Types of floors

Views:

- Solid wood flooring. This is the warmest option. The best base for solid wood flooring is tamped soil or concrete foundations. The design includes a rough flooring, logs, finishing boards.

- Leaking flooring. A cheap option, since a small number of consumables are used to assemble it. There is a concrete floor under the structures with a slope to one side. A drain hole with a grate is installed at the lowest point. Water does not linger on the wood, flows down the concrete base, is removed from the bath through the drain.

The last type is concrete foundations with cladding. The most durable, strong structures, for the creation of which you need to spend a lot of money on consumables and tools. From above, the concrete base can be covered with ceramic tiles or porcelain stoneware.

You can wrap the chimney with foil insulation

It is a two-layer material consisting of an insulating component and a foil. Thanks to the reflective layer, the room does not cool down so quickly, because up to 90% of the heat is retained inside the bath, so this is a very high-quality insulator.

Folgoizol is highly environmentally friendly, because food thick foil is used as a raw material. Such material is not afraid of ultraviolet light and strong temperature drops - the operating range is from -65 ºС to 175 ºС. Therefore, it will be quite a worthy choice for winding a pipe in a bath.

Note that often foil-insol is mounted not only around the chimney, but also on the walls and on the ceiling of the steam room. It serves for high-quality steam and waterproofing, and also insulates the bathhouse well.

Modern material includes two layers: heat insulator and foil. The second one plays a reflective function and can store up to 90% of thermal energy in a building. Folgoizol is a harmless material in comparison with other analogues, since compacted food foil acts as a foil. The material is resistant to ultraviolet light and high temperatures in the range of -65 to 175 degrees Celsius, a good insulator.

Whoever does not yet know how to insulate the chimney pipe in a sauna, we recommend covering the ceiling of the steam room, walls and chimney with foil insulation. As a result, you will get a room that resembles a thermos in construction. The heat will remain in the sauna, and the bath will quickly pick up the temperature, and then slowly cool down. Sometimes a mesh is installed on the pipe for stones in the bath, which is very convenient and practical.

Thermal insulation methods

Technologies for insulating floors in a bath:

- A simple floor option. It consists of compressed soil, a mixture of sand and gravel, a concrete substrate, a vapor barrier, expanded polystyrene, a polyethylene film, a reinforcing frame. To insulate it, you need to prepare the base, align it from bumps, cracks. On top of all layers, a screed is poured from a special insulating mixture.

- With a screed over the floor. For the insulation of the structure, a durable sheet of foam, pressed mineral wool is suitable. The base is made of a concrete slab, which is fixed to walls or strip foundations.

- By lags. It is better to use polystyrene, pressed material wool as insulation.

Advantages and disadvantages of expanded clay

When comparing expanded clay with other insulation materials, the following advantages of this insulation can be distinguished:

- Not biodegradable during use.Over time, most of the heat insulators used for thermal insulation of bath rooms undergo decomposition, which provokes the release of substances harmful to human health from their composition into the air. Expanded clay, in spite of the service life, does not emit harmful chemicals and does not deteriorate its thermal insulation characteristics.

- The insulation does not attract rodents, which allows it to be used for almost unlimited time.

- Thermal insulation of the ceiling in the bath with expanded clay guarantees high fire-resistant properties of the floor, high sound insulation characteristics and increased resistance to water vapor.

- The insulation has high frost resistance. This building material is able to withstand up to 25 full freeze cycles followed by thawing without loss of thermal insulation properties.

In addition, expanded clay is characterized by low heat transfer rates, which vary in the range from 0.07 to 0.16 W / m, which makes it possible to use it as an effective insulation for a bath room.

Types of heaters

Many owners doubt whether it is necessary to insulate the floors in the bath. Without high-quality thermal insulation of the concrete base, ice will form on its surface in winter, and it will be impossible to get rid of the cold inside the room.

Perlite is a material that is similar in structure to sand. For use as a heater, perlite is mixed with cement, water, and thoroughly mixed. The finished composition is applied in an even layer to the base, left for 7 days until completely solidified.

Perlite advantages:

- light weight;

- low thermal conductivity;

- preservation of the natural microclimate;

- lack of harmful substances;

- fire resistance;

- sound insulation, durability.

