An airlock is excess air that occupies pipe diameter or most of it.

As a result of the appearance of an air barrier heat ceases to flow along the contour further.

There are several ways to get rid of an airlock in your heating system.

Odnoklassniki

Where does the airlock come from

The reasons:

- in pipes or radiators along the contour there is damage;

- a mistake was made at the stage mounting or even designing (most often there is an incorrect calculation or execution of a pipe slope);

- low pressure (no matter what the reason) - the space that is not occupied by water is occupied by air;

- incorrect system start into operation at the end of the summer season (a common mistake is filling the circuit with a warm or hot coolant);

- fast heating water to maximum temperature;

- absence or malfunction devices for automatic air release from pipes;

- incorrect connection of the "warm floor" - due to the complex contour and the small diameter of the pipes, this part of the contour is the most problematic to connect.

Prevention of airing the heating system

If the heating system is ventilated, the elements inside are destroyed by chemical reactions and leads to subsequent breakdowns. To avoid these problems, it is important to carefully monitor the state of the heating system and periodically carry out preventive measures.

Problems can arise for various reasons, including: repair work, violation of the technology for replenishing the system, malfunctioning air vents, etc.

To avoid the formation of air jams, it is necessary to carry out a number of measures.

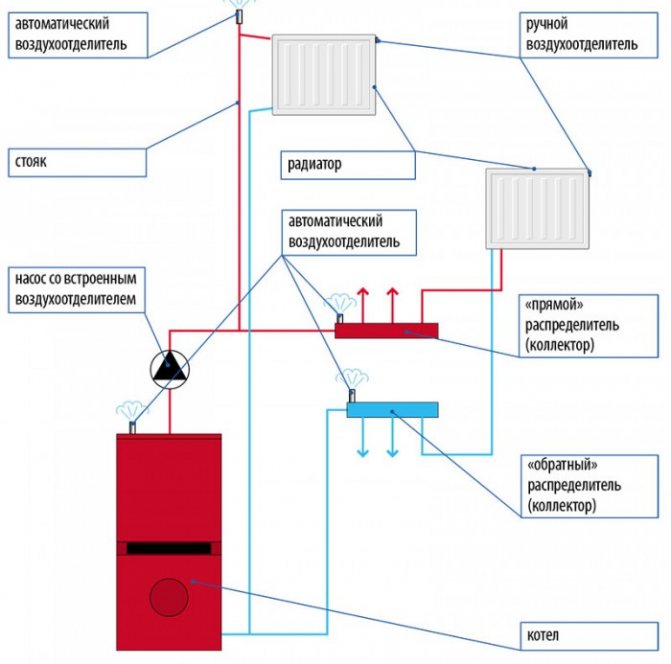

- During the installation process, you need to install special devices for venting air: an automatic air vent is installed at the outlet of the boiler and on the collectors, a Mayevsky valve must be installed on each radiator, to remove air from the pipes, air outlets for the pipeline are mounted on the risers;

- Before completing the heating system, you need to bleed air;

- During operation, it is necessary to constantly monitor the operation of the heating system: install pressure gauges and periodically check the pressure level in the pipeline, monitor the coolant level in the expansion tank, visually inspect pipes and radiators for leaks and damage, check the temperature of heating devices and its uniform distribution;

- Periodically bleed the system to get rid of blockages and silting;

- Installation of an air and sludge separator. Such a device removes gases dissolved in water. In addition, it cleans the coolant from blockages. The air separator cuts into the pipeline, air bubbles are captured from the coolant passing through it and released to the outside.

Preventive measures will significantly extend the life of the heating system and make it work as efficiently as possible.

How is it formed

With an illiterate gulf of the coolant (for example, from the top point), turbulence is formed: water tends downward and air - upward. In the process of movement, the liquid displaces air, if there are suitable irregularities on the inner surface, it stops in them. Gradually, the amount of trapped air increases.

Why is it important to get rid of it in time

Even a small amount of air in the system is highly undesirable, although a plus can be found here: the appearance of a plug - system malfunction signal... But there are much more troubles:

- weak heating radiators or lack thereof;

- noises, vibrations - create tangible discomfort;

- the combination of air and hot coolant leads to the appearance unwanted chemical processes, which leads to additional layering on the inner surfaces;

- part of the chemical processes entails acidity increase inside the system, which creates conditions for corrosion;

- if a circulation pump operates in the system, then its work can go idle, it will break.

How to determine the place where the air appeared

The easiest method for detecting traffic jams is by hearing... You need to carefully tap the battery - empty space will respond louder.

