With the advent of cold weather, people think about how to heat the room. In city apartments, this issue is dealt with by the relevant services. But, as far as a private house is concerned, the solution to this problem rests with the owner.

It is quite difficult to organize heating on your own. It is necessary not only to install heating units, but also to stock up on fuel. The task becomes more complicated when the question arises about heating not only the house, but also auxiliary buildings. In this case, the Bubafonya oven will help with your own hands. A schematic drawing of this design can be found on the net.

Modern stoves fit easily into the interior of the house

Long burning oven: working principle

When organizing heating in the house, it is worth carefully considering all the questions of interest. And you need to start with how firewood is burned, which is the most popular fuel in the private sector. The process begins with heating the wood to a certain point, when it starts to ignite.

So, after setting fire to paper or other material, the fuel starts heating. Upon reaching 250 degrees, the wood decomposes into chemical elements. White smoke indicates that steam or gas is being emitted from the wood. Subsequently, as the temperature rises, they ignite, which accelerates the thermochemical reaction.

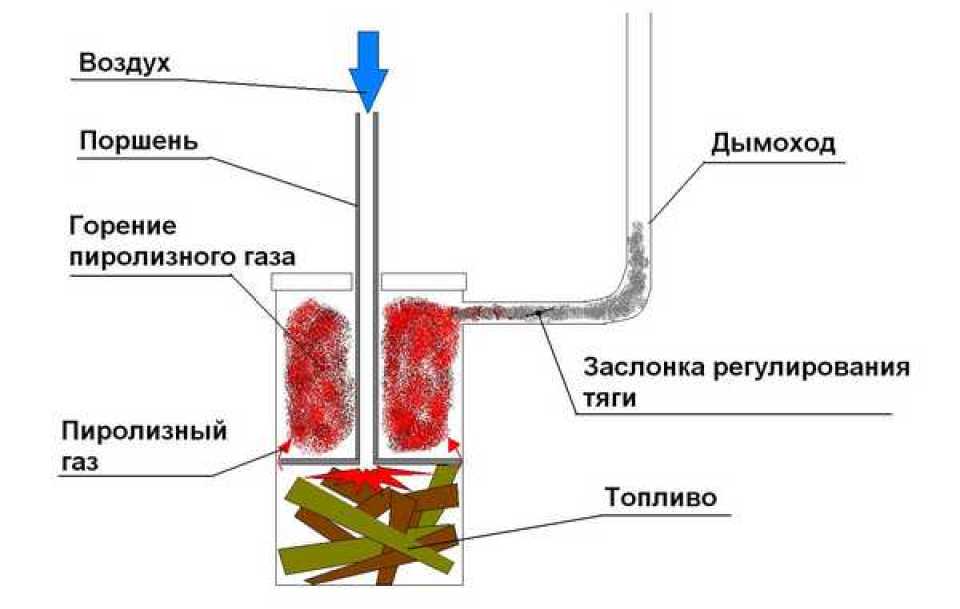

The principle of operation of the boiler is quite simple.

The study of pyrolysis has become the key to the creation of modern long-burning boilers. Thanks to pyrolysis ovens, it became possible to use wood as efficiently as possible as a source of thermal energy. The secret is that vapors and gases burn separately from the fuel. This, in turn, ensures its slow decay. As a result, one bookmark burns longer than usual.

There are several main stages of fuel combustion in such units as the Bubafonya long-burning stove:

- drying wood;

- pyrolysis;

- combustion or oxidation;

- recovery.

As a result, a small amount of ash remains after burning the bookmark. Almost all of the fuel is efficiently used.

It's pretty easy to make the unit yourself.

Furnace device

To make a Bubafonya boiler, you need to carefully consider its design. This will create a truly productive unit that will not only heat the desired room, but also save fuel. So, Bubafonya from a gas cylinder, the drawing contains the following elements:

- Housing. The main element of the oven, which is often cylindrical in shape. For the construction, a barrel, cylinder, bulky fire extinguisher or pipe is often used, to which the bottom is welded.

