Home / Solid fuel boilers

Back to

Published: 09.03.

Reading time: 6 minutes

0

167

Fuel pellets are pellets of artificial origin obtained by pressing. The raw material for them is woodworking and agricultural waste. The vast majority of household automatic pellet boilers are designed to use wood pellets.

This ensures efficient operation of sources with the least amount of maintenance and low emissions of harmful substances into the environment. Since 2010, in the EU countries, the production of fuel pellets is determined by the EN 14961-2 standard under which the designs of heating boilers have been modified.

- 1 Device

- 2 The principle of operation of automatic pellet boilers 2.1 Pellet feeding

- 2.2 Ignition and combustion

- 2.3 Ash removal

Pellets and their effectiveness as solid fuels

Pellets - Cylindrical granules compressed under high pressure resulting from the processing of agricultural waste (husk of seeds of cereals, hay or straw) and woodworking (sawdust, chips, shavings or bark). Peat and coal pellets are less popular.

This is how different types of pellets look like.

Calorific value index (specific heat of combustion) of pellets is 17.2-19.5 mJ / kg = 4.7-5.4 kW / h, which is much higher than, for example, wood, pure peat and even fuel briquettes. Burning 2 tons of pellets gives the same amount of energy as 960 cubic meters of gas, 1000 liters of diesel fuel or 3.2 tons of wood.

In Russia, the production of pellets of the "Premium" and "Standard" grades is permitted, which have an insignificant ash content of 0.4–1% and 1.5–3%, respectively.

reference... Contrary to popular belief, pellets are produced without the addition of synthetic substances: and although there are standards that allow chemistry in the composition, most of the pellets do not contain binders or improvers, and gluing occurs due to lignin released when heated.

The disadvantages include, perhaps, storage conditions - they cannot be left simply under a canopy, but must be stored in a closed room or container.

