What is a water supply manifold

The collector is a device for dividing water into several streams. The principle of operation is the same as for a conventional tee - one stream (pipe) comes out, two come out. The diameter of the collector inlet is 20-40 percent larger than the outlet diameter, therefore, when several taps are opened, there is no decrease in pressure and water flow.

The collector divides a large flow of water into several small ones, and the pressure in the taps with increased water consumption is stable due to the fact that the separation of flows occurs in a pipe with a larger diameter than in the traditional scheme. The larger the pipe diameter, the more water passes through it per unit of time.

The collector circuit of water supply is more comfortable to use than the traditional one, with risers and tees. But the cost of materials for it exceeds this parameter for the traditional one by 8-10 times. Therefore, this scheme is not used with a limited budget for laying a water supply system.

Types and types

For the manufacture of collectors used:

- Stainless steel.

- Brass.

- Polypropylene.

- Crosslinked polyethylene.

Collectors are distinguished by the method of pipe fastening:

- Threaded (with internal and external threads).

- With compression fittings for plastic and multilayer pipes.

- With Eurocone.

- With solder fittings (for plastic pipes).

- Combined (for large-diameter holes, thread, for small-diameter compression fitting, Eurocone or for soldering).

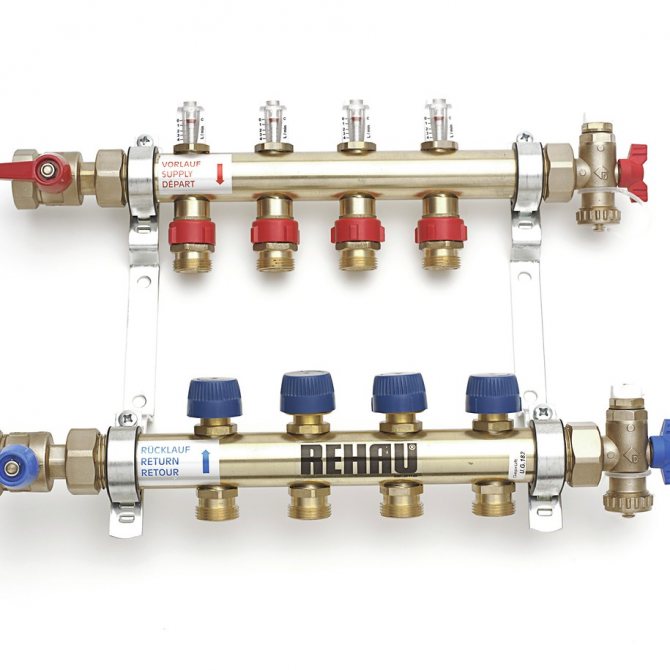

Brass manifolds

Collectors are divided according to the number of branches. They are produced with the number of taps from 2 to 6.

Each manifold is equipped with two fasteners corresponding to the diameter of the water supply pipe and intended for docking. With their help, several blocks are connected into a composite manifold without additional adapters.

If one block is enough, or special plugs are used to plug the latter.

With the help of the collector, a separate water consumer is turned off without affecting the rest. This will come in handy when replacing or repairing plumbing, cleaning the sewer, restoring a damaged section of the pipeline.

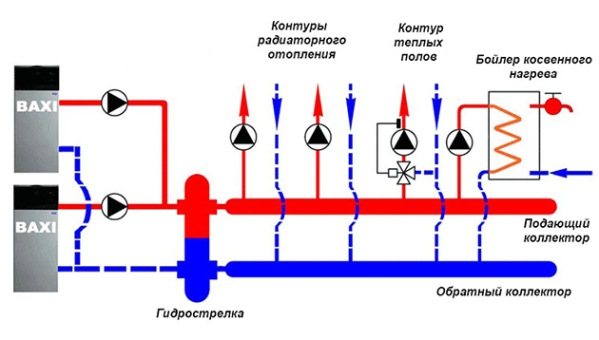

Placement of the comb in the heating circuit

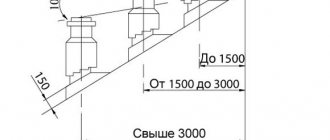

The choice of the location of the distribution manifold should be approached with special care. The ideal place for installation is a small utility room, protected from moisture. The distance from the collector to each radiator should be as equal as possible, otherwise, in too remote sections of the pipeline, there is a possibility of high pressure.

Good to know! The ratio of the distance between the manifold and the first branch, the manifold and the subsequent branch, must be within 1: 2. In other words, the first pipe can be 2 times shorter than the second.

The switchgear is mounted directly on the wall or installed in a special cabinet located a short distance from the floor.

The cabinet for the heating comb is a metal box with a front door and side openings for piping. There are overhead and built-in models.

Recessed manifold cabinet

Competently mounted water heating wiring using a distribution manifold ensures reliable operation of the entire system. Therefore, it is advisable to entrust such responsible work to professionals with considerable experience in this area.

Summing up, we can say that the collector heating system is efficient, economical and comfortable to use.The homeowner has the ability to control the flow and temperature of the coolant on each individual radiator, completely block the supply of liquid to individual nodes, and achieve uniform heating of the entire house in a short period of time.

How to choose and install a suitable manifold

Before choosing a collector, determine the number of consumers of cold and hot water (these include taps, toilets, washing machines, dishwashers and other plumbing fixtures). Determine the type of water pipes, the choice of a collector and additional fittings depends on them.