You can find suspicious places beforehand according to the degree of heating: where the coolant does not pass, there will be areas with low temperatures

Both ways do not differ in accuracy. The coolant may not pass due to a blockage of dirt and rust. This problem is solved by flushing.

How to purge the air in an apartment building

Bleeding can be done in the following ways.

Bypassing the riser to discharge

Performed housing and communal services employees. For air release, devices are installed on the upper floors.

If you cannot use them (the apartment is closed, no one is at home), you can carry out a bypass from the basement - for a two-pipe system.

The risers must be provided with dumpers... They are located after the valves. If available, you should stock up on a ball valve with a diameter like the plug.

Process:

- Risers overlap (valves).

- On one of them very slowly and carefully the plug is unscrewed. No more than 1-2 turns, so that you can feel the pressure of the water. Before turning further, you must wait until the pressure subsides.

- Screwed into place of the plug ball valve with seal.

- Installed dump opens completely, then water is supplied to the second.

For a successful result, you need to see in advance how the layout of the heating plant at home is made.

It is optimal if the radiators along the contour are on the supply riser, then the installation of the second one with a relief valve on the return will solve the problem: there will be no air. When the heating devices are distributed over two risers, there is no guarantee of one hundred percent result.

If the problem is not resolved, the same actions are performed. in the opposite direction. For this, the ball valve is moved to the second riser.

Important! Screw valves do not transfer the direction of water flow that does not correspond to the arrows on the body. If so, then you have to reset the entire system.

The usual heating arrangement is - bottom... The pipelines, direct and return flow, are located in the basement. The connection between them is via a lintel on the top floor.

How to get rid of a plug using a Mayevsky crane

Small cylindrical device. Installed on top of the radiator if there is room for this in the niche. In one-story houses all radiators are equipped with it.

Photo 1. Crane Mayevsky for airing radiators model 1/2 SL No. 430, equipped with a sealing ring,.

If the system is vertical, then the device is installed on the top floorto release the entire riser from the air at once.

Additionally, the Mayevsky crane is installed on heating devices located below the common lower point of connection to the riser. Sometimes - on heated towel rail in the bathroom. It is placed vertically through a tee, which allows you to change the position of the axis of the device.

Mayevsky's valve is very easy to operate: to release air, the valve opens and then closes. If this does not solve the problem of heating the radiator, then it will have to be cleaned.

- Before venting the circulation pump is turned offif the water flow is forced.

- All objects close to the radiator move away.

- Placed under the valve basin or bucket.

- Screwdriver or wrench begin to turn until a hissing sound appears.

- When the water appeared, the tap close.

Remove with a conventional valve

The valves must be in highest points of the contour. The air is released according to the same algorithm as with the Mayevsky crane.

Kick out through the plug

This method is used if nothing is specifically set.

To use a stub, you need:

- disable riser;

- put under the plug bucket or another container;

- if the plug is covered with paint, it softened with a solvent;

- adjustable wrench carefully and slowly turn the plug until a hiss appears, it is important not to miss this moment, because you cannot open the plug completely;

- after the hissing stops - wait the appearance of liquid;

- the plug is screwed in backif necessary, you can seal it.

Important! All manipulations are done slowly, without sudden movements.

How to expel air from the heating system

When installing the system, it is necessary to provide for the formation of a plug and ways to release it. When installing the heat pipe, air vents are installed on the radiators and the pipe. Modern heating equipment can be equipped with water and air discharge devices already on sale.

Types of air vents according to the principle of operation.

- Manual (Mayevsky crane);

- Auto.

The Mayevsky valve is a needle radiator air valve. It reliably holds the coolant and, if necessary, you can make a descent through the side opening.

The sequence of air discharge using the Mayevsky valve:

- Before starting work, a floor cloth and a container for collecting water (bucket or basin) are spread on the floor. In a private house with autonomous heating, it is necessary to stop the operation of the circulation pump during the air discharge;

- Using a screwdriver or a special key, you need to slowly turn the tap one turn counterclockwise;

- After the air leaves the system, water begins to flow, at this moment the tap is closed.

Due to the presence of debris in the coolant, the air vent can become clogged. In this case, the valve does not perform its function and a leak may occur. Cleaning is done with a needle that removes the blockage. If such a repair does not work, flushing or even replacing the valve will be required. In this case, the tap is unscrewed with an adjustable wrench and a serviceable one is screwed in. When replacing, it is required to drain the coolant.

After installation or reconstruction of the heating system, it must be pumped and de-aerated.