The principle of operation of automatic pellet boilers

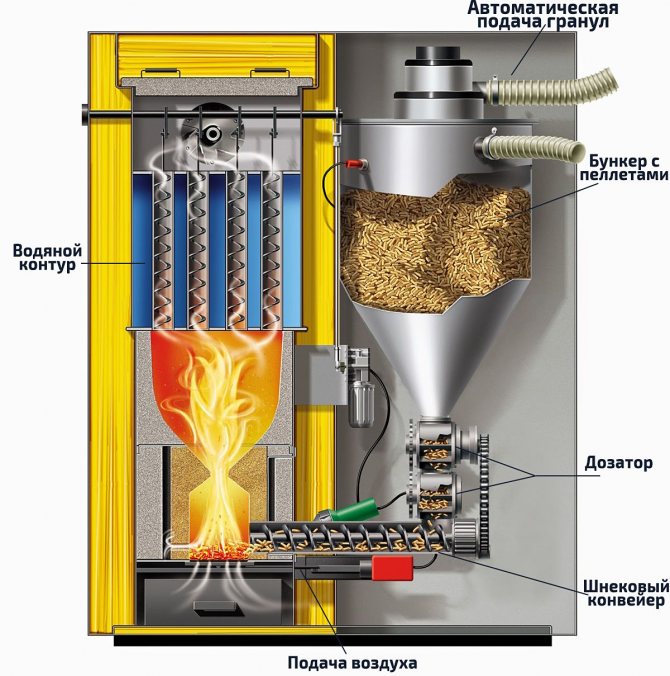

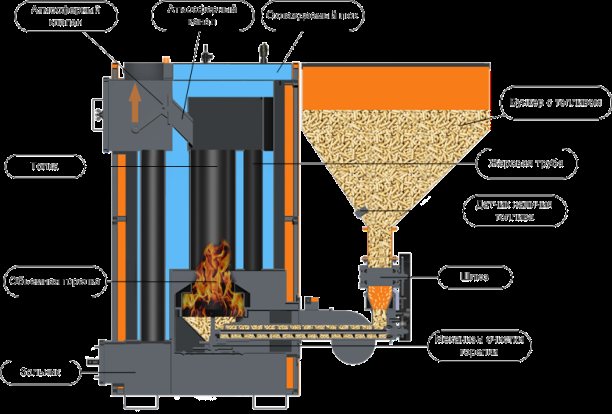

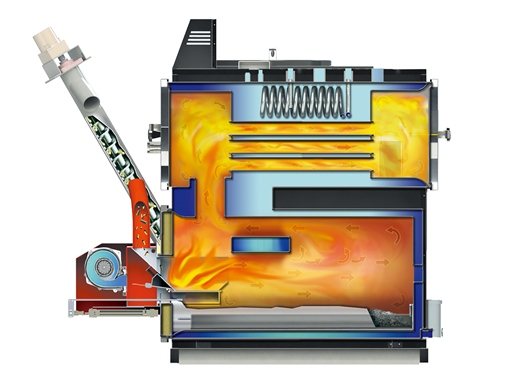

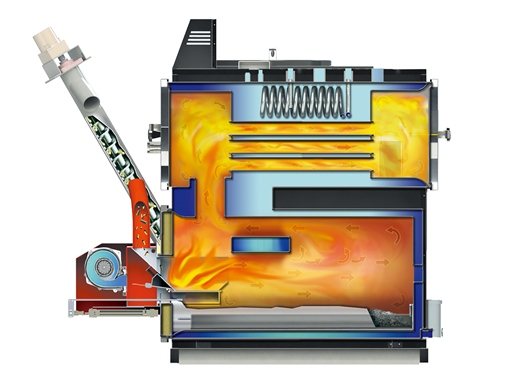

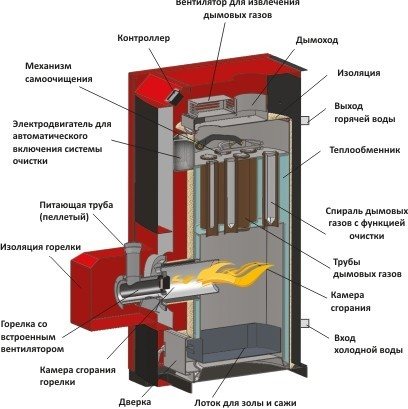

Pellet boiler Hoval in section.

An automatic pellet boiler is a steel or cast iron heating unit, which, from a structural point of view, is the same solid fuel boiler, but with the possibility of complete automation of the work process, that is, it can function with minimal human intervention.

The principle of operation of a pellet boiler consists in the sequential interaction of 3 separate systems (storage bins, a mechanism for transporting pellets to the combustion chamber and the burner itself), combined into a single device by the ABU attachment - a hardware control unit.

Accordingly, the process of equipment operation includes 3 stages:

- Supply of pellets from the bunker or from the fuel storage to the combustion chamber.

- Ignition, reaching the required temperature and maintaining combustion.

- Regular cleaning, including removal of ash and carbon deposits from the elements of the device.

From the storage, the pellets are delivered to the boiler hopper. The dispenser supplies the required amount of pellets to the combustion chamber. The pellets ignited by the burner heat up the water circuit.

In general, automatic pellet boilers designed for domestic use are very easy to maintain.The main thing is to initially correctly configure the appropriate operating mode, so that later you can turn on and off the heating with one button and simply monitor the number of granules.

Pellet feeding system

The organization of the automatic pellet feeding system directly depends on many factors (design features of the heat generator model, the availability of free space in the room, financial capabilities, as well as other personal preferences) and can be carried out in several ways:

- bulk (spontaneous) - pellets fall into the burner under their own weight, which can only be realized from the built-in hopper;

- pneumatic (vacuum) - feeding is carried out using a powerful pump that can suck pellets even from another room (up to 30 meters);

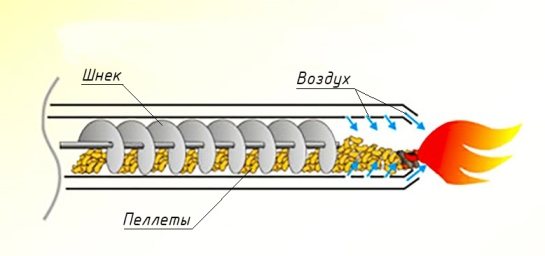

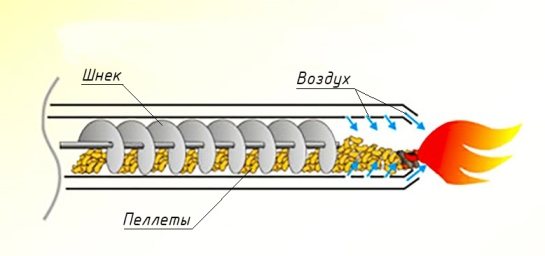

- auger (worm) - the intake of granules is carried out by means of a gear-screw mechanism, which assumes a portioned supply of new batches;

- conveyor (conveyor) - the fuel is delivered according to a standard (> 45 °) or steeply inclined (<45 °) "endless" belt with blades.

