In early spring or cold autumn, the first question that arises before summer residents is how to heat their home. Of course, there are a huge variety of options, but you need to take into account that not all horticultural enterprises have access to the gas network. But what can we say - sometimes weather cataclysms also disrupt power lines.

Filing a brick oven or fireplace is not always financially possible. In this case, an excellent solution would be a stove for giving long burning, which you can buy at specialized retail outlets or do it yourself.

Potbelly stove

How do long burning wood burning stoves work?

If you heat an ordinary stove with wood, then while it is working, that is, a combustion process takes place in its firebox, it is warm in the room. During this time, she gives off her warmth well and comfortable conditions are created in the room.

But as soon as the wood burns out, this process stops, and the room cools down rather quickly. Therefore, it requires a constant lining of wood or other type of fuel to keep it working.

By installing a wood-burning stove in the house with a long burning, it is possible to solve this problem. Such furnaces have an important structural difference from conventional ones - a large furnace compartment, moreover, consisting of two sections. In the first, the combustion process takes place directly, and in the second there are stocks of firewood.

An important nuance is that it is completely calm, without having to stop the operation of the stove, you can replenish stocks of firewood, although some models may well run on coal, pellets or other type of solid fuel.

Due to the fact that large volumes of fuel are loaded into the furnace, the air supply is limited, the flow of which can be adjusted using a gate and a blower. As a result, indirect combustion occurs, but only the smoldering of a part of the firewood.

At the same time, another part of the firewood heats up from the heat and gradually forms the so-called "fuel gas", in turn, which is also a kind of fuel, which gradually burns out.

The efficiency of long-burning stoves is quite high and ranges from 65 to 85%, which allows the most efficient use of fuel when heating a house.

In addition, long burning wood stoves for home heating can be used in two modes.

If you need to quickly warm up the room, then by adjusting the gate, you can switch to normal mode, with the most intense combustion process.

And to maintain a constant temperature for as long as possible, the usual mode of operation of the furnace is used, in which the combustion process occurs gradually.

How to choose the right oven

First, you need to determine what area the future stove will heat. This could be a small utility room, garage, workshop, or vacation home. Ready-made ovens from manufacturers are able to maintain a stable temperature in rooms ranging from 80 to 250 square meters.

You can also choose the duration of the solid fuel smoldering. According to this characteristic, furnaces are divided into three types:

- Minimum period (5-8 hours)

- Medium period (8-10 hours)

- Maximum period (10 or more hours)

The following metals are used as the material for the base of the structure:

- Steel

- Cast iron

- Brick

Materials differ in the degree of thermal conductivity and the amount of time it takes to warm up the boiler. The brick takes a long time to warm up - more fuel will have to be spent.Cast iron retains heat well, but the process of installing and transporting the stove will require great efforts. It will be most profitable to use steel - here both quick warm-up and good heat transfer. If there is a desire to make the stove on your own, you will not need to cook the boiler from scratch, a metal barrel or a used gas cylinder will do.

Some features of the operation of furnaces with long burning

Despite the high efficiency of work, such stoves for the home require increased attention to themselves and, above all, in the process of setting up their work.

A certain experience and skill will be required, which each owner develops in the process of operation, in order to ensure correct operation and not allow the entire fuel tab to burn out quickly, but at the same time, observing safety precautions.

And by shutting off the oxygen supply to the furnace, at best it will be possible to achieve the release of fuel gas into the chimney, without burning out, which will reduce the efficiency of the furnace.

In addition, the likelihood of fire is not excluded. Therefore, during the operation of stoves, it is important to adhere to safety precautions, as well as to master the technique of cleaning it correctly, since in the process of its operation, a large formation of soot is the norm.

The chimney must be straight, preferably collapsible (for the convenience of regular cleaning at least once a week).

In addition, constant monitoring of the operating device is necessary, since even changes in the weather require adjustments to the settings in order to ensure normal traction and prevent carbon monoxide and fuel gas from leaking into the room.

Video about long burning ovens:

Varieties of ovens

Manufacturers offer a wide range of various long burning solid fuel stoves. They differ in installation method and functionality. The complete set of each model has a passport with a drawing and a description of all parts of the furnace, as well as its characteristics.

Cast iron and steel devices are distinguished according to the material of manufacture. Steel can be made from regular black or stainless steel. A number of models combine assemblies and parts from both materials.

