SNiP 02/23/2003: thermal protection of buildings

The norms of SNiP affect not only the insulation of walls directly, but also regulate the corresponding measures to increase the efficiency of energy saving.

The documentation spells out the requirements for heaters, the features of their installation, the procedure for calculating energy efficiency. The documents were developed taking into account not only Russian standards, but also taking into account European requirements for insulation. The norms apply to all residential and public buildings, with the exception of those that are periodically heated.

System of regulatory documents in construction. Building codes and regulations of the russian federation. Thermal protection of buildings. Thermal performance of the buildings. SNiP 02/23/2003

SNiP was developed by qualified specialists from various fields. It takes into account all the nuances of carrying out work on thermal insulation, including the compliance of insulation with other regulatory documents, in particular SanPiN and GOST. The documents contain the basic requirements for:

- heat transfer properties of insulated structures;

- specific coefficient of heat energy consumption;

- the difference in heat resistance in the cold and warm seasons;

- breathability, as well as moisture resistance;

- improving energy efficiency, etc.

The system of regulatory documents indicates three indicators of thermal protection, two of which must be observed during insulation without fail.

Analysis of Amendment No. 1 to SP 50.13330.2012 "Thermal protection of buildings"

By order of the Ministry of Construction and Housing and Communal Services of the Russian Federation No. 807 / pr dated December 14, 2020, Amendment No. 1 to the Code of Rules 50.13330.2012 (SNiP 23-02-2003 "Thermal protection of buildings", hereinafter - SP fifty). The proposed article discusses the main amendments and additions made to SP 50 in comparison with its previous edition.

First of all, it should be noted that the basic values of the required resistance to heat transfer Rok for translucent structures, except for skylights, have undergone changes. In particular, now for the conditions of the city of Moscow with the value of the degree-day of the heating period GSOP = 4551 K day / year, the value of Rok for residential, public, administrative and service buildings, hotels and hostels (except for children's educational and general educational organizations, boarding schools) will be 0.658 m² · K / W instead of the previously required level of 0.491.

It should be mentioned that the author in works [1, 2] for the same conditions on the basis of a comprehensive energy and technical and economic analysis identified the optimal range of thermal protection of translucent barriers, which is just 0.6-0.65 (m2 · K) / W, which provides the best combination of thermal and lighting properties, as well as the minimum total discounted costs.

This is also confirmed by the data of a number of other researchers, both in our country and abroad [3–7].

In addition, if the previous version of SP 50 made it possible to reduce the value of the base value of the required value of the required value Rk of fillings of light openings by 5% by applying a reduction factor mр, taking into account the peculiarities of the construction region, when fulfilling the requirement of clause 10.1 of the specified Code of Rules for the specific characteristic of heat energy consumption for heating and ventilation of the building, the current edition no longer allows this, and the coefficient mр for translucent structures is now always taken equal to one.

At the same time, if during the selection of filling the light openings there are no certified test reports with the actual value of Rok, then for calculating their values can be taken according to interstate standards.

So, for translucent structures in PVC bindings in the climatic conditions of Moscow, in accordance with table. 2 GOST 30674–99 “Window blocks made of polyvinyl chloride profiles.Specifications ", now only three types of window units with a two-chamber glass unit with a heat-reflecting coating can be used:

- with the formula of a glass unit 4M1-12-4M1-12-I4 and with Rok = 0.66 (m² · K) / W;

- with the formula of a glass unit 4M1-12Ar-4M1-12Ar-K4 and with Rok = 0.67 (m2 · K) / W;

- with the formula of a glass unit 4M1-12Ar-4M1-12Ar-I4 and with Rok = 0.72 (m2 · K) / W.

For translucent structures in wooden bindings in the same climatic conditions according to table. 2 GOST 24700–99 “Wooden window blocks with double-glazed windows. Technical conditions "four types of window units with a two-chamber glass unit with a heat-reflecting coating are applicable:

- with the formula of a glass unit 4M1–8Ar – 4M1–8Ar – I4 and with Rok = 0.67 (m² · K) / W;

- with the formula of a glass unit 4M1-12-4M1-12-I4 and with Rok = 0.68 (m² · K) / W;

- with the formula of a glass unit 4M1-12Ar-4M1-12Ar-K4 and with Rok = 0.69 (m² · K) / W;

- with the formula of a glass unit 4M1-12Ar-4M1-12Ar-I4 and with Rok = 0.74 (m2 · K) / W.