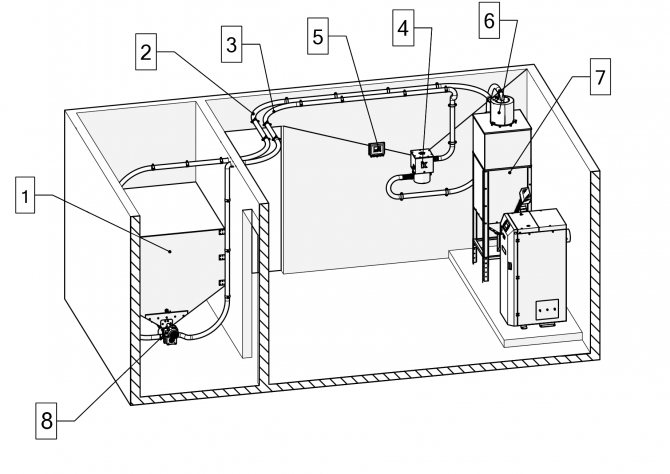

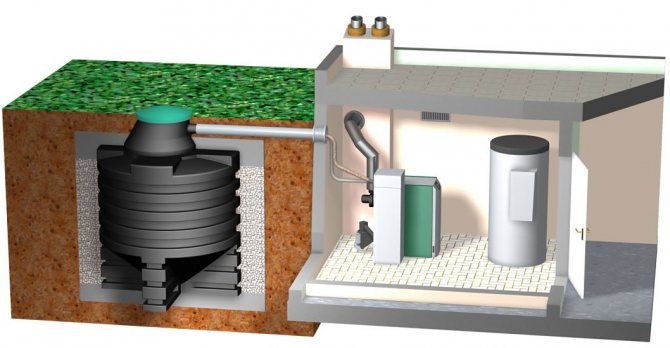

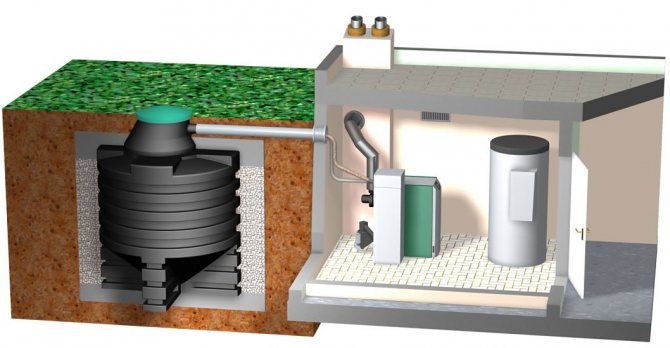

An example of organizing the supply of granules in a vacuum way from a street bunker.

In addition, for greater ease of installation, the above options can be subjected to various modifications, as well as combined with each other.

One loading of pellets can be enough for a rather long period - from 2-4 days to 1-3 months, up to the entire heating season (depending on the volume of the built-in or separate hopper). At this time, the ABU controller evaluates the situation itself and ensures the continuity of the heat generator.

Ignition and combustion maintenance

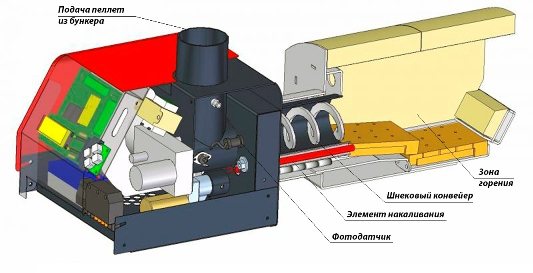

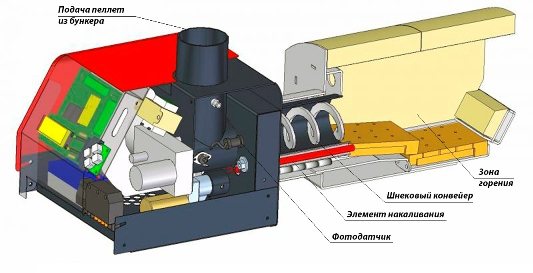

After pressing the start button, the electric ignition system is activated:

- The glow plug (or heating element) ignites the fuel, the flame sensor turns on.

- The fan blows in air and creates a stable combustion flame.

- The photosensor detects the presence of a flame, the glow plug turns off.

- The boiler goes into heating mode, pellets are regularly fed to the burner.

- When the temperature reaches 60–70 ° C, the maintenance mode is activated.

- The volume of incoming air and the pellet feed rate are reduced.

- When the temperature drops (sudden cold snap), heating starts again.

- Periodically, the burner will turn on / off in the specified mode.

The fully automated pellet boiler is also equipped with a temperature limiter and a coolant overheating sensor. When the supply of a new batch of fuel to the burner is interrupted, the system goes into the afterburning mode - the fan burns out the residues at full speed for 5-10 minutes.

The work can be stopped by manually pressing the "Stop" button or (in case of any error) by a program command of the device. Modern GSM modules make life even easier: they are synchronized with mobile gadgets and immediately notify of emergency shutdown, end of pellets, etc.

Ash and carbon deposits removal

The frequency of maintenance of heating equipment, i.e. removal of carbon deposits and ash remaining from the combustion of pellets, depends on the degree of its equipment:

- model without automatic cleaning - once every 3–10 days;

- self-cleaning model - once every 4-6 weeks

That is, the built-in self-cleaning system does not completely eliminate the need for manual cleaning, but only allows you to significantly reduce its frequency.

