Can this be done at all?

It is quite possible to patch up a pipe under pressure, which unexpectedly gave a leak, on your own using improvised means.

The only caveat is if the leak is minor, and the water oozes slightly, and does not gush in an endless stream.

When the accident is more serious, you will need to urgently tighten the valve that controls the water supply to the coolant, and then call the repair service.

Repair of cast iron and steel pipes

The choice of this or that method for eliminating a leak depends not only on the place of the defect, but also on the material of the pipeline. Let's consider each of them.

How to fix a leak in cast iron pipes

Cast iron piping is most commonly found in sewer systems. Since the pressure in them is small, it will not be difficult to eliminate the leak. You can temporarily solve the problem on your own until the complete or partial replacement of old pipes and fittings can be done in one of the following ways.

Applying a bandage

It is quite simple to make a bandage with your own hands, using a regular bandage and cement. This procedure is performed in the following sequence:

- The cement is mixed with water until a thick sour cream consistency is obtained.

- The bandage is impregnated with the resulting solution.

- The leak is carefully wrapped in several layers. It is necessary that each subsequent turn of the bandage overlaps the previous one by about a quarter.

It will be possible to use the sewer system about a day later - during this time, the solution should harden.

In some cases, instead of cement and bandage, fiberglass in combination with epoxy glue is used to eliminate water leakage.

Due to the high reliability of the cement bandage, this method of eliminating water leaks is widely used both in the repair of cast iron pipes and steel water pipes. However, it is not recommended to use it in the places of threaded connections, since it will be very difficult to disassemble them in the future.

Patching

Before repairing the leak, drain the water from the damaged pipeline and carefully clean the defective area from corrosion, various contaminants or paint. To do this, you can use a grinder or wire brush.

After drying and degreasing the surface, a layer of epoxy resin is applied to the place of leakage and a patch of fiberglass is applied. It is important that this material is well saturated with glue. For greater security, mounting tape can be wound over the patch. It is advisable to use the pipeline at least one day after the repair.

Coining

One of the most effective ways to get rid of a cast-iron sewer leak with your own hands is to drive in lead cones into leaks and cracked pipes. Due to the plasticity and pliability of this metal, it is easily flattened, filling all kinds of voids.

In case of socket connection of pipes of sewer systems, "capping" is carried out with the help of cement and packing. If a water leak occurs in this place, then to carry out repairs with your own hands you need:

- Clean the gap between the outside of the pipe and the inside of the socket.

- Wrap the oiled tow around the pipeline and drive into the slot with a special spatula, which should tightly fill the space by 2/3 of the socket height.

- Apply the top layer of tow without any impregnation in order to improve adhesion to the cement.

- Seal the pipe joint using asbestos compound or cement mortar.The use of modern materials such as silicone or mastic is allowed.

- To avoid cracking, cover the sealing layer with a damp cloth for a day to slowly set.

When stamping the gap, do not allow the tow to get inside. Any foreign object caught in the piping can cause serious blockage in the system.

Repairing leaking steel pipes

On a straight section, a broken water supply can be repaired by analogy with a cast-iron one - by applying a bandage or patch. But since steel pipes are usually used in the arrangement of pressure lines, you should pay attention to more reliable repair methods.