For translucent structures with aluminum bindings for the climatic conditions of the city of Moscow, it is now impossible to take the value of Rok from Table. 2 GOST 21519-2003 “Window blocks made of aluminum alloys. Technical conditions ", since the values of actual Rok presented there are less than required (0.658 m² · K / W). Therefore, a test report will always be required when selecting the specified type of skylight fillings. Thus, an increase in the level of thermal protection in SP 50 for translucent structures obliges manufacturers to take measures to optimize and increase the thermal performance of their products and to confirm the declared values of the resistance to heat transfer in accredited laboratories.

It should also be noted that if before Amendment No. 1 the entrance doors and gates were considered jointly, then in the new edition of SP 50, the gates of heated premises were singled out as a separate type of external enclosing structures. Now a separate table has been introduced for them. 7a, according to which it is necessary to determine the normalized value of the resistance to heat transfer depending on the degree-day of the heating period of the GSOP and the area of the gate itself. The actual resistance to heat transfer of such fences should be determined in accordance with paragraph G13 SP 230.1325800.2015 “Fencing structures of buildings. Characteristics of heat engineering inhomogeneities (with Amendment No. 1) "(hereinafter - SP 230), using tables G.108-G.122 to calculate the specific heat losses.

In addition, in the mandatory Appendix G SP 50, the structure of the formula for calculating the calculated specific characteristic of the consumption of thermal energy for heating and ventilation of the building qfrom [W / (m³ · ° C)] was changed:

qref = kob + kvent - βKPI (kbyt + krad), (1)

where the parameters kob, kvent, kbyt and krad represent the specific heat-shielding and specific ventilation characteristics of the building, the specific characteristics of the building's internal heat inputs and the specific characteristics of the heat inputs into the building from solar radiation, respectively, W / (m³ · ° C).

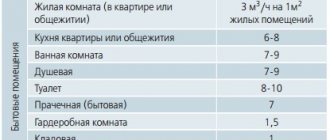

Note that now the amount of air when calculating kven for public and administrative buildings should be taken according to the air exchange table from the subsection "Heating, ventilation and air conditioning, heating networks" section 5 "Information about engineering equipment, networks of engineering and technical support, a list of engineering -technical measures, the content of technological solutions ". The problem of the discrepancy between the design and actual values of air productivity and, accordingly, the cost of heat was discussed by the author earlier in [8].

Also excluded from the new edition was the incorrect interpretation of the recuperator efficiency coefficient keff, which before the introduction of this Amendment No. 1 was always assumed to be zero, since the text of the paragraph containing explanations to the value of keff was mistakenly transferred from the previous version (SNiP 23-02-2003), where he referred to a completely different parameter regarding natural ventilation in residential buildings.

Now, if there are measures in the project to ensure the established requirements for energy efficiency and the requirements for equipping buildings, structures and structures with metering devices for the energy resources used (use of supply and exhaust ventilation with heat recovery from exhaust air), the value of the efficiency factor can be taken:

- for plate recuperators in the range of 0.5–0.6;

- for rotary recuperators 0.7–0.8;

- for heat recovery systems with an intermediate heat carrier 0.4–0.5 [9, 10].

Taking this circumstance into account will now, in certain cases, allow the building to be assigned a higher energy saving class according to clause 10 of SP 50.

At the same time, the values of the normalized (base) specific characteristic of the heat energy consumption for heating and ventilation of buildings qotr retained their previous values, which were given in table. 13 and 14 SP 50. However, when developing section 10 (1) "Measures to ensure compliance with energy efficiency requirements and the requirements for equipping buildings, structures and structures with metering devices for energy resources used" [hereinafter - section 10 (1)] for newly created buildings ( including apartment buildings), buildings and structures from July 1, 2020 to January 1, 2023, the value of qotr should be taken 20% lower than the base value in accordance with clause 7 of the Order of the Ministry of Construction and Housing and Communal Services of the Russian Federation of November 17, 2020 No. 1550 / pr "On Approval of the Requirements for the Energy Efficiency of Buildings, Structures, and Structures".

Therefore, table. 14 SP 50 for these conditions can be rewritten in the form of a table. one.

In addition, we note that in accordance with paragraph "g" of the Decree of the Government of the Russian Federation of February 16, 2008 No. 87-PP "On the composition of sections of project documentation and requirements for their content", section 10 (1) should contain information about the energy efficiency class ( in the event that its assignment to a capital construction object is mandatory in accordance with the legislation of the Russian Federation on energy conservation) and on increasing energy efficiency.