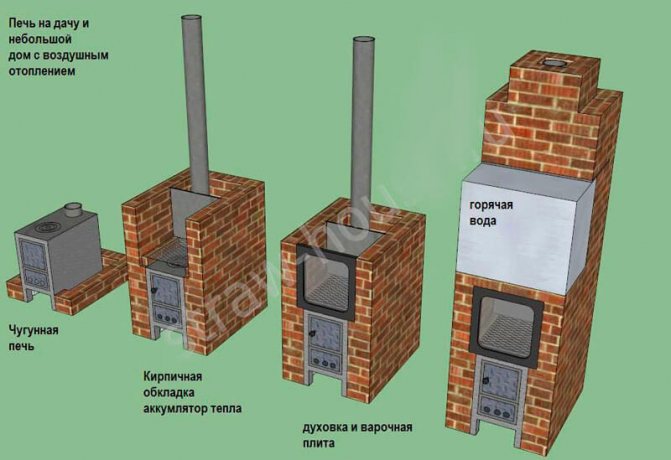

Varieties of ovens in terms of functionality:

- Heating devices. Designed for heating the house only.

- Heating and cooking. They have an oven in their design.

- Models with a water heater. They can heat water.

- Multifunctional devices with all the listed options.

Brewhouse

Heating

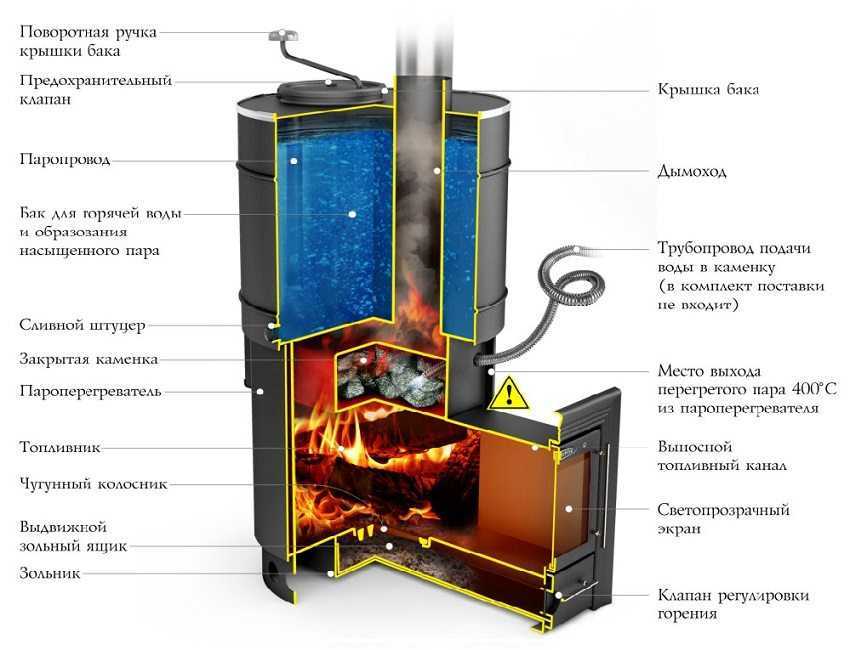

With water tank

Universal

Installation site classification:

- Corner. They are distinguished by their compactness. They can be placed in a corner in a small room.

- Wall mounted. There are both heating and multifunctional. Can be installed in kitchens and living quarters. They have a different design, so it is not difficult to choose a product for the interior of the room.

In addition to power and functional features, devices can be selected in shape, appearance, size. Many companies are engaged in the production of ovens. In the ratings, the leading places are occupied by devices from Russian companies Teplodar, Siberia, Thermal, from foreign brands Bosch, MBS Vesta and Finnish NunnaUuni.

Advantages and disadvantages of operating long-burning furnaces

This category of furnaces provides undeniable advantages for consumers during operation:

- profitability;

- small size and the ability to install in a limited area (of course, with strict adherence to safety precautions);

- light weight of industrial designs that do not need a special foundation. But in the event that a brick oven is arranged for a house with your own hands, then you still have to think about a reliable foundation for it;

- the possibility of laying fuel for long-term burning - it is enough to do this work twice a day, since one batch of firewood lasts up to 10 hours of continuous work;

- quite simple regulation of the combustion process of fuel gases formed during operation;

- the ability to use affordable, inexpensive and, most importantly, environmentally friendly fuel;

- long service life of up to 50 years.

