Features of use

First of all, people are concerned about the issue of safety, because wood is a rapidly flammable material, which means that when installing such equipment there are risks of fire, and the positive effect of gas converters leaves much to be desired.

On the other hand, the installation process is much simpler than batteries filled with hot water, for the supply of which you will have to install a cumbersome heating system.

It is not uncommon for the initial project of a wooden house to provide no heating at all, but during the operation the owner changed his mind, and the installation of heating devices is required in fact. Many gas convectors may well satisfy such needs, because they are able to operate on gas supplied from a cylinder, and not from the mains.

In order to obtain permission to install a gas convector in a wooden house, you need to make a visit to the gas or fire department, depending on the source of the gas, but first things first.

Convector test run

After carrying out all the above measures, a test run of the gas convector is carried out. It is performed according to the instructions supplied with the installed equipment.

The gas pipeline is connected to the convector using a special type of flexible hose. The unit is energized. The "Start" command is given from the remote control. This ignites the burner and turns on the built-in fans.

At the initial stage, the operation of the equipment may be accompanied by extraneous odors. This is most often caused by fading of excess paint and lubricants in areas close to hot surfaces.

Monitoring of the stability of the installation is carried out. During operation, there should be no smell of gas, smoke, extraneous sounds. The direction of air supply is adjusted, the temperature regime is set.

The advantage of gas convectors is that there is no need to build a heating system, there is no water in the equipment. This protects against the occurrence of leaks and the cost of installing piping with heating devices. The main disadvantage is the length of time required to arrange the installation of gas convectors, the presence of hot surfaces and the possibility of natural gas leakage.

There is a lot of controversy over the advisability of installing gas convectors. On the one hand, they are much easier to install than water systems. On the other hand, the efficiency and safety are questionable.

Installation

The advantages are obvious: the gas convector can be installed in an already built house, the project of which did not provide for heating. Even the presence of a highway is not required. There are enough bottled gas models.

A permit is required from fire services (if cylinders) or gas (if mains). In the wall, the design office usually asks to punch a hole of 1 m2. But according to the norms, it is necessary that the distance from the chimney to combustible (that is, wooden) structures be from 25 cm.It turns out that if the diameter of the chimney is 30 cm and it must be surrounded by the required 25 cm, then a hole with sides of 80 cm will do. In practice, workers of gas services (especially in rural areas) require simply sheathing the chimney hole with galvanized half a meter.Why do regulations require a large hole in a wooden wall? For floors made of non-combustible material, bricks, for example.

So, you can completely do with a cut hole for a pipe. How to insulate it and the wall? In addition to galvanized asbestos, basalt towels with a stainless steel screen and fiberglass have proven themselves very well. Basalt towels (cardboard) are convenient because they are simply nailed onto a tree with staples.

Safety and convenience

Despite the assurances of the convectors' sellers about their absolute safety, many "happy" owners have found that plastic window sills can melt from their work. A removable gypsum fiber box or a similar galvanized structure can serve as an exit. It is advisable to make a galvanized box not solid, but in the form of plates at an angle (something like blinds). Of course, there are no long curtains above the convector!

Fans of hot rooms in the winter cold will either have to constantly sit next to the convector in shorts, or think about another type of heating. The device warms up the air with high quality only next to itself. The farther from the convector, the cooler.

Water heating in small houses is unprofitable, and in cottages of inconstant residence there is still a danger of freezing the system. For many convectors, it makes no sense to gird the house with gas pipes or spaced balloons in the corners. It turns out that if you put a convector - then one. Moreover, the most optimal place for installation is the hallway, if the layout of the rooms is through. With the help of such a thermal curtain next to the entrance doors, it is possible to warm up the back bedroom to 18 degrees. Of course, if the house itself is only two-room + kitchen. And, of course, you will always have to keep the interior doors wide open.

Modern models are quite silent, but they can emit clicks. If this is critical, then it is necessary to choose convectors with cast-iron heat exchangers, they do not click when cooling.

Efficiency

For private wooden houses, the advantages of gas convectors are highly questionable. Small but hot surfaces are dangerous for children and unwary adults. Therefore, it is advisable to stop your choice on models that keep a low temperature, but have a large body. Also, a lot of heat just flies into the pipe. In a literal sense, the chimney can get very hot. But this heat could heat the house!