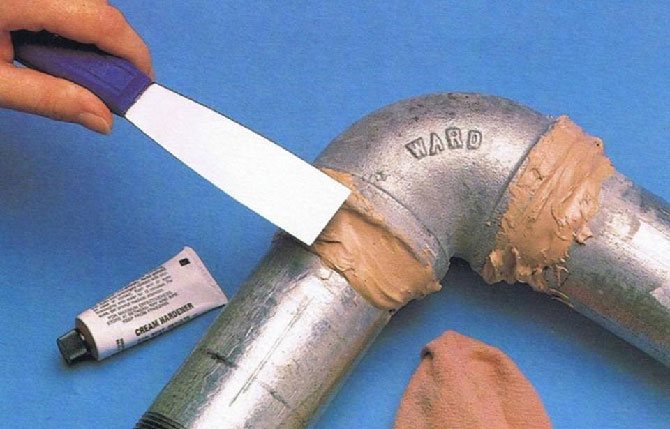

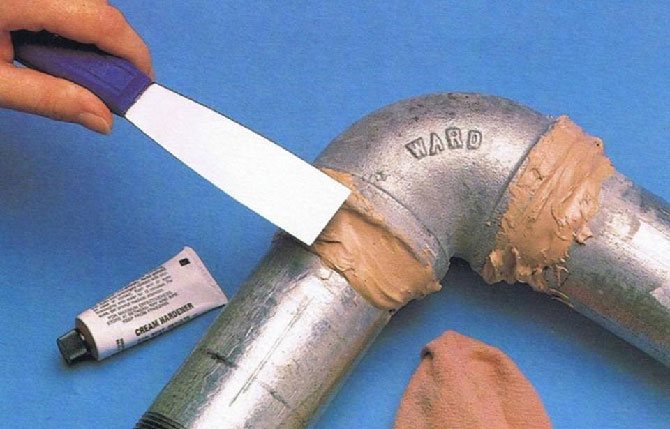

Emergency adhesive

The most technologically advanced method of eliminating pipe leaks is the use of special glue. It is enough to buy a so-called emergency metal polymer in a hardware store. It is sold in the form of two components - a hardener and metal dust mixed with resin. The glue is prepared by simply mixing them immediately before starting repair work.

This composition can eliminate water leakage in both dry and wet pipe sections. Nevertheless, it is advisable to turn off the taps - high pressure in the system is unacceptable. The piping can be used as soon as the adhesive has completely hardened.

Leak repair with self-tapping screws and bolts

If a small hole (no more than 4 mm in diameter) appears in a steel pipe under pressure, the leak can be stopped with a self-tapping screw for metal with a press washer. It must be screwed tightly into the site of the fistula.

Step-by-step instructions for eliminating water leakage when breakouts of 5 mm or more appear are as follows:

- First of all, the water supply to the damaged area is shut off.

- The place of damage is drilled to obtain an even hole.

- The thread is cut with a suitable tap.

- A pre-prepared bolt with a rubber gasket is screwed into the pipe.

This method of repairing pipes with your own hands will allow you to forget about damage for several years. But this measure, like all the others, is only temporary. It is not recommended to tighten strongly with the replacement of the defective section of the water supply system.

Material selection rules to fix the problem

When the cause of the damage to the pipe is established, it is necessary to look for acceptable ways of repair. There are several of them. Only most are suitable for low water pressure in the water supply circuit or heating system.

The most common way out of a difficult situation is to use an industrial clamp (tie). It is a metal ring with thick walls, rubberized inner surface and a fastening nut for a tie.

If such a device was not at hand, then any piece of rubber (for example, from a bicycle tube) and wire or something similar will do.

But other ways to eliminate leaks, when it comes to heating systems or hot water supply, are unlikely to work. So, often used cold welding and special sealants are not relevant for wet surfaces.

Other instantly hardening composites (epoxy resin, dichloroethane) are also excluded, since they can be used on dry and disconnected water supply lines.

Minor piping leaks can be repaired on your own... But this will only be a temporary measure. At the end of the heating season, it is recommended to undertake a major overhaul so that the system no longer malfunctions.

Ways to eliminate leaks in a straight heating pipe

Local leakage of a metal pipe in its straight section (fistula) is the easiest option for self-elimination. There are several ways that you can deal with the problem without draining the water.

Mechanical leakage repair

The classic way to seal a leak is to install a crimper on a rubber gasket while the heating system is running.

The methods are as follows:

- The damaged section of the pipe is wrapped in soft rubber (for example, a bicycle tube). Fix the patch with a metal wire, tightening it well in several turns along the length of the rubber.

- The rubber patch is secured with two narrow crimp clamps of the appropriate diameter.

- If there are several leaks, they are localized in close proximity to each other, then the leak in the heating pipe can be repaired by installing a metal holder. It is a wide clamp with an integrated rubber gasket that tightens in two places.

Note! In this way, the leak is closed temporarily, eliminating the problem for the period until a repair specialist is called or until the end of the heating season.

If a fistula has formed in a thick-walled pipe, then it can be repaired by installing a special self-tapping screw with a rubber seal in front of the cap. To do this, clean the leak and screw in a self-tapping screw with a hand drill.

Note! You can use an electric drill only if there is no coolant in the system. Otherwise, you risk getting an electric shock if water escapes from the pipe.

Chemical methods to eliminate leaks

Manufacturers of sealants for repairs offer a lot of materials for sealing leaks in heating systems with metal or polypropylene pipes.

We recommend that you familiarize yourself with: How to make a spark arrester with your own hands for a chimney?

From available tools, you can use automotive sealants for high-temperature operating conditions. With this composition, the fabric is impregnated and the pipe is wrapped, where the damaged area of the heating circuit is found.