It should also be noted that many industrial models are distinguished by their original and aesthetically pleasing design, allowing them to be used as an element of the interior.

Such wood stoves for heating a summer cottage may well solve the issue of not only a comfortable stay in the cold outside the city, but also support the style of the interior, for example, made in a rustic style.

If we talk about the "disadvantages" of long-burning furnaces, then you should pay attention to the following aspects:

- impossibility of using other types of fuel, except solid;

- regulation and management is relatively complex, requiring certain experience and skills;

- the problem of regular formation of condensate, since the gases enter the chimney quite cold;

- the need to ensure constant monitoring of the operating device.

Comparison of long burning ovens, video:

Work process

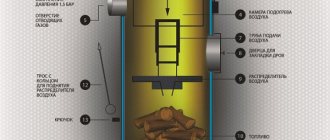

The principle of operation is that firewood is placed in the fuel chamber. When they flare up, oppression falls on them, thereby forming a chamber above them for burning gases, air, into which it enters through the oppression pipe. The blades located at the bottom of it are made as in the diagram above, to accelerate the swirl of gases emitted from smoldering. A damper on the top of the opposing tube regulates the amount of air supplied to the gas chamber. The fuel decays and the oppression moves down, until it touches the bottom of the fuel chamber. Very little ash remains and when burning, little smoke is emitted into the chimney. The diagram shows the moment of collection of moisture in the chimney, this happens because the temperature in it drops below 100 degrees.

Stove with a water circuit for home heating

Industrial furnaces with a long burning principle can be divided into several types, both in terms of their type and in terms of power and size. They can be operated both separately and in the water heating system of the house.

Depending on the power, the furnaces are divided into:

- compact samples designed for heating one small room - their power is either small or medium;

- high power models are designed to heat large rooms and even several at once;

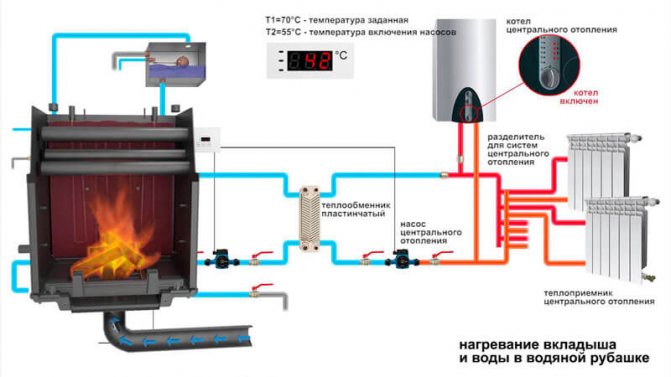

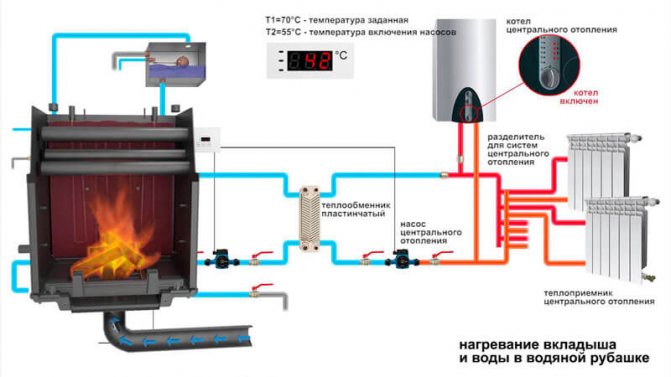

- stoves with a water circuit have the ability to heat a room not only due to direct convection effect, but also by heating water in the heating system. They differ from conventional models by the presence of a built-in tank, from which pipes are laid in the house. They allow you to create a full-fledged autonomous water heating from a wood-burning stove, even in a country house where there is no possibility of connecting to a gas pipe or a centralized system;

- models equipped with a special hob, which, as a rule, have medium or low power. Indispensable for operation outside the city, especially in summer cottages.

How to choose the right long burning stove?

Of course, each owner of suburban real estate, choosing a stove, focuses on the needs of his home for providing heat, as well as the features of the operation of such an object: seasonal or year-round.

