At the moment, there are many ways to obtain gas. Each device is based on a gasgene system. Its working principle is gas processing of wood into heat.

A gas generator has been developed as an additional method of generating energy. Today gazgen is considered to be an excellent multifunctional equipment. Such a unit is used to heat cars and rooms. The operating principle of the boiler is not straightforward. Wood-fired gasgene consists of numerous necessary elements.

It is allowed to use both purchased devices and handmade ones.

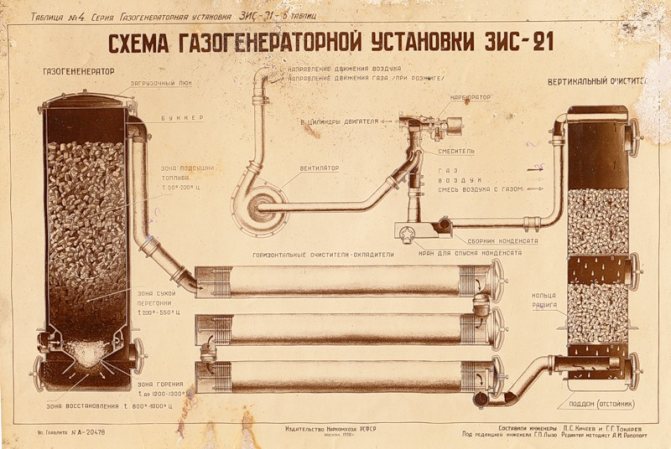

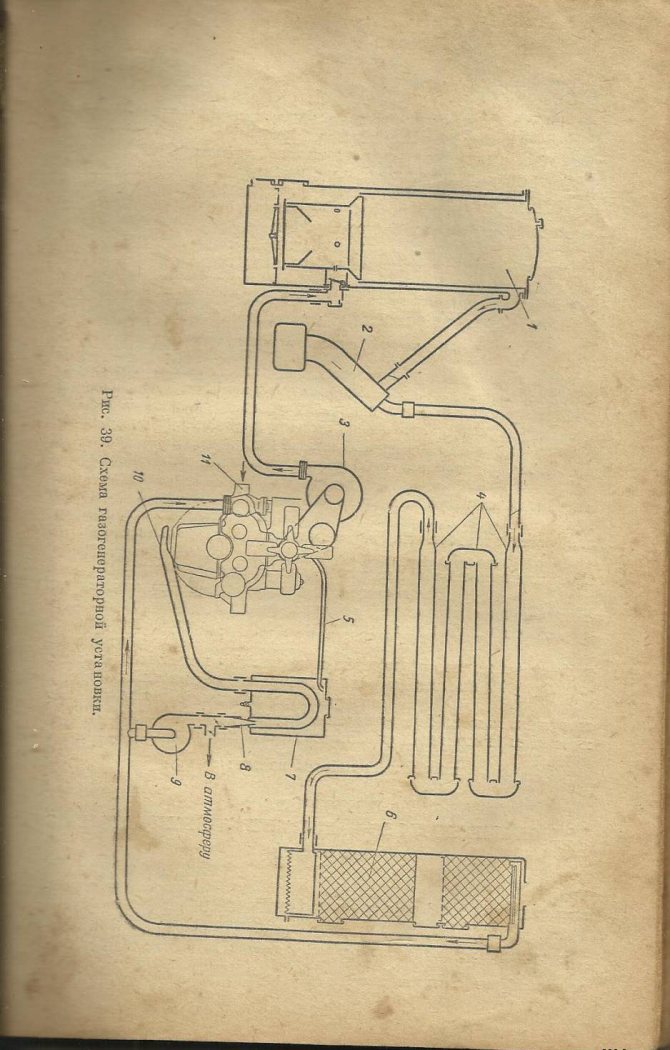

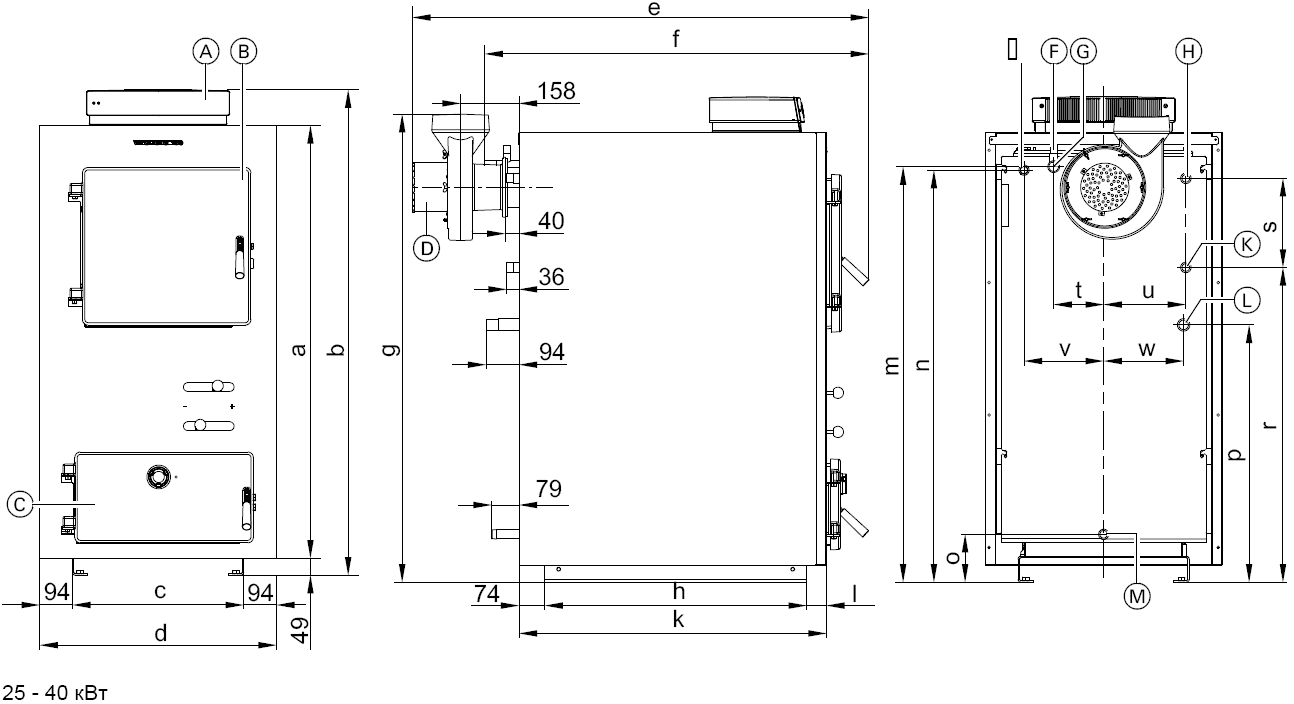

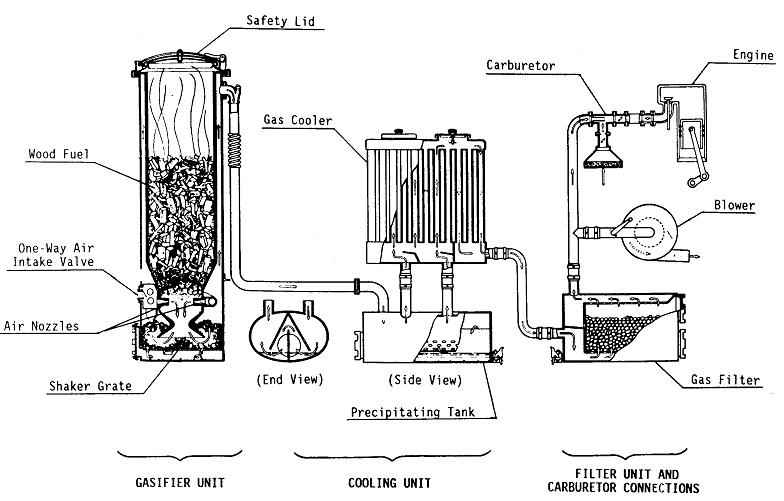

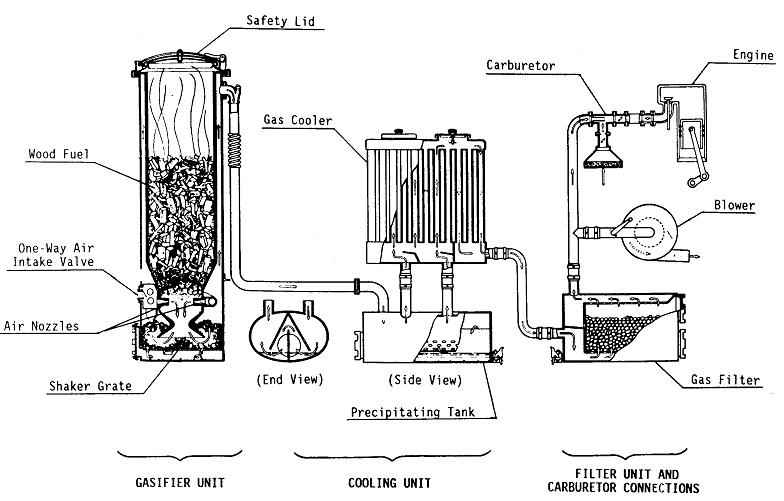

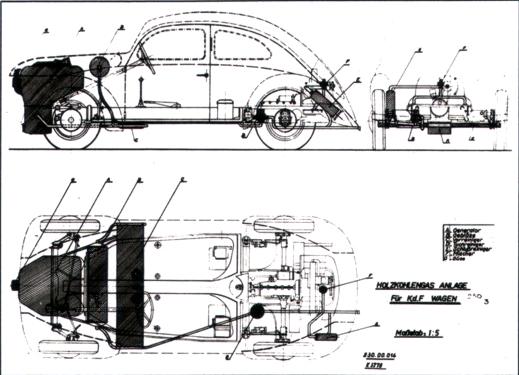

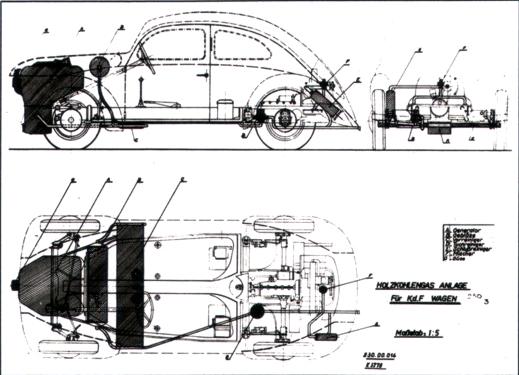

Assembly drawing:

Video about the device of a homemade gas generator

Benefits of gazgen

- The efficiency of such boilers varies within 78-96%;

- One tab on the wood burns up to 12 hours. With top burning, the time increases to 1 day. The corner burns for more than 1 week;

- The fuel material burns out completely. Because of this, the gas duct is cleaned no more than 1 time per month;

- You can set up automated work;

- The smallest number of harmful components gets into the air;

- Financially such devices are the most economical;

- It is recommended to use wood dried up to 50% as a full-fledged fuel source;

- The use of non-chopped logs, reaching a length of 1 m, is allowed;

- Disposal of polymers is permitted in boilers;

- The device is highly secure.

Advantages and disadvantages of gas generating plants

The list of advantages of this type of aggregates can include

:

- sufficiently high efficiency (75-80%), provided that it runs on dry fuel;

- the duration of the combustion process (there is no need to constantly put firewood in the firebox, the installation can work for about a day on one tab);

- the fuel burns out almost completely, forming a minimum of ash and slag, that is, it is relatively rare to clean the gas duct and ash pan;

- emissions into the atmosphere are minimal, so people who advocate respect for the environment urge the use of wood-fired gas generators instead of gasoline or diesel fuel.

