General information

Today, collectors, which are popularly called combs, are used for the aggregate connection of a number of heating and plumbing fixtures. Outwardly, this device is a cylindrical part with one input and many branches. Each branch is supplied with shut-off valves.

The principle of operation of this device is as follows - water or other liquid is supplied to the inlet under pressure. Further, it is distributed to the taps, which allow you to connect in parallel several plumbing fixtures or, for example, several circuits of the underfloor heating system.

The collector connection allows you to ensure a uniform water pressure in all plumbing fixtures when they are turned on at the same time. In the case of using combs in heating systems, uniform heating of all heating devices (radiators or underfloor heating circuits) is ensured.

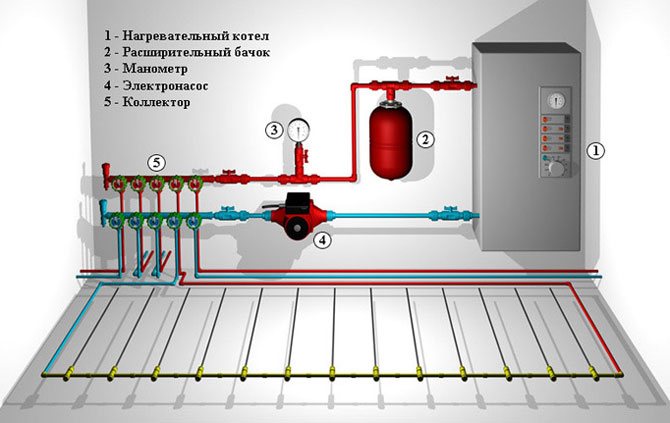

Scheme of using collectors in the underfloor heating system

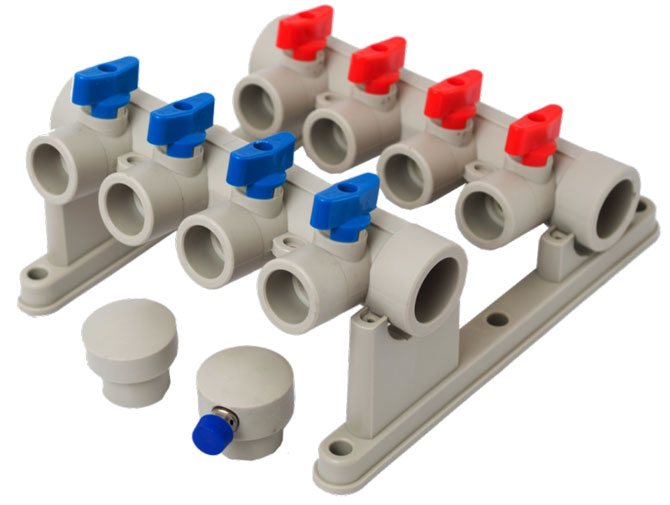

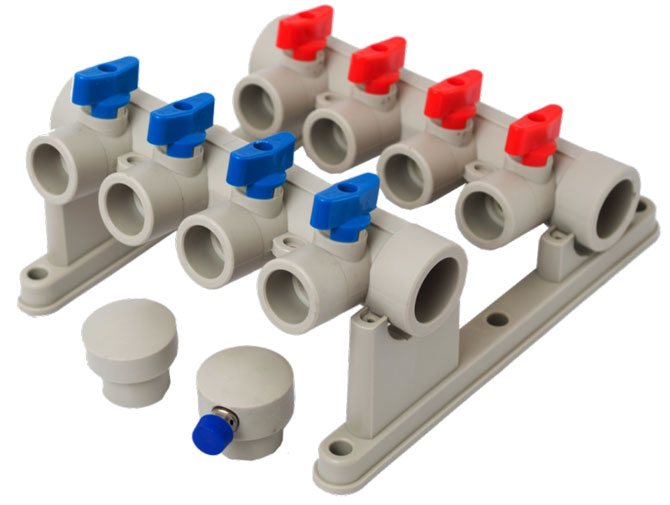

It is quite simple to assemble a polypropylene comb with your own hands, and for this you only need a set of tees and ball valves.

In this case, the device will have a number of advantages, such as:

Corrosion resistant. Tightness, as the fittings weld together reliably. Durability - virtually no scale settles on the polypropylene walls of the fittings. Cheapness, due to the fact that the price of polypropylene pipes and fittings is not high. Reliability, since polypropylene is a fairly strong material. The ability to make exactly as many bends as required. The ability to use the product both for the water supply system and for heating.

For these reasons, many specialists prefer self-assembled devices from polypropylene parts to metal collectors.