But there are basic criteria that must be taken into account:

- stove power, determined by the climatic conditions of the region and the size of the room to be heated.But models with higher power are distinguished by impressive dimensions, therefore, for small rooms it is more profitable and rational to choose a stove with a lower power, since in this case a noticeable fuel economy will also be provided;

- functionality of the oven. For example, to heat two adjacent rooms, you should purchase a model that can be installed in the partition of a house, and to provide heating for several rooms at the same time, you should pay attention to samples with a water circuit. In addition, heating and cooking stoves for summer cottages will become very useful, for example, during regular, but short-lived outings in nature in the winter;

- the presence of several modes of combustion and the possibility of fine tuning.

Wood-burning stoves and water heating in a country house

It is not only possible, but also profitable to use long-burning stoves to heat the whole house. And for this, you just need to purchase or make a model with a built-in water circuit in one of the furnaces, but it is permissible to place it around the furnace, instead of heat exchangers.

Since the stove has a long-term continuous operation, this fact is positive for the operation of the water heating system, allowing you to effectively heat the premises in the house.

But if you plan to use this heating method, then you should purchase special models already equipped with a water circuit.

It is quite possible and acceptable to remake an ordinary furnace, but it must be borne in mind that in this way, the efficiency decreases and the wear rate increases, especially due to the fact that the circuit, taking away heat from the furnace, lowers its temperature, so the fuel gas does not have the opportunity to completely burn out.

Wood-fired summer cottages equipped with a hob

Stoves equipped with a hob are indispensable in suburban life, especially in summer cottages. They differ from conventional models only by the presence of a hob, which, however, does not have special adjustment.

The intensity of its heating is determined solely by the operating mode of the furnace or an additional damper, which, however, is only available on some models.

The hob is a flat platform made of a thick sheet of metal and is mainly intended for cooking simple dishes or heating them, but there are models even equipped with an oven.

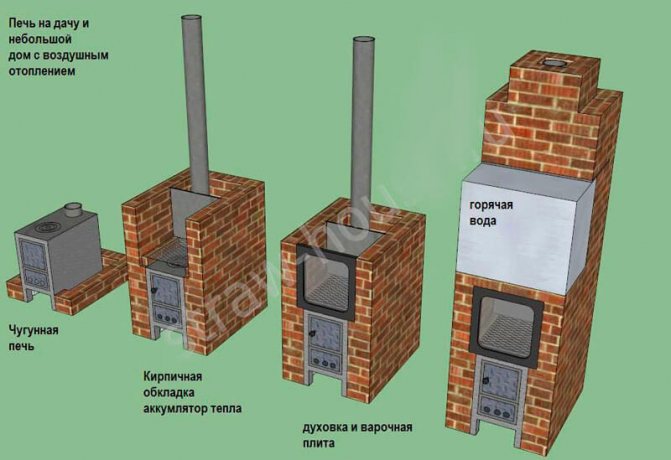

In the event that brick ovens for a house with a hob are installed with your own hands, then its functionality can be easily expanded taking into account the needs of the family. For example, it can be equipped with a full-fledged stove, on which you can quickly cook lunch while staying in the country or by installing a special oven for drying berries, fruits, mushrooms and other gifts of nature.

Long burning fireplace stoves

Not only from the fireplace itself, but even from this word, the soul of many immediately becomes warmer - they cannot imagine their life outside the city without the characteristic crackle and smell of burning wood. It is for such connoisseurs, but not only, that the wood-fired home stove, which looks like a fireplace, is intended.

Naturally, in addition to the characteristics, the manufacturers paid attention to the appearance of such products, which are distinguished by their small size, laconic shape and presentability.

Such a stove is quite appropriate in the country, since, despite some similarities with traditional fireplaces, it has:

- a closed firebox, which guarantees not only increased fire safety, but also greater work efficiency;

- glass, which is supplied to the doors of the fireboxes, allow you to enjoy the look of a real fire;

- due to the use of energy-intensive materials in the manufacture of the furnace, it is possible to ensure excellent heating of the room for a long time, since, despite the small dimensions, the firebox of these units is large enough, and the correct adjustment allows economical use of fuel.

Review of popular models

A number of models are presented on the Russian market that have long been in demand among summer residents and gardeners. They have various capacities and a set of functions, so that anyone can choose a suitable stove for a summer residence.

Garden ovens "Ermak" Stoves are intended for heating garden and country houses, depending on the modification, they can heat rooms from 70 to 300 cubic meters... Ermak stoves, depending on the model, can be equipped with a long burning mode and a hob. Ermak-Aqua furnaces allow connecting a heating water circuit, after which it will start working as a boiler.