But both in the new and in the previous edition of SP 50 there is no concept of an energy efficiency class, but there are only energy saving classes of a building, therefore, there is a certain contradiction between these documents and confusion in terminology.

As a way out of this situation, the draft section 10 (1) should indicate that in accordance with Federal Law No. 261-FZ of November 23, 2009 "On Energy Saving ..." and with clause 4 of the Rules for determining the energy efficiency class of apartment buildings (approved by By order of the Ministry of Construction and Housing and Communal Services of the Russian Federation dated June 6, 2020 No. 399 / pr), the energy efficiency class is established by the state construction supervision body.

Additionally, it should be said that in the new edition of SP 50, the specific characteristic of heat input into a building from solar radiation krad [W / (m³ · ° C)] should be calculated according to the methodology of section 10 of SP 345.1325800.2017 “Residential and public buildings. Thermal protection design rules "(hereinafter - SP 345).

If earlier the values of the dimensionless coefficients τ2jl and τ2background, taking into account the shading of the skylight of windows and skylights by opaque filling elements, were taken as tabular data, now they must be calculated using the formula (10.3) of the specified Code of Rules.

However, the feasibility of such a calculation at the stage of design work raises obvious doubts, since at this stage the section "Architectural solutions" does not include a specific model of a translucent structure with certain technical characteristics, including those with specified dimensions of bindings, but only general instructions regarding the type of filling of light openings , for example, the need to install a double-glazed PVC-bound glass unit.In addition, the list of translucent structures is drawn up only at the stage of detailed design.

Consequently, the task posed seems to be impossible, since in the absence of a complete set of initial data, it is impossible to correctly perform the calculation. In addition, if you initially use the approximate values of the glazing parameters, then after their clarification at the stage of detailed design, it may be necessary to adjust the project and re-pass the examination. Thus, once again, the team of authors, providing for certain innovations in SP 50, does not give any information about where to get the initial data for calculations, which causes quite serious questions and difficulties directly from design engineers.

We only note that for now, in accordance with the Order of Rosstandart dated April 17, 2020 No. 831 "On approval of the list of documents in the field of standardization, as a result of which, on a voluntary basis, compliance with the requirements of Federal Law No. 384-FZ" Technical regulations on the safety of buildings and structures "" mentioned in this article SP 50 (with Amendment No. 1), SP 230 (with Amendment No. 1) and SP 345 are documents of voluntary application, therefore the designers have a certain amount of time to study the data documents, and from developers - for their possible revision.

A little about basic terms

SNiP operates with the following terminology:

- Thermal protection of buildings. A combination of external and internal heat-insulating structures, their interaction, as well as the ability to withstand external climatic changes.

- Specific heat energy consumption. The required amount of energy to compensate for heat losses during the heating period per 1 m².

- Energy efficiency class. Interval coefficient of energy consumption during the heating period.

- Microclimate. Conditions in the room in which a person lives, compliance of temperature indicators, humidity of the insulated structure with GOST.

- Optimal microclimate indicators. Characteristics of the indoor environment in which 80% of those present feel comfortable in the room.

- Additional heat dissipation. A measure of the heat coming from people present as well as additional equipment.

- Compactness of the structure. The ratio of the area of the enclosing structures to the volume that needs to be heated.

- Glazing index. The ratio of the size of window openings to the area of the enclosing structures.

- Heated volume. A room bounded by floors, walls and a roof that requires heating.

- Cold heating period. The time when the average daily air temperature is less than 8-10 ° C.

- Warm period. The time when the average daily temperature exceeds 8-10 ° C.

- The duration of the heating period. A value that requires calculating the number of days in a year when it is necessary to heat the room.

- Average temperature indicator. It is calculated as the average temperature coefficient for the entire heating period.

These definitions overlap and affect each other. Some indicators may differ for the insulation of residential and public buildings.

Technology features

The necessary conditions

According to SNIP, plastering work is carried out with the following parameters:

- Interior decoration of premises should be carried out at a temperature of the treated surfaces not lower than 100C. In this case, the air temperature in the room should be kept above 00C. The optimum humidity is 60% or less.

Note! This regime must be maintained for two days before the start of finishing and at least 12 days after its completion.

