What is the benefit of autonomous heat generators of long burning

Why are standalone stoves more profitable than district heating? The fact is that powerful industrial heating boilers with 100% efficiency lose up to 30% of heat when passing through the main and distribution pipelines. Autonomous heating works without heat loss, and its performance is determined by the efficiency of the boiler used for heating. Homemade stoves can be unsightly in appearance, but have an efficiency of more than 90%. You can heat them with wood, coal and waste.

Efficient and economical wood-fired pyrolysis boiler keeps warmth for a long time

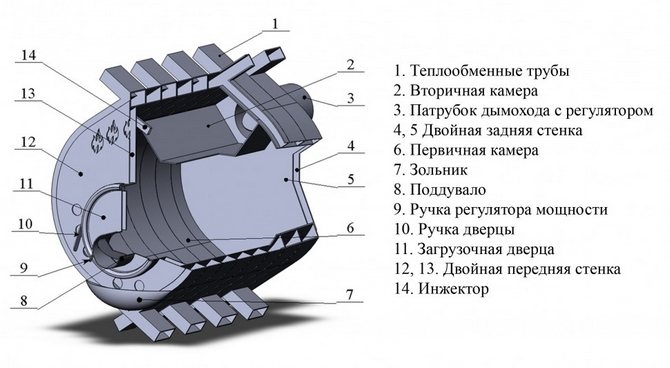

Butakov's stove

Convection ovens developed by Professor Butakov are widely available on the market and can be used to heat greenhouses, although this option is also rarely used.

This heating equipment is produced by various manufacturers, including companies:

- Zubkevich - a developer of this type of furnace;

- Termofor is one of the largest manufacturers for which Zubkevich developed the model;

- Teplodar is a clone, albeit a very successful one;

- Convectics.

Furnaces from different manufacturers have both advantages and disadvantages. When buying, be guided by the recommendations of experts and reviews.

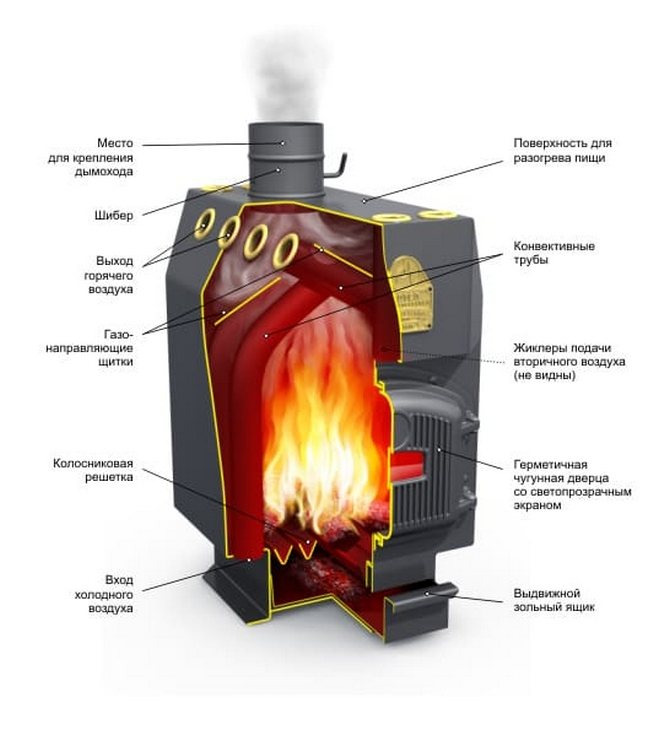

The principle of operation and functional purpose of this type of heating equipment is fully consistent with the Buleryan furnaces.

The stove body is a parallelepiped containing convective air ducts and a two-chamber firebox.

Also provided:

- ash pan;

- damper;

- chimney.

How pyrolysis proceeds

The pyrolysis process goes through four stages:

- Drying - excess moisture is removed from the wood. It is carried out during the preparation process or in the firebox due to its heat.

- Pyrolysis - sublimation of volatile components, decomposition of heavy components - resins and bitumen to volatile. The fuel mass begins to carbonize, that is, char.

- Combustion of pyrolysis gases upon reaching the flash point under the influence of high temperature and free oxygen. Carbon combustion begins when the temperature rises above 600 degrees.

- After the combustion of volatile components and the bulk of carbon, reduction reactions begin - the release of carbon monoxide, free hydrogen and oxygen.

In order for the efficiency to be high, when designing the equipment, it is necessary to ensure that the reducing gases are retained in the hot zone and heated fresh air is provided there. When it cools down quickly, the energy spent on recovery will fly into the pipe. It should not be forgotten that carbon monoxide is poisonous.

Note: One of the main advantages of a slow burning oven is ease of use. Once or twice a day, firewood is loaded into it, once or twice a week, ash is raked out.

Comparative characteristics of long-burning furnaces with traditional heat generators

The principle of operation of most heating units is based on fast and intensive combustion of fuel. The fuel is ignited from below, the fire spreads, oxygen access to the combustion zone is open. The disadvantages of this heating method are sharp temperature jumps, incomplete combustion of the fuel resource with the formation of a large amount of soot and soot, the need for frequent fuel addition and traction control.

The principle of operation of long-burning furnaces is completely different. The fire moves from top to bottom, which makes it possible to completely load the combustion space.The fuel is used gradually, its combustion occurs in the direction from top to bottom. Air is supplied directly to the fire. Such combustion is a slower process with less heat generation.

This allows you to maintain an even, comfortable temperature, which is very important for greenhouses.

In this category of furnaces, the most economical are pyrolysis (gas generating) models, in which gases formed as a result of slow combustion - smoldering - of fuel are burned. The efficiency of such a unit is significantly increased, and fuel costs are reduced.