The disadvantages include

:

- volatility of the unit, if an electric fan is provided in the design;

- a decrease in the power of the installation by 50% leads to instability of combustion, due to which tar begins to be released, which pollutes the gas duct;

- Buying a ready-made installation is not economically viable - if there is a goal to save money, you need to mount a gas generator that runs on wood, independently from scrap materials.

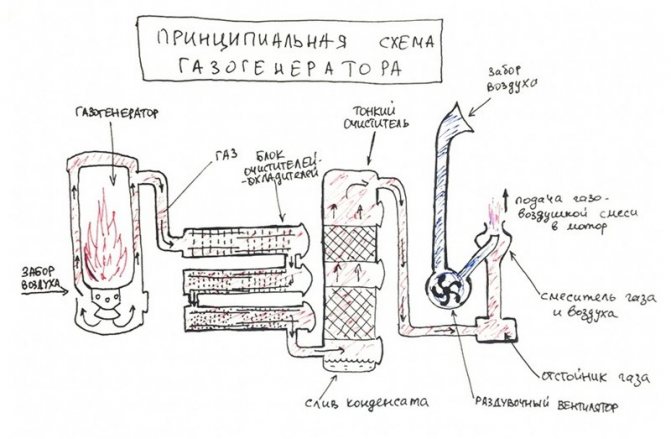

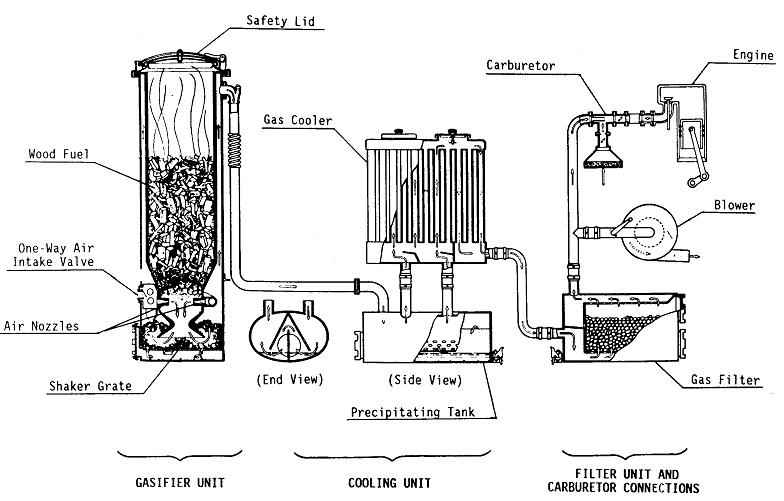

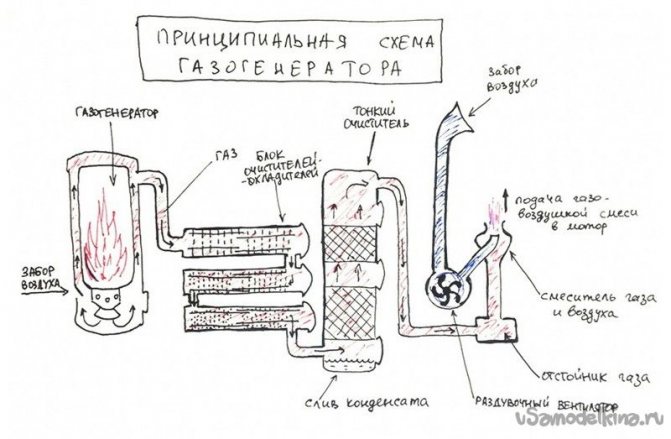

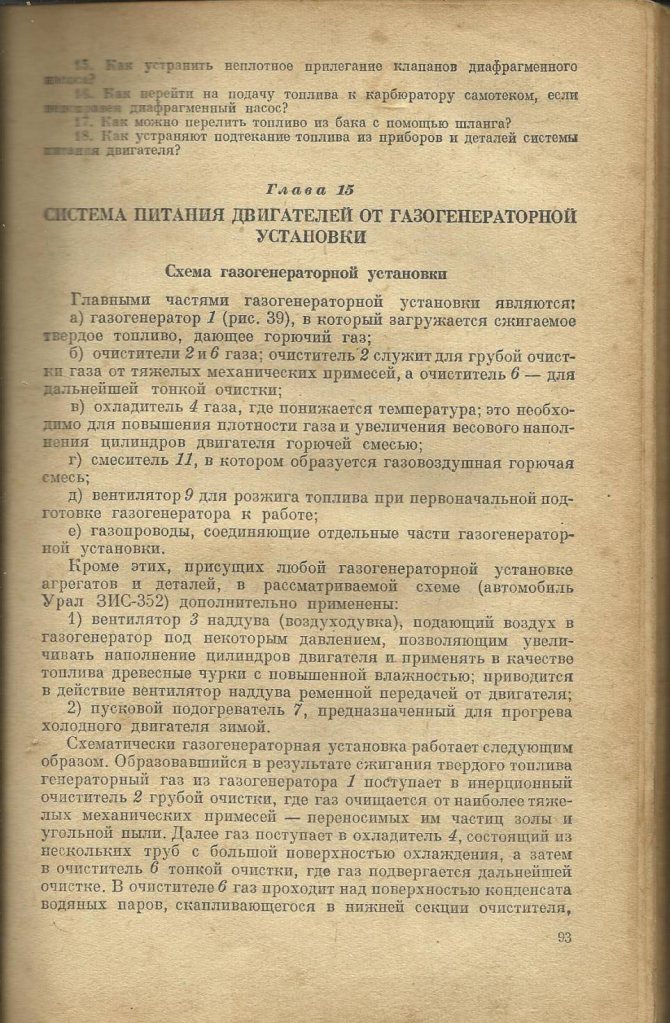

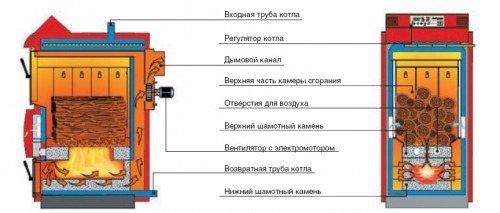

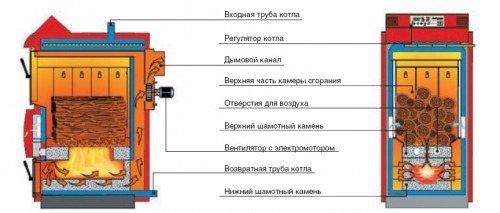

The principle of operation of the unit

Combustible gas can be produced from any type of fuel in gasgene. The main secret is that oxygen gets into the chamber. The volume of oxygen supplied is not enough for full combustion of wood. In the process itself, a sufficiently high temperature must be observed, exceeding 1200 ° C. The generated gas is gradually cooled down, getting to the source of consumption or the car engine.

