In order to create comfortable conditions in the room, it is necessary to prepare for the heating season. Nowadays, there are many options for arranging heating units. For multi-storey buildings, centralized heating is mainly used. In private homes, as a rule, various boilers are installed. Installation of a device that uses fuel when heating a room requires an additional device, which is aimed at removing flue gases. Previously, a pipe was installed, which served as a diverting device. Today, more and more new designs appear that significantly improve the operation of the heating system. Often, owners of private buildings install a coaxial chimney, which is more efficient and practical than a conventional chimney.

The uniqueness of the device

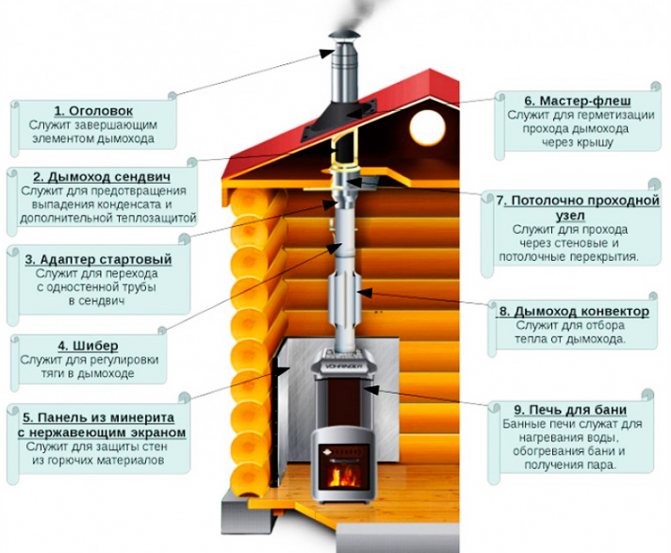

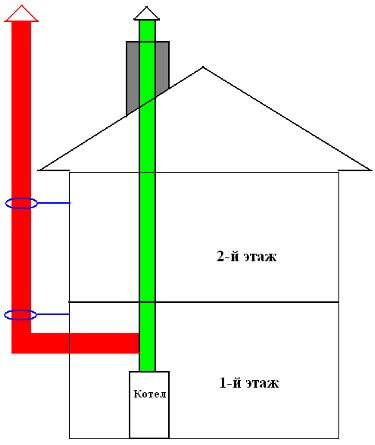

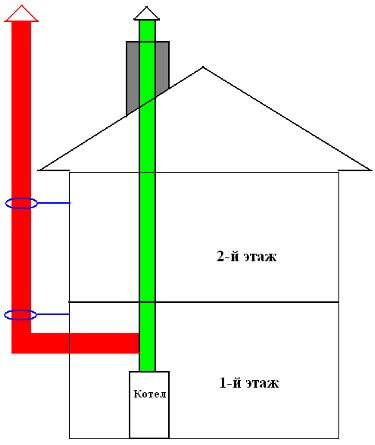

The design of such a device consists of several pipes of different diameters, which are inserted into one another. Hence the name - "coaxial".

In the middle of this device, special bridges are provided that do not allow the elements to come into contact with each other.

The coaxial chimney is installed complete with a gas boiler equipped with a closed combustion chamber.

Each of the contours of such a channel has its own task:

- one of them is responsible for flue gas discharge from the combustion chamber of the boiler unit;

- through the second is carried out fresh air supply, which is important for the complete combustion of fuel.

For boilers with a closed firebox, it is necessary to install chimneys with a length of no more than two meters. This is important because the larger the size, the thrust will be poor, therefore, the fuel will not burn completely. This is due to the formation of peculiar eddies that interfere with the exit of the products of the chemical reaction of the oxidation of the substance and the entry of air flows from the outside.

Advantages and disadvantages

As for the advantages of the coaxial design, the following points can be attributed to them:

- Quite high efficiency.

- Small size. When installing a conventional chimney, two pipes are required, and in the case of a coaxial structure, one product is required.

- There is no need for an additional ventilation system.

- Environmental friendliness.

- Staying in a boiler room is absolutely not harmful to human health, since the heating system takes oxygen not from the room, but through canals from the street.

- Economical fuel consumption.

- Due to the constant flow of cold air, the walls cannot become overheated.