The temperature of the gases discharged into the chimney is quite low, which leads to the formation of condensation. Therefore, insulated chimneys are installed for pyrolysis furnaces.

Such furnaces operate in two modes - intensive and long burning. At the beginning of the heating process, the temperature is brought to the required value, and then the draft is closed and the unit is rebuilt into an economical mode.

Advantages of long-burning gas-fired heating devices:

- In the presence of relatively inexpensive solid fuel, long-burning furnaces are an economical and efficient (up to 85% efficiency) method of heating greenhouses. The cost of many models is also quite affordable.

- Fuel is loaded 1-3 times a day, the comfortable temperature after reaching the required value is maintained by the thrust force in the firebox.

- With the help of such furnaces, it is possible to organize air and water heating systems, and heat water.

There are several types of long-burning heat generators used for heating greenhouses. They can be both homemade and factory-made.

Solid fuel stove potbelly stove

Outside the cities, firewood is the most affordable, so the most popular long-burning stove is wood-burning. It is heated not only with wood from the ridge, but also with waste wood - shavings, sawdust, fiberboard and chipboard waste, small brushwood, straw, etc. There are many heating systems for wood and wood waste. Let's consider the most efficient ones, the efficiency of which is more than 70%.

The simplest potbelly stove can be made by hand

The potbelly stove is an economical stove that appeared in Russia after the revolution, during the times of war communism, when many had to endure hardships. The genius of the potbelly stove is that it instantly warms up, as well as the simplicity of its device, the prototype of which is the Russian stove. The upper door is for storing firewood, the lower one is for regulating combustion by supplying air through the slightly open door.

The task of the stove is to keep warm in at least one room at minimal cost. When using coal, the grate is removed, and the air from the blower is directed to the firebox. It is important not to stuff it with a jam - the volume of the bookmark should be no more than a quarter of its volume. The afterburner is a long horizontal or slightly inclined part of the chimney. Made of metal, it keeps the room warm.

Important! The potbelly stove can operate on all types of solid fuels, except for sawdust. It is made in the form of a box from sheet steel or round from a barrel. Chimney diameter - 85 - 150 mm.

Such a potbelly stove will not only warm, but also decorate the interior.

When the stove is fired, any potbelly stove is red-hot, so its upper surface can be used as a cooking stove. On the sides, a screen should be installed at a distance of 40-60 mm from the oven. It protects the room from infrared rays and keeps the temperature at an optimal level.

On the basis of a potbelly stove, you can make a homemade boiler for long burning on wood. To do this, instead of the screen, a U-shaped metal water heater is installed. The distance between the body of the furnace and the boiler should be the same as the indentation of the screen.

The principle of operation of the furnace and the main structural elements

The stove consists of several casings - the outer one is separated from the inner one by a special fastening system, as well as an air gap. Thus, it turns out to achieve the correct movement of air flows entering the inside of the furnace from below. At the same time, the air heats up to a certain temperature, and then rises to the top of the device. This effectively heats the room where the device is located.

Used for refueling:

- needles;

- straw;

- firewood;

- sawdust;

- household waste.

The fuel cell is folded into a specially equipped fuel tank. In the case of using logs, it is advisable to put them vertically. Burning will start from the top, and then it will start moving down.

What does a slobozhanka oven look like

A refractory cover and a blower are connected to the Slobozhanka furnace, designed to regulate the flame. Flue gases escape through the chimney and ash through the lower sump.

Several types of air supply systems:

- An L-shaped pipe is used through which air passes. It rises upward along the side channel of the perforated screen. The screen is located at the bottom of the outside of the pipe. After that, the air enters the direct combustion zone.

- In the second version, the pipe is located in the very center - in the firebox. Air enters from below and rises to the very top of the equipment.

- The third option is made in such a way that the air rises through a pipe installed at the bottom of the furnace walls.

The first method or boiler number 1

The natural vortex is replaced by forced pressurization, and pyrolysis is divided into two stages in space: a pyrolysis chamber, a nozzle (nozzle) that forms a flow of pyrolysis gases, and a combustion chamber. The nozzle is made so that there are no parasitic turbulence behind the mass of fuel. For full control over the process, a through-blow is required.

Features of direct-flow and heat storage pyrolysis boilers:

Note: the type of fuel affects the pyrolysis rate and the composition of the gases. These factors are taken into account by regulating the outlet back pressure by throttling the chimney. Regulators for industrial solid fuel boilers are marked with the recommended fuel type.

The efficiency of once-through boilers can be higher than 90%. They require a power supply to operate. When shutting down, for further start-up of the system, it is necessary to scoop out the caked mass and make a new bookmark in the firebox.

Steam-free solid fuel boilers use different types of fuel

Materials for the manufacture of a long burning stove

Long-burning furnaces can be made by hand from sheet metal or various metal structures. Examples and drawings of such stoves are given below.

Barrel stove

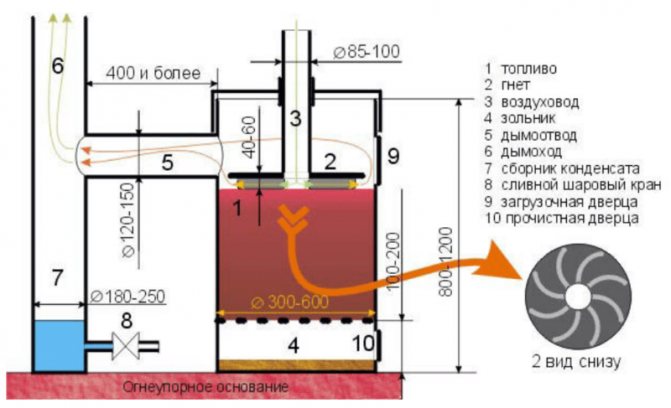

A self-made heater, designed for heating utility rooms, is made of a two-hundred-liter metal barrel. The stove operates on sawdust, shavings and other woodworking waste. Inside the large barrel, a small barrel for loading fuel is installed on a stand. Under it is an ash pan - a drawer made of sheet metal.

