PRICE LIST for thermal insulation services

| The cost of insulation with polyurethane foam (PPU), depending on the area with a thickness of 50 mm. | ||||

| Type of work | The cost of insulation when ordering an area | |||

| Up to 200 m2 | 200-400 m2 | 400 -1000 m2 | > 1000m2 | |

| PPU spraying with an average density of 25 kg / m3 | 700r / m2 | 650r / m2 | 600r / m2 | Negotiable |

| PPU spraying with an average density of 35 kg / m3 | 800r / m2 | 750r / m2 | 650r / m2 | Negotiable |

| PPU spraying with an average density of 45 kg / m3 | 1000r / m2 | 920r / m2 | 870r / m2 | Negotiable |

| Special conditions for construction companies and architectural firms! | ||||

| The cost of insulation with polyurethane foam (PPU), depending on the volume in m3. | ||||

| Type of work | The cost of insulation when ordering an area | |||

| Up to 5 m3 | 5-10 m3 | 10-20 m3 | > 20 m3 | |

| PPU spraying with an average density of 8-12 kg / m3 | 6000r / m3 | 5500r / m3 | 5000r / m3 | Negotiable |

| PPU spraying with an average density of 25 kg / m3 | 11000r / m3 | 10500r / m3 | 9500r / m3 | Negotiable |

| PPU spraying with an average density of 35 kg / m3 | 14000r / m3 | 13500r / m3 | 13000r / m3 | Negotiable |

| PPU spraying with an average density of 45 kg / m3 | 18000r / m3 | 17500r / m3 | 16000r / m3 | Negotiable |

| Special conditions for construction companies and architectural firms! | ||||

The price can be changed depending on the complexity of access to the surface.

The minimum order is 30,000 rubles.