Gas generator device

The main difference between gazgens on solid materials is that in all cases of operation of the unit on wood the process of combustion of material and wood gas is observed.

Soot is not emitted in this case.

How does the propulsion system work

Cars in which such a device is installed use gas in the form of a fuel mixture generated by burning wood, coal or other components. The principle of operation of a gas generator on a do-it-yourself car is based on incomplete combustion of carbon.In this case, a third of the energy is released and, therefore, the resulting gas has a lower calorific value than the starting material.

We watch a video about gas generators and the principle of operation:

In the process of burning wood or coal with the addition of steam, an exothermic reaction occurs between the resulting composition and water, which in turn leads to the separation of the mixture into hydrogen and carbon dioxide. This leads to a decrease in the temperature of the produced substance and at the same time increases the efficiency up to 80%.

It is possible to use gas without cooling, in case of complete combustion of solid fuel. At the same time, the gasification efficiency can reach 100%.

But since the gas is diluted with nitrogen during the purification process, its caloric content is low. But at the same time, less air is used for its combustion, therefore, it is not much inferior to traditional fuel-air mixtures.

Do-it-yourself gas unit for a car

One of the simplest units will be assembled on the basis of an old gas cylinder. At the same time, all other components are also easy to find and they are inexpensive. So, let's start assembling a car gas generator with our own hands.

Simple and eco-friendly

The balloon serves as a body. Inside, it is divided into two zones:

- Downloads;

- Burning.

And here is the core of the gas generator. It is possible to use a metal box welded from steel sheets as a body.

But nevertheless, the best option is a cylinder, since the welding places can leak over time, which will lead to an emergency. It is also important to take into account that if gas accumulates inside the generator, it can lead to an explosion, therefore it is better to assemble the structure in such a way that it immediately goes into the engine. You can find a gas generator diagram for a car on the network.

We watch the video, stages of work:

But, having chosen a gas cylinder as a basis, it is necessary to take into account the fact that a mixture may remain in it and during cutting it can cause a small explosion. To avoid this, you need to either blow it out with compressed air or cut it by filling it with water.

Next, the bottom is cut and the neck is cut for loading the fuel. The lid should be convenient for filling wood waste. Then the grate is made. In this case, it must be borne in mind that it will have a thermal load.

The next step is to prepare the cover for the hopper. It can be made of a sheet of metal, but must be insulated with an asbestos cord. So that it does not burn, you need to treat it with graphite grease. You can buy it on the household market.

Next, a lance is made, which will bear the main thermal load, as well as a filter. If wood or coal is supposed to be used as fuel, then this component is mandatory, since it will get rid of a large amount of suspended dust particles contained in them. And in order to avoid them entering the carburetor, a filter is used.

The next detail is the radiator. It can be made of duralumin radiators or ordinary water pipes. It should be borne in mind that the flow area of the radiator must exceed the size of the pipes connected to it. This will help to avoid resistance to the gas when passing through it.

We continue to make the unit with our own hands video 2:

The last detail is the cleaning filter. It can be made of modern and inexpensive materials that are easy to clean and have a long service life. A drawing of a gas generator for a car is easy to find on the network.

Next, it remains to fix the gas generator in the trunk and connect it to the engine. For this, a tube is supplied through which wood gas will flow into the motor. Together with it, the main fuel remains - gasoline. And the last step is to adjust the calorie content of the consistency.

Installation and place of installation

Installation is prohibited:

- In crowded places;

- In poorly lit rooms;

- In the cellar and basement;

- Near devices that emit harmful substances;

- Near flammable machines;

- Near self-exploding mixtures;

- Near acetylene-releasing material;

- In coal-fired and wood-fired boilers;

- Near compressors, air conditioners, and ventilators taking oxygen;

- At a distance of less than 1 m from gas heaters;

- Near thermal and electrical devices;

Install the device away from driveways and walkways. It must be fenced.

Installation must be carried out in places inaccessible to children and pets. The device requires constant supervision.

How to make a gas generator yourself?

In order to create a gas generator set, it will take a lot of effort, since it should not take up much space or be heavy, but at the same time be highly efficient. Stainless steel will be the ideal material for the housing, filter and cooling device. However, the price of this material is quite high compared to standard steel.

For the outer container, you can use an iron barrel or rolled metal (the thickness should not be less than 1 mm), and the inner one can be made from a gas cylinder or a receiver from trucks. It is worth providing holes for the ash pan so that it is possible to clean it. The combustion chamber must have a throat (at the bottom) for tar deposits. The grate is excellent from fittings. Nozzles can be bought, since they are on sale in different sizes and at a low cost. The lid can be made from sheet metal. Filters can be used fire extinguishers, and the cooler - "accordion" used in the heating system. In addition, you will need a mixer and a fan with a relay.

Repair and service

Easier to service purchased gasgen... A hand-made device requires more effort and time. The gas generator must be suspended in the event of a gas leak. It is also forbidden to use the device if it needs to be repaired. After turning off the gas generator, it is necessary to thoroughly ventilate the room, remove small children and animals from the building. All gas must be released, water drained. The mine is thoroughly cleaned from the remnants of sludge and carbide. The generator itself is completely disassembled and washed with water. At the moment there are a large number of private and public companies engaged in the repair of gas generators. The standard cost of repairs varies between 1500-6000 rubles.

