Today it is already difficult to imagine how the craftsmen managed to do without polyurethane foam. This material made a real revolution in its time.

With its remarkable insulating properties, unusual structure and ease of use, polyurethane foam has become one of the most popular materials, which is widely used today in construction and renovation work.

Scope of application of polyurethane foam

The material has proven itself well both as an excellent sealant and as a means for sealing joints between structural elements. In particular, it is convenient to seal up interpanel seams of floors, seams of facade systems, joints between beams, etc. with polyurethane foam.

In addition, polyurethane foam is used to fill voids and cracks in concrete, brick walls, etc. A means for installing windows and doors is used.

Of the non-standard methods of application, we can note the insulation of wooden floors on logs with polyurethane foam, when it "blows out" the space between the base of the floor and the floorboards. At the same time, the floor stops creaking and becomes really warm. The advantage here is that to insulate and strengthen the wooden floor, it does not need to be disassembled, because it is easy to pump the foam into the floor through a gap or a specially made small hole in an inconspicuous place.

Polyurethane foam properties

The wide scope of application of polyurethane foam is explained by its unique properties that no other material possesses. Initially, it is (as it is not difficult to guess from the name) a foam-like liquid mass. Foam is packed into relatively large cylinders under high pressure. After the foam enters the open air, a reaction occurs, the foam increases significantly in size and quickly solidifies. The result is a porous, very warm and reliable material that simultaneously performs several important functions. The surface of the polyurethane foam turns into a tough, dense and waterproof film.

The following properties of polyurethane foam can be distinguished:

- high heat and sound insulation characteristics;

- moisture resistance;

- fire resistance;

- safety and environmental friendliness;

- low electrical conductivity;

- the ability to fill even hard-to-reach voids;

- the ability to reliably glue together a variety of materials;

- ease of use.

Professional and household polyurethane foam

All varieties of this material fall into two large groups: professional and household polyurethane foam.

To use professional foam, it is imperative to use the appropriate tool - a foam gun. It is very convenient to work with such a tool, it allows the master to accurately measure the amount of material, increase its useful output and the period of trouble-free service.

Professional polyurethane foam practically does not shrink, is suitable for all types of work and, most importantly, has a predictable increase in volume. The master who uses such foam always knows exactly how much it will increase. This allows you to accurately dose the material in each specific case, which has a positive effect on the quality of the work carried out and on the savings in expenditure.

As for household polyurethane foam, it is used without a special foam gun. Instead, a special adapter tube is used, which at the top has a lever for feeding and dispensing foam.

Household foam differs from professional foam in several ways. First of all, it has a lower density, as a result of which it can sag quite strongly (shrink). In addition, household polyurethane foam is intended for single use. Even if the bottle is only half-used, it will still have to be discarded. Also, in practice, household foam often does not come out of the cylinder completely, which leads to additional expenses.

In general, household polyurethane foam is a wonderful material. Especially when it comes to not too responsible objects and works. For example, it copes better than any other material at sealing joints between building and finishing materials, filling deep cracks, installing door frames, etc.

Polyurethane foam in winter and summer

Polyurethane foam can be used in a wide temperature range, which makes it possible to carry out repair and construction work regardless of the season. In particular, if we take the extreme points, then the use of polyurethane foam is allowed in the range from -100 to +350 degrees Celsius. These are quite serious indicators that not every material used today on construction sites can boast of.

On sale, polyurethane foam is divided into three groups:

- Summer polyurethane foam;

- Winter polyurethane foam;

- Off-season polyurethane foam.

At first glance, it seems strange that manufacturers decided to produce polyurethane foam for different working conditions. Why not just release all-season polyurethane foam to keep developers and DIYers alike from the confusion? The bottom line is that all-season polyurethane foam is more expensive than winter, and winter is more expensive than summer. The difference in price is due to the fact that they contain expensive supplements. It makes no sense to use more expensive material in the summer, when "winter" additives will not bring any practical benefit and you can save a certain amount.