Manifolds with installed valves are easier to install (no need to mount each valve separately)

If the number of consumers does not match the number of taps, purchase several collectors and make one of them. To connect to a supply pipe made of polypropylene or XLPE, purchase manifolds made of these materials. They are cheaper than metal ones, are not inferior in reliability and are easier to install.

Keep in mind that the polypropylene manifold is connected by soldering, and the polyethylene one - with compression fittings.

If the water supply system does not have hot and cold water filters, a consumption metering system and a non-return valve, purchase and install them in front of the manifold. The location of the devices near the collector, in one inspection hatch, facilitates the repair and maintenance of the water supply system.

If you cannot decide which material is more durable, know that the service life of copper, stainless steel and plastics pipes exceeds 50 years, and the service life of ball valves does not exceed 20 years. Therefore, purchase manifolds without taps. If the taps fail, you will replace them and the manifold will continue to serve.

Polypropylene manifold with taps

The cost

The cost of collectors depends on the material, configuration and manufacturer and is indicated below:

- Polypropylene, 6 taps, diameter 40x20 mm, KALDE, for soldering - 1600 rubles;

- Polypropylene, 3 taps, diameter 40x20 mm, KALDE, soldered - 480 rubles;

- Polypropylene, 2 taps, diameter 40x20 mm, KALDE, for soldering - 320 rubles;

- Brass, without taps, 4 outlets, without taps, threaded connections (incoming internal thread, outgoing external), with a diameter of 1x½ inches, VALTEC - 750 rubles;

- Brass, without taps, 4 outlets, without taps, all threaded connections (internal thread), with a diameter of 1x¾ inch VALTEC - 700 rubles;

- Brass, 3 taps, threaded connections (incoming internal thread, outgoing external), diameter 1x½ inches, VALTEC - 1400 rubles;

- Brass, 4 taps, threaded connections (incoming internal thread, outgoing external), with a diameter of 1x½ inches, ELSEN - 1300 rubles;

- Stainless steel, 4 taps, threaded connections (incoming internal thread, outgoing external) 3 / 4x1 / 2 inches, FAR - 2200 rubles.

Installation

Having chosen a collector (an assembly of several blocks) for hot and cold water, purchase fittings and additional elements - fluoroplastic sealing material (FUM), rubber gaskets, adapters of the required dimensions. It is advisable to purchase collectors, pipes and fittings from the same manufacturer.

There are cases when pipes, manifolds and fittings from different manufacturers differed in size so much that high-quality assembly was impossible. And I had to buy other fittings. So please check if they are the same size before purchasing.

Before installing the manifold, install each consumer's plumbing, water filters, meters and a non-return valve. And only then install and connect the collector. This sequence of actions will reduce the load on the joints and prevent damage during installation (this is important if you have no experience of such work).

The use of collectors greatly increases the cost of laying a water supply system and increases the comfort of using water. From the article, you learned how to choose collectors, what is necessary for their installation and in what sequence to install collector water supply systems.

The kitchen leads to the scream of the one who is taking a shower in the bathroom. The classic way of wiring intra-house networks did not cope with such a situation in any way.

Do-it-yourself piping is as easy as shelling pears

Where and how best to install the comb?

The place where the comb will have to be mounted is best determined during the design of the plumbing system. But most often you have to mount it in an existing circuit. The main criteria when determining the location are:

- availability for repair and installation;

- moderate to low humidity;

- load-bearing wall on which the comb can be fixed;

- additional lighting with the ability to work in emergency mode.

Sometimes the comb is generally mounted in a separate room, or special collector cabinets are installed specifically for it.

The combs are mounted on hot and cold water pipes. In order to avoid confusion and for ease of use, manufacturers make models in different colors (red and blue).

The nuances of installing the comb:

- The installation should be done by a specialist. Without specialized knowledge, an ordinary layman will experience difficulties during installation.

- Use clamps to secure the device to an enclosure or wall.

- Installation of the assembly is done without additional sealing.

- Separate collectors are installed for cold and hot water.

- In a water supply system, this unit is mounted after the filter and pressure reducer.

- The distribution manifold must be completed with shut-off valves (control and shut-off type).

- In the case of equipping the water supply of a two-story house, it may be necessary to use a circulation pump.

Installation should be done only after the wiring system has been drawn up. Subsequently, it is recommended to consider possible system upgrades. To do this, it is recommended to leave several free connections in the comb, closing them with a cap.

Types of pipe routing in an apartment and a house

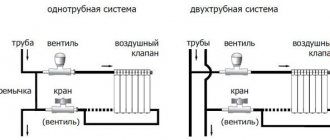

Time does not stand still, and today a scheme or a house can be carried out according to three schemes - tee, collector, and mixed.

- Tee method. The network is connected in a sequential manner, through tees. Its essence is that one pipe goes from the riser through all places of water consumption - taps in the bathroom, toilet cistern, kitchen mixer. The traditional option, the main advantage is low, the minimum amount of materials is used. The disadvantage is the dependence of each source of consumption on each other. For repair work, it is necessary to block communications throughout the room. Therefore, at each place of consumption, a separate shut-off valve is installed for repair and emergency work.

- The collector method, which is also called beam. The connection to the central water supply is made through a collector, to each place of water consumption from the riser there is a pipe. Personal for bathroom taps, separate for kitchen sink, and separate for toilet cistern. When a water distribution manifold is used, in the event of a pressure drop in the system, the pressure at each valve is the same. If necessary, you can install an individual pressure regulator for each branch. An additional convenience will be the concentration of all to one point. The disadvantage of this method will be the increased cost of installation, a pair of pipes, hot and cold water supply goes to each consumer.