Do not use perlite in ventilated areas. Any gust of wind will lead to its chaotic distribution throughout the room.

Expanded clay is made from clay. The feedstock is fired at a temperature of 1400 ° C. During heat treatment, individual granules are formed, which are used as thermal insulation material.

Strengths of expanded clay:

- high rates of thermal insulation, noise insulation;

- absence of harmful substances during strong heating;

- low price;

- low specific gravity;

- resistance to high loads.

The main disadvantage is the absorption of a large amount of water. Therefore, you need to do additional waterproofing.

Rectangular plates are made of polystyrene, with which it is convenient to insulate vertical, horizontal surfaces.

Benefits of Styrofoam:

- high thermal conductivity and density;

- easy assembly of individual slabs;

- low price.

Of the significant disadvantages, fragility can be distinguished. ...

You can also use:

- Jute felt. This is a material of organic origin, which has high strength, retains heat well. Fungus, mold does not form on it.

- Basalt slabs. Suitable for insulation of concrete floors. Before laying basalt, you need to make high-quality waterproofing.

- Penoplex. It is made in the form of durable plates of various sizes. Outwardly, it resembles foam. Does not deteriorate under the influence of moisture.

The heat trap can be made from glass or plastic bottles.

Features of thermal insulation of a bath with expanded clay

Expanded clay is a natural material, which means it is environmentally friendly. However, environmental friendliness is not the only advantage of this heat insulator. It is very popular for bath insulation due to its many advantages, such as:

- Cheapness

... Expanded clay has a low cost relative to most synthetic insulation materials. - Durability

... The material does not emit toxic fumes, does not decompose and rot. - High thermal insulation properties

... The thermal conductivity of expanded clay is 0.12 W / mK, which is especially important when operating in a bath, where high temperatures are considered the norm. - Fire resistance

... Expanded clay is a heat-resistant material. It does not burn or melt when exposed to high temperatures. - Light weight

... This allows you to use it to insulate the ceiling of the bath. - Pest resistance

... Expanded clay is not attractive to insects and rodents. - Versatility of use

... With the help of expanded clay, you can not only insulate, but also level the surface. In addition, it can be used in conjunction with a warm floor.

As for the disadvantages of using the material, among them the laborious process of thermal insulation can be distinguished. In addition, when using expanded clay for bath insulation, special attention must be paid to steam and waterproofing.

Before proceeding directly to the thermal insulation work, calculate the amount of expanded clay that is required to insulate the bath. It is better to purchase it with a margin, since fragile granules may break during transportation. It is advisable to take material with granules of different sizes. This will allow it to form the most dense backfill and reduce further drawdown.

Also pay special attention to vapor and waterproofing. The best option is Izospan or aluminum foil. But roofing material is not recommended. It is flammable and can get wet when exposed to high temperature and humidity.

Principles of work

After getting acquainted with the heaters, you can proceed to self-thermal insulation. To do this, you need to prepare tools, consumables, draw up a project, perform work.

Materials and tools

Consumables, tools:

sharp knife;

- sheets of roofing material;

- ruler, tape measure, building level;

- sand, cement, water, a container for mixing the solution;

- electric drill, whisk nozzle;

- insulation;

- waterproofing.

The amount of consumables depends on the area of the room. On the thermal insulation material, the manufacturer writes how many square meters the package is enough.

Preparation and design

In order to properly insulate bath rooms, you need to prepare the base. To do this, you need to take into account some of the nuances:

- It is necessary to carry out insulation at the main stages of building construction. If this was not done, you will have to dismantle the flooring, fill in a new screed.

- The base should be flat, without bumps, cracks, chips. To level it, you need to fill in a fresh screed over the beacons.

- It is not recommended to cover the floor in the steam room with antiseptics with the materials that will be used to sheathe the walls. They can release harmful substances when heated too much.

The insulation process varies depending on the type of room.

Thermal insulation of a wooden floor

Execution of works:

- When the concrete base is ready, it is necessary to create a frame for fixing the thermal insulation. To do this, fill a rough base of bars on top of the lag. Intermediate slats are laid out between the beams.