There is also a more modern version of the Mayevsky crane. Its advantage is the presence of a handle. To release the air, you do not need to look for a key, just turn the knob counterclockwise. Such a device can withstand pressures up to 10 atmospheres and a coolant temperature of 95 ° C.

An automatic air vent performs an independent release of air accumulations from the system. Such a mechanism is arranged according to the float-valve type. In the absence of air, the float is in the closed position. As it accumulates, the valve opens and air is released. After that, the automatic float valve returns to its original position. In the event of a breakdown of the device, no leakage occurs due to the safety shut-off valve. There is no need to drain water or relieve pressure to replace broken equipment.

If, after correctly carried out measures, it was not possible to eliminate the airing of the heating system, then additional work is required:

- Check the presence or level of the heating medium. If necessary, fill up the lack of water;

- If the level of the coolant is sufficient, then you need to lower it and pump the pipeline well using chemical flushing or pump the system with ordinary water. A chemical solution (acids and inhibitors to slow down the corrosion process) is fed into the system under pressure. This should be done to get rid of debris and silting.

Removal in a house with an autonomous heating system

The generation of the gaseous form of the coolant begins when it enters the pipes. The process intensifies when heated, air is collected under the "ceiling" of the contour.

Therefore, the inclusion of a heat source always occurs only after filling the circuit and bleeding off excess air.

Removing gas invariably entails pressure drop and decrease in the amount of coolant - in the process, you need to keep the pressure and make-up supply under control.

Raise pressure and temperature

Pressure reduces the rate at which gas is released from the liquid (at constant temperature).

In the vertical system, there is upward air movement, but it can move down with water, "hang" in the stream.

Reference! In horizontal sections of the circuit, in pipes with a slope, the gas occupies the upper position. At high water velocity, the air splits up and goes to motion along unpredictable trajectories. Therefore, the filling of the system must be slow.

By manipulating pressure, you can debug the system. Common natural pressure - 1 bar. When filling the circuit, the pressure begins to rise.

If heat is added to this, the coolant expands, which leads to an increase in pressure. Air begins to separate from water more active.

If the system is correctly designed, after filling it with a coolant, air will begin to be removed through a system of automatic valves or it is removed manually.

The drop in pressure indicates coolant leak, increase - oh airlock (it acts like a constriction of a pipeline).

Given the peculiarities of the interaction of air and water, they can be used to combat air congestion. If it is not possible to determine the location of the accumulation of air, a short-term rise in temperature and pressure will cause the air in the system redistribute... The plug will either move to a place where it can be removed, or air will escape through the automatic valves.

Causes and consequences

The following factors are the reason for the occurrence of air congestion:

- During the installation, mistakes were made, including the wrong places of bends were made or the slope and direction of the pipes were incorrectly calculated.

- Too fast filling of the heating medium in the system.

- Incorrect installation of air vent valves or lack of them.

- Insufficient amount of coolant in the network.

- Loose connections of pipes with radiators and other parts, due to which air gets inside the system from the outside.

- The first start and excessive heating of the coolant, from which oxygen is more actively removed under the influence of high temperature.

The greatest harm air can bring to systems with forced circulation. During normal operation, the bearings of the circulation pump are always in the water. When air passes through them, they lose lubrication, which leads to damage to the sliding rings due to friction and heating, or completely disables the shaft.

Water contains dissolved oxygen, carbon dioxide, magnesium and calcium, which, when the temperature rises, begin to disintegrate and settle on the pipe walls in the form of limescale. Places of pipes and radiators filled with air are more susceptible to corrosion than others.

Signs by which you can determine if there are air locks in pipes and radiators

Due to the air in the heating system, the batteries heat up unevenly.When checked by touch, their upper part has a noticeably lower temperature compared to the lower one. Voids do not allow them to warm up properly, therefore, the room is heated worse. Due to the presence of air in the heating system, with strong heating of water in pipes and radiators, noise appears, similar to clicks and overflow of water.

You can determine the place in which the air is located with an ordinary tap. Where there is no coolant, the sound will be more sonorous.

Note! Before removing air from the network, you should find the cause of its appearance and eliminate it. Especially carefully check the network for tightness

When heating is started, it is extremely difficult to identify loose connections, since water quickly evaporates on a hot surface

Especially carefully check the network for tightness. When the heating is started, it is extremely difficult to identify loose connections, since water quickly evaporates on a hot surface.