- In apartment buildings, a mixed type of communication is often used.Connection to the central water supply from the common riser to the apartment is a tee system, and directly in the apartments there is a collector system.

The collector comb itself) is a thick pipe with one inlet and several outlets.

When laying heating networks, they are used in pairs, one at the entrance and one at the exit. Do not confuse the heating and water supply collector and the sewer collector. When draining waste, this is the main line into which the pipes enter, and the collecting tank or centralized drain.

Collector method of installing a water supply system

This method of laying networks has its advantages and disadvantages. There is no universal installation method suitable for all tastes and needs. Pros:

- The ability to turn off water in one place of consumption without affecting others. A water collector will allow you to shut off the water in the kitchen, leaving the water supply.

- The entire network is managed from a single control node. It is very convenient, especially when a separate room or sanitary cabinet is allocated for this.

- Uniform network pressure. You can take a shower without scalding yourself with boiling water from someone flushing the water in the tank. The collector water supply in the apartment gives an additional bonus - a more stable pressure in the network, when the pressure in the common house system rises, the collector comb will take on part of the surplus. In addition, each of the sources can be equipped with a pressure regulator.

- only with a pipe, without additional devices, which increases the reliability of the entire network as a whole.

- It is possible to install the water supply system in parts. As the repair work in one room is completed, it is enough to connect the next consumer to the comb.

The distribution manifold for water must be made in accordance with all technical regulations.

Cons of the system

Negative aspects are also indispensable. These include:

- A large amount of building materials. The tee system requires far fewer pipes.

- Separate space is required for placing the comb. Concentration of control elements at one point adds convenience, but only if there is a place for this. It is advisable to place the collector for the water supply in a separate room or in a collector cabinet.

So that the plumbing in the apartment does not bring inconvenience, it is better to use metal-plastic pipes. Guaranteed service life of 50 years, easy to bend and install, suitable for hidden installation in walls and floors.

Step-by-step assembly of the manifold with taps 1, 2, 3, 4

The assembly of the radial water supply system includes the following steps:

- connecting the shut-off valve to the central pipe;

- installation of a coarse filter;

- connecting a water meter;

- installation of a fine filter;

- pressure;

- distribution manifold connection;

- connection of each crane or other consumer.

Piping project for large houses, it is better to entrust a specialist

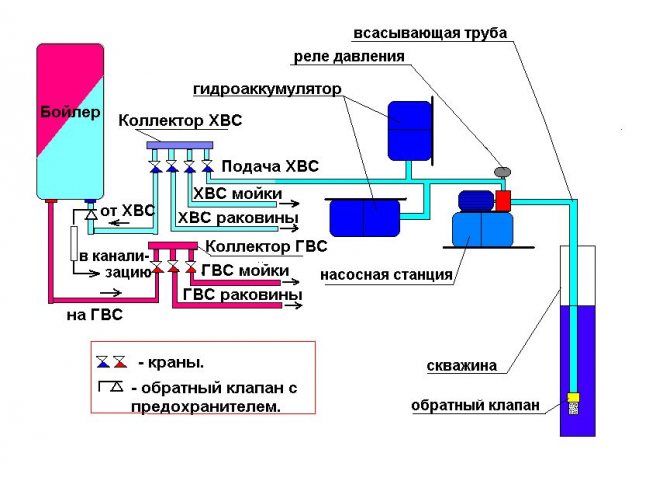

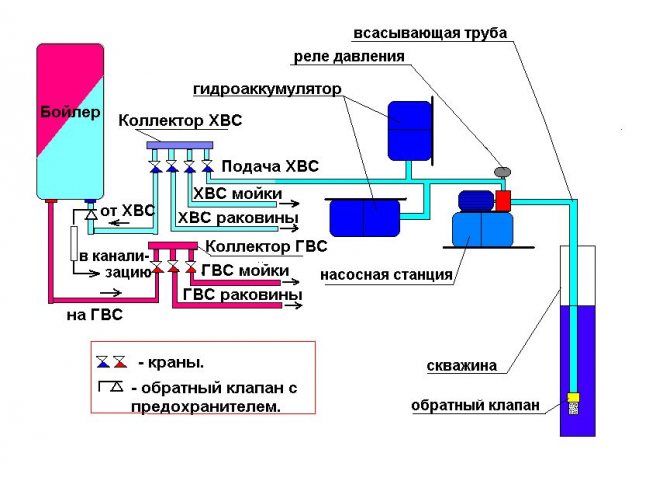

The procedure is the same for cold and hot water supply, it is permissible to use a homemade polypropylene manifold. If only cold water is supplied to the house, then one collector is installed directly, and the second after the water pump.

Distribution manifold

Now let's find out what distribution manifolds are for water supply. We already know that they allow several draw-off points to be supplied independently of each other; but how is it useful?

Benefits

In contrast to the sequential (tee), the scheme of the collector water supply system allows you to avoid a drop in pressure when water is flowing through an arbitrary device. Simply put - when you turn on the tap in the kitchen, the cries of a family member, full of pain and bitterness, do not come from the bathroom.