What is a collector

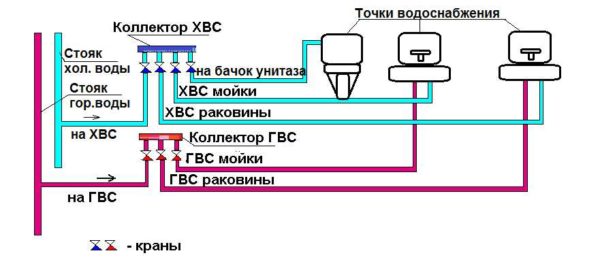

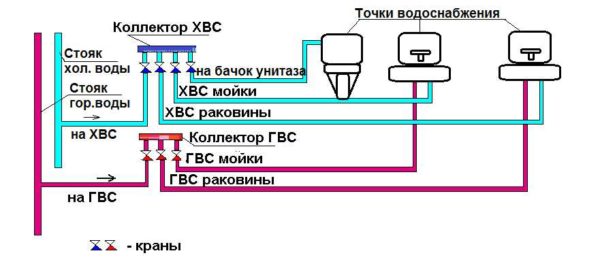

A manifold is a device for distributing a liquid, which is often called a comb, apparently due to the external similarity of the collector circuit with this item. In plumbing systems, it is designed to distribute water, for example, from a supply pipe to several taps without loss of pressure.

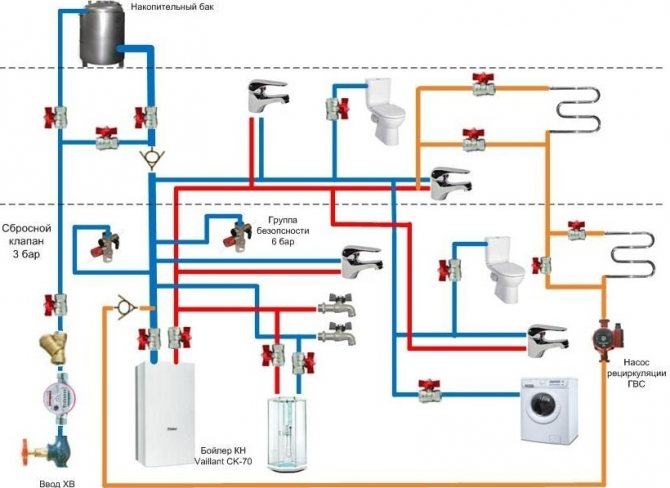

Accordingly, if two people, for example, in the bathroom and in the kitchen, use water, the pressure in the pipes and the water pressure will be equal for both.

The collector simplifies the dilution of water in different places, you can easily make a wiring for a washing machine, bath, sink, drain tank. One target pipe goes from the collector to the consumer without unnecessary wiring and soldering, which not only simplifies, but also increases the reliability of the system.

In heating systems, combs are used to distribute the coolant along the circuits; heating is usually divided into sections. For example, the first circuit is a radiator heating system, the second is a warm floor on the same floor. In this case, it is required to distribute the coolant from the heater to the circuits and make a returnable closed system.

Without a collector, such a structure will be extremely complex, it will take much more effort and material, in order to realize heating, it will be laborious to maintain and less reliable in operation.

The collector, on the other hand, distributes the coolant with uniform pressure, and returns the coolant from all circuits back to the heater. This method makes the closed system simple and reliable.

It is important! The main factor in the operability of the manifold is that the fluid inlet must have a diameter equal to or greater than the outlet ports.

Characteristics of polypropylene collectors

Polypropylene is non-toxic, in normal use it is completely harmless to both the user and the environment. The material is capable of emitting harmful vapors only during combustion. The melting temperature of polypropylene is 160 - 170 ºC.

We recommend that you familiarize yourself with: What is fire protection for air ducts for and how to choose it correctly

Accordingly, the material can withstand work in heating systems without any problems. But the disadvantage of polypropylene is the low glass transition temperature threshold. At t from -10 to -20 ºC, the material becomes hard and brittle, loses its elasticity. Therefore, the use of polypropylene in the cold is impractical.

Otherwise, polypropylene is a reliable and easy-to-install material that can be used flexibly both in plumbing and in heating.

An important advantage of the material is its price. It is lower than that of steel pipes.

Homemade collector

It is important to follow the direction

Making a homemade distribution manifold must begin with planning. You need to determine for yourself some of the components of the heating network at home.

The number of circuits where the coolant will be directed. The number of heating equipment. Do not forget to decide on its power, water temperature, and so on. That is, you need its technical specifications. If in the future you plan to integrate additional heating elements into the heating system, for example, a heat pump or solar panels, then it is best to take them into account in advance. The number of additional equipment (pumps, valves, fittings, storage tanks, thermometers, manometers, etc.).