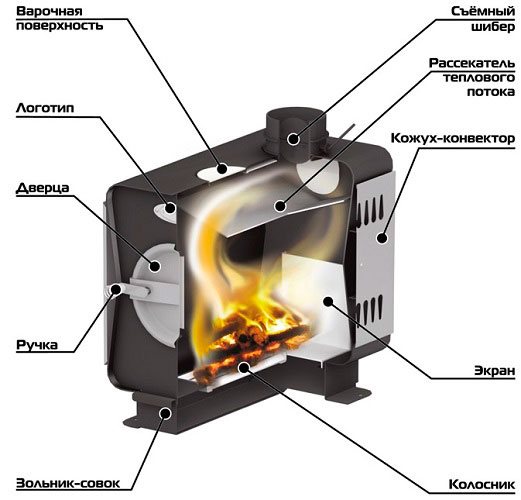

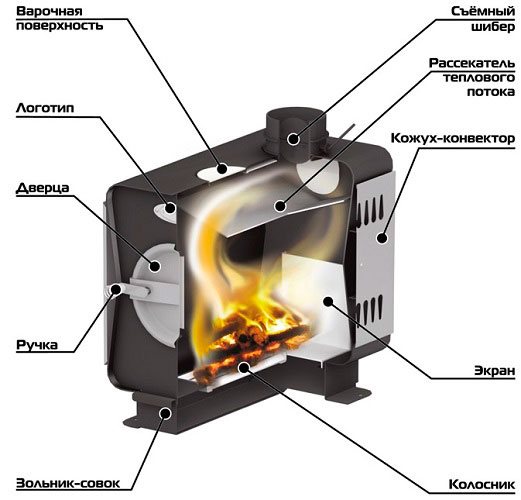

The design of the Ermak-70 OV furnace is shown in the figure. This model has the smallest power of the presented ones, it is capable of heating a country house with an area of up to 30 square meters. The small size and weight of 24 kg make its installation extremely simple - any floor can withstand such a stove, you just need to sheathe it with a sheet of iron. The operating time of the furnace in the mode of long burning is from 8 to 12 hours.

The combustion chamber is equipped with a heat flow divider, which allows the flue gases to burn out completely. A screen is installed in the rear part of the firebox, behind it is a convector casing that quickly transfers heat to the room. The firebox door is sealed due to its tapered shape. The door handle does not heat up during the firebox. The ashtray in the form of a box allows you to quickly remove ash, and, if necessary, use it as fertilizer. Above is the hob and smoke outlet.

The price for the Ermak oven, depending on the modification, is from 6 to 20 thousand rubles.

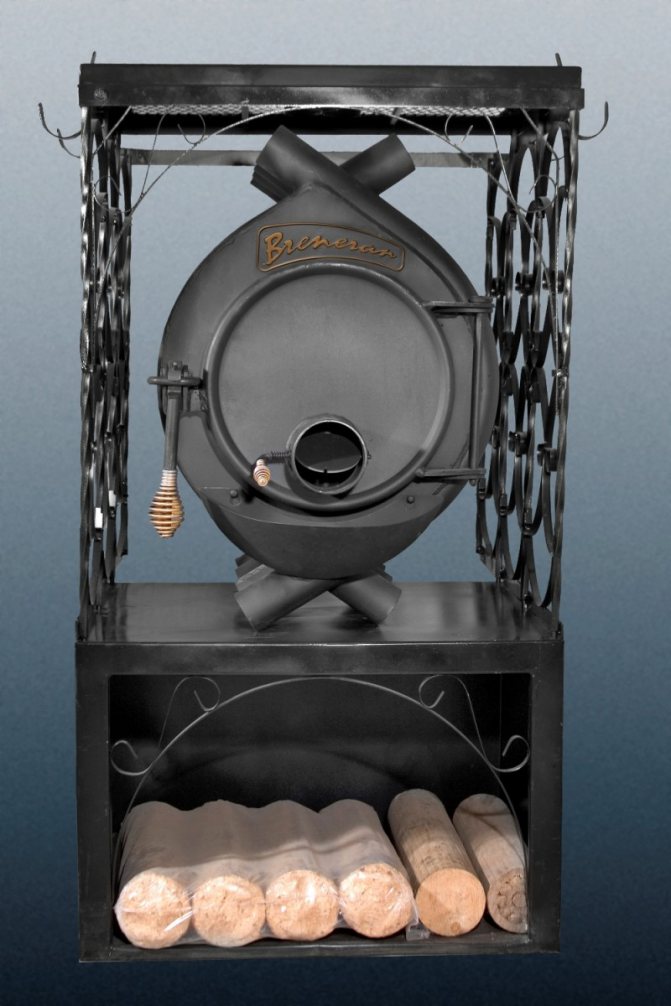

Stoves "Buleryan" and "Breneran"