- The work is carried out in accordance with a previously approved project.At the same time, before the start of finishing, all measures for protection against precipitation (roofing, glazing), sealing of seams, installation of heating systems and other communications are completed.

- When finishing the facade parts, all roofing and waterproofing processes should be completed, as well as all brackets for drainage systems and other oversized structures should be installed.

You can work only in those rooms where windows are installed and the roof is completed

Preparation requirements

As for the requirements for the walls and ceilings to be treated, the instruction recommends adhering to the following rules:

- Before applying the leveling or decorative compound, the base must be cleaned of rust, efflorescence, oil stains, traces of bitumen and other contaminants.

- Before applying a primer or plaster, the surface must be dedusted without fail.

- It is not allowed to apply finishing to the base, the strength of which is lower than the strength of the leveling compound.

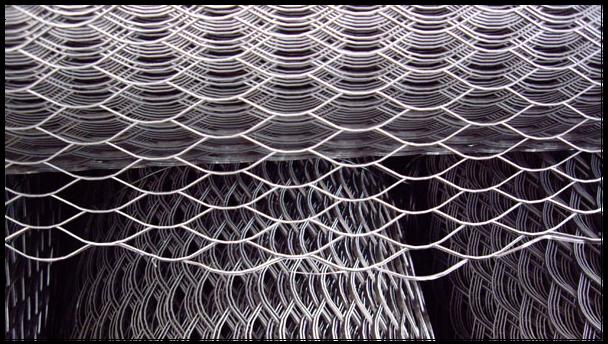

Photo of steel reinforcing mesh

- To improve the quality of adhesion of the mortar to the bearing wall in the most difficult places, it is recommended to install wire embeds.

Note! The best choice would be metal or plastic mesh. The price of such products is low, but the durability of the finish will increase significantly.

- If freezing techniques were used when erecting a brick wall, finishing can be done only after the structure has thawed and dried to a depth of at least half the thickness of the masonry.

- For the production of improved or high-quality plaster, we install lighthouse profiles on the walls. The installation level must correspond to the planned coating thickness (excluding the coating).

Placing lighthouses on the walls

The plastering works themselves are carried out according to the standard technique. At the same time, it is very important to adhere to the recommendations of the manufacturers of leveling and decorative mixtures, since the final quality of adhesion of the finish and the bearing surface largely depends on their observance.

- Improved plaster

Quality control

However, the most interesting point of this standard for us is the requirements for the quality of wall alignment set forth in it. Permissible deviations according to SNiP for plastering work relate to several aspects and depend on what level of surface cleanliness was originally planned.

Deviation control circuit

Below we provide information on the most important parameters.

Irregularities in the finish are revealed by placing a 2 m rule on the finished wall.

The largest allowable figure here is:

- For simple finishing - no more than 3 pieces per 2 m with a depth / height of no more than 5 mm.

- For improved - no more than two recesses or protrusions up to 3 mm.

- For the highest quality alignment - the same, but the size of the defect should not exceed 2 mm.

Other requirements are put forward for vertical deviations:

- With standard plastering, a vertical deviation of the plane is allowed, but not more than 15 mm over the entire height of the room.

- If an improved finish is required, a maximum of 2 mm per 1 m of height, but no more than 10 mm per room.

- When the alignment is carried out to the highest standards, then an indentation of no more than 5 mm for the entire height is considered acceptable (maximum 1 mm per 1 m).

Check vertical lines with the rule

Horizontal deviations:

- Standard - 15 mm for the entire length of the wall.

- Improved finish - 2 mm per 1 m, but no more than 10 mm per room.

- High-quality plastering - 1 mm per 1 m or 7 mm per part of the room bounded by structural elements (openings, columns, etc.).

Requirements for slopes, columns, support pillars, etc. constitute a separate group:

Checking corners and slopes

- For typical plastering, a vertical deviation of no more than 15 mm is allowed per element height.

- With an improved finish, an indent of 5 mm can be allowed, but not more than 2 mm per 1 m.

- Ideal plastering provides for an indent of no more than 3 mm to the height of the structure (respectively, 1 mm per 1 m).

The use of various heaters

The SNiP documentation describes in detail how and how to properly insulate structures for various purposes. Insulation of the facade, according to the norms, can be carried out using various heat-insulating materials, and each of them must correspond to certain parameters.