The stove itself is placed on a stand, the role of which is played by a car disc. A chimney is made of pipe cuttings with a diameter of 100-150 mm. The barrel is equipped with a sheet metal lid with a handle and an air inlet.

A log sharpened on a cone is installed inside the small barrel, it is indicated in the drawing. Sawdust is poured around it.After tamping, the log is taken out and the sawdust is set on fire. In the process of smoldering, gas is released into the space of a large barrel, where it is burned out.

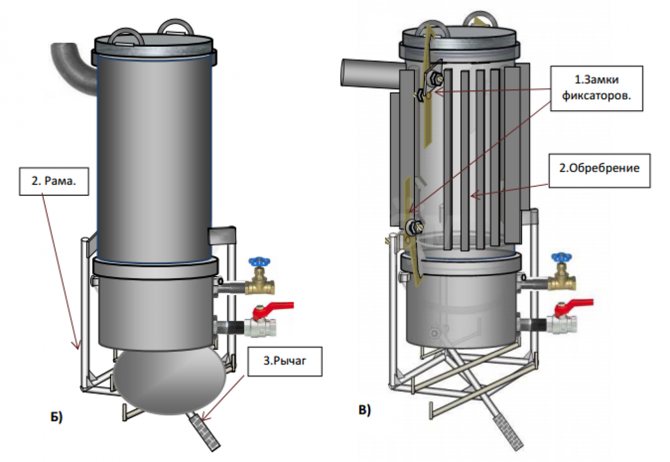

Furnace with a metal pipe water circuit

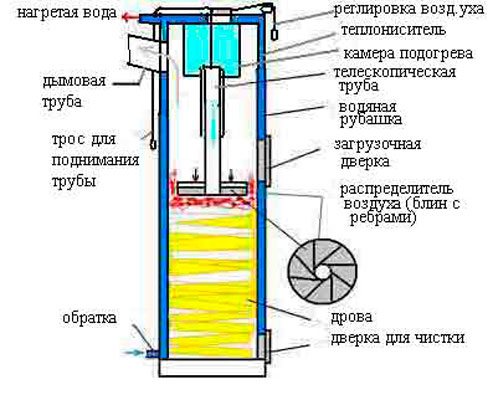

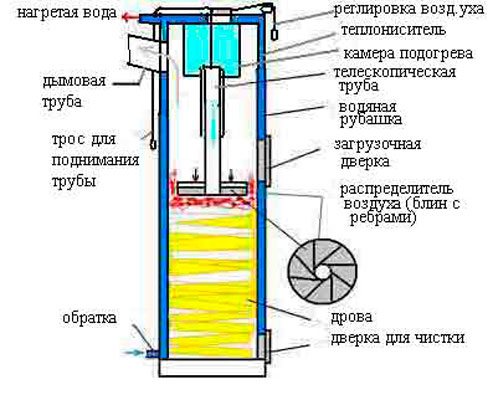

A home-made long-burning stove made of a metal pipe, which can work on wood or sawdust, is equipped with a water circuit. Loading is carried out from below; to intensify combustion, an air distributor is installed inside the furnace, pressing the smoldering firewood.

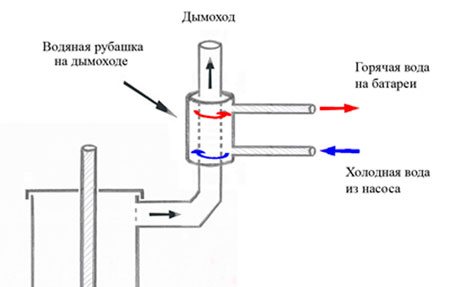

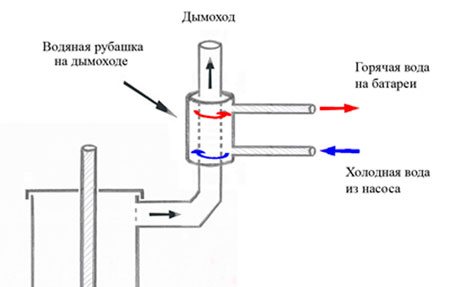

A telescopic hollow pipe is installed in the center of the disc, through which air flows directly into the combustion chamber, where, thanks to the ribs welded onto the disc, it evenly distributes it over the entire surface of the firewood. It descends on its own as the fuel burns out. You can lift it before loading with a rope.

The loading door is located in the center of the oven. Below is a cleaning door and ash pan. In the upper part there is a chimney. The stove is equipped with a water circuit with nozzles for water inlet and outlet. With such a stove with a water circuit, you can quite effectively heat small houses and other rooms, and you can make it from scrap materials with your own hands.

Waste gas cylinder furnace

A stove from a gas cylinder can be made without extra costs and finding a suitable material. The dimensions of a 50 liter cylinder are excellent for making such a stove, and the wall thickness and tightness make it safe to use.

The design of the furnace as a whole does not differ from the previous model, this can be seen in the drawing. A cut-off propane tank is used as a body. A lid with a hole for the air distributor pipe is made of sheet metal with their own hands. Fuel is loaded from the top, filling the volume of the cylinder almost to the chimney. Such a stove works on sawdust and other waste, as well as on small wood. The fuel is thoroughly rammed, ignited with wood chips or an ignition agent, and an air distributor is installed, and then covered with a lid.