Now the design of the device is being determined, especially it is necessary to take into account how each circuit will fit and from which side (bottom, top, side)

We draw your attention to some of the nuances of connection

Gas or electric boilers are connected to the manifold either from the bottom or from the top. If a circulation pump is installed in the heating system, then the connection is made only from the end of the comb. Indirect heating boilers and solid fuel units cut into the collector only from the end. The supply circuits of heating systems cut in either from the top or from the bottom.

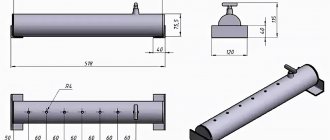

It is good if a small drawing of the collector structure is transferred to paper. This will give a visual image that will make it easier to manufacture the device. In addition, you can accurately indicate the dimensional characteristics that will have to be maintained during the manufacturing process. For example, the distance between the nozzles of the supply and return circuits should be within 10-20 cm. Do not do more or less, it will simply be inconvenient in terms of maintenance. The distance between the two compartments (supply and return) should be in the same range.

Make your device compact and beautiful. We recommend that you indicate in the figure all threaded connections with an indication of the thread sizes, do not forget to sign all the necessary contours. This will allow you not to make a mistake when connecting. Now from the sketch it becomes clear how much and what materials you will need to make a homemade distribution manifold.

Manufacturing process

Please note that the supply and return compartments can be made of round or square pipes. Many craftsmen prefer the latter option.

They claim that it is easier to work with.

So, here is the manufacturing sequence:

For all the dimensions that were indicated in the sketch, it is necessary to prepare the appropriate materials. These are practically all pipes. They are connected according to the design of the drawing in accordance with the purpose of each. The connection is made using a welding machine. Welding points must be cleaned with an iron brush, if necessary, degreased. The finished device must be tested for leaks.Therefore, all the pipes will have to be closed tightly, leaving only one. Hot water is poured into it. If none of the joints is dripping, then the work has been done at a high level. The collector must be painted and dried. It is possible to carry out installation and connection of all pipe systems with the installation of valves.

A simpler option

Now to the question, isn't it better to buy a ready-made version? There is one "BUT" here. The finished distribution manifold may not exactly fit your heating system; you will have to align the heat engineering indicators in other ways. For example, by installing an additional comb. And this is extra costs and extra volume of installation work. And a homemade comb, in which you took into account all the design features of heating your home, will definitely fit it and will work efficiently and rationally.

So it is worth thinking about the question that was posed at the beginning of the article, how to make a distribution manifold with your own hands? Let's just say it's a simple process that will take you one day. But you simply must have the skills to work with a welding machine and other locksmith tools. Without this, it will be impossible to guarantee the quality of the device.

gidotopleniya.ru

Polypropylene pipes collector Far

Hello dear forum users! Sorry if I raise a question that has already been discussed.

Multi-apartment new building, polypropylene risers, they decided to do the wiring also with polypropylene (diameter 20). I would like to supply collectors from Far. After a long study of the topics of the forum and the assortment of products - porridge in my head. Interested in the collectors adjustable 3/4 ″ conclusions 1/2 ″ (3 - DHW and 2 + 3 -HVS outlets). Bends, as it turned out, are metric and pipe, pipe is divided into Eurocone and Flat-Faced. Flat-Faced, as I understand it, is ideal for me, but it's not realistic to find them in Rostov (it's probably too late to order).

Explain which is better to take with TR or MR. As far as I understand, the conclusions of the MP are attached through the adapter MP-TP, and on the TP there is already a fitting adapter for soldering polypropylene. With TP, you can immediately fit, but there are sharp edges that can cut through the gasket.

This is such a mess. Don't throw stones at me in plumbing I don't understand.

Those who make repairs have never done the wiring with the collector, so they took over the choice. Today it was proposed to make a prefabricated collector from polypropylene tees (in one place, the distance between the terminals is minimal, as in a conventional collector (little space), that is, it looks like a regular collector), hang taps on the branches. In this regard, more questions have been added:

- How much less (or more?) Such a collector will be.

- Tees are not reinforced, how bad is that? (reinforced pipes)

- As far as I understood, ball valves (also made of polypropylene) are ball valves, i.e. to regulate it will not work? just close - open? Are there adjustable PP faucets?

I tend to Far collectors, but if the connections on the branches are a weak point, then maybe a prefabricated one is better?

www.mastergrad.com

Views

Collector groups for heating systems are sold ready-made, while they can have different configurations and the number of outlets. You can choose a suitable collector assembly and install it yourself or with the help of specialists.

However, most industrial models are versatile and do not always suit the needs of a particular house. Converting or reworking them can significantly increase costs. Therefore, in most cases, it is easier to assemble it from separate blocks with your own hands, taking into account the peculiarities of a particular heating system.

