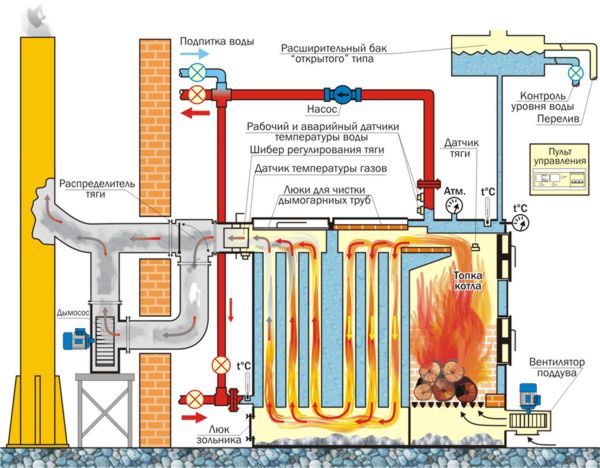

Heat flow diagram in a pyrolysis boiler

When approaching the choice of technology from a practical point of view, the factor of accessibility will be the most important. If logging is underway in your region, then it is best to purchase a wood-burning model. In regions with a developed mining industry, there is usually no shortage of coal, therefore its cost will be lower - accordingly, the operation of the coal model will be cheaper.

Unit selection parameters

If we have decided on the fuel, then further instructions for selecting a boiler for a summer cottage will relate to the features of its functioning:

For a large summer cottage, you need to purchase powerful heating equipment

- Equipment power. This parameter is key, since it will depend on whether the heating equipment can cope with heating the room in the cold season. So, if you plan to use the heater in winter, then its performance should be calculated according to the ratio of 1 kW * h per 10 m2.

Note! This value is valid for houses with standard thermal insulation and ceilings no higher than 3 m, located in the middle zone of the Russian Federation. It is better to entrust the calculation of the boiler performance for the northern regions, as well as for buildings with additional heat-insulating circuits.

- Volatility. For the efficient use of heating equipment during a power outage, we will have to purchase an expensive generator. That is why boilers with a simple regulating mechanism are usually bought for summer cottages, the operation of which does not depend on the presence of voltage in the network.

- Fuel loading volume.Everything is simple here: the larger the bunker, the less often we will have to approach the apparatus and add fuel to the furnace. If you use the dacha only occasionally, then you can purchase models with one firebox and lay a portion of firewood 5-6 times a day. But for a permanent stay, it is better to overpay a little for the auto-feed system.

The larger the bunker, the less worries!

- The presence of a second circuit. If the boiler is to be used as the main source of heat, then it would be quite logical to install a model with a hot water tank. So we will not only provide a comfortable microclimate in the house, but also get a hot water source for shower and household needs.

Solid fuel boilers for long and direct combustion

- In mechanisms operating by means of direct combustion, the process of heat transfer occurs during the combustion of the consumable, which explains the need to constantly maintain combustion. In these devices, fuel consumption is high, while the performance ratio is far from ideal. Moreover, these boilers are not automated.

- Direct fired boilers transfer heat while the fuel is smoldering and not directly from the flame. Thanks to the top burning method, this equipment is able to provide a room with constant heat. The method of supplying material for combustion is manual, and the time for warming up such devices is long.

Solid fuel boiler with heating elements: arguments "for" and "against"

Like any heating equipment, boilers with a thermoelectric heater have both advantages and disadvantages.

Arguments for":

- TEN is a reliable insurance against defrosting of the system. With a hybrid boiler, you can safely leave a house with water heating for several days without fear of seeing broken pipes, frozen walls or ice build-up on burst radiators upon your return.

- There is no connection to the fuel delivery schedule. A boiler with a heating element allows you to maintain the temperature in a house with water heating during interruptions in the supply of firewood.

- The connection diagram for a solid fuel boiler with a heating element is more economical than buying and installing two heating boilers of different types. First, only one boiler is paid; secondly, the cost of the equipment will fit into the framework of even a modest budget.

- The presence of a circulation pump in the heating circuit is optional. Natural circulation due to the density gradient arising from the temperature difference occurs both when water is heated due to fuel combustion, and when the electrical unit is turned on.

- The power of thermoelectric heaters usually does not exceed 9 kW, due to which the equipment can be connected to a regular power supply with a voltage of 220 V.

What difficulties may arise?

The main problem associated with the operation of equipment with heating elements is the formation and deposition of scale. A loose layer of calcium and magnesium salts covering the surface of the heating element significantly reduces the heat transfer coefficient, which reduces the heating efficiency.

For this reason, the maintenance process becomes more complex and the list of preventive works is expanding. In addition to cleaning the boiler from soot and checking the condition of the chimney, it is necessary to inspect the heating elements and clean them from scale. In addition, heating elements often fail, which entails the need to replace them.

Boilers of pyrolysis and pellet type

- The efficiency coefficient of the TTK pyrolysis combustion is very high. It functions by releasing a combustible gas produced when heated at high temperatures. These gases enter a special part of the boiler, where they are burned. It should be noted that such solid fuel boilers for heating summer cottages and other living quarters work in such a way that the fuel burns out almost without residue, while it is not necessary to equip a complex chimney system, since the combustion products are removed by means of a blower fan. Among the disadvantages of pyrolysis equipment is the high cost, as well as the need to use extremely well-dried fuel. In this case, the moisture content for wood should not exceed 20%, otherwise the boiler performance will significantly decrease.