- Chimney. The element is often made of a metal pipe, which has a diameter of 11 to 25 cm. It is welded on top of the body and serves to remove combustion products.

- Feed piston. The part is made in the form of a circle, on the lower part of which ribs are welded. An air pipe is attached to the center of the piston. The main purpose of the ribs is to create an additional layer of air between the piston and the piston. This has a positive effect on smoldering and the rate of gas evolution.

- Regulating valve. Everything is pretty simple here. It serves to control the supply of oxidant to the combustion chamber.

- Cap. A hole is made in it through which the air duct is passed. A secondary combustion chamber is formed between it and the piston, where vapors and gases are ignited.

These are the main structural elements. But, if we are talking about Bubafoni with a water jacket, then the scheme will look somewhat different.

The unit can be used for a complete heating system

Bubafonya furnace design

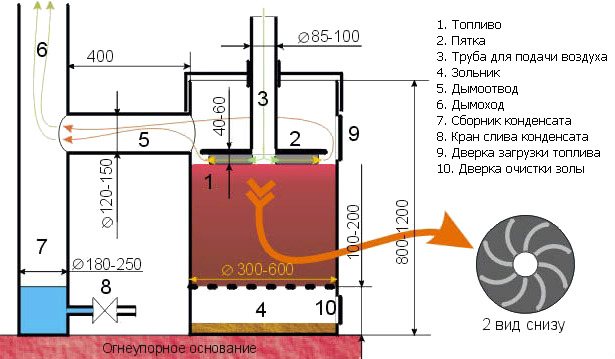

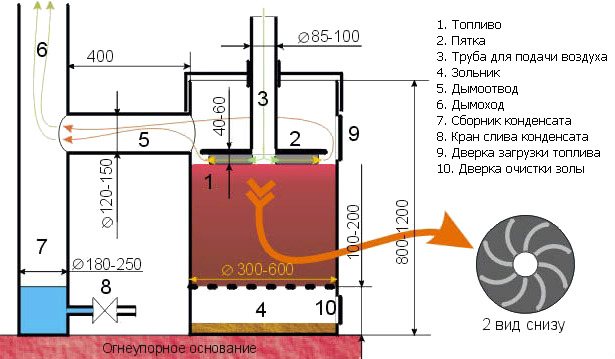

The structure consists of the following parts:

- A cylindrical body (usually a barrel, gas cylinder, pipe) in which solid fuel is burned. The body is equipped with a hole for the chimney pipe;

- Chimney made of a metal pipe with a diameter of 110-250 mm;

- Piston. Consists of a heel with "ribs" to which a pipe with a diameter of 85-100 mm is welded to supply air to the combustion chamber. Thanks to the ribs, the heel does not fit snugly against the fuel, which has a positive effect on the combustion process;

- A valve is installed in the upper part of the air supply pipe to adjust the volume of air entering the combustion chamber;

- Cap. It is a conventional metal barrel cover with a hole for the piston tube.

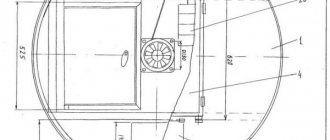

Drawing of the Bubafonya stove with dimensions: one of the possible implementation options.

Advantages and disadvantages

Before building a potbelly stove, like Bubafonya from a gas cylinder, it is worth considering its advantages:

- Simplicity of design. Possessing the skills of working with material in the form of metal and a welding machine, any person can build such a stove.

- The versatility of the fuel used. The stove is not picky in terms of energy. So, it can work on wood, sawdust, coal and wood waste. It is also quite suitable for working on pellets, the popularity of which is growing rapidly.

- Burning duration. One bookmark can be enough for a long time. So, the unit will heat the room throughout the day. Of course, the exact value directly depends on the size of the combustion chamber, as well as the presence of additional circuits.