The only drawback of the device is as follows: at subzero temperatures, a smaller diameter pipe may freeze over, since the flue gases give off their heat to the inner channel along the way and at the outlet already have a rather low temperature. That is why the formation of condensate accumulations in the pipe is a normal phenomenon. With a decrease in indicators to -15 ° C, a rolled metal product may succumb to severe freezing, which leads to undesirable consequences.

It is believed that coaxial structures are not suitable for the harsh climate of Russian cities. At first, this system was developed for the southern countries. However, many experts agree that the freezing of the pipe is the result of an illiterate design of this system. Whatever the cause, the end effect is the same: the galvanized chamber and burners quickly deteriorate.Repairing such equipment is considered quite expensive.

Most often, such problems are observed precisely in those types of chimneys that are manufactured according to parameters that can significantly increase efficiency. For this, the diameter of the pipe is made as small as possible, which practically brings the temperature indicators of the flue gases to the dew point.

For southern countries, such values do not affect anything, but in Russia, with the first serious drop in temperature, freezing of the pipe entails a complete installation of the heating system. Manufacturers can only shrug their shoulders, since this device is not tested in such conditions.

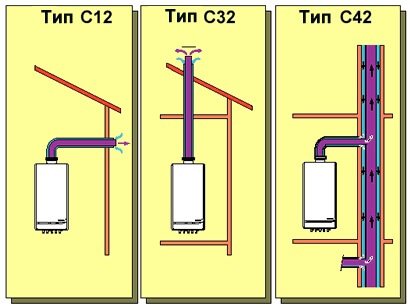

Types of chimneys for gas boilers

The chimney for a gas boiler, as already mentioned, can be very diverse. The following are the most common methods for arranging outlet structures. So, a chimney can be represented as follows:

- Brick channels.

- Ceramic pipes.

- Metal chimneys.

- Coaxial pipes.

Each of these types has its own natural positive and negative sides. Further, we will consider not only their main functions and properties, but also the advantages and disadvantages, in a particular case. Considering that a gas boiler was taken as an example, on the basis of it, the selection of the most profitable house of the outlet channel will be carried out.

Coaxial chimneys

The most modern way of installing a chimney pipe for a wall-mounted gas boiler. Its main principle is the pipe-in-pipe scheme. The main purpose is to work with systems and boilers, in which the boiler furnace "area" is of a closed type. That is, air is not taken in through the room as in classic boilers. In such structures, as already understood, the intake of air supplied for combustion in the boiler occurs through the street directly, bypassing the room.