Styrofoam

In order for insulation using foam plastic to comply with SNiP standards, one should be very careful about the choice of material, since not all plates meet the requirements. The documents prescribe foam plates that have:

- density not less than 100 kg / m³;

- specific heat capacity from 1.26 kJ / (kg ° С);

- thermal conductivity is not more than 0.052.

They also limit the possibility of using foam for insulating its flammability, which should be taken into account if increased fire safety requirements are imposed on the building.

Expanded polypropylene

For such a facade insulation as expanded polypropylene, the SNiP does not spell out exact requirements, since it is a fairly new thermal insulation material. As practice shows, this material is most often used to provide waterproofing.

Low coefficient of thermal conductivity allows it to be used for insulation. But for application, specialized equipment will be required, which significantly complicates the process of applying polypropylene foam to the surface.

Mineral wool of different classes

Using mineral wool is the easiest way to achieve compliance with SNiP standards. Soft facades are not used, while the regulatory documentation allows for insulation with semi-rigid and rigid plates.

The second option is recommended for use when working with a plastered surface. Semi-rigid mineral wool is the best choice for brick walls and aerated concrete.

Expanded polystyrene, polyurethane foam - extruded materials

Insulation with any materials from this category is allowed only for basements and attics. This is due to the special quality characteristics of heaters.

In addition, the work is fraught with a number of difficulties, in particular the application of foam materials, and requires adherence to safety measures and the use of personal protective equipment.

Foam concrete, aerated concrete

According to building codes, the rules established by SNiP, the use of such heaters is relevant for the thermal insulation of industrial facilities.

PPR section Quality requirements

Requirements for the quality of the facade

Quality control of work is carried out in accordance with SNiP 3.04.01-87 "Insulation and finishing coatings" and SNiP 3.03.01-87 "Bearing and enclosing structures".

The main tasks of quality control are:

- ensuring compliance of the work performed with the project and the requirements of the current regulatory documents;

- compliance with the terms of work;

- prevention of marriage and defects in the production process;

- survey of hidden works;

- compliance with safety regulations, fire safety and industrial sanitation at the facility.

Quality control is comprehensive and includes:

- incoming quality control of materials, products and structures intended for use. Carried out by employees of the supply service and line engineers;

- operational control. Carried out by foremen and line engineers;

- acceptance control. It is carried out after the completion of certain stages by the linear engineering and technical personnel.

Requirements for the quality of the materials used for the translucent structure:

Details of products must be made of extruded aluminum profiles that meet the requirements of SNiP B V.2.6-3 "Windows and doors, balcony showcases and stained-glass windows from aluminum alloys."

Deviations in product dimensions should not exceed values, mm:

post length ± 2.0

glazing beads length ± 1.0

the length of the imposts, tying of the vestibules and the distance between the axes of the nodes ± 1,04.4

Deviations in the dimensions of the box, sash, balcony door leafs should not exceed the values indicated in the table.

| Nominal dimensions | The value of the boundary deviations | |

| Internal dimensions of boxes (mm) | External dimensions of boxes (mm) | |

| Up to 1000 incl. (mm) | +1,0 0 | 0 –1,0 |

| More than 1000 to 2100 incl. (mm) | +1,0 0 | 0 –1,0 |

| More than 2100 to 3000 incl. (mm) | +2,0 0 | 0 –2,0 |

The difference in the lengths of the diagonals should not exceed the values, mm:

boxes, doors, balcony door leaves 3.0;

other products 5.0.

Deviations from the straightness and flatness of the boxes, sashes and sheets of balcony doors should not violate the tightness of the products (when the doors and leaves are closed, the gaskets in the vestibules should be pressed without a gap).

Deviations from the straightness of the elements of showcases and stained-glass windows up to 2 m in length should not exceed 1.0 mm, and for a length of more than 2 m - 0.5 mm per 1 m, but not more than 3 mm for the entire length.

The difference in the front surfaces of aluminum profiles connected in one plane must be within the tolerance for the profile size according to SNiP B V.2.6-3, and in the connection of combined profiles - within the sum of the tolerances for the corresponding dimensions of the constituent profiles and according to GOST B V.2.6 -thirty.

Gaps on the front surfaces of structures at the joints of parts should not be more than 0.3 mm. It is allowed to increase the gap up to 1.0 mm, but with subsequent sealing of the joint.

The gaps at the joints of the linear filling fixing elements (glazing beads) are allowed not to be sealed.