- The next stage is the installation of the waterproofer.

- Insulation can be mounted on top of the waterproofer.

- From above, the heat insulator is closed with another layer of waterproofing.

The last stage of construction is the laying of finishing boards.

Insulation of concrete floors

Execution of works:

- Preparation of the base.

- Leveling the concrete slab.

- Laying waterproofing.

- Distribution of slabs or bulk heat insulators.

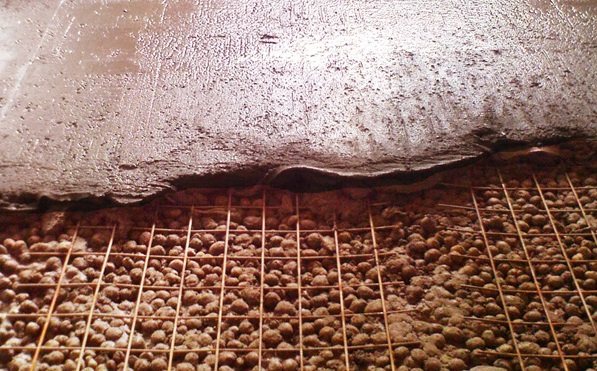

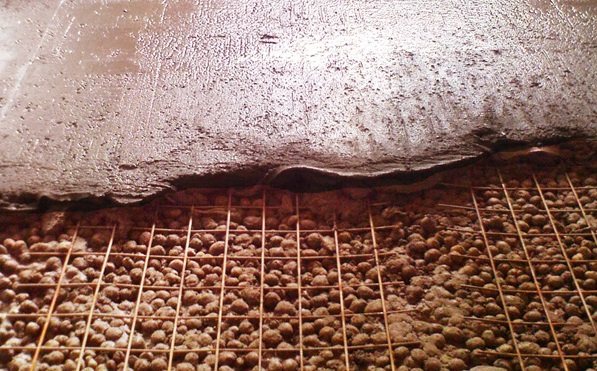

- Reinforcing mesh laying. It can be knitted from individual metal rods.

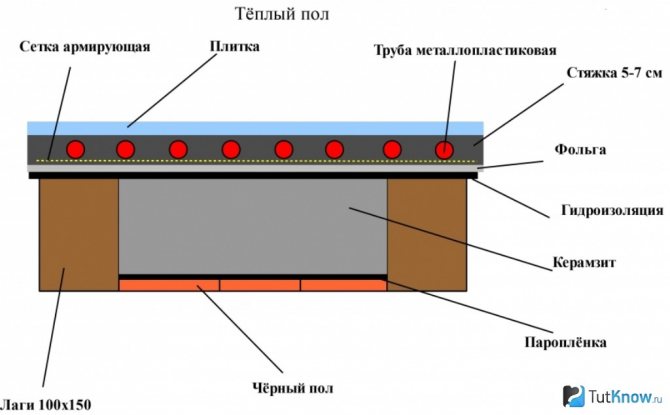

Installation of the "warm floor" system

If you only want to step on a warm floor, you can install a special forced heating system for floor coverings. It is necessary to choose what it will be - electric, water, infrared.Next, you need to purchase consumables, start construction work. Main steps:

- Prepare the base, level the subfloor.

- Install a layer of thermal insulation.

- Fasten the reinforcing mesh over the heat insulator.

- Fix the system to the grids.

- Connect the structure to a public power supply or water supply system. Check functionality.

- Pour the subfloor.

- Wait for the concrete to dry.

It remains to complete the finishing.

We make the floor in the bath from expanded clay

This article is about how expanded clay is used as insulation for floors in a bathhouse being built and about the procedure for construction work with a detailed video about insulating the floor with expanded clay.

The history of the construction of baths begins its countdown from the distant past. Archaeological excavations have brought to our time the construction of bath rooms of that time. They were built of stone or wood, but the floors in almost all buildings were earthen, of tightly compacted clay.

Insulation materials

Modern baths are erected from various materials - wood, concrete, brick, arranging them on foundations of various types. Depending on the structure of the foundation, the baths either have an underground, as in the case of a strip base, or do not have an underground. Baths built on screw piles have practically no underground in their total mass, unless the pile was lined with a serviced underground.