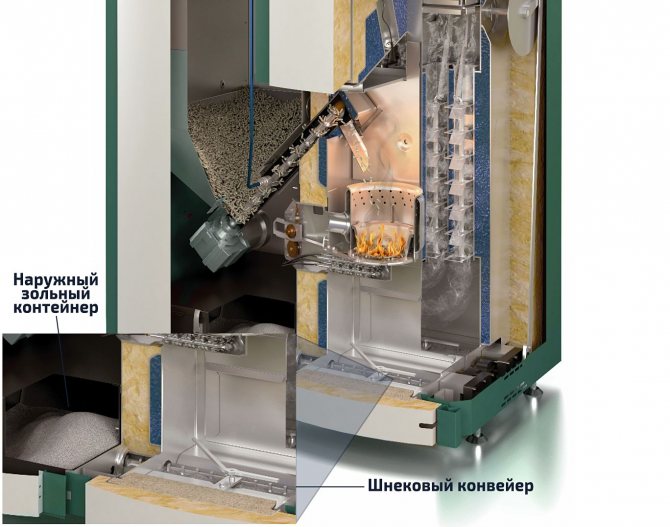

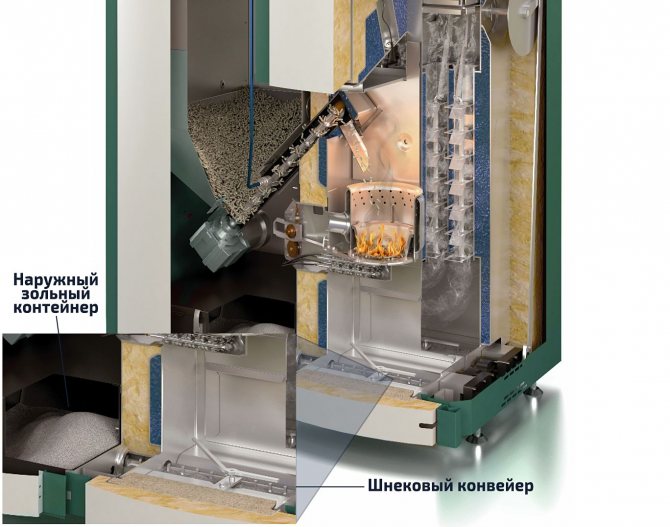

Boiler unit with automatic cleaning system.

Automatic ash removal goes through the transportation of burnt-out residues to a large outer container using a screw conveyor. When agitated, the ash is compacted, which saves space in the ash pan. The drive of this mechanism can work both from the controller of the boiler itself, and autonomously.

Automatic removal of carbon deposits from the burner is carried out by knives - the moving parts of the grate.In fact, they simply cut off the carbonized tar particles and send them to the ash box. When it is filled, the consumer is given a signal about the need for cleaning.

The device and principle of operation of pellet boilers

To mount such a solid propellant installation on your own, you will need to work hard, and first you need to figure out how it works and what it consists of. The heart of the pellet unit is the burner, which performs almost all basic functions and is connected to the boiler controller, acting on its commands. Pellet burners are of two types:

The difference between them is as follows. A retort pellet burner is a bowl (retort) filled from below with fuel by means of a screw, and air is supplied to the combustion zone by a fan through holes located on the sides of the bowl. During operation, the flame column is directed upward, which should be taken into account by the design of the boiler. The torch burner is a pipe, it is also a combustion chamber, where a screw feed of pellets takes place from one end, and a powerful flame torch comes out from the other, directed horizontally. This is achieved by forcing air into the chamber from the same side as the fuel.

Note. Flare burners are used more often than retort burners, since the latter have problems with the supply of low quality pellets. To assemble a boiler plant with your own hands, it is also preferable to use a torch burner, below we will explain why.

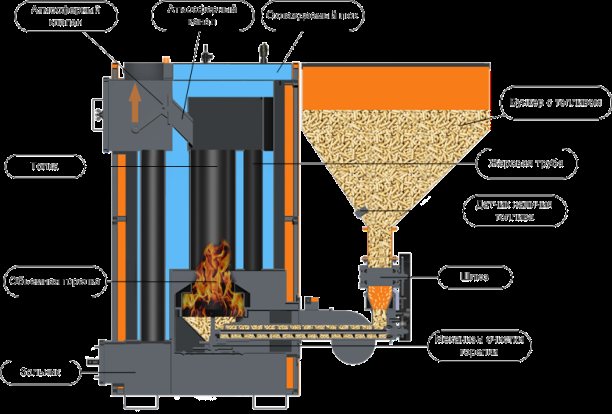

In the future, we will consider the operation of the unit with a flare burner, since this design is better suited for our purpose. So, the combustion chamber in the form of a pipe is located inside the boiler, and the outer part of the burner consists of a housing with a feed screw and a fan for blowing air. For the functioning of the electric ignition and maintaining the flame, the design also includes a control board, a photo sensor and an incandescent element. In the upper part of the body there is a fuel supply pipe.

The process is as follows: at the command of the controller, the auger feeds a small amount of pellets into the chamber and stops. The glow plug is turned on and the fan is switched on simultaneously, causing the fuel to ignite. The appearance of a stable flame is fixed by a photosensor, and the control unit notifies about it, and the latter turns off the glow element. Then work begins in normal mode, the auger conveyor resumes supply, and the fan blows the required amount of air. At the command of the same controller, pellets are poured into the burner through the nozzle, transported there from the loading hopper by an external screw conveyor.