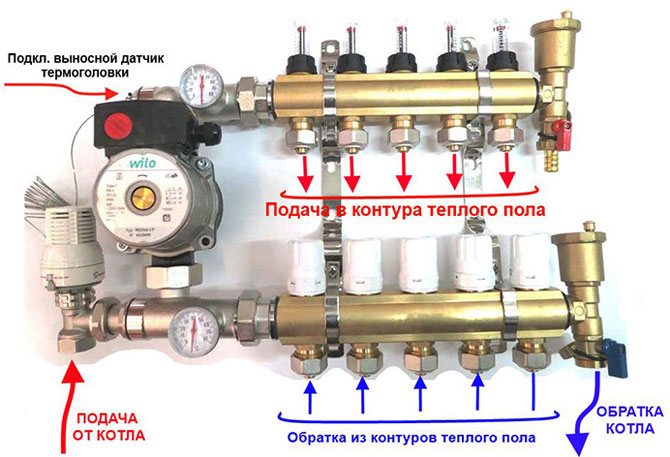

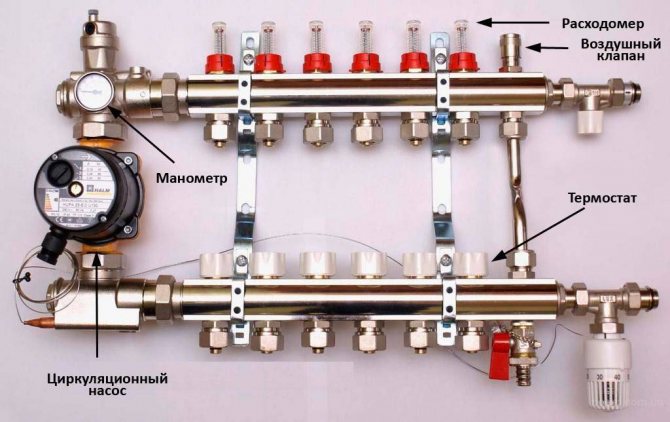

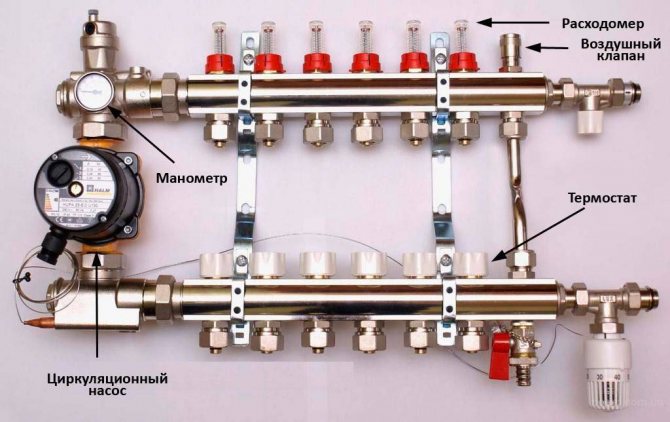

Collector group for heating system, complete

The design of the universal collector group is shown in the figure.It consists of two blocks for forward and reverse flow of the heating medium, equipped with the required number of outlets. Flow meters are installed on the supply (direct) collector, thermal heads are located on the return collector to regulate the return water temperature in each circuit. With their help, you can set the required flow rate of the coolant, which will determine the temperature in the heating radiators.

The manifold distribution unit is equipped with a pressure gauge, circulation pump and air valves. The supply and return manifolds are combined into one unit with brackets, which also serve to fix the unit to a wall or cabinet. The price of such a block is from 15 to 20 thousand rubles, and if some of the taps are not used, its installation will be clearly inappropriate.

The installation rules for the finished block are shown in the video.

