Where can you use a gas oven

The gas heating system is universal, it is used:

- for heating baths and saunas;

- as heating boilers when laying thermal communications in a room;

- as part of boiler structures to provide apartments with hot water in the summer;

- if we consider household gas stoves, then they are very popular with housewives. Thanks to the open fire, dishes are cooked on such a structure much faster.

Types and features of gas ovens

Before you build a gas oven for a bath with your own hands, you need to understand the main design features of these structures and their types.

All gas structures are classified:

- heating;

- household;

- heating.

If we consider a stove for a bath or sauna, then it is worth stopping at a heating gas structure.

Heating stoves are used in autonomous heating systems and hot water supply of private buildings. It should be borne in mind that with high air humidity, these structures are practically useless, since they cannot maintain a high temperature.

Gas household structures are ovens for cooking, which are often installed in summer cottages. They are unpretentious in care and easy to use, in addition, they are quite economical.

Gas ovens have various qualifications for:

- the type of burner that is installed in the boiler;

- the method of heating the coolant;

- the material for the manufacture of the furnace frame;

- the type of fuel to be used.

There are many types of gas furnaces, there is another type of qualification - according to the type of gas burner:

- atmospheric;

- supercharged.

The most affordable burners on the market are atmospheric burners. They are easy to install - no need to supply electricity and install special automation. In this case, injection is involved, under the influence of which air enters the zonal chamber or a special pipe installed by analogy with homemade structures.

It should be understood that this is why the efficiency of the furnace will depend on the supply of oxygen. If the blowing is weak, then the efficiency of the furnace will also greatly decrease - the combustion of the gas will be sluggish.

The most complex and expensive design is inflatable burners, which directly depend on electricity. The design feature of this unit is a special fan that blows air into the combustion chamber. The efficiency of the structures is great, its use is universal, since they can be installed in combined-type furnaces. Atmospheric units can only be installed in gas ovens.

The body material can be different:

- a rock;

- brick;

- metal.

Each material has both positive characteristics and disadvantages.

Installation rules

A do-it-yourself gas stove for a bath can be installed, but some rules should be followed for installing such a structure:

- The indoor gas pipeline should be made of copper and steel.

- If flexible connections are used for the connection, they must be pressure and temperature resistant.

- Installation of flexible hoses must be carried out in accordance with applicable standards. If they are produced in other countries, you need to take a product certificate.

- Flexible connections used for gas connections must be marked about and possess diameter 10 mm... Sleeves should not have seams, that is, be one-piece.

- The gas pipe must be protected from damage.

- If a centralized gas supply is not provided for the bath, the outlet of combustible products into the atmosphere must be installed.

Only if the above conditions are observed, a gas oven for a bath can be installed with your own hands.

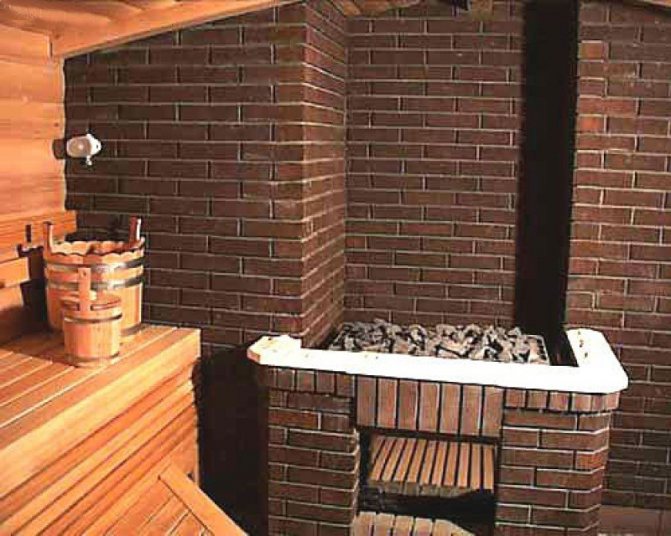

Brick and stone ovens

These designs differ in the duration of warm-up. If there is a desire to take a steam bath during the day, then you will have to start heating the bath at night or early in the morning. Of course, such a stove cools down much longer, for example, a well-heated bath, even in winter, retains heat for 2 days if there is a brick structure in it.