Note. Many manufacturers use a fuel hopper mounted directly above the burner nozzle, which allows pellets to be poured into it on their own without an additional conveyor.

Now it is worth considering the device of the pellet boiler as a whole. The design of the unit body is typical for all solid-fuel plants; it is an internal chamber made of steel or cast iron, enclosed in an external casing filled with water - a water jacket. To extract heat from flue gases, the design can provide for 2 types of heat exchangers:

In a water-tube heat exchanger, the coolant flows through pipes washed by the combustion products and transferring their heat to it. But such a device is rarely found in solid fuel boilers, usually the opposite is true in them: flue gases pass through the pipes, giving off combustion energy to the water jacket, this is the fire-tube heat exchanger. In order for the boiler to work efficiently, the heat exchanger is made in two - or three-way. This means that the flue gases, passing through the fire tubes, change their direction twice or three times to the opposite, making 2 or 3 moves. This allows them to give them maximum heat to the water jacket, and at the outlet to the chimney to get a temperature of no more than 150 ºС.

The working process is as follows: the burner burns fuel and heats the walls of the chamber, and they heat the coolant. In turn, the combustion products, under the influence of natural draft and fan operation, pass through the flame tubes, also giving off heat to the water jacket, and are thrown into the chimney. The combustion rate is controlled by the controller according to the signal from the temperature sensor immersed in the coolant at the outlet of the unit. This is the principle of operation of pellet boilers in order to automatically regulate the combustion process and, if necessary, increase or decrease the supply of fuel and air to the burner.

Reviews of household automatic pellet boilers: advantages and disadvantages

Reviews of the owners of automatic pellet boilers indicate that such a technique has both strengths and weaknesses, or rather, nuances:

| Benefits | disadvantages |

| autonomy - equipment with a GSM-module can be left unattended for weeks | the cost - the price of even the most modest options is 100-120 thousand rubles. |

| universallyst - most models also work on wood chips, husks and sawdust | energodependentlyst - without access to the network, a backup generator is required for operation |

| convenience - self-cleaning and auto-feeding minimizes manual maintenance | service - many foreign firms simply do not have a representative office in Russia |

| security - the body does not heat up, which is especially important for children and animals | pellet consumption - often real figures differ from theoretical calculations |

| purity - there are no traces of exploitation in the room, i.e. soot, dust and smoke | fuel price - the cost of pellets exceeds the cost of firewood or coal |

reference... An unexpected increase in the consumption of pellets is often associated with the inadequate quality of the product itself: if they contain impurities or their moisture content is more than 10–12%, then in order to maintain a given mode, it becomes necessary to compensate for the loss of heat capacity by quantity.

How to choose a boiler with automatic feeding

In order to choose the right pellet boiler, it is necessary to pay attention to the following indicators: type of burner and fuel supply, heat output of the unit, design of the heat exchanger and its material, automatic ignition system and ash removal.

The most budgetary options for pellet heating units with manual fuel supply. It is suitable only for homestead houses that are not intended for permanent residence of residents. Automatic pellet boilers are very expensive, but work well with large heating areas, more than 500 m2.

Semi-automatic fuel supply, the most acceptable option for most autonomous heating systems. The volume of the pellets in them is regulated manually, the rest of the functions of fuel supply and the conduct of the thermal process in the boiler are fully automated.

There are 2 types of burners in boilers using pellets:

- Flare - the simplest design, practically works without clogging of the nozzle, has a powerful horizontal flame directed into the combustion chamber.

- Retort - with vertical fuel combustion flame. They have good performance indicators in terms of economy, noiselessness and safety.

The heat output of the boiler is selected according to the standard ratio at the rate of 1 kW per 10 m2 of heated area. For the northern and southern regions, corresponding increasing and decreasing coefficients are introduced, due to the fact that the winter temperatures of the outside air in them differ from the central regions of Russia.

Also, a multiplying factor will be required for houses that have poor thermal insulation of the walls. If it is necessary to take into account the additional power for heating hot water, a correction factor of at least 1.2 is introduced.

When choosing a heat exchanger metal, it is preferable to choose a cast iron apparatus, since its service life is doubled compared to a steel device.

What to look for when choosing a boiler unit

The coefficient of performance (COP) is the most important point worth paying attention to, since it is he who shows the efficiency of the heater. Usually, manufacturers indicate an efficiency of 85–98%, but in reality it depends on the correct setting, the quality of the granules and the design features.