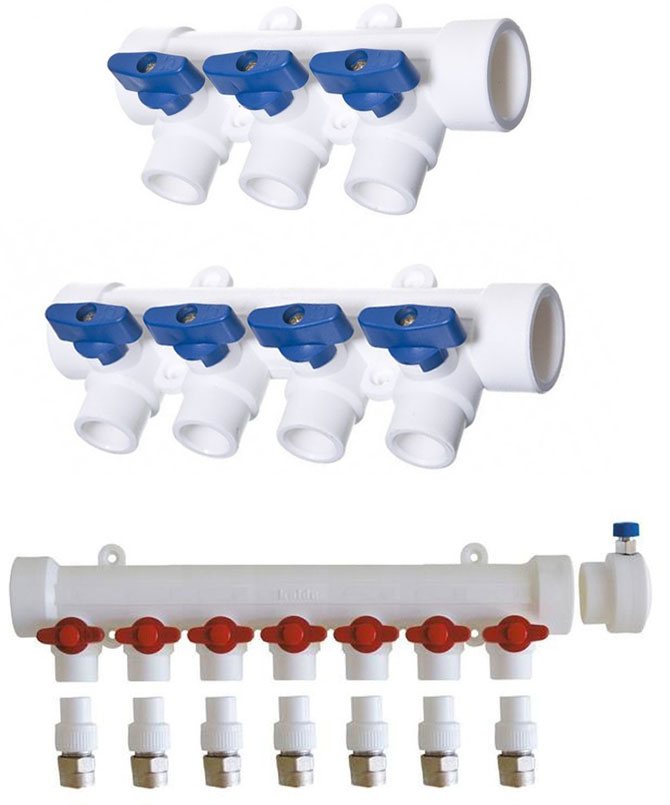

Comb - manifold unit

The most expensive items in a manifold block are flow meters and thermal heads. To avoid overpaying for unnecessary elements, you can buy a collector unit, the so-called "comb", and install the necessary control devices with your own hands only where it is necessary.

The comb consists of brass pipes with a diameter of 1 or ¾ "with a certain number of branches with a diameter for heating pipes ½". They are also connected to each other by a bracket. The branches on the return manifold are equipped with plugs that allow installing thermal heads on all or part of the circuits.

Some models can be equipped with taps, with their help, you can adjust the flow manually. Such combs have a cast body and are equipped with a union / nut thread at the ends, which allows you to quickly and easily assemble a manifold from the required number of branches.

In order to save money, the manifold for heating systems can be assembled from individual elements independently or completely made by hand.

How to make a solar collector with your own hands

This device can be used for additional heating of water... Install it outdoors on the sunny side so that the sun's rays illuminate the device all the time.

- To make it, you need several boards from which the box is knocked off.

- The back wall is closed with any sheet material: plywood, metal, OSB, fiberboard or chipboard.

- Inside fits polystyrene foam panel as insulation.

- Foil is attached on top of the polystyrene... It will act as a reflector of the sun's rays, increasing the intensity of their effect on the collector installation.

Attention! As a collector any metal pipe can be used, for example, copper from the condenser of the refrigerator. It is formed in the form of a coil and laid on top of the foil. The ends of the tube are led outside the wooden box: one is connected to the water supply network, the second is introduced into the house like a hot water circuit.

All that remains is cover the entire structure with transparent glass... Install the device at an angle so that the sun's rays fall perpendicularly onto the collector group.

Fitting connection rules

Several options were considered for assembling a manifold for a heating system, but only two of them use fittings.

- Propylene collector assembled by welding plastic, for which a special device is used. The main task is not to overheat the material. Insert pipe sections into tees along the joint axis. It is forbidden to twist parts relative to each other.

- Concerning brass fittings, then the main requirement for assembly is to prevent leaks coolant at the joints. To do this, you can use various sealing materials, for example, linseed tow, FUM tape or liquid fixative.

Tips for installing a collector for underfloor heating

Types of collectors.

Installation of such a structure for a warm floor can be done independently. The manifold for distribution is in most cases located in a manifold cabinet or in a separate room that is hidden in the wall. When installing the structure, you should take into account the nuances:

- Try to place the distribution manifold at the highest point of the heating system in relation to the level of the hinges placed. This is necessary so that, if necessary, it is possible to remove air from the installed pipes.

- The manifold for distribution should be located in the central part of the premises that are heated.

- You will need to connect circuits of the same length to one structure. If such contours are not available, the length should be as close as possible to the length of the element that is located nearby.

Output

In many cases, a manifold is a necessary wiring element. As we found out, every home craftsman who knows how to handle a soldering iron for plastic pipes can make this device from polypropylene. At the same time, the quality and characteristics of the product will not be inferior to branded combs.

You can glean some additional information on this topic from the video in this article.

Did you like the article? Subscribe to our channel Yandex.Zen

Functional purpose

To begin with, there is one very important rule, and if you do not strictly adhere to it, then the heating system of the house will work poorly. This rule states that the diameter of the outlet pipe of the heating boiler must always be equal to or slightly less than the total indicator of the diameters of all circuits consuming the coolant

The best option if it is larger.

For comparison, here is an example of a wall-mounted unit in which the diameter of the outlet pipe is ¾ inch. Imagine that this boiler will heat up three separate circuits:

- The main heating is the radiator system.

- Warm floor.

- Indirect heating boiler, which will use water intended for domestic needs.

Now imagine that the diameter of each circuit is at least ¾ inch, like the boiler. But the total figure will be three times more. That is, no matter how you want, it will be simply impossible to deliver the required amount of coolant through the diameter of the heating boiler nozzle so that it is enough for all three circuits. So much for a decrease in heat transfer over the entire area of the house.