Despite the popularity and many advantages, the stove has some disadvantages:

- compared to modern models, the stove has a low efficiency;

- it is quite difficult to clean the structure from working off;

- the design has an unattractive appearance, which makes it impossible to use it in a residential area.

As for cleaning the oven, they solve this issue with the help of a door, which is installed in the lower part of the body.

The furnace has a simple design

How Bubafonya works, its advantages and disadvantages

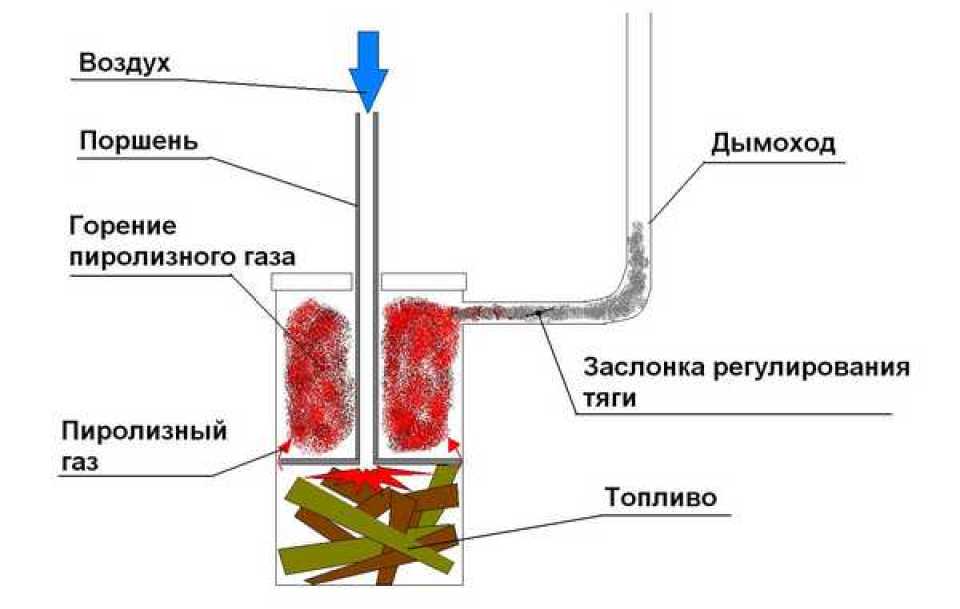

The design of this wonderful stove is such that the movable piston rests on the firewood stacked at the bottom of the firebox. It divides the combustion chamber into two parts: below it, firewood is burning, and from above, pyrolysis gases are burning out. It turns out that the firewood does not burn from bottom to top, as usual, but from top to bottom. At the same time, the process is much slower, and the fuel burns out with almost no residue. Oxygen for burning wood is supplied through a pipe that serves as a rod for a piston. In the upper part of the furnace, where pyrolysis gases are burning, oxygen enters through the holes in the lid (where the pipe from the piston is inserted, and where the lid is aligned with the body), therefore, there is no need to worry about tightness. It is even harmful - the stove suffocates when there is a lack of oxygen. Due to this separation of the chambers, the fuel burns out completely. The intensity of combustion is regulated through the pipe, to which the piston ring is welded. For convenience, people weld a small pin to the pipe, to which a metal disk is movably attached, the diameter of which is slightly larger than this pipe. Some simply block or restrict the flow of air with any object, adjusting this gap.

Approximate diagram of the Bubafonya stove

The burning time of one bookmark depends to a greater extent on the volume of the firebox: the larger the firebox, the more firewood, the longer the fuel burns. On average, one bookmark of firewood in Bubafonya from a gas cylinder burns for 4-6 hours (it also depends on firewood and other "additional" fuel). Those who made Bubafonya from a 200-liter barrel say that one tab heats them up to 20-24 hours. It is not for nothing that they say that Bubafonya is a long-burning furnace. Indeed, it burns for a long time.