Collector circuit of water supply of a private house: each device is connected to the collector with its own connection

In addition, the water supply fed through the collector with taps in the collector cabinet allows you to turn off any plumbing fixture from one point. This is very convenient in public buildings, shopping centers or mini-hotels: in the event of a water leak, you can block it without even having access to the corresponding room.

disadvantages

Alas, the collector water supply scheme has several unpleasant features:

- Material consumption. Obviously, the total length of the water supply pipes will be several times greater than with the tee circuit;

- If you put a collector on the water supply, the connections have to be laid hidden (in the grooves or screed). Agree that a dozen parallel pipes on the walls of the bathroom and kitchen are a bit overkill;

Cold water and hot water supply lines are placed in a screed, grooves or are bred in the basement

- Concealed installation entails problematic localization and elimination of leaks. If the ceiling of the neighbors below starts to get wet, it will cost you a lot of work to find a fistula in the plumbing laid in the screed;

However: 99% of leaks occur not on straight pipe sections, but on fitting connections.

- Finally, the collector wiring of water supply pipes is carried out only at the stage of construction or overhaul of housing. With an open, daisy-chained plumbing, it can be replaced at any time without damaging the finish.

Opened water connections can be changed without compromising the finish

Installation

How to put a collector on the water supply of an apartment with your own hands and dilute pipes to mixers, a toilet cistern and other devices?

- On the tie-in into the riser, a shut-off ball valve, a coarse filter and a water meter are sequentially mounted (see.Water supply meter: everything you need to know about these devices). If necessary, they can be supplemented with pressure reducers and manometers;

In this water supply system, the installation of the collector was accompanied by the installation of a pressure gauge

By the way: it is advisable to increase the diameter of the inset into the riser from the standard 15 to 20 millimeters. The instruction is due to the fact that otherwise, the section to the collector may become a bottleneck when simultaneously parsing water through several devices.

Collector water supply system: the size of the tie-in in the riser - DU 20

- Distribution manifolds of water supply (cold and hot) are attached to the capital structures with clamps;

By the way: the installation of a collector for water supply is often accompanied by the installation of a so-called water hammer damper. Its functions are fully described by the name: this device avoids pressure surges during the rapid opening / closing of shut-off valves in the corresponding circuit.

- Ball valves are installed on the collector outputs;

Assembling the water supply manifold: you need to install ball valves on the outputs

However: the purchase of a separate shut-off valve is not always necessary. For example, many Valtec water manifolds come with shut-off valves.

Distribution manifold - Valtec water supply manifold equipped with ball valves on all outlets

- The threads of the valves or the collector outlets are supplied with fittings-adapters, to which the connections to the plumbing fixtures are connected;

- With concealed installation, the liners are thermally insulated. Insulation will allow to avoid the appearance of cracks in the screed or sealing of the groove, due to cyclic heating by hot water pipes, and will also reduce heat loss.

Please note: all liners are thermally insulated

What pipes to use for water distribution?

As we have already mentioned, the water supply scheme of interest to us - collector - implies a hidden laying of connections. At the same time, for reasons of fault tolerance, all serviced fitting connections must be mounted openly.

The conclusion is obvious: our choice is pipes supplied not in straight sections, but in coils.

The list includes:

- Cross-linked and heat-resistant polyethylene;

- Metal-plastic;

The collector water supply system in the apartment is mounted with metal-plastic on press fittings

- Corrugated stainless pipe (see Corrugation for water supply pipes: one step away from perfection).

Corrugated stainless steel for water supply

Attention: for central hot water supply with water supply from an elevator unit, we strongly recommend using only stainless steel pipes. In force majeure circumstances, the stainless steel will perfectly tolerate overheating, up to the maximum 150 degrees for the supply line of the heating main, and pressure surges. Polymer and metal-polymer pipes cannot boast of such a margin of safety.

The metal-plastic pipe in the photo collapsed during a water hammer

The only exception to the general rule is polypropylene. Polypropylene pipes are supplied in straight sections, but their connections are maintenance-free and are not inferior in strength to an integral section of the water supply system, so they can be safely laid in a screed or grooves.

Polypropylene manifolds for water supply can be connected directly to polypropylene connections, without additional fittings

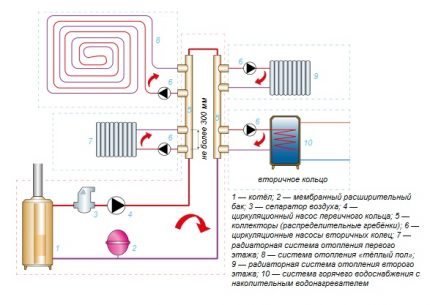

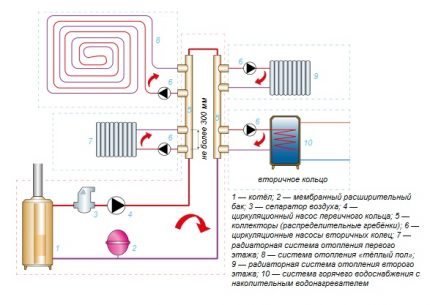

Collector method of laying heating systems made of polypropylene with the help of manufacturers Far, Rehau

Heating often requires a radial method of laying the network. Only collectors for heating will provide wiring in a private house and apartment. Advantages of heating through a manifold:

- Adjustment of heat supply in each room individually, in the winter garden and in the bedroom, the temperature should be different.

- It is possible to install a device for automatic temperature regulation in each room individually.

- A single place for managing the heating network.

- Since each heating battery is powered individually, it is allowed to use small-diameter pipes, the batteries will require more bandwidth.

- Phased installation, with the connection of new circuits as soon as they are ready.

There were also some drawbacks:

- An increase in pipe consumption, and as a result, a rise in the cost of installation and repair work.

- Mandatory use, and as a result, volatility.