This method of eliminating leaks is used not only in straight sections, but also in places of threaded connections or joints of pipes of different diameters. This is justified if it is impossible to turn off the heating at the time of repair of the joint.

To seal leaks in heating pipes, the following chemically active substances are used:

- Two-component epoxy-based sealing resins.

- Adhesive silicone mixes that set quickly (cold weld).

- Heat-resistant rubber-based mixtures.

Note! It is possible to seal a leak in a heating pipe using chemical sealants only when the heating is turned off and the system is empty.

The algorithm of actions is as follows:

- The damaged section of the pipe is degreased, dried and a sealant is applied to it in a thin layer.

- The area to be repaired is wrapped with a special fiberglass tape with a serpyanka. It serves as a reinforcing element in the mass of the hermetically sealed compound.

- The chemical composition is again applied to the serpyanka. The action is repeated.

As a result, a sealing layer forms on the pipe body, which reliably protects it from leaks.

Note! Silicone sealant adheres significantly better to smooth surfaces than rough surfaces. Contrary to habit and popular belief, the damaged section of the pipe should not be sanded with abrasives (for example, cleaned with sandpaper).

Hot and cold H2O - is there a difference in how to seal the gap?

It's all about the difference in temperature of the coolant. It is this factor that decides when choosing a material.

With hot pressure, minor damage can be tightened without third-party intervention... Larger gaps can be easily leveled with regular salt and bandage.

But when the water cools down, the flow will resume. In the cold water pipe, it will not be possible to eliminate the leak with salt and a bandage. It is easier to repair a failed DHW pipe in the summer, when it is turned off. Then there is no need to control the temperature regime in the room while eliminating the leak.

How does the material of the pipeline affect the solution of the problem?

Metal pipes are distinguished by enviable resistance and durability. Almost their only drawback is their susceptibility to corrosion. This is what often becomes the cause of a leak in the circuit.

Less often, but other pipelines also fail: plastic, polypropylene (mainly in places of threaded or fitting interface).

The most difficult to terminate are metal pipes, since electric welding is not applicable to them. After such an impact, corrosive processes only intensify.

It is enough to compress the plastic pipe in the problem area, and all manipulations can be carried out under water pressure. The main thing is not to overdo it with the screed, otherwise the plastic will crack, and then you will have to change the entire pipe.

Polypropylene pipeline is easily repaired by soldering a separate fragment, from metal-plastic - inserts are needed... In the latter case, if the damage is not large-scale, it will be enough to wind it with electrical tape or treat it with an adhesive (polyurethane, epoxy).

Sealing leaks at joints

The leak at the joints of the heating circuit can be sealed in the following ways:

- Install a classic clamping clamp, having previously eliminated irregularities with additional rubber bands.

- Close up the leak at the joint by wrapping it in several layers of impregnated elastic fabric. As an impregnation, you can use waterproof adhesives or ordinary nitro enamel.

- Minor damage can be repaired with baking soda and glue-moment. Lightly moistened baking soda is rubbed into a crevice or fistula so that it fills the entire space. Super glue is poured on top. Substances instantly react with each other, forming a strong plug.

We recommend that you familiarize yourself with: Do-it-yourself rules for installing a chimney through a wall

It is convenient, just in case, to have a ready-made kit for local repair of the Siloplast type at home. The kit includes an acrylic fistula pad and a specially impregnated leak seal tape. It is enough to wind it around the pipe and moisten it with water. For such a repair, it is not required to drain the water from the heating system.

Note! High-quality repair of threaded connections requires mandatory dismantling and diagnostics.

How to solve a problem?

When water circulates in the pipes under pressure, then most major repairs are not possible to do. Therefore, it is necessary to act in other available ways in order to at least temporarily suspend the leak and wait for the emergency service.

Using a self-tapping screw

The the option is applicable only for minor gaps with a diameter of no more than 3-4 mm.

To block the hole, a galvanized self-tapping screw is needed, which is additionally equipped with a press washer.

They just screw it into the hole and fix it.... As a result, the water is blocked. After such a repair, the pipe can last up to 3 years, but it is better to change the burst fragment as soon as possible. In addition, a self-tapping screw inside the pipeline leads to clogging of the system.

Cementing

Cast iron or steel pipes can be easily patched up using cementing.

The sequence of actions is as follows:

- With a special hard brush for metal, carefully remove the rust layer in the fistula area. The paintable metal is also removed, even if this leads to an enlargement of the hole.

