How is a boiler that serves two circuits at once

The main difference between a double-circuit boiler and a similar one with one circuit is the ability to simultaneously provide the room with heating and hot water. The primary heat exchanger, due to its location, heats the coolant so that the heating system in the entire room can function fully. The secondary one is responsible for providing the premises with hot water in the required volume.

The stability of the functioning of the principle of operation of a double-circuit boiler can only be ensured by complete serviceability and coordination of operation of each component.

Structurally, any double-circuit boiler includes such elements as:

- heat exchangers in the amount of two;

- combustion chamber, to which the burner block is mandatory;

- protective equipment;

- control system.

To understand exactly how a gas boiler of a double-circuit type is arranged and its principle of operation, each significant component of such a design should be considered in more detail separately.

Typical diagram of a double-circuit gas heating boiler

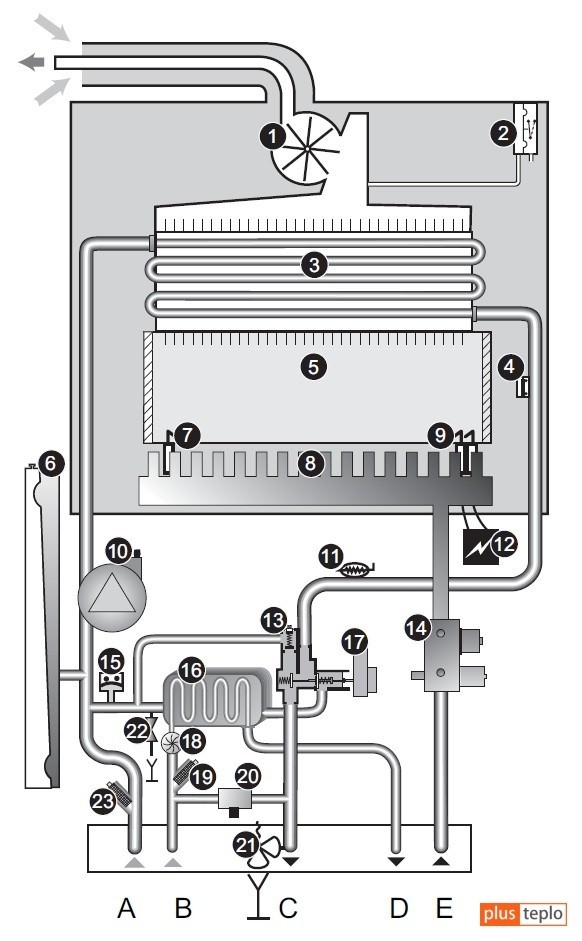

Consider a typical boiler diagram using the example of a double-circuit gas heating boiler Saunier Duval Themaclassic F 30:

Saunier Duval Themaclassic F 30 boiler (diagram)

1. Fan. 2. Traction sensor - manostat. 3. Primary heat exchanger. 4. Temperature sensor (emergency). 5. Gas combustion chamber. 6. Expansion tank. 7. Electrode for flame presence control. 8. Burner. 9. Ignition electrode. 10. Circulation pump. 11. Coolant temperature sensor. 12. Ignition unit. 13. Bypass. 14. Gas unit. 15. Water pressure sensor in the heating system. 16. DHW heat exchanger. 17. Three-way valve. 18. DHW flow sensor. 19. DHW filter. 20. Device for making up water for the heating system. 21. Heating system safety valve. 22. Water drain cock. 23. Heating filter.

A - Water inlet from the heating system. B - Cold water. C - Water outlet to the heating system. D - DHW outlet. E- Gas.

The principle of operation of a double-circuit heating boiler with two heat exchangers

When a double-circuit gas heating boiler operates in the "heating" mode, such processes occur in it.

- The gas burner heats the primary heat exchanger,

- The heat exchanger transfers heat energy to the coolant circulating (due to the pump) in it

- The three-way valve is in a position that prevents the entry of the heating medium into the secondary heat exchanger.

- All the coolant "goes" into the heating system, gives energy to the radiators there and returns to the boiler through the return line.