The maximum deviation of the cut angle of the profiles with the length of the side to be cut, up to 50 mm, should not be more than ± 20, with the length of the side to be cut, more than 50 mm - more than ± 15 '.

The design of the product must provide for the drainage of water and condensate that have got into it.

<< Предыдущий раздел | Следующий раздел >>

Gost for insulation and sound insulation

In accordance with the adopted regulatory documents, all heat and sound insulation materials, including those for facademust be manufactured in accordance with approved standards.

Based on GOST 16381-77, all technical insulation requirements must comply with the following standards:

- thermal conductivity should not exceed 0.175 W / (m K) (0.15 kcal) (m h C) at a temperature of 25 ° C;

- product density less than 500 kg / m 3;

- stable thermal and physical and mechanical properties;

- raw materials should not emit toxic substances, dust, above the designated rate.

The adopted interstate standard GOST 17177-94 also regulates indicators for an insulating material and methods for their determination, including: density, appearance, water absorption, compressive strength.

Requirements for system materials and products as part of the sftk

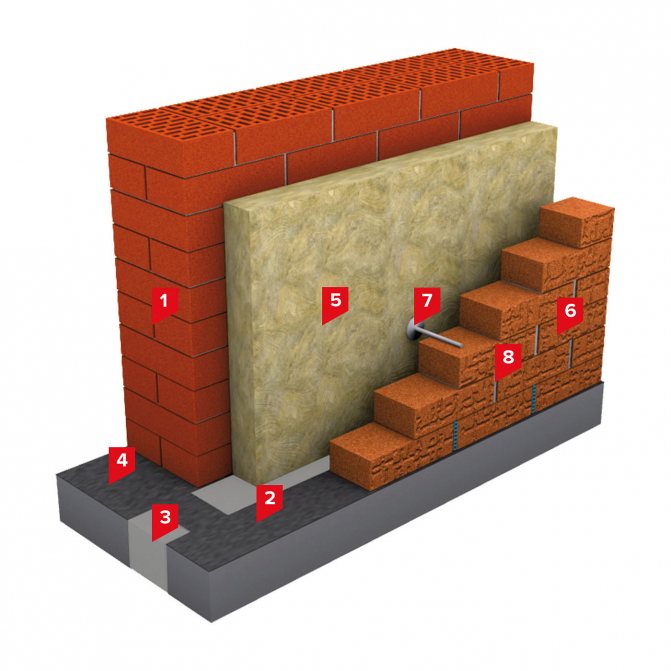

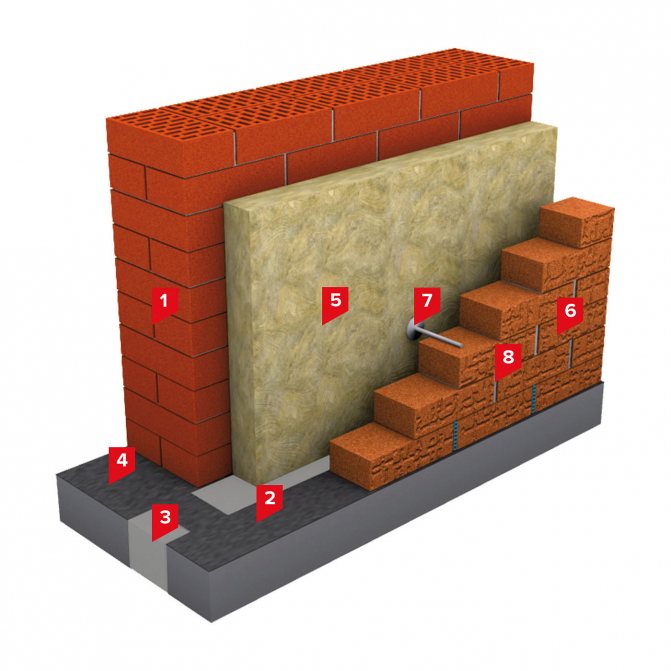

In accordance with GOST R 53786-2010, facade heat-insulating composite systems (sftk) are a set of layers applied to the outer surface of the outer surfaces, which include:

- adhesive composition;

- mechanical clamps;

- plaster composition;

- reinforcing mesh;

- facing material;

- primer composition;

- other structural products and elements.

Thermal insulation of facades received building codes snip in the corresponding document dated 23-02-2003, which approve:

- the minimum and maximum heat-shielding characteristics that a building must have;

- breathability;

- moisture characteristics insulation;

- heat energy consumption for heating and ventilation.