Main characteristics of automatic pellet boilers:

| Burner type | |

| retort (meat grinder) - "omnivorous" vertical burner, but the use of less heat-intensive fuel reduces efficiency | stocker (flare) - horizontally directed burner, efficient, but demanding on fuel quality |

| Heat exchanger material | |

| steel - durable, but (with a thickness of up to 6-8 mm) material subject to burnout | cast iron - durable, but fragile material if misused |

| Control system | |

| built-in controller - a control unit located on the boiler controls the processes of loading pellets and heating | full automation - options for supply, ignition, heating, self-cleaning, thermal and photosensor, timer and protection system |

| Maximum power | |

| The boiler power required for heating a house is calculated individually, but in any case, it is recommended to buy the device with a small margin - 10-20% | |

| Heating circuit | |

| single-circuit - intended only for heating the very space of the house | double-circuit - allows you to heat water for sanitary and domestic needs |

reference... If there are several heated systems, for example, radiators, water supply and underfloor heating, or it is necessary to create climatic zones, then it is better to purchase double-circuit equipment with additional automation that allows you to control several temperature modes at the same time.

It is also worth paying attention to equipping the boiler with a device for swirling fuel gases: thanks to it, part of the heat does not go into the chimney, but is transferred to the heating system as much as possible, which increases efficiency, and it also prevents ash formation, because pellets are almost completely burned out.

How to choose a room thermostat for a heating boiler and save up to 30% every month

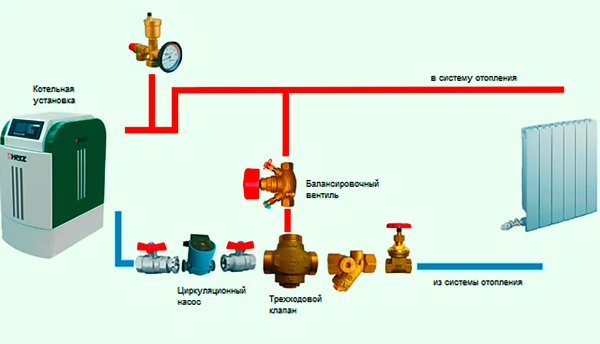

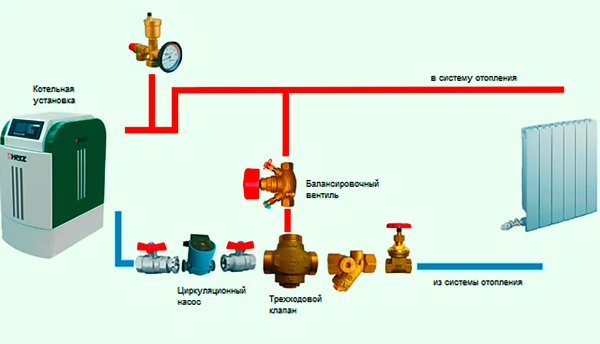

Pellet boiler piping

In practice, the installation of a pellet boiler is not much different from the installation of other solid fuel "brothers". The main task here is to correctly place all the equipment together with the fuel supply devices. Remember that there must be at least 700 mm aisles between the units of the units, and there should be a space of 2 m in front of the front panel of the unit.

If, when firing up any solid fuel boiler, after stopping, the coolant is supplied from the heating system inside, then toxic condensate mixed with ash and soot will form on the inner walls of the furnace. In order to prevent this process, which eventually destroys the metal, during installation, piping schemes for pellet boilers with a mixing unit are used.

Here the main role is played by a three-way valve, whose task is to prevent the coolant from entering the jacket of the unit from the system until it warms up. At this time, the water, driven by the pump, circulates in a small circle from the supply line directly to the return line through a three-way valve. As soon as it reaches the set temperature, the valve will begin to mix water from the system into the return line, eventually blocking the movement in a small circle. In this case, the piping of the pellet boiler must provide for the installation of a pump on the return, not the supply pipeline. Do not forget about a safety group with a safety valve and a pressure gauge, which must be installed on the heater outlet pipe.

The best known manufacturers and models: characteristics and prices

When choosing a pellet boiler with automatic feeding, you need to focus not only on the technical characteristics, but also on the manufacturer, because.not everyone will be able to ensure the timely delivery of replacement parts, as well as provide a specialist for installation, adjustment and warranty service.

Therefore, in order not to be left without heating at the wrong moment, it is better to choose a proven model from a company with extensive experience in this field.

ZOTA Pellet-15S

Wear-resistant pellet boiler of Russian production, supporting different types of fuel (pellets, firewood, briquettes). It is designed for use in harsh winter conditions that imported solid fuel boilers cannot withstand.

Those. options: power - 15 kW, bunker volume - 296 l, efficiency - 90%.

average cost: 150,000-170,000 rubles as standard.

Manufacturing firm: TPK KrasnoyarskEnergoKomplekt, Russia.

FACI 15

A compact boiler with a twin-screw feed system provides high combustion efficiency for almost any crushed biofuel. It is equipped with an "anti-slag" type cast iron retort burner, which allows to reduce the ash content of even low-quality pellets.

Those. options: power - 15 kW, bunker volume - 352 l, efficiency - 92%.

average cost: 130,000-150,000 rubles as standard.

Manufacturing firm: LLC FACI-RUS (FACI Caldaie), Russia-Italy.