Almost all types of sauna buildings have an insulated non-leaking floor. The only exception is the seasonal version, which operates in the summer with leaking floors. But, as a rule, they are located only in the warmest regions, where the cold season has a short period of time.

As a rule, the floors in baths are insulated. A wide variety of materials are used for insulation, but mainly expanded clay is used as the most acceptable, affordable and environmentally friendly insulation.

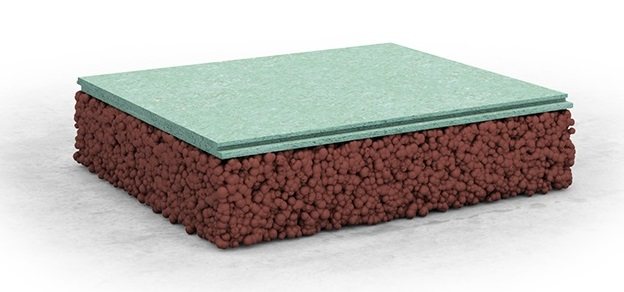

Expanded clay is a derivative of ordinary clay. Having a microporous structure, it retains heat perfectly. At the same time, it absorbs moisture diligently and is very difficult to dry. In order to avoid the process of the insulation getting wet, the insulation cushion is provided with a waterproofing layer, both from the lower part adjacent to the ground and along the upper part of the insulation coating area.

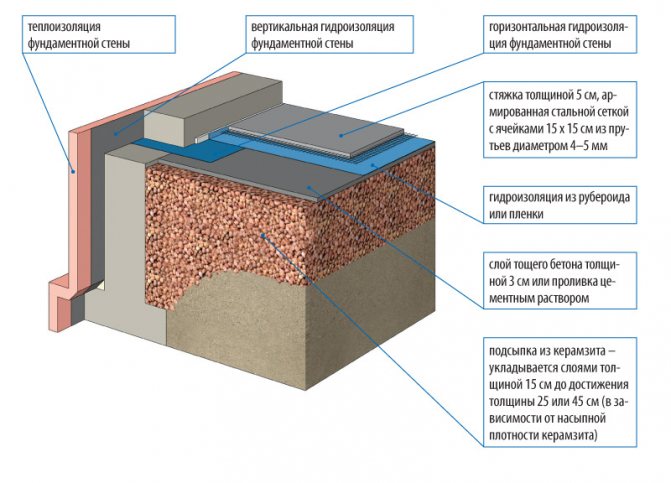

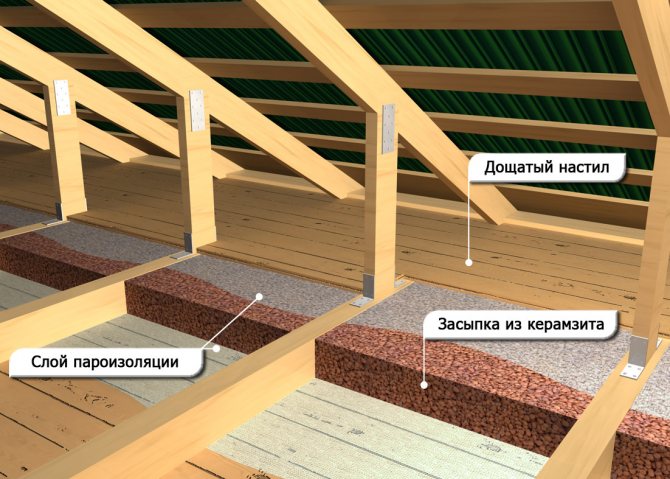

Insulation scheme

The main use of expanded clay in construction is thermal insulation. A ten-centimeter layer of a loose clay product can replace a 25-centimeter layer of high-quality wood. Granules are used for insulation of all types of floors, including floors. The calculation of the layer thickness is carried out depending on the height of the cement screed, as a rule, no more than 150 mm with a 20 mm screed and decorated on top.

The fraction of the material is of great importance. For a bath, it should be no more than 20 mm in diameter. It is better to use differently fractionated granules, starting from 5 mm.