When flushing the device, it is necessary to use water without the presence of chemical impurities.

Gas generator - wood-fired car!

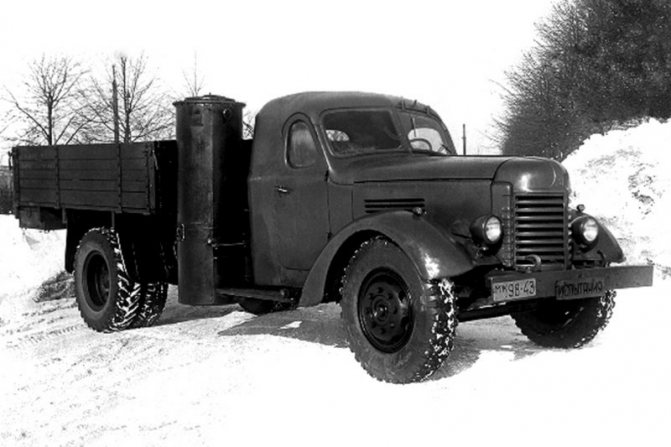

Gas generator in a car

The cost of gasoline and diesel fuel is skyrocketing as a space rocket leaves the launch pad. Hydrocarbon reserves are decreasing at the same rate. Alternative energy sources - hydrogen and electricity - are being introduced into production cars with varying success. But, as it turns out, there is another, well-forgotten alternative - a gas generator, and if in simple terms, ordinary firewood is used as fuel!

During World War II, almost every vehicle in Europe was converted to use wood for fuel. Wood gas cars (also called gas-fired cars), although they lose their elegance in appearance, are very efficient, compared to their gasoline counterparts, in terms of environmental friendliness and can be equal to electric vehicles.The rise in fuel prices is leading to renewed interest in this almost forgotten technology: around the world, dozens of hobbyists are driving their homemade gas-fired vehicles around the city streets.

Wood-fired car, gas generator, Gas generator in the car, synthesis gas, wood-fired car, car gas generator, DIY gas generator

The process of formation of a gas generator gas (synthesis gas), in which organic material is converted into a combustible gas, begins to occur under the influence of heat at a temperature of 1400 ° C.

The first use of wood for the formation of combustible gas dates back to 1870, when it was used for street lighting and cooking.

In the 1920s, German engineer Georges Amber developed a wood gas generator for mobile use. The resulting gas was purified, cooled a little, and then fed into the combustion chamber of the car engine, while the engine practically did not need to be altered.

Since 1931, the mass production of Ember generators began. In the late 1930s, about 9000 vehicles were using gas generators exclusively in Europe. The Second World War Gasification technology became commonplace in many European countries during World War II, due to the limitation and scarcity of fossil and liquid fuels. In Germany alone, by the end of the war, about 500,000 vehicles had been retrofitted with wood gas generators.

Gas-fired civilian vehicles during World War II

About 3,000 "gas stations" were built where drivers could stock up on firewood. Not only cars, but also trucks, buses, tractors, motorcycles, ships and trains were equipped with gas generators. Even some tanks were equipped with gas generators, although the Germans produced liquid synthetic fuels (made from wood or coal) for military purposes.

500,000 gas-fired civilian vehicles by the end of the German war

In 1942 (when the technology had not yet reached its peak in popularity), there were about 73,000 gas-fired vehicles in Sweden, 65,000 in France, 10,000 in Denmark, 9,000 in Austria and Norway, and almost 8,000 in Switzerland. Finland had 43,000 gas generating machines in 1944, of which 30,000 were buses and trucks, 7,000 cars, 4,000 tractors and 600 boats.

Gas generator vehicles also appeared in the United States and Asia. There were approximately 72,000 gas-fired vehicles in Australia. In total, over a million wood gas vehicles were in service during World War II.

After the war, when gasoline became available again, gas-generating technologies almost instantly fell into oblivion. In the early 1950s, only about 20,000 gas generators remained in West Germany. Research program in Sweden

Rising fuel prices and global warming have led to renewed interest in firewood as a direct fuel. Many independent engineers around the world are converting standard vehicles to use wood gas as vehicle fuel. Typically, most of these modern gas generators are developed in Scandinavia.

In 1957, the Swedish government created a research program to prepare for the possibility of quickly switching cars to use wood gas in the event of a sudden oil shortage. Sweden has no oil reserves, but it does have huge forests that can be used as fuel. The aim of this study was to develop an improved, standardized installation that can be adapted for use on all types of vehicles.This research was supported by the car manufacturer Volvo. As a result of studying the operation of cars and tractors over a length of 100,000 km, a lot of theoretical knowledge and practical experience were obtained.

Some Finnish hobbyists have used this data to further develop the technology, such as Juha Sipilä (pictured left).

A wood gas generator set looks like a large water heater. This unit can be placed on a trailer (although it makes it difficult to park the car), in the trunk of a car (it takes up almost the entire luggage compartment) or on a platform in the front or rear of the car (the most popular option in Europe). On American pickup trucks, the generator fits in the back. During World War II, some cars were equipped with a built-in generator completely hidden from view. Gas generator fuel

Fuel for gas-fired vehicles consists of wood or wood chips (photo on the left). Charcoal can also be used, but this results in a loss of up to 50 percent of the energy contained in the original biomass. On the other hand, coal contains more energy due to its higher calorific value, so that the range of fuels can be varied. In principle, any organic material can be used. During World War II, coal and peat were used, but timber was the main fuel.

Dutch Volvo 240

One of the most successful gas-fired vehicles was built in 2008 by the Dutchman John. Many cars equipped with gas generators were bulky and not very attractive. The Dutch Volvo 240 is equipped with a modern stainless steel gas generator system and has a modern, elegant look.

“It's not that hard to get wood gas," says John; it's much more difficult to get pure wood gas. John has a lot of complaints about automotive gas generators, as the gas they produce contains a lot of impurities.