The special shape of the stoves was named the inventor company.

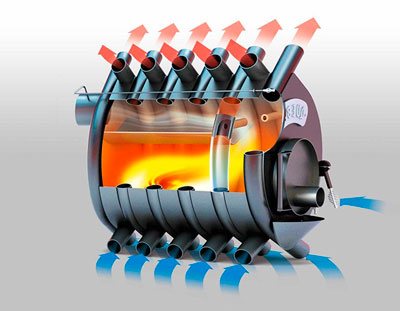

At present, almost any gas-generating furnace is called buleryan, in the firebox of which there are metal pipes.through which there is a constant convection of air flows. They also include the Breneran furnace, a Russian analogue based on basic designs.

Cold air is drawn in from the bottom, warming up, it comes out through the holes at the top of the stove. In a minute, buleryan passes about 4 cubic meters of air through the air ducts, heating it to a comfortable temperature... In this case, the walls of the furnace do not overheat.

There are two zones in the buleryan firebox: in its lower part there is a gas generation zone, where firewood pyrolysis occurs. Above - the zone of afterburning of pyrolysis gases. The large depth of the firebox allows the use of long firewood. The power of different models is from 6 to 35 kW, the price is from 8 to 38 thousand.

For effective heat transfer, the moisture content of the wood should not be more than 16%. In addition to firewood, woodworking waste and pellets can be burned in Buleryan and Breneran stoves. The use of coal is not recommended!

Furnaces "Professor Butakov" Gas generating furnaces "Professor Butakov" are equipped with a long burning mode, a hob and convection pipes. Unlike buleryan, they have a shape adapted for country houses: the smoke pipe in them is located at the top, and not at the back. This guarantees a stable draft even after a long break in the furnace, and also allows you to successfully remove condensate from the pipe.

Depending on the modification, the price of the furnaces "Professor Butakov" - from 16 to 38 thousand rubles.

Video: comparison of models of long-burning stoves.

Structural differences and material for the manufacture of furnaces with a long combustion cycle

Naturally, for the manufacture of stoves, a material that is durable and resistant to high temperatures is used. It is also important that it has a high thermal conductivity. Therefore, it is not surprising that most industrial designs are made of cast iron or thick-walled steel.

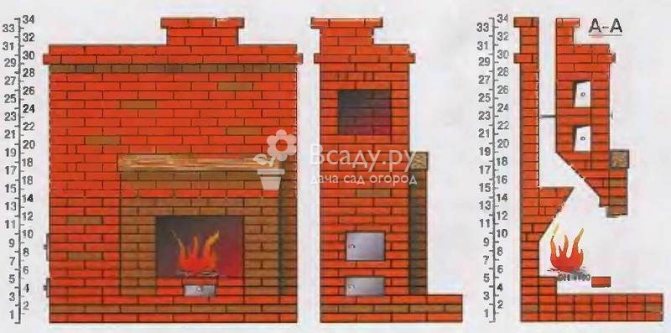

For an independent furnace device, a completely suitable material is refractory brick.