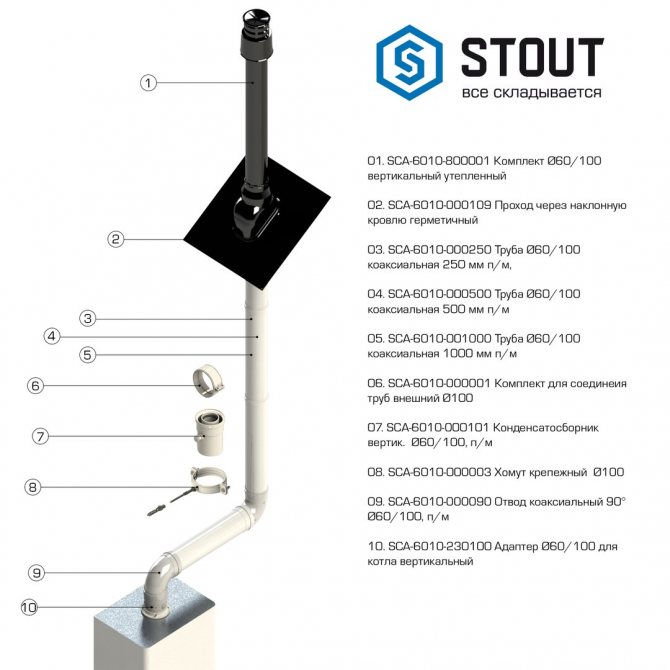

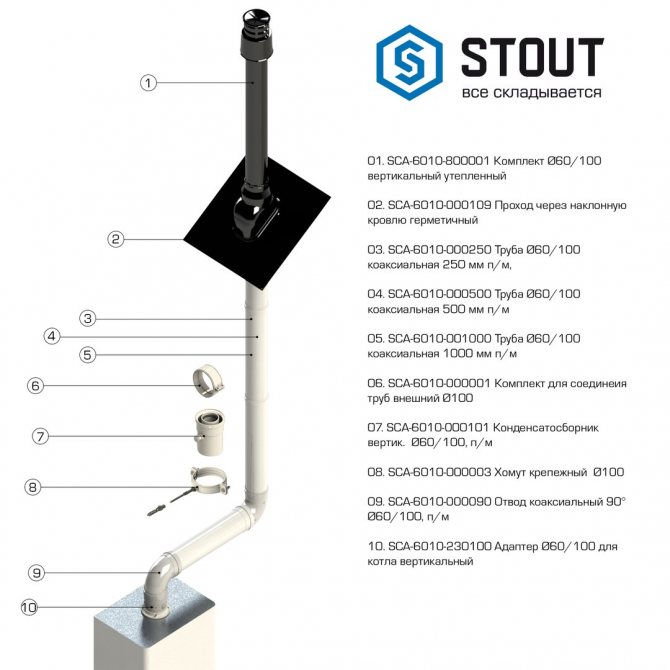

Coaxial flue - mounting kit

The supply is carried out using an external pipe, which has a perceptible opening through which the actual air enters the chamber. Moreover, it simultaneously heats up through the inner pipe, thereby significantly increasing the efficiency of the entire system. The design for a gas water heater or boiler is also due to the fact that no additional ventilation systems and stacking pipes are needed.

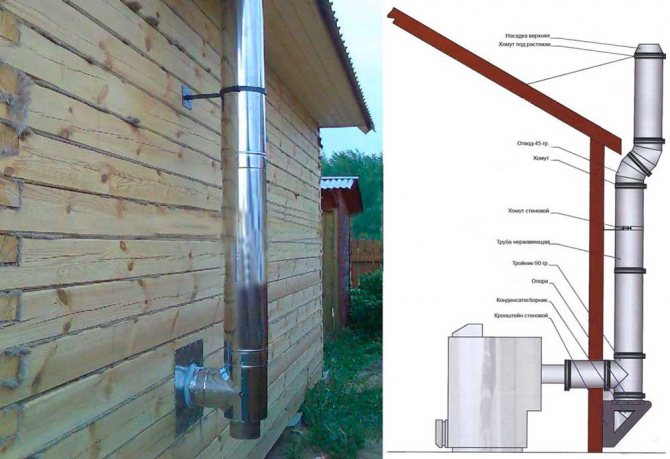

Installed coaxial chimney

In addition, the specific design also has another positive aspect regarding condensation. In such structures, moisture and other charges of oxides are, in principle, absent due to the very features of the system. This is of particular importance for the reliable and correct operation of the gas system. It is quite simple to assemble a chimney for a gas boiler with your own hands, with your own hands, the work process is much easier than arranging bulky vertical "trunks".

Read more in the article on coaxial chimneys.

Ceramic chimneys

It is not uncommon to find a chimney made of ceramic pipes or blocks in a private house. In terms of their properties, such designs are not the best and most productive, but their main plus is cost. Such systems are as simple as possible to install; they do not require complex design solutions. Often they sell ready-made channels wrapped in special "foil".

Ceramic chimney during the construction phase

Considering that the material itself is rather weak in terms of thermal conductivity, significant thermal insulation with the help of mineral wool ensures a reliable outflow. On top of the cotton wool, a body made of expanded clay is "erected", which protects not only the insulation, but also the ceramic pipe itself from damage and exposure to cold air. It is only necessary to connect a gas boiler to such a chimney in accordance with the rules listed in the section above.Also consider the fact that the properties of ceramics are not as durable as, for example, metal. The maximum temperature for such channels should not exceed 400 degrees. Therefore, the first segment, which will depart from the boiler itself, must be used only from metal.