The efficiency of such a furnace is quite high, and thanks to its sealed body, it can be used to heat rooms where people are staying for a long time. If desired, it can be equipped with a water circuit by passing the chimney through the boiler.

The second method or boiler No. 2

A pyrolysis boiler with a water heater, which does not require electricity and automation, works according to the principle of opposition of the two laws of a square-cube. This refers to the filling of fuel and the lining of fireclay bricks. The algorithm of the brick kiln:

The loading of wood or coal into the boiler with a thermal buffer is carried out gradually. Sharp temperature fluctuations are contraindicated for her. If too sluggish fuel is used, it can stall. If it is too flammable, there is a risk of an emergency. If the first heat is not suppressed, the efficiency will not exceed 76-78%, since instant heat transfer from the lining to the outside is excluded.

Furnace device

This is a vertical furnace with one combustion chamber, which is loaded with fuel from above. Rather, not just from above, but from above and from the side. This allows you to conveniently load fuel, including during the operation of the furnace, without waiting for the first tab to burn out. At the bottom of the furnace there is a hatch for ash removal, which facilitates the maintenance of the heating device.

On industrial models, special dampers are installed to regulate the air supply, as well as the gas outlet.A casing is fixed on top of the combustion chamber, passing through which cold air is heated and removed back to heat the entire room. A special chimney removes volatile combustion products outside the room.

The Slobozhanka oven drawing can be easily found on the Internet in the public domain. Inventors do not hide the characteristics of their development. On the contrary, in their opinion, Slobozhanka will enjoy special trust and demand among rural residents after they learn more about it.

English fireplace

There are legends about the attractiveness of fire, its decorative and aesthetic function is of great importance for a person. Can an ordinary person build a long-burning fireplace in his home in order to enjoy not only the warmth, but also the beauty of fire? The main thing in such devices is not heat transfer and efficiency, but the ability to contemplate fire during the day.

English-style fireplace made with your own hands will decorate your interior

There are such designs, and the British came up with them. The classic English fireplace has a smoke tooth, reminiscent of a sill in a Russian stove, which forms the circulation of flue gases, which does not let fresh air upward, directing it to the bookmark, as it happens in a potbelly stove.

Due to the large mouth, the efficiency of the fireplace is small - no more than 50%, even if there are smoke flows in the chimney. Smoldering and heat generation from evening to morning occurs only when using Cornish coal or similar coking coal. They say that in the old days the English lords stoked fireplaces with the rhizomes of pines growing on the coastal rocks.

An example of another "long" fireplace is a common Dutch woman. The blower is closed before kindling, the firewood is loaded onto a quarter of the firebox, its door remains wide open. Most of the heat escapes into the pipe, but the decorative effect is ensured.

In this article, today we will talk about General requirements for stoves in baths.

Oven bricks for baths it should be red of the highest quality (front or chamotte), seams not thicker than 5 mm, cement or clay mortar. The wall thickness is 1/2 or 1 brick.

Firebox opens in the washing room or in the dressing room. In the latter case, three walls of the stove must be in the washing room. To ensure full thermal radiation, the stove is separated from the partitions and walls by a gap of at least 25 cm. heaters, which not only heat the room and heat the water, but also give dry steam.

For this, stones of hard rocks weighing 1-5 kg are loaded into a special chamber of the heater.except for marble, limestone and flint.

The first two, when heated, stop into quicklime-boiling water, and the last one cracks and, on contact with water, fragments fly away!

In each chamber, on the side of the steam room, one or 2 doors are arranged. The volume of hot water tanks is 6-7 liters per person. Cold water should be the same or less. Boilers or tanks should rest on the walls of the stove masonry, be suspended on chains or rest on brick posts inside the furnace. The tanks should have a bottom tap, the tube of which is insulated with asbestos or bricks.

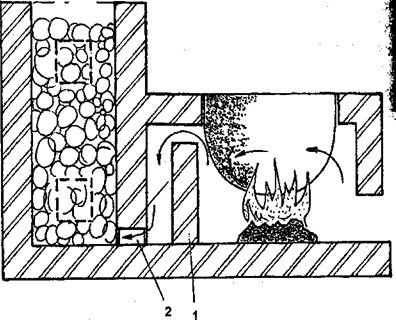

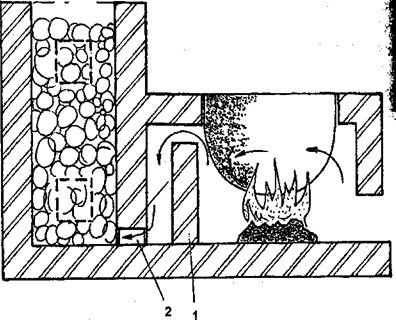

Kamenka stove with hot water boiler looks like an ordinary stove without a blower and with a wider tube - a chamber with grate bars filled with stone (see photo above).

The lower door opens after the firebox to supply heat to the floor, and the upper door serves for the generation and supply of steam. Through it the heated stones are poured. To increase the heat transfer of heated stones, it is better to place them starting from the floor level. For better heating in the walls of the chamber. from the side of the firebox, several holes are arranged for the penetration of combustion gases.

Improved stove-heater differs in that at the very bottom of the chamber there are holes for the passage of flue gases. An even more advanced furnace (see photo) has a brick screen for the directional movement of gases, which is 10-12 cm from the chamber and the stove overlap.