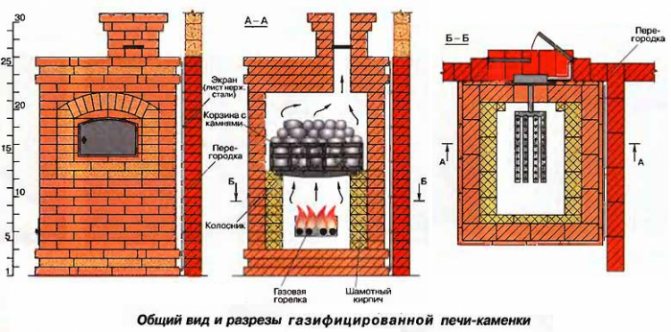

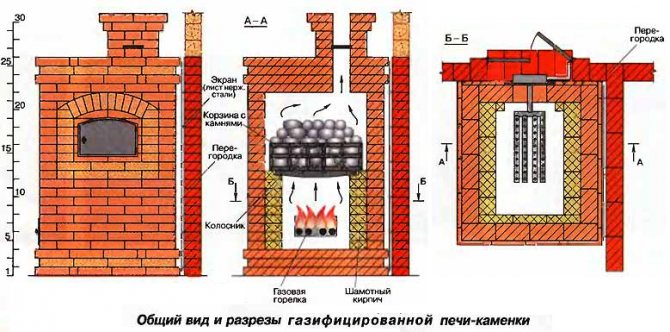

Brick structures must be installed on the foundation, since they have a decent specific gravity, differ little from the classic version of sauna stoves. The only difference is that the door will not open access to the firebox, but to the heater, which is located in the stove itself.

It is worth noting that the cost of a brick oven will be quite expensive, since a lot of material is needed for its installation.

As for metal gas stoves, they are much more popular with ordinary people, their advantages:

- Easy to install.

- The ability to build on your own, without the help of a professional bricklayer.

- The design has a low specific weight.

- Heats up quickly, thus it takes much less time to heat the room.

- Profitability, especially if you assemble the structure yourself.

Sauna stoves are divided into types according to the type of fuel:

- exclusively on gas;

- combined.

If everything is clear with the former, then the latter should be considered in more detail, since they are heated both on gas and wood. This versatility has significant drawbacks:

- bulkiness of the structure;

- it is imperative to install a blower burner;

- the complexity of execution;

- dependence on electricity;

- traditional wood stoves are much safer.

As for gas stoves, they can be equipped without having a gas pipeline nearby, since they perfectly function on propane, which is freely available and is sold in metal cylinders.

In addition, propane compares favorably with natural gas, the thermal energy during its combustion is much more efficient. This gas is economical when heating a small room in a bathhouse; you often don't have to fill up the cylinders.

But there is also a significant disadvantage - the need to equip a special room for the installation of gas cylinders, which should be at a sufficient distance from the building, outside of it. It is advisable to prepare a steel container dug into the ground.

Burner selection

Burners are:

- Atmospheric.

- Inflatable.

For homemade construction, only pressurized burners can be used. They are more difficult than atmospheric ones, but much safer.

The devices are equipped with automatic valves that turn off the gas if the flame goes out, or the stove overheats, as well as if a leak occurs. There are models with auto-ignition.

You need to purchase a burner in advance, before stocking up on all materials. The fact is that burners come in various sizes and shapes - drawings and diagrams will be developed based on this.

When buying a gas oven for heating a country house, summer cottage, bathhouse, garage, you need to pay attention to the following:

- the size of the unit, its compliance with the parameters of the structure, which it will have to heat;

- the presence of an automatic system for cutting off the fuel supply, a thermostat and a gas fuse (the latter two will require a small overpayment, but during the operation of a gas furnace they will save money);

- the ability to operate a gas burner on main and liquefied gas;

- equipment certification.