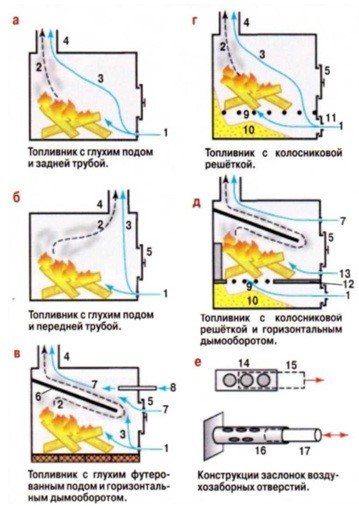

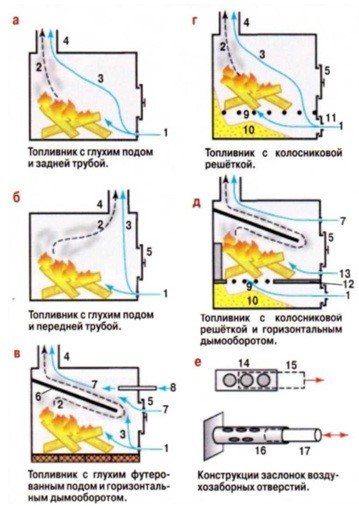

The main element of the furnace is the large-sized firebox, and the maintenance of constant smoldering is ensured and regulated by a damper located for convenience on the front side.

Direct ignition is carried out in the upper section of the furnace, to which the chimney is directly connected.

The furnaces are equipped with two dampers:

- the first, or inlet, is solid and is designed to completely stop the air supply to the furnace if necessary;

- The chimney damper has a special cutout, about a quarter of its area, which ensures, even when it is completely closed, not to block the exit to the chimney for combustion products.

Convection channels, of circular or other cross-section, located around the combustion chamber, are responsible for heat transfer. They are responsible for the air convection process in the room, as they take heat from the stove and release it into the environment.

In some models, it is possible to use these channels not only to heat directly the room in which the stove is installed, but also to connect air outlets to them to transport heat to other rooms of the house.

If you plan to install a reliable unit, then you should pay attention to cast iron models. They have a high heat transfer, can be operated for a long period of time, but I have one significant drawback - a lot of weight. Therefore, for their installation, you must first prepare a reliable base, for example, concrete.

It is imperative to observe precautions during installation and, especially in wooden houses. In this case, it is necessary to maintain a minimum distance from the wall of at least 1-1.5 m, while pre-protecting it, for example, with a sheet of iron or brickwork.

When installing in a stone or brick house, it is also necessary to maintain a distance to the wall, but in this case 30-40 cm is enough.

If pledged ovens for brick houses do it yourself, then you should first take care of the foundation for it. There are no special design differences in comparison with conventional furnaces, except that the combustion chamber must be several times larger.

In addition, in the upper part there must necessarily be a chamber for combustion of fuel gases, with which an exclusively straight chimney is directly connected.

This type of furnaces has no particular advantages over industrial designs, for example, made of cast iron, given the characteristic feature of the work.

On the walls, settling will occur very quickly and in a large volume, followed by coking of tar, ash, which will require regular cleaning not only of the chimney, but also of the furnace itself. Therefore, some craftsmen additionally cover the walls with metal sheets.

How to make it yourself

It is not difficult to make a potbelly stove of long burning with your own hands if you know the principle of operation of the installation and design features. We have already written about this above, so it is worth dwelling on the issue of manufacturing.

First of all, you need to choose a model. Let's look at the simplest one, which exactly resembles a potbelly stove. In fact, this is it. Only in it some constructive changes were made.

- The grate is removed. The firewood will lie on the hearth of the stove, so it is recommended that this element be made either from a thick sheet of iron, or reinforced with another sheet.

- Install the firebox door according to the Buleryan model door. In the door itself, it is necessary to make holes that will open and close with a special round shutter.

Design range of long burning stove

What is achieving these constructive changes? Firstly, the absence of the grate zone makes it possible to reduce the intake of air. After all, there is no space under the firewood and there is no blower. This means that the intensity of combustion decreases.Secondly, the hot gas that forms in the process of smoldering firewood does not immediately leave the firebox, it stays in it for a long time, thereby warming up the walls of the stove well. Thirdly, with the help of a round valve, it is easy to adjust the oxygen supply.

You can change this design slightly, but at the same time increase the efficiency of its work. For this, the fuel combustion chamber must be divided by a horizontal or inclined partition. But this element should not reach the front wall of the chamber by several centimeters. A gap must form between the lower chamber and the upper chamber through which hot flue gas streams must rush into the upper chamber. This increases the heat exchange area, plus it becomes possible to use the pyrolysis process.

What does it mean? You can additionally create conditions under which the flue gases will be combusted in the second chamber. To do this, you just need to supplement the structure with side tubes through which oxygen will flow into the second chamber. The gases themselves will not burn, but the air-gas mixture burns perfectly, releasing a huge amount of thermal energy. By the way, such furnaces have high efficiency, reaching 95%.

Sauna stove for long burning