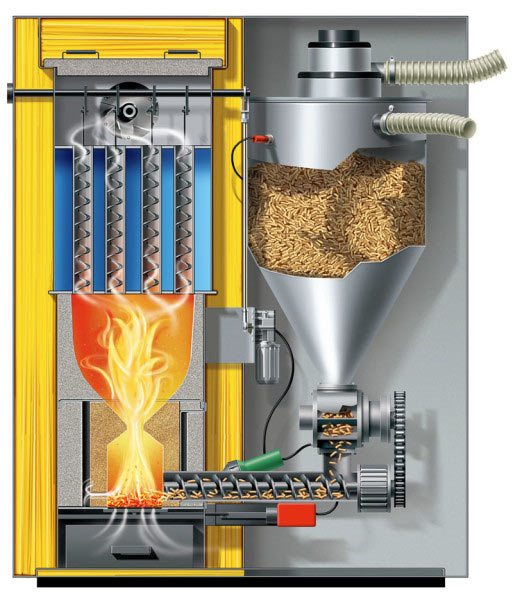

- The most functional is the pellet boiler system, where the heat source is special fuel pellets (pellets). There is practically no need to control the operation of this mechanism, since the fuel supply and ignition to them are automatic. Only the fuel material needs to be added periodically. Moreover, the efficiency of such boilers is very high, which is explained by the afterburning of gases in the system and the use of additional heat.

Advantages and disadvantages of systems

What are the advantages of using solid fuel boilers in country houses?

Heating system based on solid fuel installation

- First, the use of such devices increases the level of autonomy to the maximum.... We do not depend on the presence of gas in the mains or on the condition of the power lines. It is enough to stock up on fuel before the start of the heating season, and we are no longer afraid of the cold.

- Secondly, solid fuel systems are rightfully considered one of the most reliable and safe... In any case, you can install them yourself, unlike household gas heating boilers.

Advice! Naturally, this should be done only with the appropriate experience. And the installation of pipelines with a coolant requires skill, so here, perhaps, you cannot do without the advice of a specialist.

- Thirdly, the price of the devices themselves is quite acceptable.... And since a very powerful heating unit is rarely needed for a summer residence, here you can save a lot.

As for the cons, they are as follows:

- First, the fuel needs to be stored somewhere, preferably in a place protected from precipitation. So you have to build a wood shed or erect a woodpile shed.

In the photo - a canopy for storing firewood

- Secondly, such devices are characterized by a great need for fuel, so a lot of it will have to be purchased. So even with a low cost of firewood or pellets, you will have to spend money on heating.

- Thirdly, firewood must be periodically put into the firebox, which means that the boiler should be constantly looked after. Solid fuel boilers with automatic fuel supply are devoid of this drawback, but they are somewhat more expensive than conventional models.

And yet, for a remote summer residence, such a device will be the best choice, primarily due to the lack of alternatives. So if you are planning to purchase a wood or pellet heating boiler, we advise you to carefully study the following sections.

Steel boilers

Steel TTK, as a rule, have obvious advantages, such as an affordable price and low weight. But at the same time, long-burning solid fuel boilers have one big drawback - a short service life. In addition, if such units are installed in open heating systems, this also contributes to faster wear of the equipment.

This is explained by the fact that the coolant contains oxygen, which, as you know, is one of the reasons for the appearance of corrosion on the mechanism. All these factors, negatively affecting the operation process, reduce the service life of the boilers to 10 years.

But in those devices in which circulation is forced, active oxygen does not appear. Thanks to this, their service life is increased and is approximately 20 years.

Popular models of solid fuel boilers with heating elements

offers universal and budget models of solid fuel combined boilers: Kupper PRO, Kupper OK, Kupper OVK with heating elements with a capacity of 9 kW, as well as Kupper Praktik, in which heating elements have a power of 6 kW (can be replaced with more powerful ).

Advantages of combined heating boilers "Teplodar":

- High efficiency. The improved design of the heat exchanger allows to increase the heat removal area by 60% without changing the overall dimensions of the boiler.

- Insulation of the case with mineral cardboard minimizes heat loss.

- Solid fuel boilers "Kupper-OVK10" and "Kupper-OVK18" are equipped with a cast iron stove, which allows them to be used for heating or cooking.

- The design of the Kupper series boilers allows the use of all types of solid fuels. It is possible to switch to gas or pellets, in these cases the boilers must be equipped with a gas or pellet burner, also produced at our factory.

- The basic package includes a unit for installing heating elements designed to maintain the temperature after the end of the solid fuel combustion process. Boilers with a capacity of 15 kW can be equipped with an automatic draft regulator.

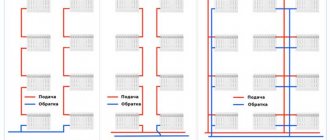

Coppers of the "Kupper" series are universal: they can be the base for any heating system - open, closed, with forced or natural circulation of the heat carrier. Design features allow connecting the water circuit from either side, which greatly simplifies the installation of the heating system.

A solid fuel boiler with an electric heating element minimizes the risk of defrosting the system with a water circuit when there is no possibility of regular firing up. Installation of a solid fuel / electricity hybrid boiler will allow for a short period of time to leave the system unattended, as well as to avoid replacing the water in the heating system with antifreeze. Reliable equipment guarantees the safety of the heating system even in extremely low temperatures.