Teplodar Kupper OK-9 with APG 25 burner

Universal boiler equipped with an APG 25 pellet burner, also suitable for conventional solid fuels, including wood and coal. The simple combined design is easy to modify, if desired, you can switch to a gas burner.

Those. options: power - 9 kW, bunker volume - 200 l, efficiency - 68–95%.

average cost: 80,000-110,000 rubles with a torch burner.

Manufacturing firm: OOO Teplodar, Russia.

Biopellet P-15

A boiler with an original, but well thought-out design, which is easy to assemble and maintain, even by an untrained specialist. It is unpretentious in the quality of the pellets, it can be heated with both white and gray varieties without the risk of stopping the burner due to contamination.

Those. options: power - 15 kW, bunker volume - 200 l, efficiency - 92%.

average cost: 160,000-180,000 rubles as standard.

Manufacturing firm: OOO Dozatech, Russia.

START-50-GR

A powerful domestic-assembled boiler with an impressive size bunker and imported components (automation and burner). It is known for its high reliability and durability, thanks to its cast iron parts (burner, boiler door, grate) and a durable 6 mm thick steel heat exchanger.

Those. options: power - 50 kW, bunker volume - 400 l, efficiency - 95%.

average cost: 230,000-250,000 rubles as standard.

Manufacturing firm: LLC Heating boilers "START", Russia.

Calculating the minimum required power

The easiest way to calculate the required boiler power (N) - according to the formula:

N= S × W oud/10

- , where S is the heated area of the house, taking into account all residential and utility rooms;

- W beats - the power required for heating 10 m2 (in accordance with the climate).

In central Russia, a medium-heated room with a ceiling height of 2.5–2.7 m and an area of 10 m2 can be fully heated with a power of 1.1 kW.

Thus, the minimum required power of a pellet boiler for heating a house 10 × 15 m will be calculated using the formula 150 m2 × 1.1 kW / 10 = 16.5 kW.

How to remove ash from the boiler?

Pellet boiler diagram.

Pellet boilers have special ash containers in which ash is accumulated. Simple models use a manual ash removal method. As it accumulates, you need to stop the boiler, remove the container, empty it and reinstall it. The frequency of this procedure depends on the settings of the boiler and the quality of the fuel. So, it is necessary to remove ash:

- every 5-7 days with high-quality pellets;

- every 2-3 days when using agropellets;

- every day when burning coal.

The automatic pellet boilers are equipped with automatic ash removal equipment. Ash is transported to a large external ash container using a screw conveyor.In this case, in the process of moving, the ash is compacted, which leads to a decrease in its volume. The drive of this mechanism works either from the boiler controller or from autonomous automation. The presence of a fuel warehouse, automatic ash removal and cleaning of gas ducts allow to make the maintenance of the pellet boiler system to a minimum.

Standards and requirements for installation

Installation of long-burning boilers with automatic pellet loading is carried out taking into account the existing fire safety rules (PPB):

- placement in a separate room - a boiler room (basement or annex);

- covering the floor in the room with the boiler exclusively from non-combustible material;

- a room without high humidity, equipped with a ventilation system;

- the minimum distance from the boiler to the pellet storage place is at least 1 m;

- fireproof partition between the external fuel storage and the boiler;

- organization of the chimney in accordance with the building codes of the joint venture and SNiP.

Despite the fact that before installing the pellet boiler, you do not need to contact any regulatory authorities (for approval and examination), as practice shows, it is rather difficult to independently install and connect weather-dependent equipment, therefore it is better to entrust these matters to professionals.

Pellet boiler piping

Due to its impressive size, the boiler is installed in a special stoker room, where a place should be taken to store the fuel supply. Pellet boiler installation rules:

- The surface must be leveled.

- The floor and walls near the boiler must be finished with non-combustible materials.

- The chimney is arranged in the same way as for any solid fuel boiler (insulation and condensate collection are required).

- The diameter of the flue pipe must match the diameter of the flue gas outlet on the boiler.

- It is imperative that the room has adequate ventilation.

As with any other boiler, you need to take care of installing an expansion tank and a safety group. The boiler is connected to the heating pipes through ball valves and filters. After connecting to the heating supply and return, the system is filled with a heating medium. The system is subjected to pressure testing and put into operation.

How much fuel will be needed for the heating season?

Pellet consumption (M x) for a limited period of time is calculated by the formula:

M x= X /fuel heat capacity

, where X is the heat loss during the heating season, determined by the formula:

X = S × D × 24 × 0.9 × 70

- , where S is the heated area of the house, taking into account all residential and utility rooms;

- D is the duration of the heating season;

- 24 - the number of hours of boiler operation per day;

- 0.7 - coefficient of boiler operation;

- 70 - average heat loss per hour (for a typical residential building).

For the calculation, you can take a house of 150 m2 from the previous example. If you heat it for about 6 months (175 days) a year, then the heat loss will be X = 150 × 175 × 24 × 0.7 × 70 = 30870 kW for the entire season or 177 kW per day. Accordingly, the consumption of pellets for the same period will be equal to M1 = 30870/5 = 6174 kg (season) and M2 = 177/5 = 36 kg (day).