- When in the house, the installation of an expansion tank is required to bleed air. The volume of the tank is at least 10% of the volume of the entire heating system.

Stages of assembling a radiant heating system:

- installation of a pressure pipeline from the boiler supply connection to the first collector;

- connect the first manifold for heating with the upper union of the battery;

- connecting the lower battery union to the second manifold;

- installation of a circulation pump between the second collector and the receiving connection of the heating boiler.

Heating systems that are installed inside floors and walls require a flexible flexible pipe. It is unacceptable to use connecting unions and fittings in places with closed access.

How to make a distribution manifold for water with your own hands: diagram

This is not a difficult matter, but a responsible one. The main thing is to properly plan and understand what network needs to be assembled, consumers will be involved, and what bandwidth is needed. You can assemble a manifold for heating with your own hands from plastic or metal. In essence, it is a pipe with one inlet and several outlets. It is easier to buy a heating manifold, but a device with the required characteristics may not always be available.

When designing a collector, it is necessary to consider:

- the diameter of the supply and return circuits must be three times the diameter of the consuming circuits;

- the supply and discharge of water or steam should be at the ends;

- the distance between the supply and return inputs is not less than 10 cm;

- provide for the possibility of connecting additional sources of consumption.

WATCH THE VIDEO

A do-it-yourself polypropylene collector is suitable for water supply. The plastic will cope with the operating temperature and pressure of the water supply. Collectors for the heating system are made of metal. The distribution manifold for water is able to make heating communication as efficient as possible.

In apartments, a simple wiring of water pipes is most often performed. A pipe runs from the riser. Further, with the help of tees, there are branches from it to plumbing fixtures. At the same time, few people know about another type of pipe routing - collector. And in vain, because such a system has a number of advantages that need to be discussed.

But first you need to talk about the types of wiring that exist in plumbing today. The first type is tee wiring.

In such a system, all consumers are connected from one pipe using tees. It is possible to install shut-off valves in front of each consumer in case of an accident.

Collector wiring.

This system has clear advantages over the tee system. A shut-off valve is installed at the entrance of the water supply to the apartment. The difference lies in the fact that each device has a separately supplied pipe. Moreover, all valves are concentrated in one place.

Manifold piping - all valves in one place

Sometimes you can find a mixed system.

This means that it contains elements of tee wiring and collector. For example, water can be supplied to the washbasin and the bathtub from the collector (that is, a separate pipe for each consumer), and the toilet bowl, bidet can be connected with a tee wiring.

How to make heating wiring with your own hands, how to install

It's easy enough to find on the Internet self-assembly diagrams of distribution manifolds, and at the same time, there is not enough information about the specific steps required to assemble this device. Note that the reader who decides to independently assemble the wiring must first draw up a sketch, according to which further work will be carried out.

Before making a drawing, you need to decide on the equipment, which will be used in the process of work and with which the finished device will work - radiators, expansion tanks, underfloor heating, consuming circuits, boilers, heaters, etc.

All working circuits will be connected to two devices - supply and return; this means that you, as a master, will have to assemble a simple coplanar collector, the design of which we described above. When the sketch is ready, the only thing left to do is to assemble the manifold.

The coplanar collector has a fairly simple device, so it will not be difficult to make it even for beginners who have not previously undertaken the assembly of such devices.

The master will need the following:

- Two hollow metal tubes with a round or square cross section. The length and diameter of the section is determined based on the required dimensions of the collector. These pipes will act as combs.

- Metal hollow tubes with double-sided threads. The optimal diameter is 3/4 inch, for the subsequent attachment of adapters and connecting the circuits to them.

- Cranes-adapters for circuits.

- Welding machine, cutter, markers for marking, building level, drill with a drill for metal, the diameter of the drill must correspond to the section of the nozzles for the contours.

The assembly is carried out according to a pre-made drawing: along the length of the combs of the inlet and outlet collectors, marks are made for the holes, into which the pipes with a double-sided thread are then placed. The distance between the pipes must be at least 100 mm.

Further, the structure is assembled using a welding machine in accordance with the drawing drawn up earlier. After assembly, it is necessary to clean the seams from scale, degrease and paint the surface of the distribution manifold.

Advantages and disadvantages

First you need to talk about the shortcomings of the collector system. Why is it not that collector wiring of water pipes is installed in all apartments? The answer here is quite simple: you have to spend a lot of money on creating a system. Much more work remains to be done than when creating a tee system.

So, to power a washbasin and a toilet, for example, you will need five meters of pipes for tee wiring, and nine meters of pipes for collector wiring. In addition, special shut-off valves for manifold wiring are expensive.

If the renovation in the apartment is not related to the global replacement of water pipes, then there is a difference between one pipe on the wall and six pipes. Therefore, most often the collector system is created when the entire water supply system changes and it is possible to hide the pipes in special boxes or in the wall. Undoubtedly, the collector wiring of water pipes has advantages.

The main advantage is the ability to control all plumbing fixtures from one point.

In a small apartment, such a feature may not say anything to the owner. However, when it comes to hotels, large establishments, such a system is a real boon. And then what if a pipe burst in a hotel, for example, in one of the rooms? Disconnecting the entire hotel from the water supply is suicide, especially if the establishment has a high "star rating". The hotel's rating will drop the moment the water is turned off. But if you close the water supply from the collector to one room, that's another matter.

The collector system is especially useful on the heating system. For example, you can reduce the temperature on one of the radiators using the throttle valve. In the water supply system, you can limit the use of water, for example, at the washbasin, where children often like to play around. What if they leave the tap open and leave?