Of course, individually, all circuits will work fine. For example, the main circuit (radiator) without the inclusion of warm floors will completely master the heated space. But as soon as you turn on the underfloor heating system, everything, neither here nor here, will not have enough coolant. The coolant has enough temperature, its volume is not enough.

This rather serious problem is solved by installing a distribution manifold in the heating system. In fact, this is a structure made of stainless metal pipes, in the device of which the devices for the input and output of the coolant distributed along the circuits are installed. To regulate temperature, pressure, flow volume and its speed, shut-off valves are installed along the outputs, which performs all the necessary functions.

The most important thing is that with the help of the distribution manifold, you can control the temperature regime in a single room. And this will not affect the neighboring rooms and the temperature of the house as a whole.

Collector device

The collector consists of two pipes:

- Connects the flow line from the boiler to the flow circuits of the heating systems. This compartment helps the distribution of hot water. His device especially helps in the case when the question arises of repairing one or another branch. In this case, on a certain circuit, where it is necessary to carry out repair work, the shut-off valve closes. It simply shuts off the coolant supply.

- The return compartment regulates the pressure inside each circuit, which ensures the quality of the movement of the coolant. And, hence, the quality of heat transfer from heating systems.

Anyone who does not understand what is the essence of installing a distribution manifold begins to build various additional installations into the heating system: a circulation pump, valves for various purposes, and so on. Let's face it, this will not help; they cannot be used to increase the volume of the coolant. You will simply make unnecessary expenses that will turn out to be in vain.

Attention! If you are the owner of a large multi-storey building, it is recommended to install a separate distribution manifold for each floor.

Features of the beam scheme of collectors for heating

The optimal scheme can be considered a polypropylene heating manifold, which is shown in the photo, in the case when the house has several floors or the building has a large number of rooms and utility rooms.

So, the connection diagram of the heating manifold implies that it will be installed on each floor (sometimes there can be several of them), and pipes are already laid from it. As a rule, the instruction provides that the installation of heating system elements is carried out in walls or cement screed.

A draft of the heating structure and its branches should be drawn up before starting repair work, so as not to spoil the base for laying the flooring later.

What is it needed for

When installing water-pressure systems, there is a rule: the total diameter of all branches should not exceed the diameter of the supply pipe. With regard to heating equipment, this rule looks like this: if the diameter of the outlet of the boiler is 1 inch, then two circuits with a pipe diameter of ½ inch are allowed in the system. For a small home heated only by radiators, such a system will work efficiently.

In fact, there are more heating circuits in a private house or cottage: underfloor heating, heating of several floors, utility rooms, and a garage. When they are connected through a branch system, the pressure in each circuit will be insufficient to effectively heat the radiators, and the temperature in the house will not be comfortable.

Therefore, branched heating systems are performed with collector systems, this technique allows you to adjust each circuit separately and set the desired temperature in each room. So, for a garage, plus 10-15 ° C is enough, and for a nursery, a temperature of about plus 23-25 ° C is needed. In addition, warm floors should not heat up more than 35-37 degrees, otherwise it will be unpleasant to walk on them, and the floor covering may deform. The manifold and the shut-off temperature can solve this problem as well.

Video: the use of a collector system for heating a house.

Collector groups for heating systems are sold ready-made, while they can have different configurations and the number of outlets. You can choose a suitable collector assembly and install it yourself or with the help of specialists.

However, most industrial models are versatile and do not always suit the needs of a particular house. Converting or reworking them can significantly increase costs. Therefore, in most cases, it is easier to assemble it from separate blocks with your own hands, taking into account the peculiarities of a particular heating system.

Collector group for heating system, complete

The design of the universal collector group is shown in the figure. It consists of two blocks for forward and reverse flow of the heating medium, equipped with the required number of outlets. Flow meters are installed on the supply (direct) collector, thermal heads are located on the return collector to regulate the return water temperature in each circuit. With their help, you can set the required flow rate of the coolant, which will determine the temperature in the heating radiators.

The manifold distribution unit is equipped with a pressure gauge, circulation pump and air valves. The supply and return manifolds are combined into one unit with brackets, which also serve to fix the unit to a wall or cabinet. The price of such a block is from 15 to 20 thousand rubles, and if some of the taps are not used, its installation will be clearly inappropriate.

The installation rules for the finished block are shown in the video.

Comb - manifold unit

The most expensive items in a manifold block are flow meters and thermal heads. To avoid overpaying for unnecessary elements, you can buy a collector unit, the so-called "comb", and install the necessary control devices with your own hands only where it is necessary.