Boiler operation schemes in heating and hot water mode

The operation of a double-circuit gas boiler in the DHW system (hot water supply)

- Gas burner, heats up the primary heat exchanger,

- The heat exchanger transfers heat energy to the coolant circulating (due to the pump) in it

- The three-way valve is in a position that prevents the heat carrier from entering the external circuit of the heating system.

- The coolant circulates through the secondary heat exchanger, heating it.

- Cold tap water, passing through the secondary heat exchanger, heats up and "goes" into the hot water supply line.

Advantages of heating boilers with separate heat exchangers:

- The primary heat exchanger is less susceptible to corrosion and the formation of deposits (scale) on it, since the coolant circulates in a closed loop and does not constantly and significantly change its chemical composition.

- The secondary heat exchanger is more susceptible to "attack" by "aggressive" tap water. The salts that make up it, over time, clog it, and the heat exchanger fails.

It is important! If the secondary heat exchanger fails, it is possible to operate the boiler in heating mode. So without hot water - but warm.

- The secondary heat exchanger is cheaper to replace than the bithermal one.

Disadvantages of heating boilers with different heat exchangers: higher cost in comparison with bithermic ones.

The principle of operation of a double-circuit gas heating boiler with a bithermic heat exchanger

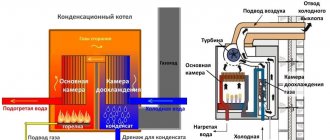

Diagram of a double-circuit boiler with a bithermic heat exchanger

When the boiler is operating in hot water supply mode, the gas burner heats up the coolant in the external circuit. And already from it the running tap water, which is in the inner tube of the heat exchanger, heats up.

Note! When the boiler is supplying hot sanitary water, the circulation of the heat carrier in the heating system does not take place! The coolant is closed in the boiler circuit. Simultaneous circulation of liquid in both circuits must not occur!

Advantages of boilers with bithermic heat exchangers: lower cost than boilers with separate heat exchangers.

Disadvantages: increased thermal "load" on the heat exchanger (heating of the heat carrier and hot water).

Gas burners as part of a double-circuit boiler

The burner of a gas boiler is responsible for obtaining the required amount of heat, which can ensure the correct operation of the heating system in each room of the heated object. Also, the water is heated to the required temperature and is already hot supplied in the proper volume. Thermal energy can be obtained by burning appropriate volumes of fuel. For this, the burner is placed in the combustion chamber, where, in addition to gas, air is also injected, which helps to maintain the flame.

Depending on the selected mode, the burners can be conditionally divided into single-level, multi-level and simulated. In the first version, the equipment operates only in two modes - "start" and "stop", is highly economical, inexpensive and has a simple design. Double-deck burners can operate at full or partial power. Its advantages can be fully appreciated, starting in spring, when there is no need for heating, and therefore it makes no sense to operate the device at full strength. The modulating burner is considered the most expensive, with its help you can adjust and regulate the power of the boiler. The latter is economical and lasts quite a long time.

Structurally, burners are open and closed. In the first case, the air, without which full combustion of fuel is impossible, is supplied from the room where the boiler is located. Such a system is equipped with a chimney, with its help natural draft is provided.

Atmospheric heating boilers are equipped with a conventional metal pipe, while turbocharged models are equipped with a coaxial chimney. They can be installed vertically, but often they are located at an angle - this option is connected to a common shaft, through which smoke and combustion products are fully removed.

Special attention should be paid to turbocharged models of gas boilers, in which closed-type combustion chambers are installed. Oxygen enters them forcibly, and therefore they are considered more reliable and do not pose any danger in the process of work, which makes them in demand in residential premises. In addition to the chimney, they need a special channel - it is through it that oxygen will be supplied to the chamber.

For turbo boilers, coaxial pipes are required in order to remove smoke and draw in fresh air from the street. In some models, there are two such elements, in addition they are equipped with a pipe for air supply.

All of the above models are necessarily equipped with fans that promote smoke, as well as automation and a multi-level protection system.