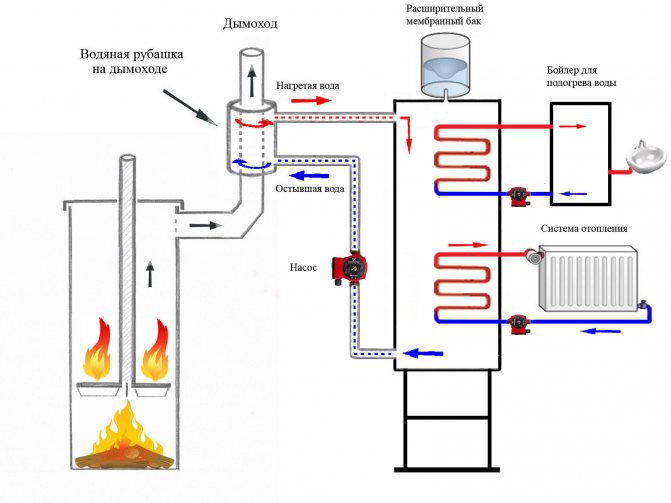

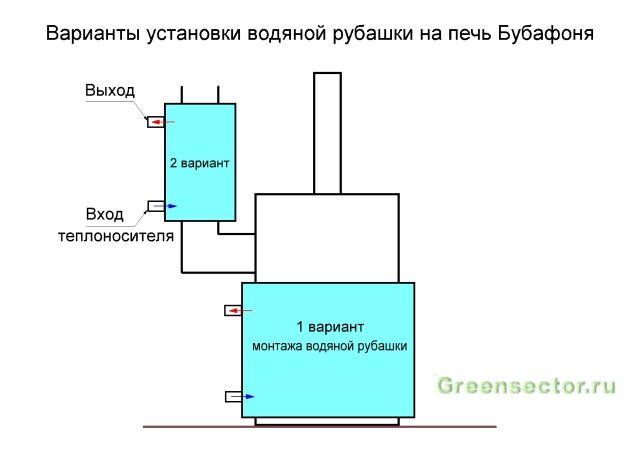

Despite the obvious advantages, this stove also has disadvantages: the first is a small "radius of action" with high heat transfer. It is warm near the stove, even hot. A little further away - it's cold. But this problem is solvable. To improve the situation, they act in two ways: arrange forced convection (air change) using a fan or make a water jacket, and heated water is passed through pipes to heat the room.

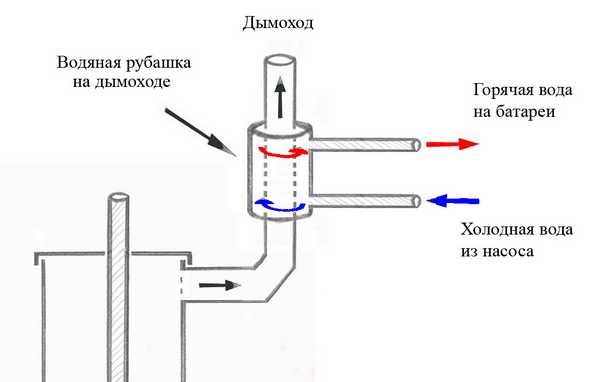

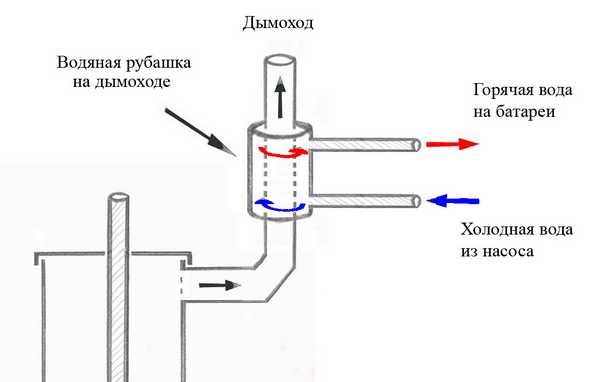

If everything is simple with the fan, then the water jacket can be made in two ways: around the body or remove heat from the chimney pipe. A shirt on the chimney is easier to implement. This option also has one more advantage: then the heat from the furnace body is used for heating, as well as that which used to go outside through the chimney. Now it also heats your room. In addition, when installing a water jacket on the pipe, the smoke at the outlet will no longer be so hot and you can not bother so much with the insulation of the wall around the pipe. How to correctly lead the pipe through the wall or roof, read here.