Algorithm of action

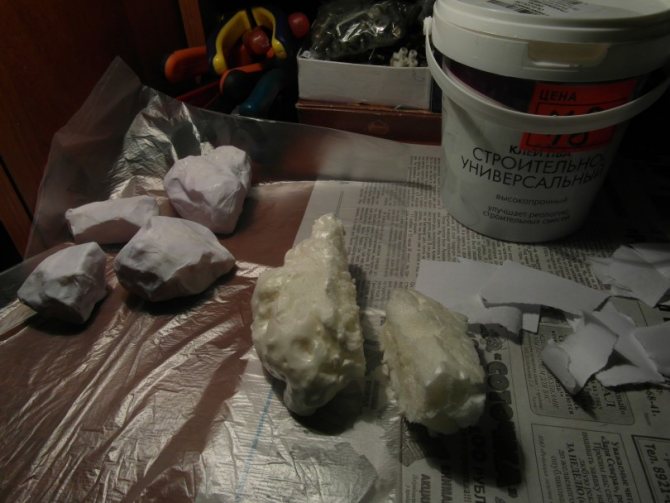

Crafts from polyurethane foam for the New Year, or garden sculptures for decorating a plot in the summer are made according to the same scheme:

First, a frame is created, the parts of which are connected with tape. The frame is filled with a weighting agent to give the figure stability.

After assembling the frame, foam application begins. The material sets in an hour, and dries completely in a week.

It is necessary to apply layers on a horizontal surface, rotating the workpiece laid flat in the desired direction.

After the surface takes the desired volumetric shape and hardens, proceed to its processing. First, they cut off the excess parts on the figures with a clerical knife, and where there is not enough material, add, dry and then also trim it with a knife.

The surface is sanded with emery wrapped around the block.

After that, dust is hit and a layer of putty is applied to better level the surface and create protection from ultraviolet radiation.

The final stage is painting the figures from the mounting foam for the garden. The paint is applied in two layers, and finally a colorless varnish is applied. The yacht type of such paints and varnishes is best suited.

Important! You need to apply paint and varnish only on well-dried foam, otherwise the figure will be permanently damaged.

Multi- and one-component polyurethane foam

Manufacturers offer two types of foam: one-component and multi-component. It must be said right away that in fact the amount of all components in the polyurethane foam is the same.The difference is that in one-component polyurethane foam, all the ingredients have already been mixed together in production conditions, and multi-component polyurethane foam has to be prepared for work independently, adding hardeners and various additives that are included in the kit to the material.

Of course, it is more convenient to use one-component polyurethane foam. All you need to do is shake the can, screw the adapter tube onto it, and the foam is ready to use. In most cases, especially for home use, it is recommended to purchase just such a polyurethane foam.

It makes sense to purchase multicomponent foam only for particularly demanding types of work and facilities where it is required to achieve maximum quality and reliability. The fact is that when mixing all the ingredients of the foam, despite the fact that it is hermetically sealed in cylinders, a number of chemical reactions still occur between the individual ingredients, which reduces the performance and negatively affects the characteristics of the material. If you mix the ingredients just before using the foam, you can achieve better results. However, in most cases, as already mentioned, it makes no sense to achieve a safety margin, since it will be excessive.

How to use polyurethane foam

From advertising materials, you can find out that polyurethane foam is extremely easy to use. Before using the foam, the balloon is brought to ambient temperature. Then it is shaken for 1 minute. As a result, the foam will become homogeneous, which will have a positive effect on its properties.

After that, the adapter tube is screwed to the cylinder. It should be screwed on tightly and securely so that the foam during operation does not leak between the cylinder and the tube, but completely comes out of the tube.

During use, a container with polyurethane foam is kept upside down. This achieves a uniform exit of material from the tube, as well as its full use. Otherwise, if you hold the cylinder with foam incorrectly, the foam will come out in jerks, and some of the material will remain inside the cylinder and will not come out, since the air that is pumped into the cylinder to provide pressure will be consumed much faster than the foam itself has time to run out.

When the foam comes out, it immediately begins to grow in size and then hardens. During this time, it is forbidden to touch the foam with your hands or any objects, as this may interfere with the process. When the foam hardens, its excess is cut off with a knife, and the surface is putty, painted or simply covered, for example, with a plinth or platbands.

Materials at hand

The list of materials at hand varies depending on the garden figure chosen for the manufacture, but the invariable set consists of the following items:

- Polyurethane foam. It is better to replace a conventional spray can with a tube with a pistol, which is much more convenient to work with.