- Cut the bandage to a certain length and dip it into the cement solution.

- They wrap a crack with it in several passes to form a kind of cocoon.

- Cover with cement on top to consolidate the result.

After completing the repair work, the pipe must be given time to dry completely. Usually a day is enough.

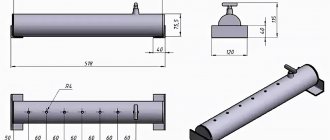

Clamp

A clamp is understood as a fairly simple structure consisting of a metal ring, a rubber gasket and a tightening bolt.

Such a device is sold in stores, but in emergency situations, you can quickly make it yourself. You will need a piece of plastic rubber, scissors and a metal clamp that matches the diameter of the pipe.

Further actions:

- clean the area of damage from rust;

- put on a collar, and a rubber gasket is slipped under it;

- the clutch is tightly squeezed.

If the pipe is very rusty, the clamp will be almost the only way to disguise the leak. This is because welding cannot be used here.

Bandage and table salt

The salt is ideal for sealing leaks on pressurized hot water pipes. Step-by-step instruction:

- Spread the digestive salt over the bandage, in as large a layer as possible.

- Wrap it around a hole, preferably more tightly.

After getting wet, the salt sets into a crust, which prevents the further flow of water. The method is not particularly convenient to implement, but it will work if nothing else is at hand.

Sealant

It is not productive to use a sealant (also called "cold welding") to eliminate leaks in existing pipelines, since there is no guarantee that the problem will be 100% solved.

This is because such formulations are designed to work on dry surfacesand condensation is present on the pipes under pressure.

But with a small crack, you can try to seal it with a heat-resistant sealant. Outwardly, it is similar to plasticine.

Split off a small piece, carefully crumple with your fingers and insert into the hole, followed by smearing on the sides... Large gaps will not work like this, you first need to insert a wooden chop.

Glue

Here you will need fiberglass cloth and BF-2 glue.

Step-by-step actions:

- the problem area is thoroughly cleaned of rusty particles and degreased with aviation gasoline (acetone will serve as an alternative);

- wait 15 minutes for the surface to dry;

- cut a tape of such a width from the fiberglass that it completely overlaps the leak;

- an adhesive composition is applied at the edges, and epoxy resin is applied to the center;

- applied to the crack, pressed by hand and wound;

- fixed with copper wire.

The patch will dry for about a day if the batteries are hot. In summer, when the room is cool, it takes about five days.

Wire or harness

A method somewhat reminiscent of the one with a clamp... Only instead of it they take a medical harness and any metal wire. The damaged pipe fragment is tightly wrapped with rubber and tightened with a wire.

Wooden chopik

It is necessary to quickly cut out a wedge-shaped peg of a suitable diameter from any piece of wood. Then they hammer it into the hole with a hammer.

Leak at the junction: methods of elimination

Pipes often leak due to poor joint insulation

Most often, the user is faced with the fact that a plastic pipe is leaking at the junction. The installation of new connecting fittings (the line was incorrectly installed), or the replacement of the entire wiring (the wrong material was selected - for example, polypropylene was chosen for cold water supply) will eliminate the leak in the metal-plastic pipe.

Advice: "It is recommended to coat all joints with a sealant (for example, a universal heat-resistant sealant for heating pipes can be used)".

A similar defect is observed in cast iron pipelines, but it will be somewhat more difficult to cope with it. You can seal a leak in a heating pipe in the following ways.

Caulking of joints of cast iron pipes

The joints of such highways can initially be sealed in different ways. Based on this, one or another algorithm of actions is selected.

If the pipes were minted with lead, in order to eliminate the leak in the heating pipe, you will have to:

- Strip to base metal (joint).

- To stamp out the resulting gap, for which it is recommended to use a blunt chisel. The implementation of such a repair option is explained by the softness of the lead, which easily fills the gap.

It will be more difficult to eliminate the leakage of the heating pipe, during the sealing of which cement mortar was used:

- Remove cement residues with a hammer and narrow chisel.

- Remove the seal and clean up the formed gap.

- Drive a new sealant (for example, tarred fibers) into the gap, after which it remains to cover it with a cement solution (one in ten).

Tip: "When starting to drive new strands, you should take care of their pre-treatment with a special mixture, which consists of cement (seven parts), asbestos (three parts) and water (added gradually until the mixture looks like plasticine)."