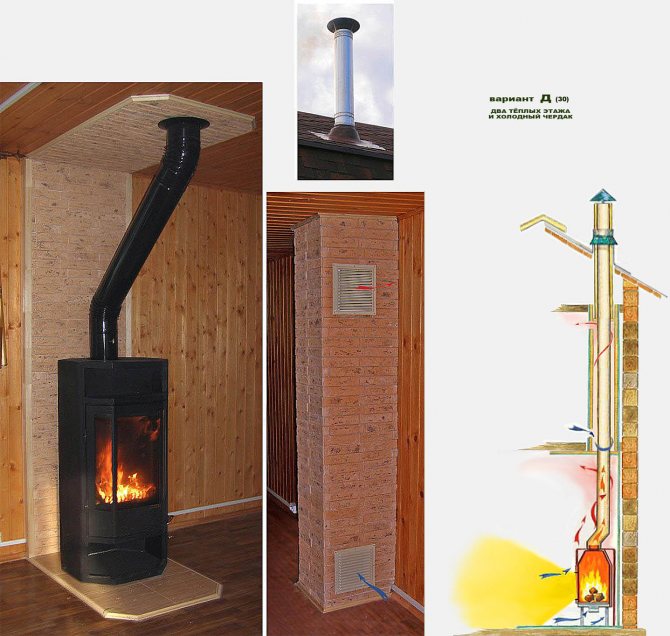

Brick chimneys

If we consider a classic chimney, which is more than several centuries old, then you need to understand all the features of operation, problems, and the like. The chimney for your brick gas boiler is a rather complex structure that requires a lot of time and effort to build. In addition, a sufficiently powerful "pillow" is needed for a brick chimney for a gas boiler, and if the question concerns the construction of such a channel in an already built house, then the question of choosing one or another type of discharge is decided by itself, the brick is clearly not suitable. So, given the difficulties of construction, as well as internally rough walls, which every now and then will accumulate soot, brick structures do not look presentable against the background of all other proposals.

Read more in the article on brick chimneys.

Metal chimneys

Stainless steel channels are by far the most common due to their amazing characteristics. Positive sides:

- Simplicity of design.

- The ability to manufacture various formats.

- Wear resistance.

- Resistant to aggressive environments.

- Ease.

A metal channel immediately leaves the gas boiler, without additional sections that cut off the high temperature. The ability to use not only for gas, but also for solid fuel boilers, where the temperature can reach up to 1000 degrees.

In addition to ordinary metal pipes, it is possible to purchase ready-made sandwich panels sheathed with insulation. Their principle of operation is exactly the same, however, due to a layer of insulation and a double layer of metal, less condensation is formed. Also, due to less contact with cold walls, traction works much better and, accordingly, the smoke separation of the entire system is improved. Of the specific features of metal structures, this is the mandatory installation of "umbrellas" from debris, clogging.

Selection of a chimney for a bath

There is no individually designed chimney system for arranging heating in a bathhouse. They select it depending on the type of boiler, the type of fuel and the design characteristics of the room. The arrangement of such chimneys for different stoves is practically the same. Coaxial pipe is usually manufactured made of high quality plastic or aluminum... When purchasing such a system, you must pay attention to the presence of all jumpers, which are designed to prevent the pipes from touching.

It is not recommended to design a coaxial chimney on your own, since many different nuances must be taken into account in the process. Any mistake can lead to undesirable consequences that are quite expensive.

All recommendations for proper design can be found in the Russian SNiP 2.04.08-87 "Safety rules in the gas industry." Without special skills and knowledge, these requirements will be difficult to understand. To simplify, you can purchase a completely turnkey system, which includes all the necessary certificates. By their design, such devices are horizontal and vertical.

Manufacturers

A universal option for most popular gas boilers is the coaxial design of the STOUT brand. All components of the system are ideally matched to each other, easy to install and maintain, adapted for use in our country.

A variety of elements allows you to create absolutely any smoke exhaust system. The manufacturer gives a two-year warranty on all products.The manufacturing process is carried out at the same factories in Italy, where a similar but more expensive product is produced. STOUT is the choice of those who do not overpay for the promoted brand name, but are used to choosing only high quality.

Coaxial chimneys of the company Baxi produced for boilers that run on gaseous fuels. Their construction is made of the highest quality stainless steel.

Company Immergas produces horizontal coaxial flues. It is possible to use such a device for gas boilers, as well as for units operating on liquid fuel.

Firm Buderus is engaged in the manufacture of horizontal chimney systems. Two types of steel are used for their production: galvanized and stainless steel.

Coaxial chimney for gas boilers Hermann It is manufactured in certain sizes: the diameter of the inner pipe is 6 cm, the outer one is 10 cm. Such systems are performed both horizontally and vertically.

Coaxial chimneys of the company Vaillant are manufactured with some design features that allow the device to be used in conjunction with boilers from other companies.

Korean manufacturer Navien manufactures chimneys that can be used with floor-standing or wall-mounted boilers with a capacity not exceeding 75 kW.

Coaxial chimneys of a popular company Viessmann produced in several versions with diameters 6/10 cm, 8 / 12.5 cm, 10/15 cm. By design, they can be both vertical and horizontal.