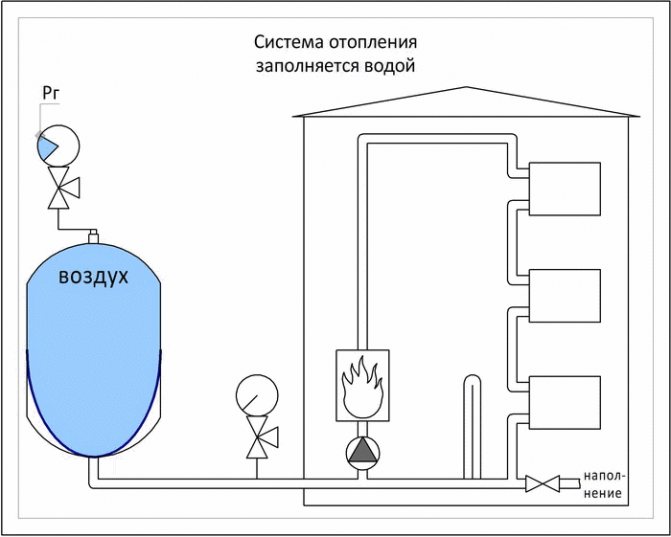

If it enters a closed-type natural circulation system

The organization of heating of this type involves the removal of air through the expansion tank installed in the highest position.

TO overflow connection the hose is connected, the possibility of pouring out the liquid is provided.- Opens low head make-up, turns off when water comes out of the hose.

- Next, air is released from each battery (plugs, Mayevsky faucet).

- After that, the coolant is added to the system. (about 2/3 of the boiler volume).

Then the boiler turns on, the radiators should start heating up. Repeat the process if necessary. When the slopes of the pipeline are observed, the air escapes by itself. If it does not work out, the coolant can be heated, then the air will come out more actively.

Forced circulation

For diluting systems with forced circulation, you will need two people. The second makes sure that the pressure does not drop below 1 bar (the pressure is generated by a pressure pump or through the make-up from the water supply).

Important! Initially, the coolant must be cold, Heating is switched on after filling the entire heating line.

- All opens shut-off valves, excluding plums.

- Overlap all radiator taps, only the last radiators in the branches remain open.

- After starting the water supply, the main lines, boiler and expansion tank. At this stage, the air leaves the air vent at the top point of the circuit and the valve of the safety group (it is recommended to install it for boilers with any type of fuel).

Further open taps on the first battery from the boiler, the air is released through the Mayevsky cock, then the valves are closed.- To be filled in one by one all radiators.

- From the circulation pump air is vented.

- After filling the entire circuit, the pump is switched on and the heat generator is activated. Circuit pumping takes about 15 minutes.

- After heating the lines, the valves on the radiators one by one open, you need to release air from each one again.

At the end of the procedure, the pressure should not exceed 2 bar... The underfloor heating system is filled last.

If there are several branches, they are filled one by one, air exits through the manifold valves. The filled branch is closed, heating starts after the entire system is full.

To simplify the process of squeezing air out of the system, care should be taken to have:

- Mayevsky cranes on radiators, if the heating main goes below the batteries;

- automatic valves, when the pipes go higher.

This is a complex process that takes a lot of time. However, you should not rush when carrying out work - haste, inattention can lead to the appearance wandering airlock... It will take a lot more effort to fix this problem.

How to bleed air in autonomous systems

For autonomous heat supply systems with forced circulation of the working medium, everything is different. Typically, the pressure generated by the pumping equipment exceeds the height of the heating circuit and it can function even if the pipes are airy.

But in the process of movement of air bubbles in pipes and batteries, extraneous sounds arise - hydraulic noises. If they are distributed continuously, it will deliver a lot of unpleasant moments for residents.

In addition, air contributes to the formation of corrosive processes in the steel parts of the heating circuit, such as panel radiators, pipes made of black steel, and cores of bimetallic devices.

When there is no oxygen, it does not come into contact with the coolant and rust does not appear. Now it is clear why the air lock in the heating system of a private house interferes so much.

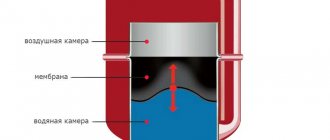

Air separator

A sophisticated and efficient device designed for autonomous systems, especially vast extent.

Photo 2. Air separator model ZUVL 20 for vertical pipes,.

It takes air from the water and automatically removes it. There is a top air vent... Double-acting separators are produced - for capturing air and impurities. In this case, the device is equipped with a valve to remove accumulated impurities and particles.

There is a mesh inside the device, which provokes turbulence and the appearance of air bubbles.