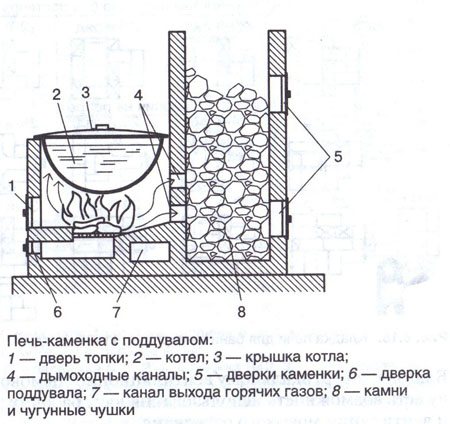

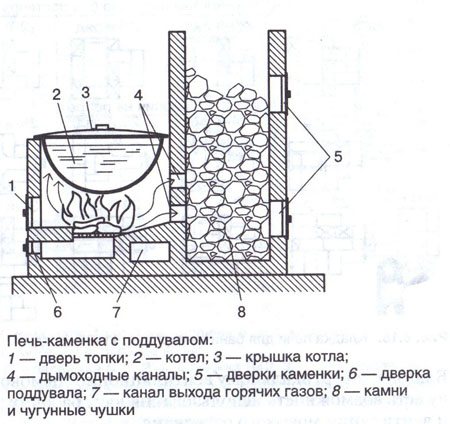

Heater stove with blower ( see photo). The bottom of the boiler should be at a distance of 50 cm from the bottom of the firebox, its sides should have a gap of 5 cm from the walls of the furnace for efficient flow of hot gases.

Attention!

To avoid a fire, the pipe at the attic floor should have a cut of 1.5 bricks (38 cm), and 15 cm from the bars of the roof sheathing.

The simplest do-it-yourself stove

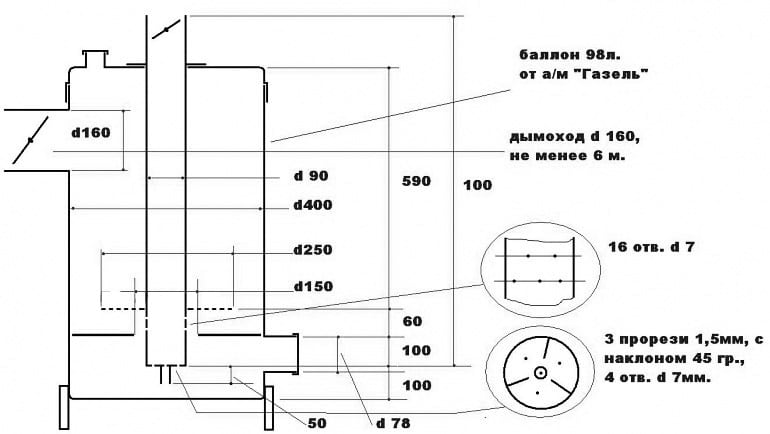

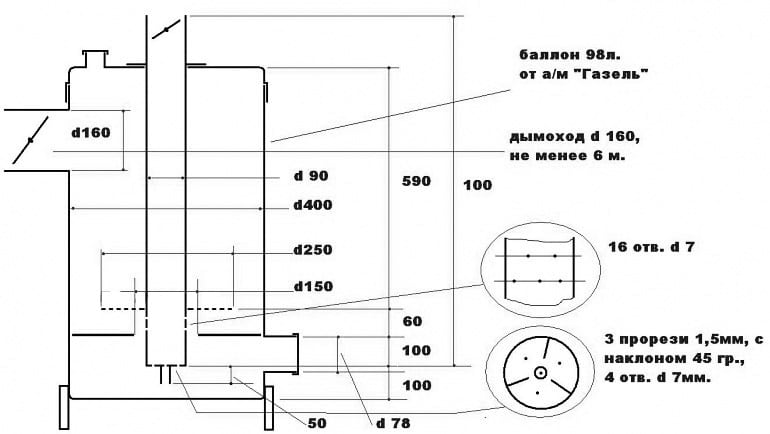

Solid fuel boilers for long burning, which were mentioned above, are difficult to do with your own hands according to the scheme. The drawings below will help the DIY master build the simplest heating device on his own. Equipment power - 35 kW, efficiency - up to 85%, burning time - 12 hours. Coal or fuel pellets are used as fuel. Loading with wood reduces the efficiency to 75%, the burning time is reduced to 8-10 hours.

A drawing of the furnace design will help you make it yourself

Manufacturing

For reliability, it is worth looking for drawings for DIY oven assembly... Next, you need to prepare the tool. For the manufacture of we need ovens:

- welding machine and a set of electrodes depending on the thickness of the metal used;

- drill with a set of drills for metal;

- Bulgarian and several grinding and cutting discs;

- various small tools (hammer, chisel, tape measure, etc.).

Scheme and the possibility of design improvement

Slobozhanka is a full-fledged miracle wood-fired oven with a hob. Air is supplied to the smoldering tab from the side along a U-shaped trajectory: down the L-shaped duct and then through the perforated casing. Access is provided to all layers, which contributes to more active pyrolysis, therefore Slobozhanka works well on coal and pellets. It is an economical device with an efficiency of over 80%.

The power of the equipment can be increased by complicating its design: stretching the inner perforated casing over the entire circumference. To equip a blower with a throttle, a third narrow casing is made to cover the air intakes from the outside.

Vertical Slobozhanka is made on the basis of a barrel

A bit of theory

The Slobozhanka stove, which provides long-term combustion, is a generalized concept, the models differ in:

- the system and principle of air supply to the furnace;

- the size of the firebox;

- the presence of the main and / or additional ignition unit.

A common feature for all models is the use of a top-type solid fuel combustion and ignition system.