Firm Protherm manufactures both types of coaxial flues in sizes 6/10 cm and 8 / 12.5 cm.

The design of similar devices of the company Daewoo designed in such a way that the installation can be carried out from either side of the boiler.

Horizontal and vertical chimneys of the company Ariston are made of enamelled steel.

Installation diagram of a coaxial chimney

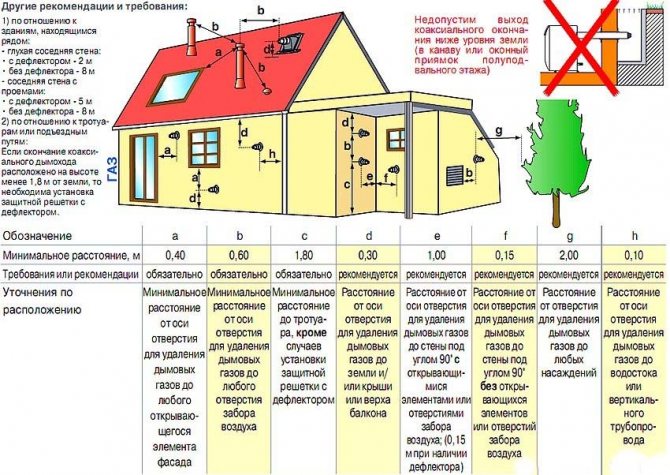

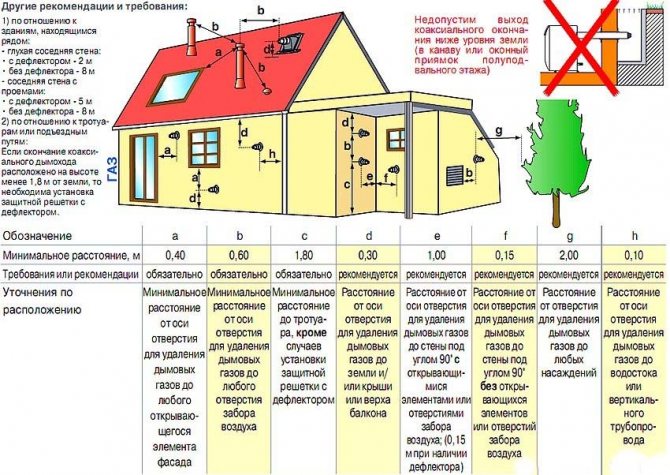

In this section, we'll break down two of the most popular installation options. So, the first option is to install a vertical coaxial chimney in a wooden house, according to

SNiPs, the following features of the scheme should be taken into account:

- The head should be located at least two meters from the ground.

- The norms, rules for installing a coaxial chimney imply the need to make a hole for the pipe, 1-2 cm more from the section. In wooden walls, ceilings, at least 5 cm.

- Distance from doors, window openings, ventilation fences, at least 50 cm.

- From the windows located directly above the pipe, more than 1 meter.

- From neighboring houses, at least 2 meters.

- Directly at the exit from the building, there should be no trees, walls, pillars and the like.

- When arranging such boilers, it is not allowed to combine them for two different heating systems, that is, natural draft and forced, in which case it is forbidden to combine.

It is allowed to lead the channel even through an adjacent room, but it must be borne in mind that the horizontal length of the coaxial chimney, in this case, should not exceed 3 meters (with natural draft). No more than 5 meters with forced draft.

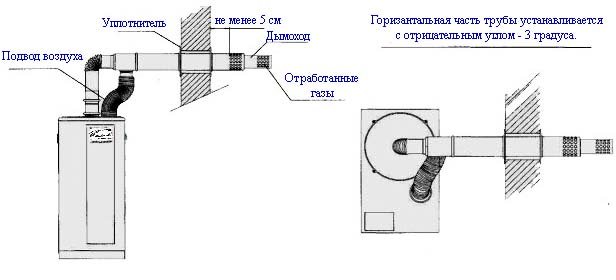

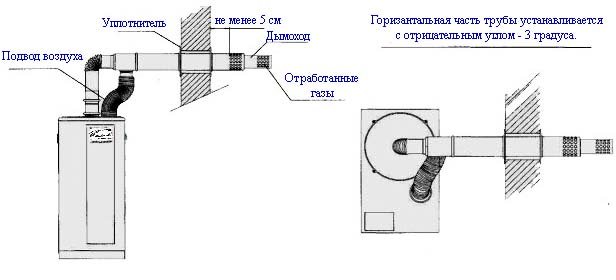

Horizontal duct layout

Install a coaxial chimney for a wall-mounted gas boiler and in a "lying" position. There are some design features of a coaxial chimney:

- Possibility of placing no more than 3 meters of horizontal section.