Connecting a double-circuit boiler

The double-circuit boiler can be made in a floor-standing or wall-mounted version. The installation of a wall-mounted unit is somewhat simpler: for it there is no need to specially equip the place, and all connections are made in the same way.

Before installing a double-circuit gas boiler, it is necessary to order the development of a project and coordinate it with representatives of supervisory services. After the approval of the project, the work is performed in the following sequence:

- Boiler placement... The installation of a wall-mounted double-circuit device must be carried out using special fasteners, taking into account the weight of the unit and the material of the wall. In order to avoid accidents, it is necessary to ensure the most reliable fixation on the wall. Installation of a floor-standing boiler is carried out on a previously prepared and reinforced base;

- Heating circuit installation... To connect the heating main, it is necessary to use the corresponding inputs and outputs of the boiler.

It is recommended to install a filter at the boiler inlet (return) to prevent dirt from entering.

- Gas connection... The connection of a double-circuit gas boiler to the mains must be carried out by a specialist with the necessary approvals. The connection diagram includes a gas valve, a meter and a thermal shut-off valve.

- Installation of the exhaust system... A double-circuit boiler usually has a closed combustion chamber, so the gases are removed through a coaxial pipe. It is put on the outlet and taken out into the street through a hole in the nearest wall. The installation diagram of such a chimney and the basic requirements for its maintenance are given in the instructions for the boiler;

- Electrical wiring... It is highly advisable to connect the electrical part to the outlet through a voltage stabilizer;

- Filling with water. Water or a special coolant is poured into the heating line of a double-circuit boiler. If water is used, it must be thoroughly cleaned. The use of excessively hard water can lead to premature failure of the hydraulic group. It is necessary to connect sanitary water to the DHW circuit under pressure generated by appropriate equipment, for example, a hydraulic accumulator;

- First start... A double-circuit gas unit is a technically complex device, so only a specially trained engineer can correctly configure it. Many manufacturers only provide warranties for their products if installation and commissioning has been carried out by authorized installers.

The boiler is the most important part of an autonomous heating system. Therefore, special attention should be paid to its installation. Correct connection of a double-circuit gas boiler is the key to its reliable and trouble-free operation throughout its entire service life.

What are the heat exchangers of gas boilers

A heat exchanger in a gas boiler is responsible for receiving heat in order to transfer it to water later. If we are talking about a double-circuit boiler and its principle of operation, then there is a primary and secondary heat exchanger. The first is located above the burner and is represented by a tube with ribs, a curved snake. The water heated to the required temperature in the heat exchanger moves into the three-way valve, after which it enters the heating system. The secondary heat exchanger is represented by a whole system of plates curved by waves, all of them are combined in a single block, on which 4 holes are also located.Through 2 of them, the flow of water is carried out, 2 more are responsible for the movement of the coolant, which is supplied to the heating circuit.

The system of two heat exchangers is called double. There are heating devices on the market that use a bithermal heat exchanger. It is characterized by a complicated configuration. For its manufacture, copper is used, the element itself is represented by tubes located in each other: the heat carrier moves along the outer one, the inner one serves for the movement of water, with the help of which the supply of hot water is ensured.

Gas boilers equipped with such heat exchangers are difficult to operate, the latter being difficult to descale. However, such heating devices are in demand, since they are small in size and heat water very quickly.

How does the boiler work in different modes

The device has important features. To understand them, the principle of operation of a double-circuit gas heating boiler should be considered in different modes separately.

For heating

The three-way valve is brought into a special position. This means that the working medium from the primary heat exchanger enters the heating circuit.

The mode is as follows:

- The coolant temperature is monitored by a sensor. When it cools down by 1 °, the sensor sends a signal to the controller - the gas supply opens and a flame flares up on the main burner.

- After heating the coolant to a temperature 5 ° C higher than the value set by the user, the boiler turns off.

- After cooling down, steps 1 and 2 are repeated.

If there is a remote thermostat, the boiler also takes into account the air temperature in the house. The most advanced models are equipped with weather-dependent sensors that determine the outside temperature. When it is changed, the heater has time to correct the heat output in a timely manner.