No, the apartment will not be flooded, but the meter will be able to run about seven to eight cubic meters of water in a few hours, until the adults find the open tap. If the tap is opened halfway, then the numbers on the counter will be half as much.

Another situation can be imagined. With tee wiring, a shower and a toilet are connected. You bathe in the shower, hot water dilutes the pressure of cold water. Then, at this time, your wife went to the toilet and flushed the toilet with water from the cistern. What will be next? The cold water pressure is immediately distributed equally to the shower and toilet. The fact that water will drain slowly into the toilet is not a problem. But getting under the boiling water from the shower is not very pleasant. In the case of collector wiring, the water supply to the shower and toilet will be the same in any case.

Implementation of the project

Example of manifold wiring

In order not to become a victim of the above situation, you need to connect a collector with a correctly selected pipe diameter. For the shower and the tank, you can make a pipe from a half-inch product. At the same time, the entrance to the collector should be several times larger.

But you shouldn't be zealous either. There is no need to put an entrance doubled. A slight increase in the input channel compared to smaller outputs will already give a positive result.

It is convenient to work with these materials. The benefits of using plastic should not be repeated.

It turns out that the work can be difficult, but the result is worth it. Collector wiring allows you to save money on the purchase of tees. And if metal-plastic pipes are installed, then tees for them are very expensive. But, nevertheless, there are no special restrictions. The owner himself makes the decision. It should be noted that each owner can independently perform collector wiring. But just before starting work, it is necessary to draw up a diagram on paper, which can then be implemented in practice.The collector system for distributing water pipes requires accuracy in work.

As you might guess, the system will have many pipe connections, adapters, valves and other elements. Therefore, it is very important to pay special attention to every detail so that later you do not have to redo all the work, which will add even more hassle.

Today you can buy metal-plastic pipes, stainless steel pipes and in any construction or specialized store. There are also all kinds of connections, adapters, taps. That is why it is necessary to have a work flow chart in advance. It will allow you to buy the required amount of building materials for the system.

The plumbing system is a rather complex structure, consisting of many components. Each of them is irreplaceable and important in its own way.

In addition to the pump and the water source, it is also required to use, in fact, the line through which the water will flow to the consumer. It is called a collector.

Features and purpose

The collector is an important part of the water supply system in an apartment or private house. It performs an important function - it stabilizes the pressure in equipment that consumes water and, in fact, delivers it from the source to the consumer.

This can be, for example, a mixer or a toilet in an apartment. A simple example known to many can be cited. When someone is taking a shower, do not turn on the water in the kitchen, as this will lead to a temperature drop.

That is, a person in the bathroom can burn themselves with hot water or cool down with cold water, depending on which kitchen tap was turned on. If the apartment has a collector, such problems will not arise.

The manifold for the pipeline is installed first on the hot water supply, and then on the hot water supply system. Installation is carried out using a collector pair.

If a collector is installed in the heating system, then the liquid is first supplied to the batteries through this device. The water supply works in a similar way: the central branch goes into one collector, and is not divided into a large number of branches.

Classic wiring diagram

Any water supply system (home or in an apartment) is designed to supply water from a source to a consumer. And if there is only one consumer, the scheme is clear, but what if there are several?

Then earlier they acted simply by inserting a T-shaped splitter into the pipe. The next consumer was connected to one outlet, and a water-consuming device to the other.

This solution is widely used today in water supply for houses and apartments. After all, it has important advantages over the others: simplicity of design, availability and small length of pipes.

But this approach also has disadvantages:

- difficult repair - to carry out the procedure for one consumer, it is necessary to turn off the entire system;

- if several consumers are disconnected, the pressure in the system is significantly reduced: the further “along the pipe” from the source, the worse the indicator. In such a situation, the close consumer will actually be in a privileged position. An example with the simultaneous consumption of water in the bathroom and in the kitchen was given above.

How to properly install a heating comb

Let's make a reservation right away that the difficulty lies not in the installation of the distribution manifold itself, but in the correct choice of the element, its connection and piping. The choice of the comb is carried out according to the maximum thermal power of the heating system, it is indicated in the passport for the product. For example, a device with a distribution pipe diameter of 89 mm (DN80) and 1 ”fittings (DN25) is designed to operate in a system with a maximum power of 50 kW. If it exceeds this value, but does not reach 100 kW, then the diameter of the collectors will already be 109 mm (DN100).

For reference. On sale there are distributors made of shaped pipes.In fact, they do not differ from round ones except for the cross-sectional shape. The cross-sectional area is important here, not its configuration, although from a hydraulic point of view, a spherical passage is better.

It is quite simple to install the comb: you need to attach it to the wall or install it on the floor (depending on the provided fasteners) in a horizontal position, after which you can start strapping. There are 2 connection options:

- without additional circulation pumps and hydraulic switches;

- with an individual pump on each branch and a hydraulic arrow for equalizing pressures.

Note. The line coming from the heat source, in any case, is connected to the end fittings of the collector.

First, we will analyze the first option, it is the simplest and is used in the case when several radiator heating circuits need to be powered from the boiler room. Then the temperature of the network water in all branches can be the same, which means that its regulation is not required. All consumers are connected directly to the comb, and circulation is provided by one pump, which is located near the boiler.

An important point: the pump unit must be carefully selected in terms of capacity and generated pressure, for which it is necessary to perform a hydraulic calculation of the system in advance.