- The number of knees should not exceed two.

- The distance from the window is at least 600 mm.

- Distance from the branch pipe to the outlet channel, no more than 1 meter.

Installation diagram of a horizontal chimney

Also, remember the important aspects, do not use a joint and sealant. To do this, use only special rubber gaskets. Also pay attention to the fact that it is forbidden to use homemade adapters to connect to the boiler.The elements of the coaxial chimney must comply with the manufacturers' standards.

Installation requirements

Installation of such a design has its own rules, which should be described in the instructions attached to the equipment. Gas supply services and the Ministry of Emergency Situations can make adjustments and additions.

When installing a coaxial chimney, it is important to take into account certain requirements:

- It is necessary to observe the distance from the chimney to the adjacent building, which is calculated taking into account the technical characteristics of the structure and the design features of the chimney itself. In the absence of a deflector, the distance should be approximately 8 m.With this traction amplifier, it is important that the gap from window structures to the pipe is at least 5 m.If the wall is absolutely flat, without doors and windows, the distance can be reduced to 2 m. that SNiP does not say about the requirements for horizontal chimneys, therefore, it remains to follow the instructions from the manufacturer.

- The maximum permissible length of the coaxial pipe should not exceed 5 m. In multi-storey buildings, collective chimneys can be used to lengthen the duct. This problem is also solved by connecting to a common chimney system.

- Attention should be paid to the importance of creating a slope in the duct to allow condensate to escape outside the structure. The slope according to the ground level should be 3 degrees.

- It is important that all elements are connected before the pipe enters the wall.

- The distance to the ceiling structure of the building must be at least 20 cm.

- It is necessary that the outside part of the canal has a length of at least 20 cm.The optimal size is 60 cm.

Stages of installation of a coaxial chimney

The chimney for a coaxial boiler must be installed in accordance with provisions such as SNIP standards, carefully thought out, of high quality and work properly. A coaxial chimney differs from a vertical and traditional device in that it is not difficult to install it, and a number of special skills or training is not required, it is imperative to follow the instructions so that the installation technology is not violated. Only in this way can you be sure that the product is working properly and that the penetration of smoke into the room is categorically excluded.

Stages:

- The connection at the first stage consists in preparing the site for the future location of the boiler. Floor-standing boilers should be installed on footboards, and wall-mounted ones on the surface of the outer wall.

- Outlets on the chimney should be marked on the surface of the same wall near which the boiler will be installed, but only at a height of 1.5 m. The diameter of the place where the chimney is planned to be located should be slightly larger than the size of the chimney itself.

- It is required to install a special connecting element, through which the installation of the heating boiler and chimney will be carried out. Each turn and pipe joint is secured with a special fastening clamp.

The installation of the coaxial chimney is strictly prohibited by means of adhesive tape or sealant. The hole in the wall space must be laid with a special non-combustible insulation.

If forced ventilation is installed in the boiler, then only the horizontal section of the chimney must be installed.

If there is a need to make a turn in the pipe, you can use a special swivel elbow, and a maximum of 2 elbows can be installed per chimney. Installation of the pipeline on the wall surface is carried out using brackets and so that they are necessarily present at each joint. At the end of the coaxial chimney, it is undesirable to install such additional elements as an umbrella, deflector and others.

Passing a coaxial device through a wooden wall

In SNiP and fire safety rules, there are no recommendations for the installation of horizontal chimneys. However, there are general requirements, according to which the passage of the pipe through a wooden wall must be carried out with certain cuts. To a greater extent, this condition is met not in order to protect the structure from fire, but to exclude incidents with fire services in the form of fines and instructions.

The passage of a coaxial chimney through a wall made of non-combustible materials

The process of preparing the hole required for the output of the pipe is not particularly difficult. An opening of the required diameter is cut, the slope of which is directed towards the ground. The size of this hole must be equal to the corresponding chimney value. A special extension cord is inserted into the opening made, which fulfills the requirement for the location of the connection to the wall.