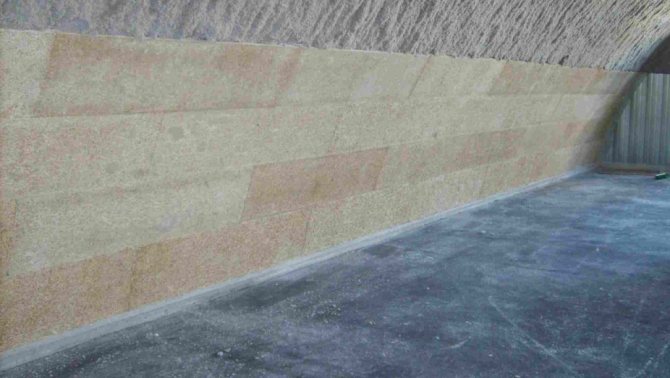

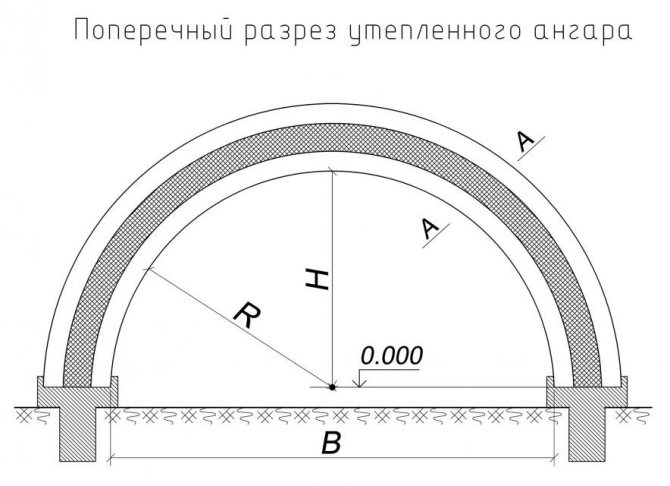

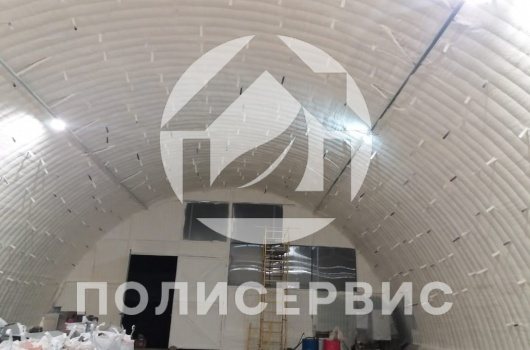

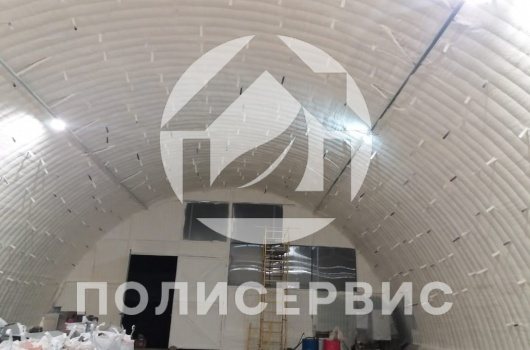

will perform seamless insulation of hangars of any geometric shape (arched, hipped, straight-walled) using sprayed polyurethane foam. We work at facilities in Moscow and the Moscow Region, and are ready to consider applications from neighboring regions.

Insulation materials

Mineral wool and foam is an affordable and effective way to insulate a hangar

The hangar can be insulated from the outside and inside. The choice of material depends on the configuration of the building and its purpose. Most often used:

- sandwich panels;

- sheet insulation;

- liquid thermal insulation materials.

Insulating a hangar is very similar to insulating a garage. You can find out more in our article: Insulation of garages

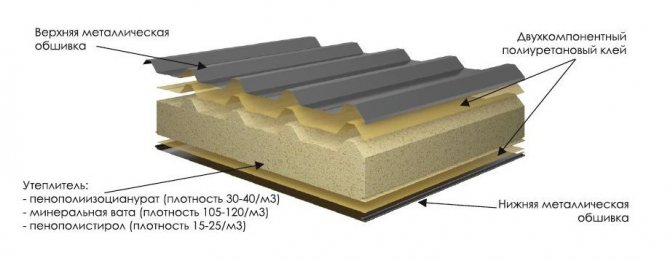

Sandwich panels

There are several material configurations:

- with expanded polystyrene;

- with dense mineral wool;

- with polyurethane foam (polyurethane foam).

In any case, the panel is made of metal sheets, between which the insulation itself is located. The panels are available for both outdoor and indoor installation. materials: ceiling and floor slabs, "sandwiches" of an angular configuration.

The peculiarity of the panels is in a wide selection of external finishes. The outer surface can be treated "like wood", imitate brickwork or embossed plaster, it can be painted.

If the hangar's appearance matters, it is worth taking a closer look at the various sandwich panel options.

Insulation in rolls and slabs

Heaters in rolls and slabs are easy to use, they are made from both natural and synthetic materials. Mineral and glass wool, non-woven fabrics and foamed polyethylene provide a stable microclimate even in a metal structure.

Roll materials are a very convenient way to work with large rooms

Roll materials are laid with an overlap so as not to form "cold bridges". When installing insulation in slabs, they adhere to a different technology: the material is fixed on the crate with glue, dowels and self-tapping screws.

Fasteners create an increased load on the walls of the building. In addition, the tightness of the slabs themselves, the layers of waterproofing and protection from steam is broken, and unnecessary "cold bridges" appear.

The disadvantage of insulating metal structures with plates and roll insulation is the complexity of processing corners, joints and uneven surfaces.In addition, heaters are susceptible to mechanical damage; on top of them, a sufficiently rigid and durable outer skin must be mounted.

Ecowool, polyurethane foam spraying

Liquid insulation materials have appeared on the market not so long ago. They are able to fill even the smallest gaps and "hard-to-reach" places, providing an even coating layer and reliable thermal insulation.

Ecowool is well suited for frame structures. A solid foundation is pre-built, the gaps in which are filled with insulation. With such a thermal insulation scheme, it is imperative to provide for hydro and vapor barrier.