How gas ovens work

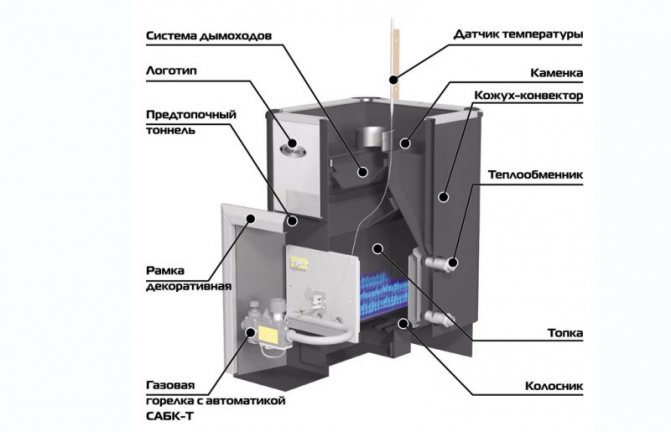

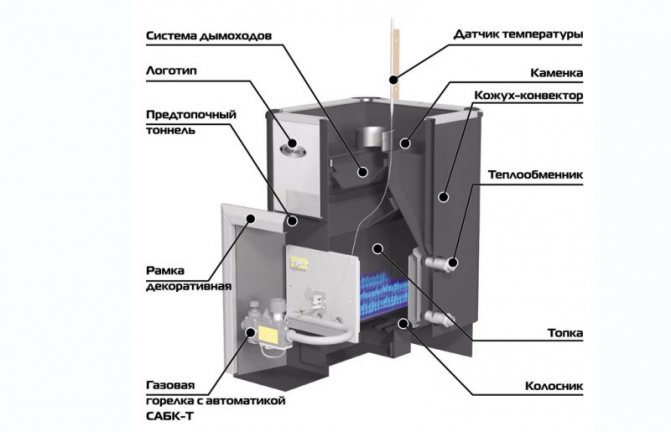

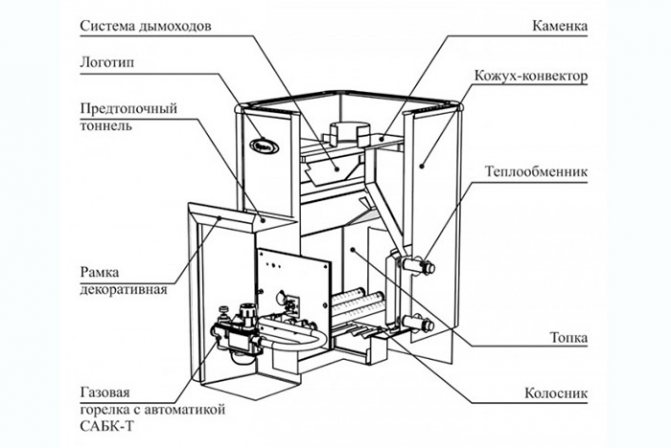

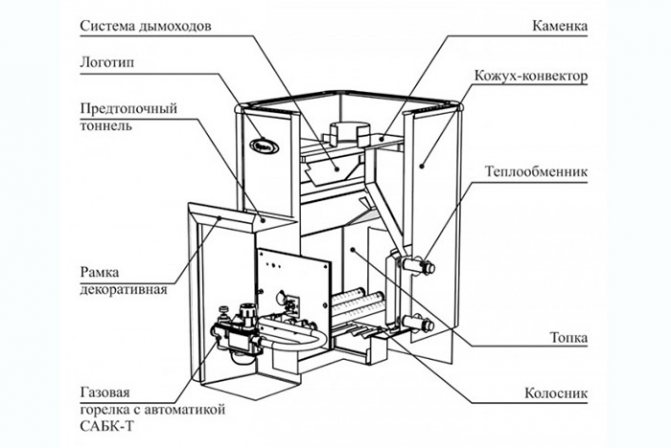

To have an idea of \ u200b \ u200bthe device of a gas oven, consider the main structural elements:

- a housing that is made of metal or other material that protects the internal contents;

- a fuse, which is installed in case there is an attenuation in the furnace - the gas is shut off instantly and automatically;

- thermostat responsible for temperature;

- sealed chamber. It is on this unit that you should pay special attention when choosing a design in a store or making a gas oven yourself. The safety of people living in the house depends on the integrity and reliability of the camera;

- the chimney serves to remove combustion products from the bath room.

As for the principle of operation, it is quite simple. The gas burner, to which the gas is supplied, is located inside the housing. There is a heater and a chimney on the body. As soon as the burner is triggered, the combustion process begins in the working chamber, from which the furnace body and stones are heated, and the waste products come out through the chimney.