Pipe joints are sealed with cement

Cement is suitable for sealing metal pipes

There are situations when there is nothing else at hand except cement. It turns out that this is quite enough to seal the leak in the heating pipe.

The sequence of actions is as follows:

- Clean up the joint.

- Remove the old seal, for which it is not recommended to use heavy tools, otherwise the pipe could be damaged.

- Prepare cement, water and a wide bandage.

- Dissolve the cement in a small amount of water - a slurry should form, in which a bandage (or a piece of gauze) is moistened.

- Wrap up the heating pipe with a treated bandage. In this case, each joint is evenly wrapped.

- The structure remains to harden, and after 2 ... 3 hours it is processed with sandpaper and painted over with a suitable paint.

How to stop a leak in a hidden pipe?

It will not be particularly pleasing when a pipe hidden under a building structure begins to leak. Moreover, if only recently renovations have been made. Since it is not always possible to quickly reach the source, it is necessary to know how to temporarily stop the flow.

Here are a few tricks that are suitable for a water supply system in a private house:

Powdered mustard is poured into the expansion tank. Then the water circulation is resumed.

In just a couple of hours, the mustard will seal the microcracks from the inside of the pipeline. When the leak has been repaired, the circuit should be flushed.- The heating system is temporarily filled with an industrial sealant. It will settle on the inner surfaces of the pipeline and thereby stop water seepage through microscopic gaps. After a major overhaul, the coolant is changed to a new one.

Large holes cannot be repaired in this way. Then they turn off the system, dump water from the riser and start straightening. Namely, it will be necessary to disassemble the structure and replace the problem spans. In case of living in an MKD, neighbors are warned about the upcoming event.

How to fix a heating pipe leak

How to fix a heating pipe leak

how to fix a leak in a heating pipe

According to the law of meanness, a heating pipe leak manifests itself in the midst of the heating season, with an increase in the temperature of the coolant in the pipes or with an increase in the total pressure in the system, and in order to eliminate this leak, it is necessary to take temporary measures in which the coolant leak must be eliminated under pressure , without overlapping the heating riser. Of course, if you can shut off the water supply without problems, then it is best to immediately replace the damaged section of the line, or repack the leaking threaded connection. But the whole problem is that in most of our "Khrushchevs" the valves are not able to completely shut off the heating pipes, and you still have to wait for spring, when the water is drained from the entire line. The article will talk about how to eliminate the leakage of heating pipes without draining the water from the system.