John from Holland is firmly convinced that wood gas generating plants are much more promising to be used stationary, for example, for space heating and for domestic needs, for electricity generation, and for similar industries. The Volvo 240 gas-fired vehicle is designed primarily to demonstrate the possibilities of gas-fired technology.

A lot of admiring and interested people always gather near John's car and near similar gas-generating vehicles. Nevertheless, automobile gas generators are for idealists and in times of crisis, says John. Technical capabilities

The gas-fired Volvo 240 reaches a top speed of 120 kilometers per hour (75 mph) and can maintain a cruising speed of 110 km / h (68 mph). The “fuel tank” can hold 30 kg (66 lb) of wood, enough for approximately 100 kilometers (62 miles), comparable to an electric car.

If the rear seat is loaded with bags of wood, the range is increased to 400 kilometers (250 miles). Again, this is comparable to an electric car if passenger space is sacrificed for additional batteries, as is the case with the Tesla Roadster or the Mini Cooper electric car. (In addition to everything in the gas generator, periodically you need to take a bag of wood from the rear seat and pour it into the tank).

There is a fundamentally different approach to re-equipping cars with gas generator systems. This is a way of placing a gas gene on a trailer. Vesa Mikkonen took this approach. His most recent work was a gas-fired Lincoln Continental 1979 Mark V, a large, heavy American coupe. Lincoln consumes 50 kg (110 lb) of wood for every 100 kilometers (62 miles) and is significantly less fuel efficient than John's Volvo. Mikkonen's weight also refitted the Toyota Camry, a more fuel efficient vehicle. This car consumes just 20 kg (44 lb) wood for the same mileage. However, the trailer remained almost as large as the car itself.

Optimization of electric vehicles can occur by reducing the size and lightening the overall weight.This method is not suitable for cousins with gas-fired vehicles. Although since the Second World War, gas-fired vehicles have become much more advanced. Wartime cars could travel 20-50 kilometers at one gas station, had low dynamic and speed characteristics.

Jost Konin's gas-fired wooden car

“Move around the world with a saw and an ax” - under this motto the Dutchman Joost Conijn made a two-month trip across Europe in his gas generator car with a trailer, without worrying about gas stations (which he had not seen in Romania).

Although the trailer in this car was used for other purposes, to store an additional supply of firewood, which increased the distance between the "refueling". Interestingly, Jost used wood not only as fuel for the car, but also as a building material for the car itself.

In the 1990s, hydrogen was considered as an alternative fuel of the future. Then high hopes were pinned on biofuels. Later, the development of electrical technologies in the automotive industry attracted much attention. If this technology does not receive further continuation (there are objective prerequisites for that), then our attention will again be able to switch to gas-fired vehicles.

Despite the high development of industrial technologies, the use of wood gas in cars is of environmental interest compared to other alternative fuels. Gasification of wood is slightly more efficient than conventional wood combustion, as conventional combustion loses up to 25 percent of the energy it contains. Using a gas generator in a car increases energy consumption by 1.5 times compared to a car running on gasoline (including losses due to preheating of the system and an increase in the weight of the car itself). If we take into account that the energy necessary for needs is transported and then produced from oil, then gasification of wood remains effective in comparison with gasoline. It should also be borne in mind that wood is a renewable energy source, but gasoline is not. Benefits of gas-fired vehicles

The biggest advantage of gas-fired vehicles is that they use renewable fuels without any pre-treatment. And converting biomass into liquid fuels such as ethanol or biodiesel can consume more energy (including CO2) than the original feedstock contains. The gas generator vehicle does not use energy to produce fuel, except for cutting and chopping wood.

The gas generator vehicle does not need powerful chemical storage batteries and this is an advantage over the electric vehicle. Chemical batteries tend to self-discharge and you should remember to charge them before use. Devices that generate wood gas are, as it were, natural batteries. There is no need for high-tech processing of spent and faulty chemical batteries. The waste generated by the gas generating plant is ash, which can be used as fertilizer.

A properly designed automobile gas generator is significantly less clogging the air space than a gasoline or diesel vehicle.

Gasification of wood is significantly cleaner than direct combustion of wood: the emissions to the atmosphere are comparable to those from the combustion of natural gas. During operation, an electric car does not pollute the atmosphere, but later, to charge the batteries, you need to apply energy, which is still produced in the traditional way. Disadvantages of gas generator vehicles

Despite the many advantages in the operation of gas-fired vehicles, it should be understood that this is not the most optimal solution. The installation that produces gas takes up a lot of space and weighs several hundred kilograms - and you have to carry this whole "plant" with you and on yourself. Gas equipment is large due to the fact that wood gas has a low specific energy. The energy value of wood gas is about 5.7 MJ / kg, compared to 44 MJ / kg for gasoline and 56 MJ / kg for natural gas.

When operating on gas generator gas, the speed and acceleration cannot be achieved as with gasoline. This is because wood gas is about 50 percent nitrogen, 20 percent carbon monoxide, 18 percent hydrogen, 8 percent carbon dioxide, and 4 percent methane. Nitrogen does not support combustion, and carbon compounds reduce gas combustion. Due to the high nitrogen content, the engine receives less fuel, which results in a 30-50 percent reduction in power. Due to the slow combustion of gas, high revs are practically not used, and the dynamic characteristics of the car are reduced.

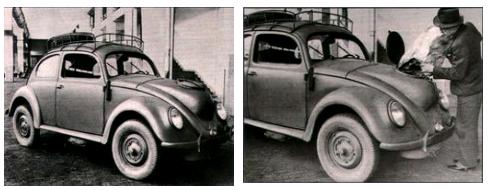

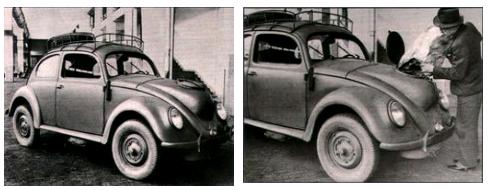

Opel Cadet equipped with a gas generator set

Cars with small engine displacement can also be equipped with wood gas generators (for example, the Opel Kadett in the picture above), but it is still better to equip large cars with powerful engines with gas generators. On low-power engines, in some situations, there is a strong lack of engine power and dynamics.