But the convector on cylinders is a good solution.

From the author:

welcome, dear friends! We propose to talk about how the installation of a gas convector is done with your own hands

.

These heating devices are less popular with consumers than their electrical counterparts. The fact is that this type of heaters implies the presence of a centralized gas supply or a gas cylinder. But such models are much cheaper to operate. They are usually installed in summer cottages or in country cottages - that is, in those locations that do not need constant heating.

Requirements for the premises

Requirements of gas services for premises:

- The ceilings should be at least two and a half meters, which is important, because many wooden houses are built with low ceilings, and this is with the lowest-power equipment;

- The ventilation duct in diameter must be equal to or exceed 100 mm, the material from which it is made must comply with SNIP, and the lower part of the ventilation duct must be at least 200 mm below the ceiling;

- Bottom gaps on interior doors must be at least 25 mm;

- Each room should have windows allowing to ventilate the room;

- The boiler room should be equipped with a door to the adjacent non-residential premises, and when installing a boiler with a capacity of more than 150 kW, a separate entrance door;

- The internal space of the boiler room must have at least 7.5 m3 in volume, for new houses this requirement has been doubled;

- Chimney - must be equipped with two walls, its diameter must be greater than or equal to the incoming pipe of the equipment;

- Lighting in the boiler room must be safe; for this, open bulbs without shades are not allowed;

- In the case of external wiring, it must be placed in specialized cable channels;

- The indoor gas control system must be installed in a wooden house if the boiler is in the basement.

Finally

Although the gas convector is not a very popular heating means, it is safe to say that it justifies its cost and the effort spent on its installation. Such a device will be the best option for a country house where you come to rest in winter. The heater is able to warm up the air in the room very quickly

, it is more economical than its electric counterpart, and can also be powered by a gas cylinder. Perhaps the only significant drawback of the device is that it heats only one room, and not all rooms, as a boiler with a heating system does.

Installation of a gas stove and convectors

It is prohibited to install the convector at a distance of less than 4 meters from open sources of fire, including a gas stove. The hose suitable for the convector must have a dielectric insert, this will prevent a fire in the event of a short circuit in the wiring in a wooden house.

An important factor is the grounding of sockets located near the gas stove and convectors, although in a house made of wood they must be grounded a priori.

There are three types of hose connections that are allowed to the gas stove in a wooden house, namely:

- Rubber-fabric - its plus is that it does not conduct electric current, but it is more susceptible to mechanical damage compared to analogues;

- Metal sleeve - when using it, a dielectric insert from the gas stove to the main is necessarily inserted, but otherwise it has the best performance among analogues. In addition, it is recommended by the latest approved standards. Its only drawback is the price, it bites;

- Rubber with metal braid - it is more capable of withstanding serious shocks, and also, thanks to the rubber core, does not conduct current.

When buying a hose, pay attention to the colors; there are characteristic yellow colors on its braid, which are used only for marking gas equipment.

When buying a metal sleeve, you should pay attention to its coating; some manufacturers targeting other markets, with other regulations, use yellow insulation, which does not fulfill its main functions. Always ask for accompanying documents when purchasing, and keep them in a safe place.