It is possible to protect the chimney from icing only by installing additional elements. It is recommended to purchase a special nozzle that will prevent condensate from freezing. This device will also help in case of incorrect design and subsequent installation without the desired slope. The nozzle helps to maintain the temperature inside the pipe at a certain level.

The distance from the gas supply duct to the chimney should be approximately 60 cm.

Chimney requirements for gas boilers

The chimney for the boiler must comply with certain characteristics and standards, otherwise, most likely problems will arise later during use. For example, here are the basic rules for a chimney:

- The slope that is allowed to be allowed, in no case, should exceed 30 degrees, regardless of the location.

- The length for the lateral "shoots" should not exceed the permissible values, namely 100 cm.

- It is forbidden to intentionally or arbitrarily make ledges, ledges in the channel.

- Cross-sections located across are prohibited due to a violation of the retraction system and the passage of traction.

- The number of "tees" is not more than three.

- It is allowed to make roundings, but remember that their radius should not be lower than the very diameter of the chimneys.

- When cornering, it is better to foresee the installation of special "containers" for collecting condensate, as well as hatches for prevention.

- In the event that for the chimney it was preferred to use a channel not of a round shape, but, say, oval or even elongated rectangular, then the width of one of the sides should not exceed the width of the other side twice.

- At the very bottom of the canal, a "drip" and a collection of moisture are arranged.

- Even minimal system deflections are prohibited.

- Take into account the fact that when installing several sections, they must be inserted into each other at least 0.5 whole from the original diameter.

- Any gaps between.

- Please note that in places where you want to install a floor or in walls, it is forbidden to skip non-solid sections. The connection is made either before or after the pass.

- The connection must be tight, use additional special means.

- Remember one more important factor, the inclination of the chimney towards the heat source cannot be more than 0.01 degrees.

- Remember to keep the inner walls as smooth as possible. Even small roughness creates an obstacle for the passage of soot, which subsequently accumulates there.

- Consider two rules: the length of the horizontal section for buildings that are still at the construction stage should be no more than 300 cm, for houses already built no more than 600 cm.

- Also remember that the distance between the pipe and the finishing material, the overlap, if it is combustible, should not be more than 250 mm. or 50 mm. if the material is fire resistant.

- In places where the flue duct needs to be led through the ceiling, high-quality thermal insulation is made.

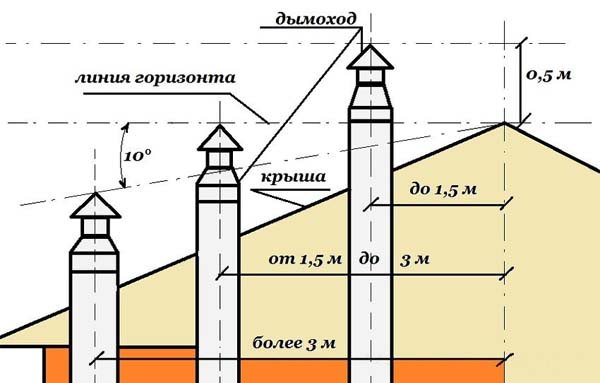

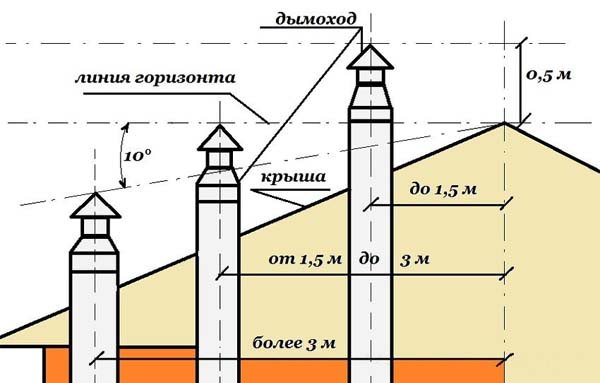

Height standards

Chimney requirements when installing a gas boiler

As you can see, the requirements for chimney ducts for gas boilers are quite serious and should not be neglected. In addition to the listed points, there are also special standards for the device regarding the height. So:

- If the distance from the led out pipe to the roof to the ridge is more than 300 cm, then you have complied with the standard values. This arrangement is allowed without increasing the chimney height.

- At the same level with the ridge, pipes must be installed that are at a distance of more than 150 cm.

- If the distance is less than 150 cm, it rises to a height of 50 cm from the ridge.

In addition, remember the rule, if the roof has a common roof and is flat, the head rises by at least 50 cm.