Heating costs per month are calculated by multiplying the average daily consumption of pellets by the number of days and the price of pellets per 1 kg, i.e. 36 × 30 × 8.5 = 9180 rubles.

How to calculate the consumption of pellets?

Considering the fact that the fuel is supplied in bulk or in bags, it is, in principle, not difficult to calculate the consumption of pellets per 1 kW or per 1 m2. There is no need to convert units of weight to volume, since the delivery always takes place in kilograms, and the heat of combustion of the fuel is also measured in kW per 1 kg of weight.

Good quality pellets have excellent calorific value; burning 1 kg of such fuel releases almost 5 kW of thermal energy. Accordingly, in order to receive 1 kW of heat for heating a house, it is required to burn about 200 grams of pellets. The average consumption of granules per unit area is easy to determine based on the fact that heating each 1 m2 of area requires 100 W of energy.One condition is important: the height of the ceilings should be within 2.8-3 m. 100 W of heat will be obtained from 20 grams of granules, seemingly simple arithmetic.

But it was not there. The above figures are correct if the pellet boiler has absolute efficiency - 100% efficiency, and this does not happen in real life. In fact, the efficiency of such heat generators, although higher than that of solid fuel boilers, is still only 85%. This means that after the combustion of 1 kg of pellets in the furnace of the unit, not 5 kW of energy will be obtained, but 5 x 0.85 = 4.25 kW. And vice versa, to release 1 kW of heat in pellet boilers, 1 / 4.25 = 0.235 kg or 235 grams of fuel is spent. This is the first nuance.

The second nuance is that 100 W of heat per 1 m2 of the room is required when the ambient temperature is the lowest, which lasts for 5 days. On average, during the heating season, the cost of heat energy is half as much. This means that the specific heat transfer per unit area is only 50 W. It will be incorrect to determine the consumption of pellets in a pellet boiler for 1 hour relative to 1 m2, the figure will be small and inconvenient. It would be more correct to calculate the weight of the pellets burned per day.

Since Watt is a unit of power per hour, then per day for each square of the room you will need 50 W x 24 hours = 1200 W or 1.2 kW... For this purpose, you will need to burn such a mass of pellets per day:

1.2 kW / 4.25 kW / kg = 0.28 kg or 280 grams.

Knowing the specific fuel consumption, we can finally get values useful for financial calculations, for example, the season average weight of pellets used per day and per month in a house with an area of 100 m2:

- per day - 0.28 x 100 = 28 kg;

- per month - 28 x 30 = 840 kg.

It turns out that 8.4 kg of fuel is consumed per month for heating 1 m2 of a building. At the same time, according to user reviews in various forums, heating a well-insulated house of 100 m2, located in the middle lane, takes about 550 kg of pellets, which in terms of the square is 5.5 kg / m2. This means that the consumption of pellets in the boiler in the amount of 840 kg per month with a building squared of 100 m2 is very large and is suitable for calculating poorly insulated houses.

Let's summarize in the form of the results of calculations for dwellings of various sizes. We got the following monthly consumption of pellets for heating a private house:

- 100 m2 - 840 kg with low insulation, 550 kg for good insulation;

- 150 m2 - 1260 kg and 825 kg, respectively;

- 200 m2 - 1680 kg and 1100 kg under the same conditions.

For reference... In many boiler installations, the controller has a function that allows you to see on the display the consumption of pellets in kilograms for a certain period.

Price

The cost of pellet boilers with automatic fuel supply:

| Model name | power, kWt | Average price, rub. |

| ZOTA Pellet-15 S | 15 | 153 000 |

| FACI 15 | 15 | 146 000 |

| Kupper OK-9 + APG 25 | 9 | 101 000 |

| Biopellet P-15 | 15 | 171 000 |

| START-50-GR | 50 | 242 000 |

| ACV ECO Comfort 25 | 25 | 217 000 |

| Kiturami KRP-20 A | 30 | 236 000 |

Where to buy a pellet boiler with automatic feeding?

In Moscow

- Hermes, st. Bulatnikovskaya 20, office 17 from 9:00 to 18:00, tel. +7 (495) 384-19-66;

- Pechi-fireplaces, st. Jubilee 4-A from 9:00 to 18:00, tel. +7 (495) 215–56–94.

In St. Petersburg

- TechnoDom, 57 Stachek ave. from 10:00 to 19:00, tel. +7 (812) 671–00–88;

- TeploTorg, st. Anchor 10 from 9:30 to 18:00, tel. +7 (812) 612-40-02.

And in conclusion: an automatic pellet boiler, despite the fact that it is, of course, easier to maintain than many other options (for example, coal, wood, pyrolysis), still requires attention - both in terms of cleaning and the plan of the purchased fuel. These factors should be considered before buying.

Pellet boilers