Gas heater. Defects in work

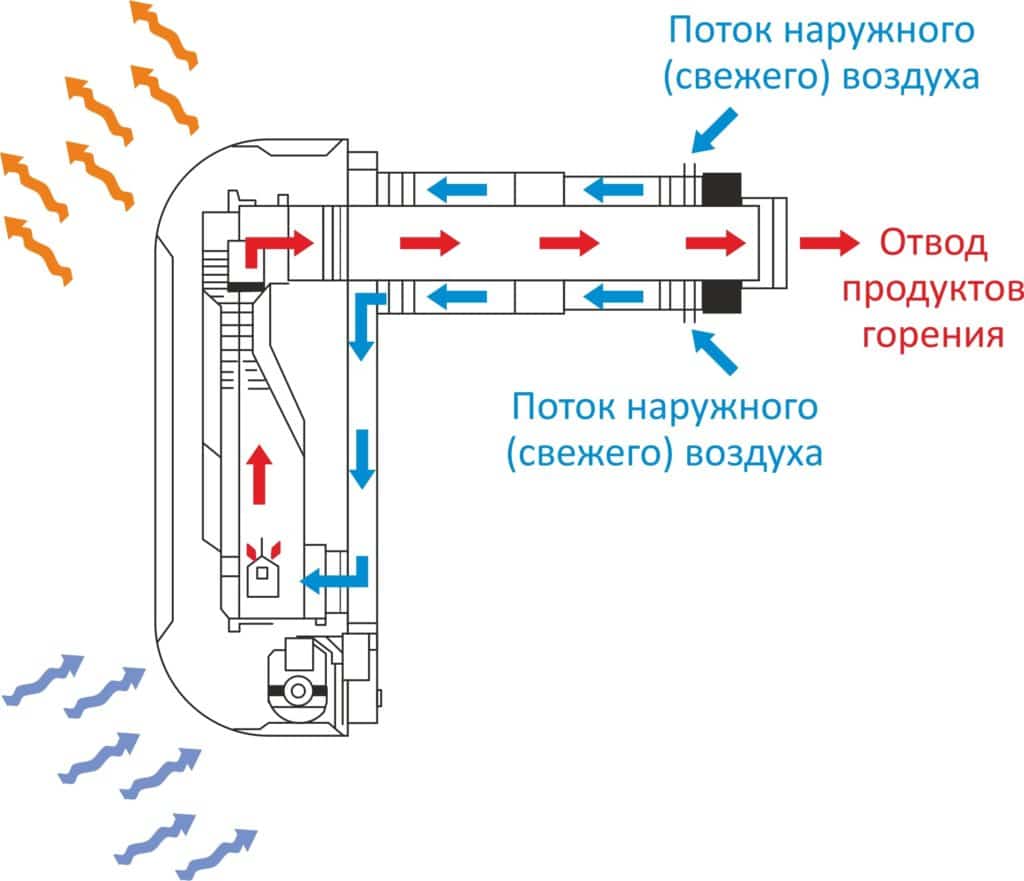

Next, you should deal with the disadvantages of convectors. The main disadvantage of such a device is that you have to break through the wall to complete the installation. And here a hole is needed for the coaxial gas outlet, which is a special tube in the pipe through which the exhaust gases escape. The fresh air required for combustion is supplied to the convector through an external pipe. It can be assumed that the hole in the wall may be located in a certain area where the convector itself will be placed. If they are located under each window of each room, then there will be a lot of holes in the walls, and they cannot be hidden or taken out into one section. In addition, additional space must be made in the wall for the gas supply.

In the case of using a standard heating complex in a living room of 30 square meters with two windows almost under each window, it would be worth installing one convector. However, this option is unacceptable with gas convectors. Here it is necessary to install one convector with increased power in a certain area on the outer wall of the room (where the most optimal conditions for supplying gas and creating a branch for exhaust gases are present). This setting does not imply the creation of a temperature balance in the room. One corner will be hot enough and the other cold. To create the proper comfort, one low-power convector should be placed under each window. However, this raises the question of price, which will double, although the aesthetics of the room will increase. Hence the conclusion - the installation of this heating option will be in many ways inferior to the standard water heating system.

The gas convector includes low inertia. In other words, it heats up quickly enough and cools down with the same interval. This feature can be attributed to both pluses and minuses. It all depends on how you use the device. Using it in a residential area can negatively affect the comfort of the temperature regime, and its installation in a garage, shed or workshop will undoubtedly give positive results.

Another nuance in the operation of a gas convector, which can also be considered a plus and a minus, is the presence of a combustion chamber, where the gas heats the chamber, which subsequently heats the air. For the durability of the convector, there must be steel in its design that is resistant to fading. It is good if the device is equipped with just this type of specialized steel (nevertheless, the price of the device will double in this case). If the convector uses cheap steel, then it runs the risk of failure very quickly due to corrosion, burnout and other factors. If the combustion chamber in the convector is created using 10 mm cast iron, then the service of the device will be durable.