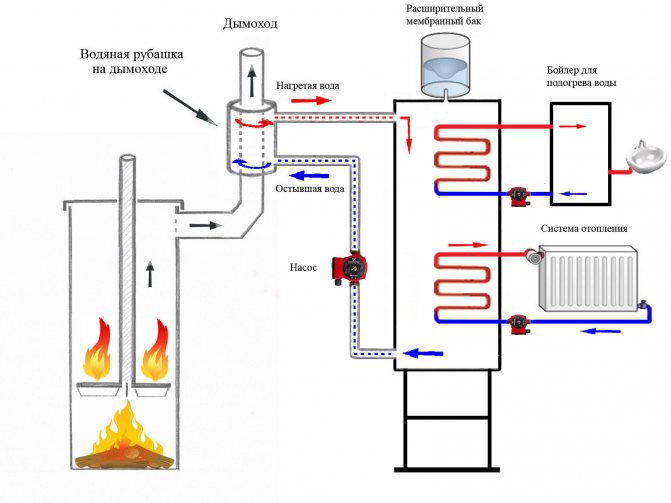

The Bubafonya stove can be used to organize water heating by making a water jacket on the body or pipe

Another important drawback is not the most attractive look. If Bubafonya is used in a technical room - in a garage, a greenhouse, in a country house, then there is nothing to worry about. As it is, so it is. Well, if you want to use it to heat the house, you will have to hide it somewhere in the boiler room, basement, in an extension. You can still refine it. For example, brick it. By this, by the way, you will greatly increase the comfort of being near the stove: the brick will extinguish most of the hard radiation, soften it, and become a kind of heat accumulator: the brick will heat up, and then, when the stove goes out, it will gradually cool down and give off the accumulated heat.

Read about how to make a protective brick screen here.

It is not recommended to paint Bubafon: it is useless - the paint will burn, and even poison it when burning. The paint will withstand only in one case, if it is heat-resistant, but it must be applied according to all the rules, and this is not at all easy and expensive.

The disadvantage of "Bubafonya" is an unprepossessing look, but it heats up very well and burns for a really long time

Do not forget that Bubafonya is an iron stove. It will not work just to put it on a wooden floor - a fire could happen. And very quickly: the pyrolysis temperature is very high (350 ° C and higher), therefore, the furnace body has a high temperature. So it will be able to burn seriously, and the wood of the unprotected floor or nearby walls will burn. So we pay close attention to fire safety and prepare a place for the stove: we use asbestos-cement plates, metal sheets, bricks, heat-insulating materials (mineral wool or cardboard and other heat-resistant materials).

The operation of the furnace is also somewhat problematic, but this is the reverse medal for simplicity of design. It is inconvenient to select ash and load fuel. Actually, there are two options: accept it as a fact or make changes to the design. But how they (changes) will affect the efficiency of the furnace is difficult to say. It must be said that very little ash from wood and sawdust remains, so it does not need to be cleaned often.

There is one simple option for modifying the Bubafonya stove, which makes it easy to remove ash: to cook a special ash pan. It consists of the same pancake as the piston, but without a hole and with the edges bent upwards. We weld a thick metal rod to the middle of the pancake-ash pan. Then, when assembling the furnace, we put an ash pan on the bottom, on it - fuel, fire it up. Then we put the piston on the rod of the ash pan, and at the end - the cover. With this design, the ash is collected in a pallet, which is easily pulled out of the cooled and disassembled boiler by the rod.