Oxygen is fed into the firebox from the bottom, but as noted above, in different ways. There are three ways to supply air:

- with the help of an L-shaped channel (pipe) to the lower part of the combustion chamber, a kind of upper lateral supply of oxygen from the side to the bottom of the furnace;

- from the bottom directly in the center (a special pipe is used) upwards, that is, the distribution also goes from the bottom up;

- from the lower side, while the walls of the stove warm up well.

We suggest that you familiarize yourself with How to choose a wood-burning fireplace for home and summer cottages: an overview of the best options for hearths based on reviews and recommendations

The Slobozhanka stove, in order to ensure long-term combustion, can have two main principles of operation:

- lateral (the energy carrier burns from above to the bottom of the firebox with a certain inclination at a certain degree to the chimney);

- central (the energy carrier burns from top to bottom of the firebox with flame distribution to the sides of the firebox).

How it looks - look at the photo.

Greenhouse oven

Remember only one thing, no matter what design you choose in order to assemble the stove with your own hands using the presented drawings, heat transfer, which means that the efficiency will be quite high and this is confirmed by the reviews.

Slobozhanka with a mushroom hat

The traditional Slobozhanka has disadvantages:

- She does not accept oily and tarry fuels. Household waste, chipboard and fiberboard waste form hard deposits at the edges of the holes in the inner casing and the perforated casing of the air duct.

- Careful refueling of the incomplete bookmark is required, since at least a small smoldering area should remain free near the perforation of the casing. If this is not foreseen, after the bookmark burns out, the stove will cool down.

The design with a central conical perforated air duct with a mushroom head is the development of one of the Soviet p / i. Created on the basis of the Slobozhanka. The cone was freely installed in the firebox discharge hatch and removed for cleaning.

The edges of the cap threw fuel to the edges, and a glowing ring was formed under it, which was necessary to heat the stove. Additional loading could be done in any quantity and at any time. Due to the edges of the hat, air was directed into the decay zone, which ensured the omnivorous design.

The disadvantage of the "slobozhanka with a fungus" was that when burning household waste or raw pine, it was necessary to check the carbon deposits. The cone could stick tightly. To take it out without distorting it, in this case it was difficult.

Modern and ancient Russian stove

The Russian stove never went out at all. She slowly glimmered in her corner during industrialization, electrification, gasification, and has always been the object of close attention of specialists due to her remarkable qualities. Now the Russian stove is experiencing a rebirth; its efficiency and versatility played a significant role in this ...

By the way, Bill Gates has a real Russian stove in his dining room, in which pies and pies with meat and other dishes of Russian cuisine are baked for him. Many foreigners are openly interested in this miracle of "Russian engineers". At the London auction of the Batier brothers, a large English businessman was sold a stove made by a Russian master - Vasily Fedorov, for twenty thousand dollars.

Experience with high-efficiency slow-burning furnaces

When calculating according to ready-made formulas and simplified methods, the efficiency of a Russian stove comes out somewhere around 25-30%. This value has long inspired doubts, and in 1927 the USSR People's Commissariat of Land conducted field tests. The result stunned the specialists: the exact measured value turned out to be 68%! This is higher than the efficiency of a large CHP! At the same time, a competition was announced to improve the furnace. The samples developed at VTI (All-Union Thermal Engineering Institute), Grumm-Grzhimailo and Podgorodnikov showed an efficiency of about 80%. Research on Russian stoves is still ongoing: it is not yet clear how such an efficiency is achieved.

The Russian stove is unique in its essence. Being a very important element of everyday life, the Russian stove has rightfully taken its well-deserved place in history. In the old days in Russia there was a custom that during matchmaking, the matchmakers who came, entering the hut, first baptized themselves in front of the icons, and after that they put their hands on the stove, which showed the purity and decency of their intentions and "joined" in this way, to the family of the owners, were considered close people ...

And if someone ever received an invitation to sleep on the stove, then after that he in this family was forever revered as a relative.

The Japanese have developed a super stove!

In different parts of Russia, Russian stoves had different shapes, sometimes very unusual specimens were found, but the basic dimensions were nevertheless observed quite strictly. The Russian stove is a massive structure, the average Russian stove had the following dimensions: the width of the Russian stove was 2 arshins (about 142 cm), the length was 3 arshins (about 213 cm), and the height from the floor to the bed was 2.5 arshins (about 180 cm)

The Russian chimney stove (stove without a chimney), used in Ancient Rus for a long time, was the prototype of the famous “Russian stove”.When the huts began to be heated "in white", they had to attend to the material for the pipes. Since hot gases were flowing through the pipe directly from the firebox, it had to be made of refractory material - from broken clay or brick. In order to capture the smoke coming out of the furnace as best as possible, the pipe expanded immediately in front of the mouth of the furnace, forming a so-called casing. For its resemblance to a piece of women's clothing, he was also nicknamed epancha. Subsequently, for stability, the epanchu began to be propped up from below with two racks, which rested on a brace. It is possible that it was these sixes that gave a new name to the heat, which began to be called the six.

Six is a shelf in front of the mouth of the oven, on which the hostess could keep cooked food warm. On a pole at the side were raking up hot coals for the next furnace.

The most hi-tech cuisine in the world.

In a simple Russian stove, the pole is mainly intended for pots and cast irons, which are brought from here with the help of grips into the stove. During cooking, cast iron pots from time to time are put on the pole to check the degree of readiness of the brew and add something. The hostess pushes them here at the end of cooking before sending them to the table.