We must not forget about the tank with water, in which it will be heated from burning in the oven. It can be installed above the stove and attached to a pipe, which, when heated, will give off heat to the liquid. But some craftsmen build a tank attached to one of the walls of the furnace.

In addition to all of the above, for gas stoves for a bath, you need to build a protective case, which is built on top of the main one, in places where the stove is close to the walls of the bath.

Advantages and disadvantages

Today, gas fuel is chosen by many inhabitants, if there is such an opportunity in the region, since it is considered the most economical fuel. It should also be noted that gas-fired ovens have many advantages:

- The design is simple when compared with solid fuel stoves, for example, in gas stoves for a bath, there are no huge furnaces and ash pans - they are not necessary.

- Ease of operation of the gas unit. The wood stove must be constantly monitored and fuel must be added as it burns. As for the gas boiler, it is enough to set the basic parameters: the rate of fuel flow, temperature regime, pressure and automation will monitor all this. It should be noted right away that when building a structure on your own, you should not save on automation - gas requires a responsible attitude.

- There is no need to constantly clean the gas structure - there are no ash residues and solid waste.

Gas ovens have drawbacks, but there are few of them:

- registration of documents and permits for the installation of gas equipment - one-time, but there are some difficulties;

- sometimes there are difficulties in winter with high fuel consumption;

- in some areas, the pressure in the system may decrease, but this is quickly eliminated.

Manufacturers

Russian-made gas ovens (Teplodar, Rus, Troika, Termofor) have good reviews. They are of high quality and are presented on the domestic market in a wide range. They have a nice design, steel firebox, door made of metal or heat-resistant glass. Such units are distinguished by high performance, simplicity and unpretentiousness in use. Some models are equipped with special valves to regulate the temperature.

A gas stove for heating a summer house, a private house is a profitable and practical option. If desired, you can assemble it yourself, but in case of an oversight, such a device can lead to a leak of fuel material and an explosion. Therefore, it is very important to observe safety precautions.

How to make a gas oven with your own hands

If you decide to create a gas oven with your own hands, then it will not be difficult. The main thing is to determine the sequence of the work and know the main nuances, which we will consider further,

Do not be afraid of complex schemes that can often be found on the Internet, if you understand how to deal with a drawing, then there will be no problems.

Training

First of all, we create a project on paper. The pipeline will be marked on it, which will go to the bath. You should not do this yourself, as it is very likely that you will make mistakes. Contact a special service, which has specialists - they will not only make a detailed project, but also lay communications to the place of installation of the furnace.

In addition, you will have to go through the approval procedure with the management of the gas service and obtain permission from the fire service.

But these actions need to be performed only if the furnace will operate from a gas main. Completely different spare parts must be installed on gas equipment, since the fuel will come from the cylinders.

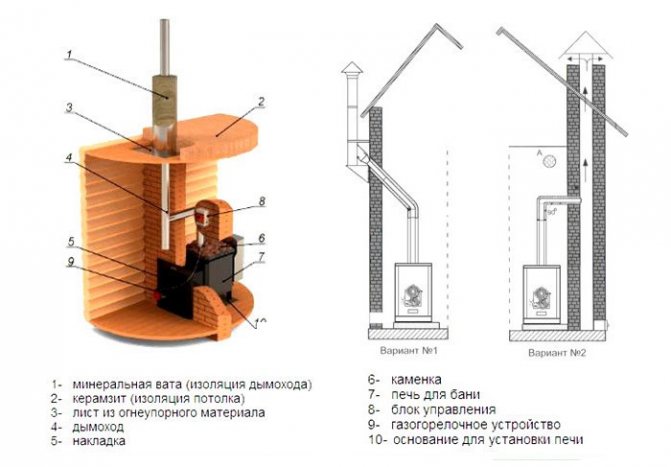

When drawing up a project, you need to develop a good ventilation system that looks like a chimney. This work must also be entrusted to professionals, since with poor ventilation of the room, there is a possibility of carbon monoxide poisoning if a heating failure occurs. Before inviting specialists, it is worth preparing all the permissive documentation - employees have the right to refuse installation if there is no agreement.