Since the resistance of the branches is different, then to ensure the required flow rate of the coolant in each of them, it is necessary to balance. To this end, during the installation of the comb with your own hands, you should install not ordinary shut-off valves on the return pipelines, but balancing valves. With their help, when the system is running, the flow rate in each circuit is regulated, with a certain skill and the availability of time, this can be done "by eye".

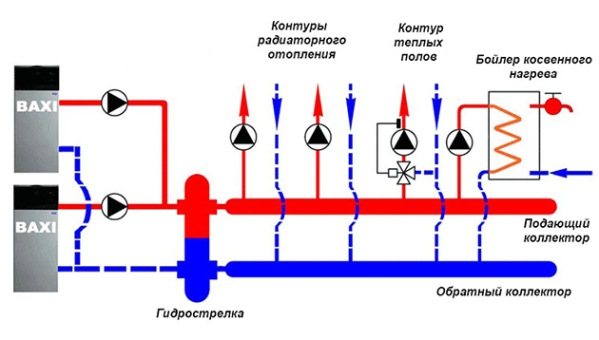

But what to do when consumers need to supply water at different temperatures? For example, it is necessary to provide a heating agent for radiator heating (t = 45-80 ° C), underfloor heating (t = 30-45 ° C) and an indirect heating boiler for hot water supply (t = 80 ° C). Then you cannot do without mixing units with three-way valves designed to reduce and control the temperature. Only now it will be impossible to realize this without individual pumps on the piping to the comb. An example of a strapping is the following scheme:

As you can see in the figure, here, in addition to the distribution manifold, there is a hydraulic separator, which creates a zone of zero resistance in its section. Thanks to this solution, all pumps work independently and provide the required coolant flow for their circuits. The only condition: the actual performance of the boiler pump must be greater than that of the units of all branches combined.

Important. In order to correctly install and connect the comb with a hydraulic arrow to the heating system, it is necessary to perform a hydraulic calculation, otherwise the pumps cannot be selected in terms of performance.

Collector water supply system

The aforementioned disadvantages do not have to be faced if a manifold unit for a water supply or a parallel system is used.

The manifolds look like cylinders with an inlet opening at the end and several outlet openings on the sides. The latter are joined by liners - one for each consumer.

Pipes from the source are connected to the collector inlet. Using manifolds for connecting the water supply, a large number of consumers can be connected in parallel. If there are unclaimed outputs, plugs are placed on them.

As a result, each consumer in the apartment receives a stable pressure.

Collector solution advantages:

- On such a system, all consumers have “equal rights”: if the pressure drops, everyone receives the same amount of water as the others.

- Serviceability - All valves, gauges and other gauges are installed at the manifold outlet so they can be found in one place.If it is necessary to repair the system at one consumer, it is turned off, the rest consume water, as before.

- Pressure can be controlled in each instrument by installing pressure regulators on each manifold.

The collector system has one significant drawback - the presence of many wiring. As a result, the costs of pipes and the laboriousness of the installation of the system increase.

As a result, the design becomes much more expensive and its appearance deteriorates. Therefore, collectors are good helpers if hidden wiring is done.

Quite often, a mixed system is used in residential multi-apartment systems: on the floor, consumers use a collector circuit, from the riser to the floor - a tee.

However, whichever system is, it should be chosen, taking into account the projects and calculations of the house.

Installation rules for heating systems

Since the manifold can be installed either on the heating system or on the water supply system, it is worth considering each option, how the solution is implemented.

Pipes to radiators have different lengths. Even modern designs are characterized by a certain hydraulic resistance, which is directly proportional to the length of the product.

Heat loss also occurs. Therefore, in order to equalize the temperature, the heating system must be regulated. Therefore, instead of conventional valves, it is worth using two chokes for each device.

The assembly of the heating system with the manifold takes place in the following order:

- the pressure pipeline carrying the coolant to the first collector is fixed to the supply boiler nozzle;

- pipes from the collector are diverted to the upper fittings of the radiators;

- a second collector is installed not far from the first; pipes from the lower radiator connectors are connected to it;

- the injection pump is connected to the second manifold;

- from the pump, pipes are introduced into the receiving boiler union.

Such a device is used for closed and open heating systems. In the first case, a sealed expansion tank is mounted at the top point of the pipeline, in the second - an open one.

It should be noted that the receiving and supplying collectors must be in the middle of the house. This is due to the fact that it is from this point that the shortest distance to windows with radiators.

Design features (video)

Installation rules for water supply systems

The collector water supply is assembled like this. The swivel valve is connected to the central pipe. A coarse filter is installed on it.

Next, a back pressure valve is installed, which resists the outflow of water into the pipe if there is no pressure on it. The manifold is connected to the valve.

Several branches with valves depart from the collector, to which the pipeline is connected to each consumer. The procedure is repeated for a cold and hot water pipe.

If the central pipe has only cold water, then an input to the boiler must be connected to the first collector. And its output is inserted into a separate manifold that distributes hot water.

Therefore, it is necessary to choose a collector, taking into account the number of taps in the house.

When choosing a place where the collector wiring of the water supply will be installed, it should be remembered that all pipelines will begin their journey from this point.

This method is often used for apartments. The collector is installed behind the cistern. This allows you to minimize the distance to the bathroom or kitchen, as well as the cistern itself.

Installation is carried out using a collector assembly pair. First, the collector and fasteners are connected, then the place for fixing on the wall is marked.