Although the pole was mainly used as a stove rack, in some cases it was used as an open fireplace. For example, you need to heat up a brew, and the stove has cooled down long ago - do not refuel it again. The sixth came to the rescue. A small forged tripod called a taganka was placed on it. A cast iron, a saucepan or a kettle was placed on top of the taganka rim. The mouth of the furnace was closed with a damper so that its handle was turned towards the firebox. Opening the view, under a tripod they kindled a small fire made of short chicks. If it was not necessary to acquire a tagank, two bricks were taken out of the podpechka and placed on the edge at some distance from each other. A fire was also made between the bricks, and a pot of food or a kettle of water was placed on top.

In the side wall of the stove, shallow niches were made - stoves, where wet mittens and a torch for kindling were usually dried. Poultry was kept in warm guardianship in cold weather. The Russian stove always had numerous shelves and niches, which served both to increase the surface area of the stove, and, therefore, to increase heat transfer, which made it possible to warm up the room faster, and for storing all kinds of dishes and household utensils.

How to make a Russian stove? (Video)

Pottery was fired in a Russian oven. In the Russian stove, they burned not only dishes, but also toys. Moreover, the toys were burned, as a rule, during a conventional firebox. Brewers - they brewed beer in the oven, loopers (as in the old days people who wove baskets were called) - steamed willow rods in the oven to make them soft and flexible ...

Sleep on the beds - strong and deep. 6 hours is enough to get enough sleep; you always wake up vigorous, with a clear head. The indicated properties of sleeping on the beds refer to the oven that slowly grows out overnight. A similar, but much weaker effect is obtained by using a good branded electric blanket with automatic adjustment according to physiological parameters.

Places on the stove were allocated to each member of the family according to a strict hierarchy system, the old people usually - below, to the right of the mouth, and the kids - on the beds (the upper part of the stove, the so-called "bed").

Local disobedient, mischievous, careless children were often reproached: "It can be seen that they did not make you on the shelves!"

DIY Russian stove: drawings and ordering (+ Photo)

LAYING WOOD

Few people know that it is necessary to put firewood into the Russian stove in a special way "with a cage" (although you can heat with what "God sent": brushwood, deadwood, straw, kurai (dry weeds), dung, anthracite, coal-seed, peat briquettes, peat crumb , sawdust, and in the treeless parts of the country, straw, reeds, weeds and even dung were used, but bread only needs to be baked on wood or charcoal.Otherwise, the taste will turn out to be store-bought.)

They try to chop firewood and select the same size, without large knots, so that they burn out at the same time and give good coals. At the same time, in order for the coals to turn out to be uniform, they no longer put firewood, but try to heat the stove with one batch of firewood, keeping the heat from the coals as long as possible. To melt the Russian stove, firewood is laid with a well.

Stacked from 7 to 13 logs with a long wooden shovel. preferably as far from the mouth as possible. The first log is laid across the furnace. Three of the following along the furnace with their distant ends on the first log., 5,6,7 across the second, third, fourth and so on.

Such a well is made in order for the firewood to catch fire and burn out at once. For this, at the very bottom, between the logs, bundles of long torches are laid and set on fire.

The Russian stove works only on slowly burning solid fuel. Rapidly burning liquid and gas require a lot of air, the flow of which the Russian stove cannot provide. Placing a fuel oil nozzle or a gas burner in the crucible is not only useless, but also life-threatening.

FOOD

The Russian stove in the peasant hut was heated every day in winter and summer. She heated the hut, prepared food for the family. Moreover, due to its large mass, the heated furnace retains the heat given to it by the flame for a very long time, i.e. cools down for a very long time. Thus, the food - cooked in the morning remained hot until late at night, the cooked porridge - steamed and became crumbly, the milk put in the oven - languished practically without the intervention of the owners, who worked all day in the field or around the house, and in the evening they feasted on such a beloved in Russia drinks such as baked milk, yogurt and fermented baked milk, which was also used to prepare feed for cattle. The dimensions of the Russian stove were very impressive. Two-bucket cast iron passed freely through the wide mouth. A clay pot with beer malt passed along the height.

The design of the Russian oven made it possible to cook on it not only porridge, but also to bake bread (and it can be baked about sixty kilograms at a time, which was a week's supply of bread for a whole family), pies. In addition, mushrooms, berries, fish, grain, etc. were dried both in the oven and on the oven.

In the attic, in the chimney, special smokehouses were arranged.

The design of the oven made it possible to use the same parts for various types of heat treatment of food. Food could be boiled or steamed, fried, baked or simmered.

Usually:

• fried at the entrance to the firebox;

• cooked in a firebox;

• previously prepared food was heated on a rack;

• simmered food inside the oven, after the fire;

• on the bottom - baked.

The culinary Russian oven, in which cooking has been worked out for centuries, is still unique. Modern kitchen stoves, ovens, microwaves and steamers already give a completely different effect.

The secret of the taste of food cooked in the Russian oven is that the heat of the oven is evenly distributed and the temperature does not change for a long time. Dishes with food do not have direct contact with fire, allowing the contents to warm up evenly from all sides, without burning.

In a Russian stove, without any partitions and nooks that complicate or even make it impossible to repair or clean, a virtual complex smoke channel is formed, surpassing any labyrinth in efficiency. There is only one thing to regret: the name or names of the geniuses who created it remain in obscurity.

OVEN - BATH

To treat various colds and that could bake. The patient was pushed into the stove on a special bed so that he could sweat thoroughly. Outside, the oven was sprayed with water or kvass, and the thick "bread" steam was a kind of inhalation and had a beneficial effect on the patient. Also, in the ovens, babies were treated for rickets. The kids were coated with clay and placed in a warm stove. Such a general heating of the body led to the correction of bones.