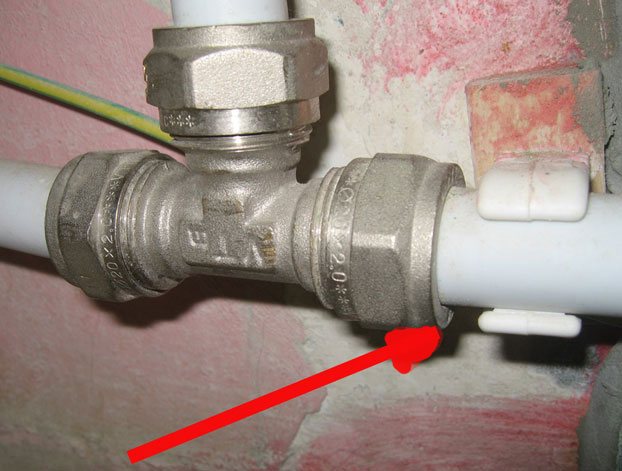

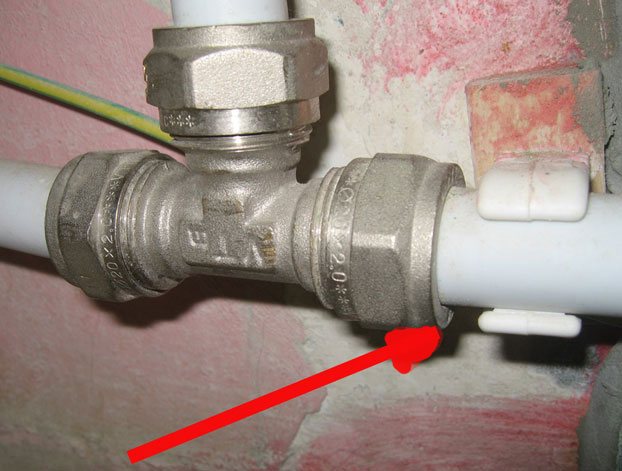

If the fistula is directly on the pipe itself, due to its wear, then the easiest way to eliminate it is how to make a wooden stool. The most economical way to eliminate pipe leaks has been used for many decades, for this you do not need special devices, but rather soft rubber (bicycle or car camera), and ordinary clamps or soft knitting wire. A strip of rubber is wound tightly over the leak and a few centimeters to the sides, and pressed in with several clamps or tightly fixed with a knitting wire. One of the clamps should fall directly on the place of the leak, and two more - additional, securing.If for some reason it does not work to eliminate the pipe leak with improvised means, you will have to go to the nearest plumbing store and buy a special bandage, consisting of thick rubber and an analogue of a clamp, which wraps around the pipe around the entire perimeter and is pressed in with bolts. Due to the significant (about 60mm) area of this band and the significant crimping force, it will be possible to eliminate almost any leak, and even connect the pipes.

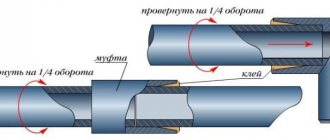

If it is necessary to eliminate the leakage of the threaded joint of the heating pipe and the fitting (elbow, tee, coupling), then the task will become somewhat more complicated - since due to the difference in the diameters of the pipe and fitting, it will not be possible to press the clamps directly into the place of the leak, and in the factory band everything is designed for a certain diameter, and the rubber seal just won't close. In this case, you can try, by winding the rubber tightly, clamp it with clamps directly near the leak (one clamp for the pipe, and the other for the fitting). If this method turns out to be ineffective in your case, then the above-mentioned factory bandage, but somewhat "improved", should help. The elastic that comes with the clamp is not used, but the rubber is wound from the chamber, and in such a way as to slightly compensate for the difference in diameters, a couple of turns on the fitting, and three or four turns on the pipe (depending on the circumstances). From above, the rubber is pressed in with a clamp, which will become slightly skewed, but will crimp the junction well and reliably eliminate the leak (see the photo at the beginning of the article).

At the end of the heating season, the bandage will definitely need to be removed, and constant measures should be taken - repacking the connection, or replacing the pipe section.

I do not presume to argue that various compositions such as "cold welding" will definitely be useless, because progress does not stand still, but I warn you against experiments - in the end it will be more expensive. Just remember that you need to fix the leak in the heating pipe, which is not only hot, but also under pressure, that is, the water is constantly oozing out. But if someone reading this article successfully used some kind of composition in this situation, please share your experience, tell the manufacturer and the name of the composition that helped you. Your experience will help other people facing a similar problem.

I sincerely hope that this article will help everyone who read it and that your neighbors will not be flooded.

Heading: Heating and water supply

Preventing the recurrence of the problem

It is easier to prevent malfunctions in the heating circuit than to suddenly look for ways to fix them. So before the start of the heating season, communications are checked by testing, especially focusing on hazardous areas.

These include:

- even spans;

- threaded connections and welds;

- area of joining of sections at radiators;

- places of implantation of heating equipment;

- near fittings;

- hard-to-reach areas.

First, everything is checked by eye, then - with a running contour.

Causes and localization of leaks in the heating system

Leaks in the heating system occur for various reasons and at different points in the circuit: on straight sections or at pipe joints.

Leaks in straight sections

The cause of leaks in metal heating pipes, which have been in operation for more than one year, in more than 95% of cases is metal corrosion (rusting).

Even thick-walled galvanized pipes in heating circuits will corrode over time. The destruction of metal in contact with water is a natural process that has not yet been completely defeated.

The trigger for metal destruction can be:

- mechanical, chemical internal damage to the pipe;

- changes in temperature or pressure;

- damage to the protective outer layer.

Note! If a leak occurs in an old heating pipe, then most likely this is a warning about the total wear of the entire system.

In autonomous heating systems, which are mounted from modern polymeric materials, the reasons for leaks are the wrong choice of pipes.

When the owner, through ignorance or for reasons of economy, acquires pipes for cold water or pipes that are not intended for operation under pressure for hot water systems or a heating system. In this case, simple sealing of the leak is indispensable; a complete replacement of communications is often required.

Leaks at the joints

Leaks in the connection area occur if the thread has become unusable (for example, it stuck and was torn off).

We recommend that you familiarize yourself with: Instructions for connecting the toilet to the sewerage system

If there are leaks at the fitting sites, the prognosis for effective local repair is more favorable. Here, a leak in the heating system can be repaired by changing a worn out gasket that has lost its elasticity.

In more serious cases, it may be necessary to replace the union (wedge) fitting or valve.