Most modern apartments use a variety of water systems. At the same time, individual citizens regularly experience problems with water supply. They are associated not only with the lack of water, but also with its pressure, and sometimes with a sharp temperature drop.This article will discuss why such problems occur and what are the ways to fix them. At the moment, with various options for the layout of the pipeline of the apartment, not all users understand the special difference in the existing water supply systems.

The most common are three schemes:

- Serial / tee.

- Fan / collector.

- Mixed (serial or parallel).

Actually, a manifold for a water supply system is a device that ensures the distribution of flows in the water supply system along the existing distribution circuits. Also, collectors are used not only in water supply, but also in heating, compressed air pipelines and other systems.

In the event of a lack of pressure in the water supply system, the installation of a collector may well be the answer to the question "how to increase the pressure in the water supply system". The presence of a collector in the water supply system allows not only to simplify the supply of water to various users (plumbing and household appliances, kitchen, bathroom, etc.), but also to eliminate the need for additional seals. The latter is especially important, because it is in the places where the pipes are connected that the main threat of possible damage and breakthrough of the pipe lies.

Also, the presence of a collector makes it possible to neglect such an indicator as the pressure of the water supply in the apartment, since if there is a collector, a separate pipe is supplied to each user and the water pressure (as well as its temperature) remains unchanged for all users. It is also possible to shut off individual pipes without prejudice to other users.

For most people who decided to buy a water supply manifold, such a decision resulted in an improvement in the comfort of using the water supply in the apartment. In the presence of one pipe from the riser, the water pressure often weakens (there may be a temperature difference), the purchase and installation of a collector can eliminate such a problem.

In many ways, the principle of operation of the collector is similar to the principle of operation of the tee. That is, there is one source of water at the inlet, and two or more are obtained at the outlet. An important feature of the collector is that the pressure in the water supply system does not decrease.

This is due to the fact that the diameter of the inlet is 1.5 times the diameters of the outlet.

Water pressure

Since the installation of a collector solves the problem with the pressure in the water supply system, it is important to understand how much water pressure should be in the water supply system a priori. Pressure is measured in atmospheres and bars. 1 bar equals 10 meters of water column. Accordingly, if it is necessary to deliver water to a height of 20 meters, a power of 2 bars will be required.

The answer to the question, what is the pressure in the water supply system in the apartment, will depend on the height of the floor.

However, it is important to note that a pressure of 2 atmospheres is usually enough for everyday use, which includes a shower, washing dishes, washing, running a washing machine and many other procedures. A pressure of 4 atmospheres is able to support the operation of a jacuzzi or, for example, watering a garden plot.

So what is the optimal water pressure in the plumbing of an apartment building? Currently, the water pressure in the apartment, in accordance with building codes, is equal to 4 bars (atmospheres). In practice, the pressure in multi-storey and especially old buildings is much lower than normal. In such cases, the installation of a collector is required.

Types and types of collectors

To determine which type of collector is suitable for the apartment, the type of pipes of the water supply system should be taken into account. This is due to the fact that the mounting methods for the collectors are different, not all collectors can fit plastic pipes. At the very least, problems may arise during the installation of the device. It is also important to decide on the material of the product, which affects the price of the product.

There are several types of collectors:

- Brass manifolds (nickel plated possible).

- Steel manifolds (stainless steel).

- Polypropylene manifolds.

- XLPE collectors.

The cost of collectors depends on the material of manufacture and ranges from 400-2500 rubles. Also, the types of collector differ in the method of attaching pipes to it:

And collectors are also divided by the number of taps (from 2 to 6).

Manifold modifications

Today, there are many varieties of collectors for heating systems on the equipment market.

Manufacturers offer both connecting links of the simplest design, the design of which does not provide for the presence of auxiliary valves for regulating equipment, and manifold blocks with a complete set of built-in elements.

A manifold block that includes all the necessary functional elements to create conditions for the uninterrupted and high-performance operation of the heating system

Simple-to-design devices are brass models with inch bore branches, equipped with two connection holes on the sides.

On the return manifold, such devices have plugs, instead of which, in the case of a "build-up" of the system, you can always install additional devices.

Intermediate assemblies, which are more complex in design, are equipped with ball valves. For each branch, they provide for the installation of shut-off control valves. Fancy expensive models can be equipped with:

- flow meters, the main purpose of which is to regulate the flow of the coolant in each loop;

- temperature sensors designed to control the temperature of each heater;

- automatic air release valves for draining water;

- electronic valves and mixers aimed at maintaining the programmed temperature.

The number of circuits, depending on the connected consumers, can vary from 2 to 10 pieces.

Regardless of the complexity and versatility of the equipment, materials that are resistant to external factors are used in the manufacture of manifold block combs.

If we take the material of manufacture as a basis, then intermediate prefabricated collectors are:

- Brass - they have high performance parameters at an affordable price.

- Stainless - Steel structures are extremely durable. They can withstand a lot of pressure with ease.

- Polypropylene - models made of polymeric materials, although they differ in a low price, are inferior in all characteristics to their metal "brothers".

Models made of metal are treated with anticorrosive compounds and covered with thermal insulation to extend the service life and increase the operational parameters.

Separating structures made of polymers are used in the arrangement of systems heated by boilers with a capacity of 13 to 35 kW

Details of the device can be cast or equipped with collet clamps that allow connection with metal-plastic pipes.

But experts do not advise choosing combs with collet clamps, since they often “sin” by leaking coolant at the valve junction. This is due to the rapid failure of the seal. And it is not always possible to replace it.

Collectors are used in one- and two-pipe heating schemes. In one-pipe systems, one manifold supplies the heated coolant and receives the cooled