The gas generator set itself can be made smaller for a small car, but this reduction will not be proportional to the size of the car. Gas generators for motorcycles were also designed, but their dimensions are comparable to a motorcycle sidecar. Although this size is significantly smaller than a device for a bus, truck, train or ship. Ease of use of the gas generator vehicle

Another known problem with gas-fired vehicles is that they are not very user-friendly (although they have improved significantly over the technology used during the war). However, despite the improvements, a modern gas generator takes about 10 minutes to reach operating temperature, so it will not be possible to get in a car and leave immediately.

In addition, before each subsequent refueling, it is necessary to remove the ash with a shovel - working off the previous combustion. The formation of resins is no longer as problematic as it was 70 years ago, but even now it is a very crucial moment, since the filters must be cleaned regularly and efficiently, which requires additional frequent maintenance. In general, a gas-fired vehicle requires additional hassle that is completely absent in the operation of a gasoline vehicle.

The high concentration of the lethal carbon monoxide gas requires extra precautions and controls against possible leakage in the pipeline. If the installation is in the trunk, then you should not save on the CO sensor in the car. The gas generator system must not be started in a room (garage), as there must be an open flame when starting and entering the operating mode (figure on the left). Mass production of gas-fired vehicles

Gas generator Volkswagen Beetle, produced at the plant

All vehicles described above are built by amateur engineers. It can be assumed that if it was decided to produce gas-fired cars professionally in the factory, then most likely many of the disadvantages would be eliminated, and the advantages would be greater. Such cars could look more attractive.

For example, in Volkswagen vehicles manufactured at the factory during World War II, the entire gas generator mechanism was hidden under the hood. On the front side in the hood there was only a hatch for loading firewood. All other parts of the installation were not visible.