The comb consists of brass pipes with a diameter of 1 or ¾ "with a certain number of branches with a diameter for heating pipes ½". They are also connected to each other by a bracket. The branches on the return manifold are equipped with plugs that allow installing thermal heads on all or part of the circuits.

Some models can be equipped with taps, with their help, you can adjust the flow manually. Such combs have a cast body and are equipped with a union / nut thread at the ends, which allows you to quickly and easily assemble a manifold from the required number of branches.

In order to save money, the manifold for heating systems can be assembled from individual elements independently or completely made by hand.

Marking and scope

It is necessary to start the installation of a water supply system from polypropylene pipes with the choice of the type of pipes. They are single-layer and three-layer, differ in wall thickness and, accordingly, have different purposes. To make it easier to navigate, they are labeled:

- PN10 - single-layer pipes designed for cold water in low pressure pipelines. Suitable for the distribution of polypropylene plumbing in private houses.

- PN16 - single layer pipes with a thicker wall. They can be used both for transporting cold water in systems with increased pressure (centralized), and for distributing the hot water system. The maximum permissible temperature is + 50 ° C.

- PN20 - three-layer pipes with fiberglass reinforcement layer. They can be used for installation of a water supply system for transporting hot water, low-temperature heating systems. Maximum temperature + 90 ° C.

- PN25 - three-layer pipes, reinforced with aluminum foil. They are used mainly for heating, can be used for hot water supply, but it is not economically feasible: these are the most expensive pipes, and their qualities for hot water supply are excessive.

According to the colors, there are gray and white polypropylene pipes. This is not reflected in the quality, so choose according to your aesthetic preferences. Some firms (mostly German) paint their products green. If the wiring is hidden - in the walls or in the floor - you will not find anything better, since the Germans are leaders in quality.

To install a water supply system from polypropylene pipes, you will also need fittings

To make it easier to navigate in the field of application, colored stripes are applied along the PPR pipes. Those intended for cold water are marked in blue (light blue), for hot water and heating they are marked in red, universal ones - in orange. Some manufacturers have adopted a different marking. They mark products for heating and hot water supply in red, and do not apply them to those intended for cold marking.

From the above, the following conclusions can be drawn: it is better to install a water supply system from polypropylene pipes in an apartment from PN 16 for cold water and PN20 for hot water supply. In a private house, you can do with PN 10 for cold water and PN 20 for hot water supply.

Installation features

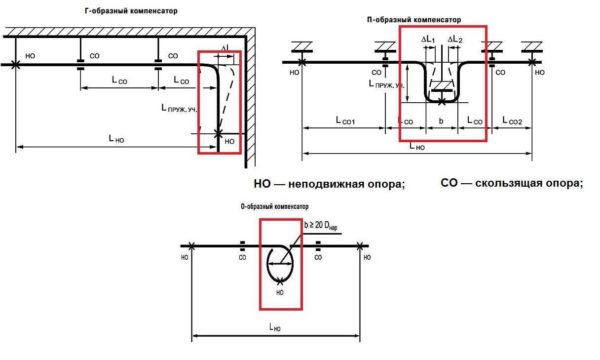

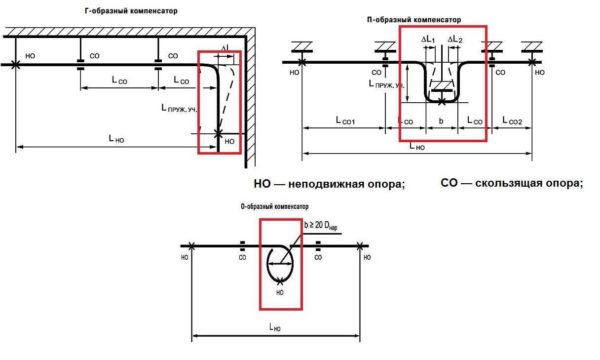

Single-layer PPR pipes PN 10 and PN 16 have a high coefficient of thermal expansion: with a temperature difference of 100 ° C, each meter becomes 1.5 cm longer.Even taking into account the fact that such a temperature difference in real life is unattainable, this is a very large figure. To prevent this increase in length from destroying the water supply system, compensation loops (compensators) are provided in the system.

Types of expansion joints for polypropylene water supply

If the length of the pipeline is small and cold water is diluted at the same time, the compensator can be omitted - the difference in length will be small, but it is advisable to make at least an elementary L-shaped compensator on the hot water supply (see figure).

System planning

Due to the fact that the PPR of the pipe does not bend, when developing a wiring diagram it is necessary so that there are as few detours and turns as possible. After all, they are all made with fittings, and they have a solid cost (compared to a pipe). Therefore, we try to optimize the layout - to make as few turns, detours and bends as possible.