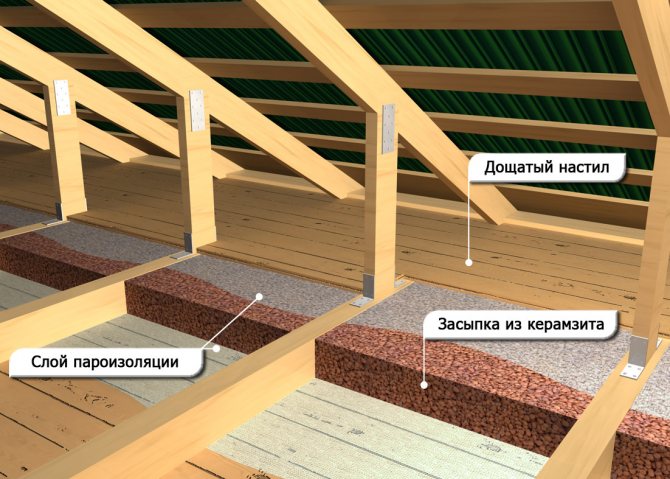

Installation of floors in a bathhouse using flooring made of insulating and heat-insulating layers is not difficult, and does not even require special construction skills. The device for the insulation cushion begins with the laying of hydro and vapor barrier, which is overlapped between the logs. Its joints are carefully sealed with a sealant or construction tape, avoiding the formation of gaps.

On the insulating layers, beacons made of rapidly hardening concrete are installed - a mixture of alabaster and cement in equal proportions. The first beacon is installed in close proximity to one of the walls, and the rest of the beacons are installed in relation to it through a uniform step. After the concrete has hardened, the insulation is poured.

Work order

Loose material should be filled with great care, since the split granule loses its thermal insulation properties. If broken granules are evident, they should be removed. After backfilling with expanded clay, you can start creating a screed on the floor surface and only after that create a finishing coating and floor finishing.

For this, a layer of waterproofing is once again laid on its upper part. Now this is done so that water from showers or steam rooms does not seep into the insulation layer. For additional strength, you can use a metal mesh or lay a mesh-netting and spill it with cement milk so that the floor structure does not undergo deformation at the time of creating the screed.

Video instruction on warming the floors of the bath with expanded clay.

After a couple of days, you can do the screed. Any coverage can be chosen, up to the use of the "Warm floor" system and laying in the base of the mats of electric heat-insulated floors under ceramic tiles or laminate. The period of "setting" of the screed is a week, while the period of complete drying of the cement is 28 days. The final drying of the screed will be indicated by the complete absence of dark spots on its surface. Only after that, it can be considered that the task of insulating the floor with expanded clay is fully completed.

Recommendations

Also, attention should be paid to floors that are fixed on pile foundations. Stages of work:

- Tie the pile heads with special screw beams.

- Lay a layer of waterproofing on a wooden base made of beams.

- On the undersides of the beams, fill in the rough beams.

- Lay sheets of thermal insulation, cover them with a waterproofing film.

- Put in a finishing coat.

It is important not to confuse the installation method of the waterproofing film. The instructions are on the packaging.

Concrete floors in bath rooms need to be insulated. If this is not done, they will be very cold despite the warming up of the premises. For thermal insulation, you need to choose one of several types of materials. It is important to take into account the peculiarities of insulation when carrying out work on your own.

To the rescue - sandwich pipes

One of the options than to wrap the pipe in the bath is thermal insulation. For the production of thermal insulation, foamed polyethylene is used, hidden between two layers of foil, and the upper layer of foil in the material is designed to protect the chimney from overheating.

Thermal insulation has appeared on the building materials market relatively recently. The thickness of such material ranges from 2-10 mm.

If a stove is installed in the bath, then refractory bricks are used for the construction of the chimney. He is able to stay warm for a long time.

We suggest that you familiarize yourself with: Drainage device in the washing bath

When building a brick chimney, it is not worth saving, but it is advisable to approach this issue very responsibly, because its durability depends on the quality of the work performed.

In this case, the best way to isolate the pipe in the bath from the ceiling, roof and other roof elements is to mount sheet metal on these surfaces.