Installing a gas oven

Before starting the installation of furnace equipment, you need to prepare a reliable and heat-protected base:

- an asbestos sheet is laid on the floor where the structure is supposed to be installed;

- then it is covered with a piece of sheet iron and screwed tightly to the boards. If the floor in the bathhouse is made of concrete, then it is not necessary to carry out these manipulations;

- further, the nearby walls are protected, which are also sheathed with asbestos and iron. Even if the equipment is installed at a considerable distance, it is worth making sure - the heat negatively affects the material of the walls;

- now on sale there are special screens that can provide additional protection not only to walls. Experts advise to install them around the stove from the side of the steam room - they will prevent those present in the bath from touching the hot surface.

Further, the installation is carried out in accordance with the gas supply system and the presence of curtain walls in the bath. In the case of installing a furnace that will operate from a gas main, it is worth buying a special metal hose connected to the inlet pipe. The distance is calculated in advance - it is important that there is no strong tension when laying it to the installation site of the furnace equipment. Passages are arranged in the walls and partitions, which subsequently need to be well insulated so as not to drown the street in winter.

Important! It is undesirable to use a rubber hose for the connection, since it is unsafe, and it lasts for a short time. It is better not to spare money and buy an element made of heat-resistant and moisture-resistant material. In addition, modern hoses for connecting gas equipment are easy to use and reliable.

If you decide to install balloon equipment with liquefied gas, then it is worth preparing a special room that will be located at a decent distance from the bath structure, protected from direct sunlight and summer heat. You can go in two ways - build a special shed, the walls of which will be additionally insulated with foam or mineral wool.

Dig a pit, the walls of which can be upholstered with a board so that they do not crumble, pour concrete. After installing the cylinders in this recess, they construct an insulated cover, which can subsequently be sprinkled with earth.

Next comes the assembly and connection of the gas oven. The installation of the structure must be carried out strictly according to the instructions, since different manufacturers have their own specific nuances during assembly - various fasteners and installation method.But there are rules that apply to all models without exception:

- the minimum distance between the wall and the stove is 30 cm. If the walls are prepared and protected with refractory material - 15 cm;

- the chimney is discharged through the assembly on the ceiling and roof;

- nail a sheet of metal to the floor in front of the firebox - sparks can fly out of it.

If the model of a gas stove provides for the installation of a water tank on a pipe, then you can adjust it in height so that it is convenient for all family members to use it.

As soon as the furnace is installed in a permanent place, they start assembling the control system, if it is not built into the structure. In this case, it is tedious to strictly follow the manual that usually comes with the oven.

Today there are many models in which an auto-ignition is provided, it does not work without electricity, therefore, before assembling the structure, a separate cable is pulled into the bath, protecting it with a special corrugation from high temperatures.

If there is no built-in fan, then before each ignition it is necessary to check the draft in the structure - for this, a match is lit and brought to the furnace window.

If there is a gas stove in the bath, then the room will be completely warmed up in winter to the desired temperature after 8 hours. This is not an accurate indicator, everything will depend on the power of the structure, the quality of insulation of the walls, ceiling and floor.

If external temperature sensors are installed, the oven will turn off automatically.

Requirements for garage ovens

It is important to remember that a garage, although a secondary structure, usually made of bricks or blocks, is still fire hazardous. That is why, first of all, fire safety rules must be taken into account here.

What exactly should you pay attention to?

- Refractory foundation;

- Reflector installation;

- The maximum distance from the furnace to the place where fuels and lubricants are stored;

- Correct selection and installation of the chimney.

These are just the main requirements. There are many more little things that a fire inspector can pay close attention to. They will have to be corrected during the operation of the gas appliance.

Now let's talk about what the garage oven will work on. Since we are talking about hand-made devices, it is also worth using an energy carrier that will not “beat” your financial situation very much. Of course, it is ideal when a gas pipe is led to the garage. But in a city that's unlikely. But in a private house, this option is very good.

- First, gas is budgetary.

- Secondly, in terms of operation, a gas stove for a garage is very convenient.

- Third, gas reduces fire safety risks. Thus, by installing a safety unit on the device, such an oven can be safely used.