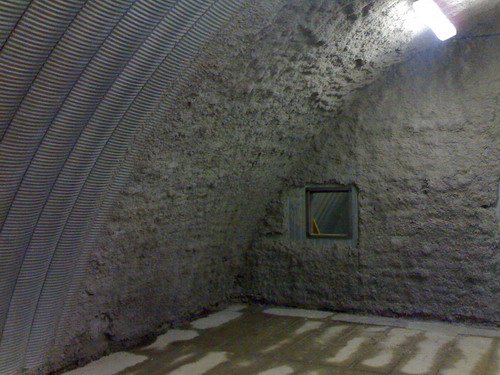

The spraying of mineral wool is almost monolithically connected to the wall

Thermal insulation of the building with polyurethane foam does not require the installation of additional structures. PPU is evenly sprayed, like paint, over the entire area of the walls. For high-quality insulation from the cold, you will need to apply the composition several times. Walls can be finished with a finish (plaster, paint, drywall) or left uncoated: surfaces insulated with polyurethane foam are not destroyed by mechanical stress.

The polyurethane foam cover easily tolerates high humidity and contrasting temperatures. It is better to additionally protect the surface from direct water and sunlight.

How is PPU insulation

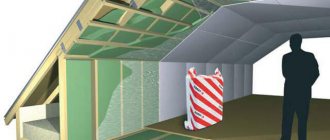

PPU spraying can be performed outside and inside the object. The heat-insulating layer is formed directly on the working surface due to the connection and reaction of the components of the PU foam system. Installers apply the mixture evenly to the entire structure, including beams, seams, vertical and horizontal elements. The finished insulation is a polymerized material with a low thermal conductivity of 0.03 W / (m * K), has the properties of steam and wind protection. Closed-cell polyurethane foam also improves the waterproofing of the structure.

Requirements for the insulation of hangars

- Low thermal conductivity - good insulation does not let heat through, keeping it inside the room.

- Lack of hygroscopicity - a material that absorbs moisture is not suitable for hangars, since it will quickly get wet and lose its thermal insulation properties. When laying, you will have to make a solid multi-layer "cake" of insulating materials, and this will significantly lengthen the time of work and increase their cost. But even in this case, there is no guarantee that the insulation will not get wet and mold will not appear in it.

- Low temperature resistance... Hangars, unlike residential premises, may not be heated for some time, therefore, they are not insulated with material that is afraid of frost.

- Durability - warming of hangars is a long, laborious process, associated with high costs, and it is unprofitable and inconvenient to carry out it every 10 years. Therefore, it is advisable to choose a heater that will last as long as possible.

- Fire safety - in the light of the recent unpleasant events associated with fires in our country, the use of combustible insulation will create big problems with the fire service.

- Safety for human and animal health... If it is planned to equip the hangar with places for keeping animals, a warehouse for storing food products or production facilities, it is impossible to insulate it from the inside with a material that emits harmful substances. This threatens with problems with auditing organizations.

- No condensation... The appearance of wet drops on the walls promotes the growth of mold and fungus and the development of pathogenic microorganisms. In a damp room, stored materials and equipment quickly deteriorate, and animals and people get sick.

- Low structural load... Heavy insulation cannot be used in hangars, as it significantly increases the weight of the structure, leading to collapse.

- Unattractiveness to rodents... Mice and rats can gnaw or take away all the insulation, at the same time spoiling the valuables stored in the hangar. The presence of rodents in a building that serves as a livestock house or warehouse for storing food will cause big problems with sanitary and veterinary services.

The table shows the properties of the most commonly used heaters. We recommend that you familiarize yourself with it in order to make the right choice.

| Insulation | Manufacturing material | Thermal conductivity W / (m * K) | Layer thickness for insulation, mm | Price category | Condensation | Harmlessness | Fire safety | The likelihood of rodents, mold and mildew | Notes (edit) |

| Isover | fiberglass | 0,048 | 250 | cheap | formed | on contact with skin causes dermatitis, harmful to eyes | burns, combustion products are toxic | rodents and fungus start | |

| Rockwool | stone wool | 0,045 | 233 | expensive | formed | contains poisonous phenol | the toxic phenol contained in the material burns | rodents and mold won't start | |

| Expanded polystyrene | styrofoam option | 0,040 | 200 | expensive | formed | contains carcinogenic styrene | burns with the release of toxic substances | mice and rats gnaw | due to the stiffness of the slabs, it is not suitable for semicircular frameless hangars |