This is how the "Bubafonya" looks from the inside when the fuel smolders in it

Self-fabrication of the structure

The construction of the boiler is carried out in several stages:

- arrangement of a place for work, preparation of the necessary materials and tools;

- manufacture of parts and assembly of the stove;

- arrangement of a chimney;

- construction of a solid base for the furnace.

Each stage is carried out in a specific sequence.

Before creating a furnace, you need to deal with all its details.

Drawing creation and calculation of basic values

To build a structure, it is necessary to develop a drawing on which the following values are indicated:

- Height and diameter of the body. The values are interrelated. The height of the structure is several times the diameter. In this case, the section should be in the range of 30-80 cm. Structures with a diameter of 30 cm are unproductive, and from 80 cm - uneven combustion of firewood. Therefore, experts recommend choosing an average value between these values.

- Wall thickness. The best option is considered to be a case with a thickness of 4 mm. If the walls are thinner, this will significantly reduce the efficiency and service life of the furnace.

- Piston pancake size. Here calculations are carried out according to a certain formula. It is important to determine the size of not only the pancake itself, but also the height of the ribs.

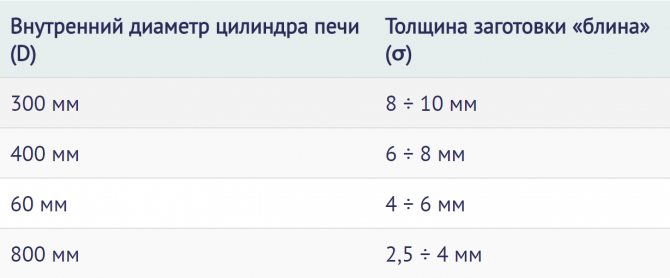

- Pancake thickness. There is a developed table with the required values depending on the body diameter. This parameter is very important, since it will determine the force with which the piston will press on the bookmark. In turn, this will affect the operation of the entire unit. So, for example, if the pancake is heavy, then the air gap will be so small that the fuel will go out over time.

During development, special tables are used

- Required chimney area. The density and volume of the fuel are taken into account, as well as the energy release during its combustion. When calculating, special tables with the required values are used.

- Air intake diameter. Knowing the size of the chimney, it is very easy to perform calculations.

Knowing all the meanings and having a drawing at hand, you can start making a furnace. The main thing is to carry out the calculations correctly. Before starting work, everything must be carefully checked.

Work must be carried out in a specially separated place

Preparatory stage

The work is carried out in a room that is protected from atmospheric precipitation and productive ventilation. The place should be away from residential buildings so as not to cause discomfort to neighbors and households. Having chosen a suitable room, you can start preparing materials. For this you will need:

- Housing for the unit. Often a gas volume is used for this. A steel or cast iron barrel, steel pipe is also suitable. The workpieces must be free from signs of corrosive process and other damage.

- Legs material. A metal profile, fittings and steel tubes are used as supports. The structure must be securely installed on the base.

- Pens. Two on the casing for easy transport and one on the lid for easy maintenance.

In addition, you will need the following auxiliary materials:

- Sheet steel;

- two pipes with a diameter of 10 cm and 15 cm;

- metal profile or channel;

- materials for the base.

As for the tool, here you need the following set:

- a hammer;

- vice;

- Master OK;

- Bulgarian;

- level and tape measure;

- welding machine and electrodes.

Important! When cutting and welding parts, do not forget about safety precautions.

It is necessary to work with the cylinder very carefully.

Assembly of the unit

The manufacture and installation of the stove and chimney is carried out in the following sequence:

- Carefully cut off the top valve and then the cylinder cap. It is preliminarily recommended to flush it. In the future, the cap will be used as a cover.

- Attach the legs to the bottom. To check the accuracy of their installation, it is worth using a level or plumb line.

- Cut a circle out of steel. In the center, make a hole for the air duct. Weld a circle and a pipe.Prepare the trims of the channel of the required size and fix them on the lower side of the circle. Thus, the furnace piston is constructed in several stages.

- Make markings for the air duct on the hood. The hole should be such that the pipe moves freely in it. Make a cut. Clean the edges. Weld the handles to the lid. It will be enough to use fittings.