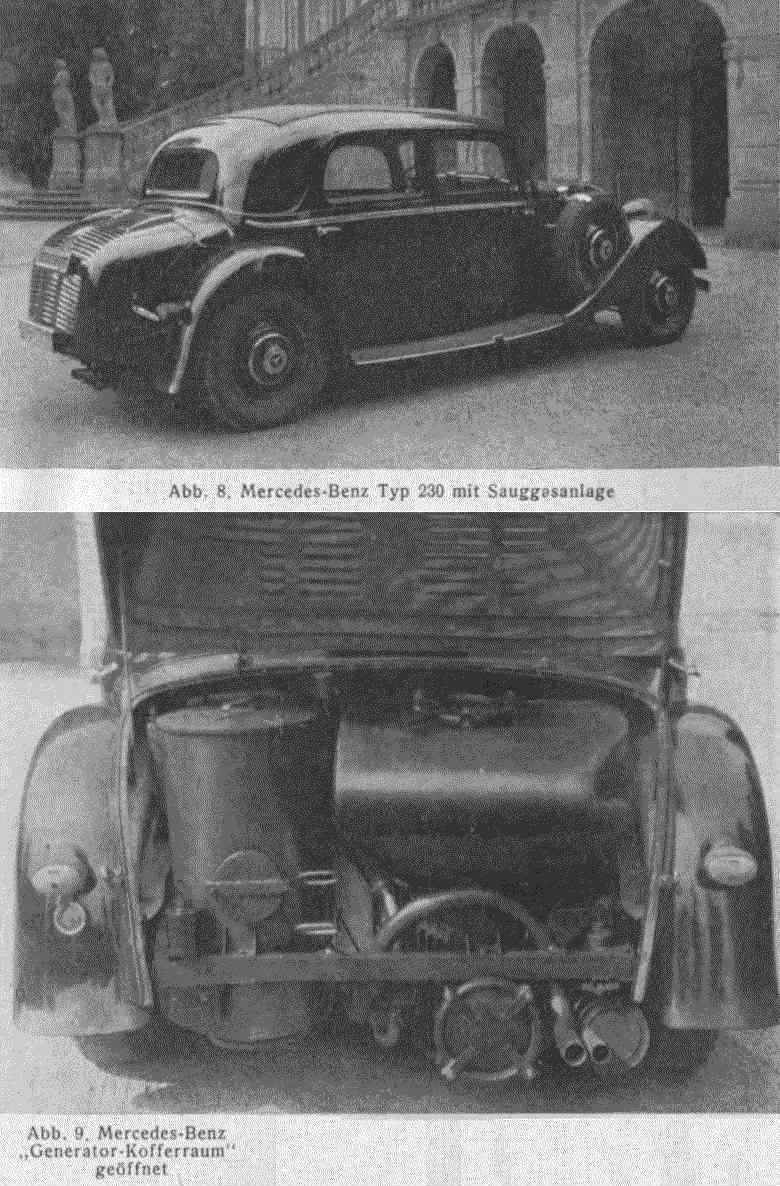

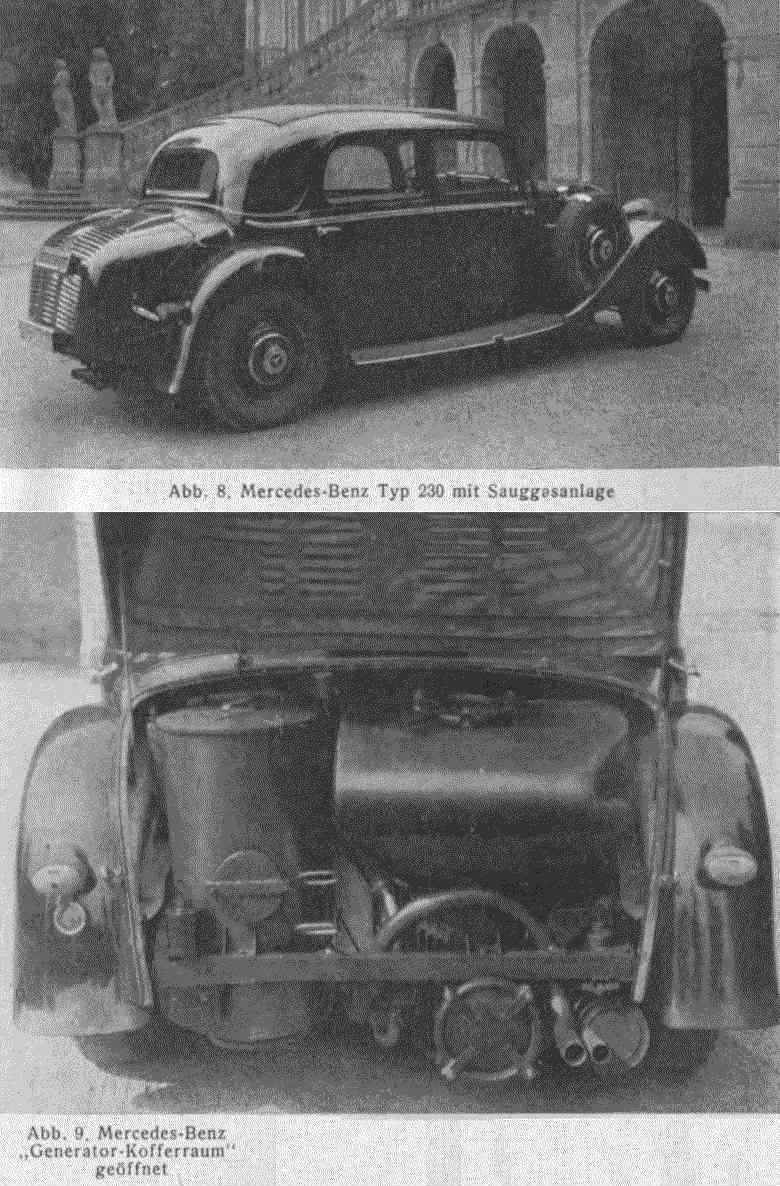

Another option for a gas-fired vehicle produced at the factory is Mercedes-Benz. As you can see in the photo below, the entire gas generator mechanism is hidden under the hood of the trunk.

Gas generator Mercedes-Benz 230, manufactured at the plant

Deforestation

Unfortunately, the increased use of wood gas and biofuels could lead to a new problem. And mass production of gas powered vehicles can exacerbate this problem. If the number of vehicles using wood gas or biofuels begins to increase significantly, then the stock of trees will begin to decrease by the same amount, and agricultural land will be sacrificed for growing crops that are processed for biofuels, and this can lead to hunger. The use of gas-fired technology in France during World War II caused a sharp decline in forest reserves. Likewise, other biofuel production technologies lead to a decrease in the cultivation of plants useful for humans.

Although, the presence of a gas generator vehicle may lead to a more moderate use of it:

- warm up the gas generator for 10 minutes or use a bicycle to move to the grocery store - most likely the choice will be made in favor of the latter;

- chopping wood for 3 hours for a trip to the beach or taking the train - probably the choice will be in favor of the latter.

To start and warm up the gas generator, you need to spend at least 10 minutes

Be that as it may, gas-fired cars cannot match the gasoline and diesel vehicles. Only a global shortage of oil or a very large rise in its price can force us to switch to a gas generator vehicle.

- The most catastrophic landslides in ...

- How one post accidentally changed the world

- Elon Musk presented a new prototype of the CyberTruck electric pickup truck

- 24 amazing ways to use alcohol, oh ...

- The owner of BMW has been repairing the car for two years. In the end…

- What the ancient Greeks knew about the different types of love, and ...

DIY making

Making gazgen with your own hands - painstaking and difficult work... You will need special materials to complete it. Steel is needed to make the hull and fuel tank. For special containers - heat-resistant material. You will also need heat-resistant gaskets made of any material other than asbestos, as it releases hazardous substances. Pipes are required to connect the nodes. Filters will be required to remove any impurities.

Do-it-yourself plot about gazgens

When making a gas gene with your own hands, it is important to take into account that all parts and assemblies of a gas gene must be breathable.

Manufacturing process

How to make a gas generator with your own hands? One of the possible options is described below. We take a 40 liter gas cylinder and cut out a circle at the top of it, as shown in photo 1.

This tank will house the loading area and the firebox.

A meter piece of pipe with an outer diameter of about 50 mm will serve for air supply (photo 2).

The bottom and cover of the housing can be made of 5 mm thick sheet steel. For coarse and fine filters, housings from fire extinguishers are suitable. The grate can be welded from reinforcement (photo 3).

It is better, of course, to find cast iron rods for the grate or find a finished product of suitable dimensions.

To make a lock for the generator column cover, an old car spring is suitable (photo 4). When the pressure inside the generator rises, such a lock will work like a valve in a saucepan - a pressure cooker.

A piece of rectangular pipe can serve as the basis for fastening the cover parts (photo 5)

The connection of the main body parts is carried out by electric welding; when installing the cover parts, a bolted connection is used.

Thus, almost all the parts needed to make a gas generator with your own hands can be found in scrap metal.

Diesel generators are a good alternative to gas powered generators when more power is needed. Read about diesel power plants in the article at the link:.

And about powerful 100 kW diesel generators, the principle of their selection, use and maintenance, you will learn in this detailed article.

Nuances of gas generator operation

It is mistakenly believed that a home-made gas generating unit is capable of operating on wood with a moisture content of up to 50%. It should be borne in mind that the higher the fuel moisture level, the lower the efficiency of the heat-power device. To optimize the workflow, it is worth using hot gas to heat and dry firewood in the bunker. For this purpose, a gas pipeline is laid between the body and the loading chamber: part of the thermal energy is spent on drying fuel resources.

Combustible gas, so necessary for heating houses, cooking, as fuel for cars and other useful devices, is not only mined from underground. The source of this valuable product can be firewood, peat, woodworking waste, coal and even certain types of garbage, for example, pieces of old linoleum or stripped parquet, plastic unsuitable for further use, etc. To obtain gas in this way, you will need to purchase a special device or make a gas generator with your own hands. How to build it yourself - we'll talk about it now.