The main advantages of gas convectors for wooden houses

All the complex nuances that needed to be understood were sorted out before choosing this equipment, it remains to list advantages of gas convectors for wooden houses:

- Efficiency - if a wooden house is assembled in accordance with the rules and does not have shrinkage crevices, then a very small amount of gas will be required to heat it;

- The smallest boiler allows you to heat a room with a total area of up to 350 m3, and this is the size of a huge house, but subject to ceilings at 2.5 meters;

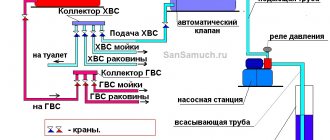

- There are double-circuit boilers that will supply your house made of wood not only with heat, but also with hot water, the price for them is slightly higher, but there are pluses on the face;

- Both automatic and manual ignition can be used to supply heat to the convector;

- Provided that the ventilation standards are met, the natural outflow of gas is carried out without difficulty, and the danger of their accumulation is not observed.

How to install the convector correctly

- Installation of a gas convector in a wooden house. During operation, the case heats up to 50-55 ° C. It is necessary to insulate wooden surfaces in contact with heating parts of the structure. The rules for installation in a wooden house prescribe the manufacture of fire breaks in the roof. If a coaxial pipe is used, insulation is not required at the place of passage through a wooden wall. The surface of the coaxial chimney heats up slightly due to the special design of the burner and pipe.

- Location from the floor. Air heating of a country or residential building has certain features that affect the efficiency of heating. For maximum performance, install the convector as close to the floor as possible.As a result of this solution, the intensity of circulation of convection flows increases and the efficiency of the equipment increases.

- The gas pipe is supplied to the heater exclusively along the street. A shut-off valve must be installed at the connection point.

A test run is carried out in the presence of a gas service representative. A corresponding note is made in the documentation of the convector.

Which is better, a gas convector or a boiler

Air heating is recommended for use in country houses that are not heated during the winter season. During installation, there is no need to use a water circuit, you can heat the building only from time to time. Even at a negative temperature in the room, you can warm up the room in 20-30 minutes.

A gas convector for a home on bottled gas is inferior to a boiler connected to a main pipeline in terms of efficiency, but superior in functionality. The choice of an air heater is justified in the absence of gasification. With a fully filled cylinder, the heater will work for approximately 10 days.

The convector heats the room better and faster and uses less fuel for this, but its efficiency is limited by the properties of convection flows. Heating intensity decreases as obstacles arise: walls, furniture, etc.

For heating a country house or small rooms, a convector-type heater is optimal. But for residential heated houses with large rooms, it is better to install a traditional gas boiler.

The current market for heating devices is quite wide. Among such devices, it is worth highlighting the gas convector. The range of heating systems includes a lot of gas convectors of various shapes.

The process of installing a gas convector in a wooden house

There is nothing easier than fixing the converter to a wooden wall, for this you will need:

- Self-tapping screws;

- Crosshead screwdriver;

- Mounts (included with the converter);

- Building level;

- Pencil.

First, you should check how far from each other are the loops for which the gas convector is hung. Most often they are wide enough, which allows already on the mounts to move it to the left and right, at a distance of about 5 cm.

Measure the distance between the centers of the seats, for the upper and lower loops it will be the same. Transfer these dimensions to the wall, observing the height you need from the floor, most often it ranges from 10 to 20 cm.

The self-tapping screws used must be at least 40 mm long, this will ensure reliable fixation to the wall in a wooden house.

Attach the self-tapping screws to the designated points, and double-check with the help of a convector whether the distances coincide by bringing it to the caps of the screws. If so, then you can safely fix the hooks to a wooden wall.

When the fasteners are screwed in, place a level on them and check the slope relative to the horizon, it can be leveled by loosening one of the fasteners and lifting it slightly. Now you can hang the gas convector on the wooden wall.

Do-it-yourself converter chimney

Gas converter chimneys have a simple device, they can be made by hand.

At its core, the convector is a large diameter pipe with welded pockets on it, which can be made of pipes of a smaller diameter, rectangular metal profile or metal plates.

Metal chimney converter

Making a chimney-converter from iron is within the power of those who know how to use a welding machine.

Step-by-step instruction:

- Step 1. You should take a pipe with a diameter similar to the one that comes out of the stove (usually it is at least 15 centimeters), and cut it in relation to the length of the chimney. On average, it is 55 centimeters.

- Step 2. You need to take a pipe with a diameter of 5-7 centimeters and cut it into 6 pieces, 45 centimeters in size.

- Step 3. Weld 6-8 of the resulting blanks to the main one.They should form a complete circle around it.

- Step 4. The chimney convector is ready.