They also steamed in the oven. There is enough space in the Russian oven.The heating stove occupied at least a third of the hut, and two adults could get inside at once.

Of course, you can't swing a broom in it, but it is quite possible to steam gently. It is not known what is more in such ingenuity - zeal (why waste heat in vain, put cast iron and the water will warm up) or "Emelevskaya" laziness (why heat the bathhouse if you can wash in the stove).

After kindling, they cleaned the underneath, carefully sweeping the ashes and lined them with straw so that they would not burn, put cast iron with water inside, after which the stove could be used as a kind of mini-bath. A clean rug was placed on the pole. Then the man climbed into the oven and sat on the straw. It was possible to splash from a bucket onto the hot walls, or you can simply wet a broom and shake it behind your back. If you want to breathe fresh air, you can lie with your head to the mouth. Men steamed first, then mother and children. The adults washed themselves, often one at a time, and the children and the elderly were brought inside on a wooden shovel.

They washed themselves with lye, used ash or an egg to wash their hair. They served steam, pouring water over the hot walls of the stove. Russian people liked to wash in the stove, the bath was heated, only for a large company.

That is why the proposal “to steam in the oven”, which sounds suspicious and even wild for a modern person, sounded completely normal in the context of old Russian times.

Interestingly, girls washed in the stove more often than men. In some areas - for example, in the Vladimir province - it was generally considered a sin for girls to bathe in a bath. Only married people were allowed to go there, and girls or widows had to use home-made Russian stoves. Or maybe they themselves did not want to wash there, frightened by stories about the bathhouse - evil spirits, the owner of the bathhouse, who could throw a red-hot stone from the sauna stove at an unwelcoming guest and close the door tightly. The Russian stove was in the house, where icons hung and every corner was sprinkled with holy water. Therefore, it was calmer to wash in it.

LIGHT SOURCE

A fired oven in winter was one of the main sources of light, and spinning was the most important female handicraft in those days. Sitting on a bench near the mouth of the stove, the woman turned the spindle with her right hand, twisted a thread with her left hand and, of course, kept glancing in that direction. If the stove was to the left of the entrance, the light fell not convenient for work. Even at the beginning of the 20th century, there were many chicken huts in the Russian village; homemade craftswomen worked at the stove. It is no coincidence that in the dictionary of V. I. Dal, a hut with a left-sided stove is called a "slob hut" for the fact that in such a dwelling a woman cannot spin from her hand.

PLACE IN ISB

There are three traditional options for orienting the furnace mouth.

The most ancient is South Russian. The stove is located in one of the corners farthest from the entrance. The stove corner (not to be confused with the corner in which the stove itself stands) occupies the space from the mouth to the wall opposite to it. If it is separated by a curtain or partition, then it will be a "kitchen". The angle lying diagonally from the mouth is called large, or red. There is a table, a chest, long benches and icons hanging here. In the fourth corner, beds are arranged under the ceiling (flooring made of sleeping boards). Fenced off by a curtain, it becomes a "bedroom". The washstand, buckets of water, and all the kitchen utensils are in the stove corner. The red corner is both an entrance hall, a dining room, a living room and a place for work. This layout of peasant houses is common from the southern Moscow region to the middle reaches of the Don.

The second option is North Russian. The mouth ("chelo", "whole") of the main bread oven faces the wall opposite the entrance and was illuminated by a side window. The stove was close to the side wall. Between them there were 20-30 cm, where the kitchen utensils were kept. Between the stove and the end wall, above the entrance, wooden planks were arranged. A similar layout can be attributed to the north-central Russian.In cross houses and five-walled houses with a cut, the stove was located so that it was possible to heat either all the rooms or several of them. In this case, a stove was made with a firing or a fire-place. The significance of the space of the hut increased from the entrance to the opposite wall, where there was a "front corner" with icons and a table. The least honorable place was the part of the hut near the entrance, located between the bed and the stove, “under the threshold”. The rules of politeness forced those who came to the house to stop at the entrance and wait for an invitation to go further. The space between the stove and the wall, where the "front corner" was located, was called "kut". It traditionally belonged to a woman and was mainly intended for cooking and sewing. There was a "box" with the mistress's belongings - a chest with a dowry taken from the parents' house. There was an entrance to the underground near the stove. A small shop adjoined the stove from the side of the front door.

In the third version, the axis of the furnace is perpendicular to the longitudinal axis of the house. In the north, this variant is called "Finnish", as it is found in the dwellings of Russified Finns, in the south - Ukrainian. The stove is next to the door, but the mouth is looking not at the opposite from the entrance, but at the side wall. Accordingly, the red corner is located in the same way as in the North Russian hut, but the stove is at the entrance, all in sight, so it is both a kitchen and a hallway.

The middle location of the stove in the house is completely uncommon for the dwellings of the East Slavic peoples.

FURNACE IN A MODERN STYLE

There is no limit to perfection. New technologies, new materials, new construction opportunities appear. Tastes and views change.

Some modern Russian stoves additionally contain a boiler with piping around the house.

The stove, in addition to its direct functions of the beginning, becomes the subject of interior decor. In any room, the stove will always be in the spotlight, it will always be the "nail". An invariable feature of the stove is that it is a center of warmth and comfort.

Here are the collaborations between designers and stove-makers.

Online conference:

"How to build an eco-house" 2017

Source: ecoschool.info

If you liked this material, then we offer you a selection of the best materials on our site in the opinion of our readers. A selection - TOP about existing eco-settlements, ancestral estates, their history of creation and everything about eco-houses, you can find where you find it most convenient VKontakte or Facebook

If your page is not displayed correctly, the video does not play or you find an error in the text, please click here.

News from our partners