Making a stove for a bath with your own hands: instructions

Necessary materials:

- gas burner, atmospheric;

- a gas cylinder that has already worked out;

- metal door for the combustion chamber;

- a used brake disc from a large car - for a heater;

- gas pipe with a cross section of 50 mm - for gas supply;

- pipe 100 mm - for the chimney.

Manufacturing:

- Cut off the gas cylinder with a grinder according to the drawing.

- Drill 2 holes for gas and air supply with a bit.

- Form round parts for the baffles that divide the cylinder into working areas.

- Weld the structure by inserting the blanks into the places where it will be located: a firebox, a blower and a heater.

Important! If the water container is on top, then it is worth welding the pipe to remove the smoke.

A blowing must be made from a pipe with a cross section of 50 mm. To do this, make several holes with a cross section of 5 mm, weld a piece of pipe to the main cylinder - in the place where the blower will be located.

Then, in a similar manner, install the gas supply pipe, which should be opposite the firebox, where the burner will stand.

At this stage, the manufacture of a gas stove can be considered complete, all that remains is to install the internal equipment.

Heating the garage with gas

If, nevertheless, you decide to make autonomous gas heating of the garage, then you can use both stationary and mobile equipment:

Stationary equipment

This type includes various gas stoves and boilers, for the installation of which in the garage you need permission from the relevant services. The main requirement is the possibility of building a special boiler room, where the gas boiler itself, intended for heating the garage, will be located. It is prohibited to put gas equipment in the same place with a car.

When buying and installing, certain costs will be required, but they are higher in comparison with electric heating equipment or even more stove heating. In the future, all the costs for a gas stove in the garage will be fully justified and the entire system of such heating will cost much more profitable than other types of heating.

Mobile gas equipment

If you do not plan a whole gas stove for the garage or there is no need for constant heating of the garage, then you may well avoid purchasing and installing expensive gas appliances and laying pipes. Then it is quite possible to use gas cylinders and other heating units that can be connected to them. Heating the garage with bottled gas is a great option, unless of course you want to open a permanent workshop or production. It is possible to calculate the gas consumption knowing which heating device will be used. Also, taking into account the mode of operation and the power of the devices, it is possible to calculate the most suitable volume of gas cylinders.

It is better to store gas cylinders in a metal cabinet, additionally insulating against freezing, and it is desirable that the cabinet is above the floor level. Because the gas in the cylinders is heavier than air, and if it leaks, it will be easier to find the problem.

Heating with a gas cannon is the most efficient method of quickly heating the air in a garage. Powerful appliances can raise the temperature in a room in minutes. Less powerful ones are used for local heating of a separate part of the room or in the repair area. For the same purposes, gas convectors are also used to heat the garage. They operate on liquefied bottled gas and differ in their positive heat output.

The power is approximately calculated according to this formula - we divide the area of the room by ten: S / 10. It is also worth considering the fact that the higher the useful power, the higher the gas consumption will be. Most gas convectors have additional fans (powered by the mains supply) to circulate the air more quickly.

A gas burner can also be used to heat the garage. In it, as a rule, the use of mini-gas cylinders is usually provided, since this device serves more for cooking than for heating. DIY gas burners can be connected through a reducer to standard cylinders, but this should be done with caution. Each home-made gas burner implies receiving heat from an open fire, which in itself is not very safe. The burner itself can be directly part of a more powerful heating device.

Industrial models

Despite the fact that a regular brick wood stove can be converted to use gas, it is better to give preference to ready-made models. The choice of such units is huge. The devices differ in their features, technical characteristics. What unites them, perhaps, is only one undoubted advantage - ease of use.

No desire to re-equip the chimney for gas equipment? You can always opt for stoves with a coaxial chimney. Such heating devices can be installed even in a city apartment without worrying about the removal of combustion products. Such models are more expensive, but they are much more efficient and easier to operate.

You can choose a heat-intensive or non-heat-intensive model. For a summer cottage, to which the owners come from time to time in winter, a heat-intensive stove will be the best choice. It is able to accumulate heat, like a regular wood-burning one. Cooling time depends on the specific model and is 4 - 12 hours. Non-heat-intensive stoves, in fact, are gas stoves. To maintain heat, it is necessary to ensure its constant combustion.