The wooden roof structure can ignite on contact with the hot pipe. To avoid a fire in the bath, they isolate it. Most often, mineral wool, fixed with wire, is used for this purpose. From above, the pipe is plastered with clay-sand mortar and covered with a layer of galvanized roofing steel.

It is recommended to insulate the exit of the pipe in the area of the ceiling and roof with asbestos sheets. They have good protection against high temperatures. The walls at the inside of the pipe are covered with galvanized metal sheets. Conventional iron is not suitable for such work, since they are susceptible to corrosion. It is advisable to make a box around the pipe where it goes through the ceiling.

It is recommended that before starting work on the insulation of a metal chimney pipe, treat its outer part with a heat-resistant sealant.The special sealant can withstand temperatures up to 1000 ° C. The applied agent will prevent the insulating materials from sliding on the outer surface of the metal pipe.

It is a unique material with polyethylene foam sandwiched between a pair of foil sheets. With the help of thermal insulation, you can qualitatively insulate the chimney, moreover, independently.

The thickness of the thermal insulation varies from 2 to 10 mm, and the thicker the material, the greater its resistance to high temperatures.

The top layer of foil serves as a reliable protection of the pipe from significant overheating. With the help of a wire or tape of a metal master, heat insulation is attached, which is then wrapped around the chimney.

At elevated temperatures, refractory red brick retains its operational properties, therefore it is in demand when building a chimney in a bath with a stone stove. In this case, you are guaranteed the protection of the pipe from fire and long-term preservation of heat.

The service life of the structure depends on how well the brick pipe is folded. Do not skimp on materials during the construction of the chimney, because then the repair will be much more expensive for you.

Let's take a closer look at how to isolate a pipe in a bath from the ceiling:

- Use asbestos to line the pipe outlet on the ceiling and through the roof.

- Using galvanized material, insulate the walls from the inside of the pipe. Standard iron sheets are completely unsuitable for this purpose due to their tendency to corrosion.

- Run a box around the pipe where it passes through the ceiling.

- Pour expanded clay into the box to preserve heat and protect wooden floors from fire.

You professionally wrapped the pipe, but the work on the arrangement of the chimney did not end there. The next step is measures to insulate the stove, ceiling and walls of the bath.

Modern metal stoves are mounted on a foundation, while sheathed with sheets of the same material on the back and side of the wall. If you independently beat the stove with only metal, then its appearance will not be very aesthetic. It is better to make the external brickwork with red brick, which insulates the stove from fire and keeps the heat in the bath.

Due to the fact that asbestos emits toxic substances at elevated temperatures, it is not recommended to use it in a steam room. Natural felt is considered harmless, which, moreover, is a good insulator. For the price, this material is more expensive than asbestos sheets, and when smoldering, it emits a specific smell (felt does not ignite), which can be immediately felt.

If you intend to install the stove on a wooden floor, then first it is better to spread the felt material in a couple of layers, then lay out the brick in three rows. For walls and floors, it is advised to lay sheets of metal as an insulator, the height of which varies from 50 to 70 cm.

Having followed all our recommendations correctly, you will extend the term of operation of the entire smoke exhaust structure and protect it from fire. And you will no longer have any questions about how to wrap chimney pipes.

How to insulate timber floors

For the wooden floor of the baths on piles - insulation is also protection, which can significantly extend the service life of the entire building. That is why it must be of high quality and reliable, especially if done by hand.

Thermal insulation of a wooden bath floor consists of the following steps:

- laying logs on the rough floor surface;

- filling the space between them with insulating material (mineral wool, expanded clay or expanded polystyrene);

- installation of waterproofing;

- laying floorboards.

Important! When laying the boards on the floor of the bathhouse on piles, you need to make a slight slope to drain the water.

Thermal insulation of the floor with expanded clay

On the territory of Russia there is no such housing, baths or other household buildings that would not need to be insulated, since in most of the territory of our country the temperature in winter drops much below the zero point of the thermometer. Perhaps the most important object where thermal insulation is used in rooms is the floor.A warm floor that resists cold well is a guarantee of the health of the residents of the house, and it's just nice to walk not on ice tiles, but on a warm floor.

With the help of expanded clay, you can significantly reduce the heat loss at home through the floor.