- Step 5. You should connect it to the pipes.

Advice! After the converter is ready, for better heating, it should be painted black, and for an aesthetic look, it can be closed with some interesting plate made of metal or galvanized sheet.

Stainless steel chimney convector

Stages of creation:

- Step 1. You need to purchase a thick stainless steel chimney pipe and sheet.

- Step 2. Using rivets, attach a sheet of stainless steel in large waves to the main pipe.

- Step 3. The convector is ready.

Finished model of a chimney convector for a pipe, made of stainless steel

In the cold season, various devices are used to heat the room. One of the most popular today is the gas convector. As a rule, after purchasing this device, the question arises: how to install a gas convector?

Installation can be done independently, you just need to adhere to the necessary requirements.

If the installation is carried out in compliance with all requirements, then the room will be warm, and the device will function correctly, without endangering you.

Gas supply to the convector

Close the gas valve in front of the meter.

This process requires special attention, in any room, and even more so when it comes to a wooden house. The main thing here is to check whether all the elements of the gas supply correspond to the description of the accompanying documentation.

Ball valves with yellow handle markings are screwed onto the convector. Until the moment of start-up, they must be in a closed state. It is necessary to screw a hose or a sleeve to the gas cylinder or the main line, be sure to check for the presence of a paranite gasket in the union nut of the hose.

The next step is to connect the other end of the hose to the tap installed on the gas convector. Here you should also check if there is a gasket. After that, you need to compress all connections using spanner keys.

Calculate the force, it is important not to crush the gaskets, otherwise the gas will pass through the damaged parts of the system.

Now you can open the gas and the taps on the convector. Using a shaving brush, apply the foam solution to all joints. After making sure that there are no leaks, you can proceed to the first start.

The first start-up in a wooden house is made with the windows open for ventilation.

Gas supply main stages

The gas convector has been installed, now you need to deal with the gas supply. This stage is quite difficult and responsible at the same time. To supply gas, do the following:

- According to regulatory documents, the pipe suitable for the convector must go down the street. There are two options here: the first - the pipe has a pre-drawn threaded connection, the second - there is no such connection. If there is a thread, then you can screw on the gas valve yourself, which will cut off the gas supply to the convector. In the absence of a tap, it must be done. To do this, call professional gas welders from the local Gorgaz or a similar office.

- After installing the gas valve, it is necessary to lead the metal-plastic pipe to the convector itself. Using a tape measure, calculate the length of the pipe, along the way determining the presence of fittings.

- You need to buy pipe and fittings. The principle of the purchase is that the seller must check the availability of a certificate of conformity of these pipes and fittings to this type of work.

- Lay the pipe, fix it with clips every m. To install the clips, you need to drill holes in the wall.

- When installing the required fittings, carefully lubricate the pipe and the fitting itself with silicone to provide additional sealing. The silicone will also serve as a lubricant and facilitate pipe installation.

As a result of the work, you should get a convector mounted on the wall with a gas pipe connected to it.

Now the last step of the installation remains. A test run is required.

Before starting, open the gas valve and brush over all fittings and threaded connections with a brush dampened with a solution of soap or shampoo. This will allow you to spot any inflated bubbles (if any) that indicate gas leaks. If this happens, immediately close the gas supply valve. After checking the joints, start the convector. To do this, press the gas supply button for one minute. This will allow the gas to pass through the pipes and enter the combustion chamber. Press the piezo igniter, the spark should ignite the gas. A blue flame will burst into the furnace.

Adjust the convector operation to a comfortable temperature. During the first few hours of operation, you may smell an unpleasant burning oil smell. This is normal, as the convector is new and the combustion chamber burns out. If the smell lingers for a long time, then it is worth turning off the gas and re-checking all joints and threaded connections.

It is advisable that all work on the installation of gas convectors is carried out by a professional who has sufficient experience in performing such work. This is also due to the fact that self-installation of the convector may void your warranty on the device. The gas convector must be accepted on the balance sheet by Gorgaz.

You must have documented tie-in permission on hand. In addition, all decisions on the installation, as well as the conclusions of the commission for the acceptance of the device into operation must be documented and signed in the proper way.

The current market for heating devices is quite wide. Among such devices, it is worth highlighting the gas convector. The range of heating systems includes a lot of gas convectors of various shapes.