- In the upper part of the body, make markings for the chimney opening. Make a cut. The hole must match the dimensions of the pipe. This will allow the parts to be sealed. Weld the pipe to the body.

The arrangement of the chimney must be approached very carefully. To provide adequate traction, the channel must have two elbows. They connect at right angles. The two pipe sections are cut at a 45 degree angle. In this form, they are welded together, which ensures a smooth transition of the channel.

In addition, it is worth building a protection for the pipe in the form of a cap. Such a special device makes it possible to protect the channel from precipitation, which can cause the stove to fade. At this stage, the assembly of the unit can be considered complete. All that remains is to create a solid foundation and install the boiler.

Particular attention should be paid to creating a pancake.

Foundation creation

The foundation for a homemade boiler is being built in the following sequence:

- Dig a hole 150x150 cm. At the same time, its depth should be close to 30 cm. The exact area of the base directly depends on the size of the unit.

- Make a cushion of rubble and pour concrete on top. Level the surface with a trowel. When the mortar is dry, check the area with a spirit level. Align if necessary.

- After the concrete is completely dry, lay out several rows of refractory bricks.

When laying bricks, special attention should be paid to the evenness of the surface. This will determine how reliably the boiler will be installed.

Bookmarking and lighting should be done very carefully.

Putting on the "shirt" for Bubafonya

Reviews about the operation of the bubafonya oven are mostly positive. The heat output of a boiler made from a gas cylinder is enough to heat a room with an area of up to 60 m2. The only design flaw is uneven heating. The easiest way to fix it is to blow the case with a fan. Note that it is much more profitable to make a Bubafon boiler with a water jacket, which can heat several rooms.

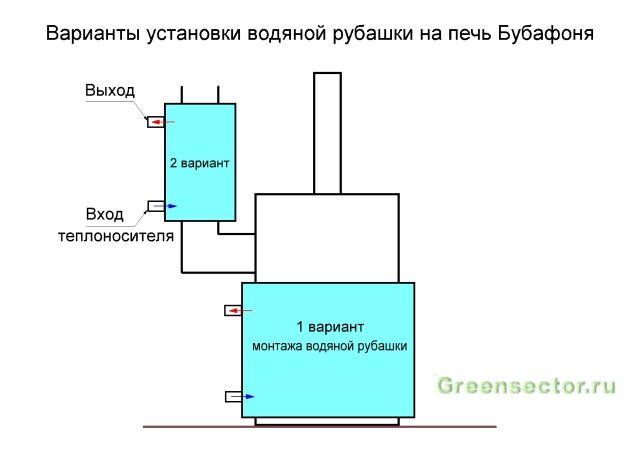

The masters offer two places for installing the water circuit: on the boiler body or on its chimney, which is very hot. The easiest way is to make such a system according to the "pipe in pipe" principle, putting a barrel or pipe of a larger diameter on the boiler body or on the flue channel. The open ends of the "jacket" must be welded tightly and the inlet and outlet pipes must be cut into it for connection to heating devices.

It is possible to make a heat exchanger from a water pipe by installing its coils in an outer steel casing and filling them with sand for a more even heat transfer. In addition, the coil can be placed inside the brickwork around the boiler drum.

Furnace ignition

You need to fire up the unit in the following sequence:

- remove the lid from the boiler and remove the piston;

- place the fuel correctly, otherwise combustion, as well as the working process of the furnace, will go wrong;

- additionally lay a layer of chips and sawdust on top;

- moisten a rag in kerosene or other flammable liquid and put it on top of the bookmark;

- install the piston and cover with a lid;

- throw the lighted paper through the air duct, since the match will not give the desired result.

When the fire starts, you need to close the valve somewhat, which will limit the air supply. Otherwise, the fuel will start burning and not smolder. And as you know, the basis of work is precisely the decay of wood, and not its combustion.

The shirt will hang the efficiency of the unit