| Styrofoam | Styrofoam | 0,040 | 200 | cheap | formed | contains carcinogenic styrene | easily flashes and burns with the release of toxic substances | mice and rats gnaw, infect mold and fungus | due to fragility and lack of plasticity, it is not suitable for semicircular frameless hangars |

| Expanded clay | clay | 0,180 | 950 | cheap | not formed | harmless | does not burn | rodents and mold won't start | produced in the form of clay balls. Suitable only for floor insulation |

| Basalt mats | basalt | 0,045 | 240 | expensive | formed | contains poisonous phenol | the toxic phenol contained in the material burns | rodents and mold won't start | |

| Stone wool | rocks | 0,039 | 200 | middle level | formed | some varieties contain toxic formaldehyde | the phenol contained in the insulation burns | rodents and mold won't start | there are phenol-free options. Better to keep warm with them |

| PPU | polyurethane foam | 0,020 | 100 | middle level | not formed | emits harmful substances when applied. Inert after drying | does not burn | rodents and mold won't start | applied by spraying directly onto the insulated surface |

As you can see from the table, most materials are either poorly suited for such insulation, or are very expensive. The best option is polyurethane foam - an inexpensive sprayed material that meets all the requirements for insulation for a hangar.

Our work on this service

Insulation of a hangar in St. Petersburg 1550m2

Insulation of a hangar in St. Petersburg 1000m2

Insulation of a hangar for a car service, 300m2, Moscow

Insulation of a hangar for a car service, 400m2, Kubinka

Advantages and disadvantages of polyurethane foam

Polyurethane foam Polyurethane foam is known as regular foam rubber. In everyday life, we often find soft, and in construction they use hard. This material has a closed cell structure, the plates are produced with an edge, which simplifies and reduces the cost of installation. The use of special components makes this material fireproof.

In addition to slabs, it is produced in the form of foam, which is applied to the surface with special equipment. Due to the use of foam, "thermal bridges" will be completely absent, the coating will be continuous.

The main advantages of using polyurethane foam:

- It is unlikely that foam polyurethane foam can be used on its own for insulation - the equipment is expensive and special protective clothing is required, including a gas mask

- low coefficient of thermal conductivity (almost 1.5 times higher than that of foam and almost 2 times more mineral wool);

- moisture resistance;

- operating temperature from -70 to +110 degrees;

- 30 years - the designated service life (with proper installation, much longer);

- no deformation during the entire service life;

- resistance - rotting, fungus, the influence of moisture does not affect its properties;

- has sound insulating properties;

- environmental friendliness - approved for use even in food warehouses.

Disadvantages of polyurethane foam:

- the price is higher than expanded polystyrene;

- low resistance to ultraviolet radiation.

Read about how to insulate a house with polypropylene urethane here.

What is hangar insulation for?

Hangar insulation by polyurethane spraying

A hangar is a functional structure used in various fields of activity. The choice of model depends on consumer needs. When insulating buildings, the type of installation technology is taken into account.

High-quality insulation of the hangar makes it possible to expand the scope of the building. It can be used as a premises for a sports complex or a production workshop.

Thermal insulation provides sound insulation, reduces heat loss. Multi-layer insulation provides the building with strength and rigidity, serves as protection against rust and condensation.

Polyurethane foam spraying technology

Apparatus for applying polyurethane foam under pressure.

This substance is applied directly to the interior surfaces (walls and ceiling) of the room. It is important that no preparatory and finishing work is required. The solidity of the resulting layer and its rigidity increases the strength of the entire structure. Polyurethane foam is applied without seams. This is how it differs from sheet material.

No wall mounts required. It is applied by spraying under a pressure of 14 atm. In turn, the foam fills in all gaps, cracks and defects on the surface. The layer thickness should be about 2-3 cm, and in some cases - 5-10 cm. It all depends on the location of the hangar, weather conditions.

After warming, additional finishing of the premises is not required. Treated surfaces lend themselves well to washing with water, they can be painted if desired by the hangar owner. Thermal conductivity of polyurethane foam is 0.02, while mineral wool - 0.06, expanded polystyrene - 0.04. The lower it is, the more valuable the material is.