Serial (tee) connection

Installation of a water supply system from polypropylene pipes with serial connection of consumers (plumbing and household appliances) is used in small systems. Usually they have 5-6 connection points. With such an organization of the water supply, one pipe departs from the riser, it sequentially bypasses all connection points. In the case of PPR-plumbing, all branches are made using tees, therefore this type is also called tee.

Installation of a water supply system from polypropylene pipes by serial connection of consumers

The advantage of this system is that a small number of pipes are needed, and the minus is that the pressure on each branch drops. As a result, with one or two working parsing points, the third located further from the riser, the pressure may simply not be enough.

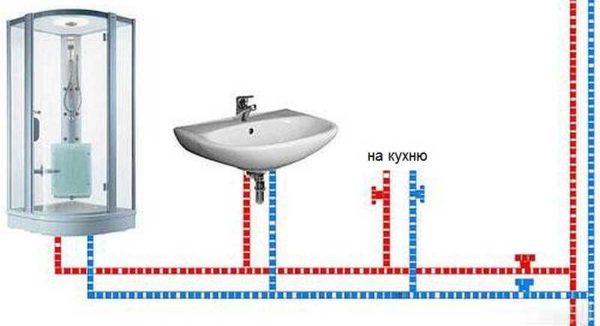

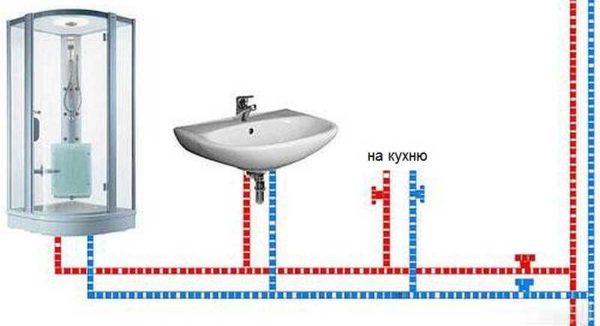

Parallel (collector) wiring

A parallel connection scheme is also called a collector. This is because after the outlet from the riser, a special device is installed - a collector. This is an element with one input and several outputs. Available in polypropylene and metal. For plumbing, polypropylene collectors are more suitable (and cheaper).

The connection diagram is such that a separate pipe is drawn from each branch to each consumer (sometimes to a small group of consumers).

Parallel diagram of the installation of a water supply system from PPR pipes

The advantage of such a system: the pressure at all points of water parsing is the same, the disadvantage is that a lot of pipes are required. Another plus - if any branch fails, only one consumer does not work. The rest of the system is functioning normally. By the way, in order to be able to turn off individual devices, taps are placed at the outlet of the collector (usually ball valves, but if you need the ability to adjust the pressure, you can put a valve).

Eyeliner with plumbing and household appliances

In each of the methods of installing a water supply system from polypropylene pipes, a pipe is suitable for a specific consumer. There are two ways to connect to the system: flexible and rigid.

Rigid piping is more reliable: PPR pipes and fittings are highly durable. In addition, in this case, there is only one thread - at the point of consumer connection. But this type of liner requires high precision of execution: the error can be only a few millimeters. It is difficult to achieve this when installing a polypropylene water supply system with your own hands, therefore, flexible eyeliners are more often used. Just be careful, in some cases it is impossible to use it: connect gas boilers or gas water heaters, supply water to storage water heaters, water heated towel rails are recommended only with a rigid connection.

Rigid liner options

Soft liner, on the other hand, does not require high precision - errors are leveled by a flexible stainless steel braided hose or a hose that is used to connect a washing machine or dishwasher. The tubes are taken out approximately in the area where the equipment is installed or plumbing is connected. It ends with an adapter for metal, to which a flexible hose is connected (with its second end, it connects to the device).

Flexible hoses are connected to adapters

This option is less reliable, since a lot depends on the quality of the flexible liner. Also, not the most pleasant moment is the presence of two threaded connections, and this is a potential place for a leak.

Installation rules

Before starting work, you need to draw up a diagram, mark on it all the necessary fittings and system elements (meters, filters, taps, etc.), put down the dimensions of the pipe sections between them. According to this scheme, we then calculate what and how much is needed.

When purchasing pipes, take with a certain margin (meter or two), fittings can be taken exactly according to the list. It will not hurt to agree on the possibility of a return or exchange. This may be necessary, since often in the process, the installation of a water supply system from polypropylene pipes throws up some surprises. They are connected mainly with a lack of experience, and not with the material itself and happen quite often even with the masters.

Plastic clips take the same color

In addition to pipes and fittings, you will also need clips that attach everything to the walls. They are installed on the pipeline every 50 cm, as well as near the end of each bend. These clips are plastic, there are metal clips and clamps with a rubber gasket.