- Stationery knife for trimming unnecessary elements.

- Latex gloves to protect your hands. Fabric products will quickly deteriorate.

- Sandpaper for sanding the surface.

- Brush with external paints.

To create a frame, crafts usually use plastic containers and cans, rigid wire, planks, hoses and double-sided tape. If in the process of work the foam gets on the skin, a special cleaner or kerosene will help get rid of impurities.

Advice! The garden figure, made with the use of polyurethane foam, is lightweight, therefore, at the stage of formation, measures are taken to make it heavier. The plastic container can be partially filled with sand or small stones. The wire protruding from the paws of the animals will help to fix the craft on the ground.

How to use a foam gun

The foam gun is the simplest device.Shake the can with foam, remove the cap at the top. The can is then inverted and screwed directly into the gun. Moreover, the cylinder must be screwed in very tightly so that there are no gaps or cracks. Further, the foam is used for its intended purpose. The foam outlet is regulated by a pistol using a specially designed handle.

If the cylinder runs out of foam, but work needs to be continued further, the empty cylinder is unscrewed, after which the gun is immediately rinsed from the remaining foam with a special solvent for the foam. Such a solvent is sold along with the foam itself in any hardware store, so finding it on sale is not a problem. Only after the gun has been flushed with solvent, the next cylinder is screwed to it, etc.

If the cylinder did not have time to be used up, and the work has already ended, the cylinder is not unscrewed and left with the pistol. But at the same time, the outlet of the pistol must be flushed with a solvent.

How to foam hard-to-reach places

If you need to foam some hard-to-reach place, it can be very difficult to work with the tube usually supplied with the can. To perform such an operation, you can put a thin flexible hose on the standard tube of the spray can.

When the area to be treated with foam is too high, the end of the flexible hose can be secured to a holder or a regular stick. And do not forget, the can should always be kept upside down!

By foaming a very narrow gap, you can heat the extension hose with a match, pull and break it.

At the break point, the hose diameter will be very small, which will guarantee a high quality sealing of a small space.

How to wash polyurethane foam

If polyurethane foam gets on your skin, clothing, interior items or appliances, it must be removed as soon as possible. First, mechanically remove as much foam (which has not yet had time to harden), as possible. Moreover, it must be removed from the edges to the center, and not vice versa, so that the stain does not become even larger than at the beginning.

After that, take a rag, moisten it with a foam solvent and wipe the material, trying not to rub it in, but gently clean it off the surface. To remove polyurethane foam, you can also use the popular solvent 646, acetone, gasoline. Here in detail about how you can clean off the foam.

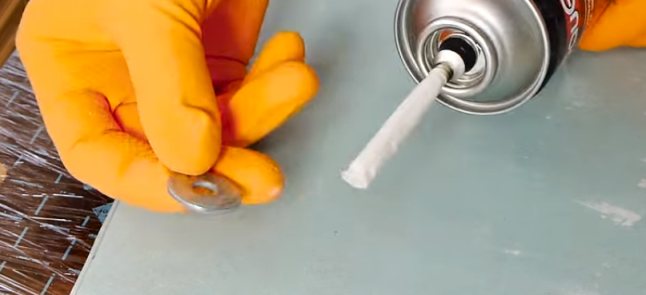

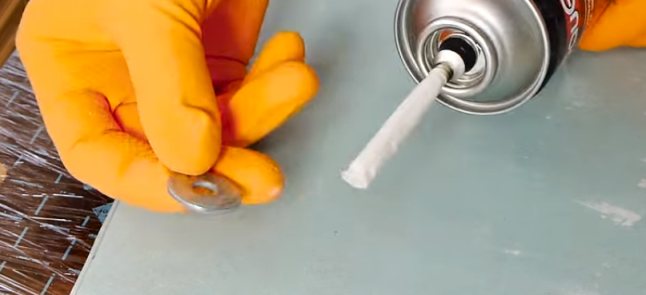

What to do if the tube attached to the spray is lost

If this much-needed tube is lost, then you can put a heat-shrink tube on the spray can dispenser, and use a wide enough washer as a dispensing stop.

In this case, you can work with the foam just like with a regular native pipe.