When heating water

When the user opens the tap, the liquid in the DHW line starts to move, and the flow sensor sends a signal to the controller. That switches the three-way valve, and the substance circulating in the heating circuit is sent from the primary heat exchanger to the secondary. This process is shown in the video.

A boiler operating in this mode ignores the heating system. Therefore, with a large flow of hot water, it will be cold in the room. In such a case, it is better to purchase a separate single-circuit boiler and a gas water heater.

The amount of hot water prepared per unit of time depends on the power of the heater. This parameter is indicated in the technical specifications (for example, 11 l / min). It is necessary to clarify which temperature difference between the inlet and outlet is implied (dt). For some manufacturers it is 35 ° C, for others it is only 25 ° C.

With a boiler power of less than 20 kW, the hot water performance is low. In such conditions, a model with a built-in boiler is more convenient.

Its advantages:

- Heating of the liquid is carried out during periods when the heating system does not require heat.

- Even with the smallest power, the performance is sufficient for several parsing points.

- Hot water immediately comes out of the tap.

There are also disadvantages:

- large dimensions;

- time-limited hot water capacity (depends on the volume of the boiler).

It is also necessary to take into account the increase in gas consumption, which is due to heat loss in the storage tank.

Summer time

When switching to this mode, the boiler performs the following actions:

- The three-way valve is moved to the position "To the secondary heat exchanger".

- The main burner ignites at the command of the flow sensor.

- After heating the coolant to the set temperature, the boiler turns off, then, when the substance cools down, it turns on again.

Thus, in summer mode, the device works only as a water heater.

How the boiler is controlled

In order to ensure the stable and safe operation of such heating equipment, it is better to choose automation. It controls the temperature of the water in individual components, maintains the temperature of the coolant at the proper level and is responsible for the competent principle of operation of the double-circuit boiler. In the event of potentially dangerous situations, the boiler automatically turns off - a similar manifestation is shown if:

- decrease in pressure in the gas system;

- maximum heating of the coolant;

- lack of traction.

In those gas boilers that are on the market today, mainly "smart" control is used, the software of which allows you to select one of the available operating modes.

The specifics of the operation of boilers with two circuits

Those who think that both circuits in such a system heat up immediately at the same time are mistaken, in fact, everything works completely differently. In normal operation, such equipment operates on an ongoing basis only in order to heat the coolant circulating in the system. How often it will turn on and how intense the flame seems during the operation depends on the temperature sensor that monitors these processes. Together with the burner, the pump starts, but only if the circulation of the coolant naturally does not have any effect on the operation of the heating system. After the temperature of the latter reaches the desired level, a signal is sent from the sensor that the activity of the burner should be reduced. After that, the boiler works only in passive mode until the temperature indicator reaches the programmed level. Next, the sensor sends a signal to the automation, which, in turn, starts the valve, which is responsible for supplying fuel.

It is enough to first familiarize yourself with certain subtleties of the functioning of gas boilers equipped with two circuits in order to understand what advantages can be obtained from their operation. Moreover, the purchase of such heating systems allows you not to purchase additional equipment, which may be required in any other case in order to provide the house with hot water. Even if one circuit fails, the second can be operated further, replacing one circuit will still be much cheaper than repairing an entire heating installation.

A double-circuit boiler may well be operated in the summer, when there is no need for heating and it is only necessary to provide heating of water intended for domestic needs. In this way, you can really save money, since buying two units at the same time, each of which functions autonomously, will cost much more.

A little more about the features of work

A three-way valve is used to prevent media from entering the second circuit. Thus, it was possible to achieve the supply of heated water from the boiler to the system through one line (supply) and return through another (return). It is worth paying attention to the fact that the double-circuit wall-mounted gas boiler is designed in such a way that the carrier moves in a circle without forming a raid. But this applies to the first heat exchanger. In the second, water is taken from the pipeline. As practice shows, the quality of the medium often leaves much to be desired. For this simple reason, it makes sense to install filters in front of the media that will remove insoluble compounds. If the hot water supply circuit breaks down, then the boiler can operate in the room heating mode. Thus, you will not be sitting in a cold apartment or house during the winter.