Figure 2. GOST standard for thermal insulation materials.

Application area

SNiP of 23-02-2003 determines those structures to which the scope of the document applies.The list includes reconstructed and under construction residential premises, warehouses, production facilities and agricultural buildings with an area of more than 50 m2, where there is a need for temperature control. The document concerns the application external insulation systems in high-rise buildings, where it is necessary to take into account the peculiarities of fire safety rules.

It should be noted that the approved norms do not apply to:

- periodically heated residential buildings (several days a week);

- external insulation systems refrigerated buildings, greenhouses and greenhouses;

- religious buildings;

- temporary structures;

- objects that are monuments of cultural heritage.

Thermal protection of buildings

SNiP, adopted on June 26, 2003 No. 13, establishes the norms for thermal protection of the structure in order to save money. Based on energy efficiency insulation, all buildings are divided by a document into several classes, with the most ineffective options (D, E) at the design stage technical solution of the system not allowed. Subjects of the Russian Federation should stimulate the conduct of heat insulating operations for facades buildings.

Insulation of the facade must have the following characteristics:

- the resistance to heat transfer of elements should not fall below the standardized value (elementary requirements);

- the specific heat-shielding value should not exceed the established norm (complex requirement);

- the temperature of the internal area of the insulation must be within the permitted values (sanitary standards).

Heat resistance of enclosing structures

SNiP of 23-02-2003 states in section 6 that in areas with an average temperature of 21 ° C or more in July, it should be determined by the formula:

Where t (n) is the average value of the ambient temperature in July.

This facade count is suitable for residential and hospital settings, maternity hospitals, pre-school education and training organizations. This group also includes industrial enterprises where it is required to maintain optimal temperature conditions and humidity levels in the room. If the enclosing multilayer structure is heterogeneous and includes framing ribs, it is worth making calculations based on GOST 26253-84.

Air permeability of enclosing structures

Air permeation prevention level buildings and structures with enclosing elements, should be equal to the accepted rate of resistance to air permeation.

Figure 3. Facade structure.

The table indicates the rate of transverse air permeability of insulation G (h), kg / (m2 * h).

| Construction type | Transverse air permeability value |

| External facade of residential, public buildings | 0,5 |

| Walls of production facilities and buildings | 1,0 |

| External façade panel joints |

Facade insulation

Facade insulation

The middle of the last century was marked by a technological breakthrough in the insulation of building facades. With a difference of several years in various European countries appeared multilayer facade systems of "wet" type and ventilated facade systems, which are widely used in the reconstruction of old and construction of new objects. But, like many other advanced building technologies, facade systems came to Russia much later - in the 90s of the XX century.

Due to its high thermal performance, sound insulation properties, reliability and durability, the construction of facade systems of both types has become the main method of insulation and decoration of external walls. However, the experience of using such systems is too small: when choosing materials, in the design and installation process, builders make many mistakes, the consequence of which can be a significant deterioration in the properties of facade systems, a decrease in their service life, destruction and even a threat to human life and health. Consider the typical mistakes made when insulating the facade, and simple ways to avoid them.

No. 1 - When choosing thermal insulation

many problems arise from the incorrect selection of the components of the facade systems. Sometimes this is due to a lack of awareness among builders, but more often it is due to an attempt to reduce costs by using cheaper, low-quality materials. First of all, this applies to thermal insulation. Mistakes in the choice of thermal insulation materials lead to a deterioration in the thermal performance of the facade system, moisture condensation in the thickness of the insulation and on the surface of the walls, the appearance of mold and a decrease in the service life of the structure.

Facade insulation must have a number of properties. First of all, the low thermal conductivity of the material. It is important that high heat-shielding properties are maintained during operation, therefore, thermal insulation must be hydrophobic and, at the same time, have high vapor permeability in order to avoid condensation of water vapor in the thickness of the wall.

The fire safety of the thermal insulation material plays a significant role. In particular, in the construction of ventilated facade systems, experts recommend using materials that, in accordance with GOST 30244-94 “Building materials. Flammability Test Methods ", belong to the class of non-combustible (NG).

Thermal insulation made of expanded polystyrene, depending on the brand, refers to combustible or hardly combustible materials (G1-G4). As for thermal insulation made of glass wool, then, as a rule, a heater with a density of less than 40 kg / m3 belongs to the NG class. Fire safety requirements for all types of facades are fully met by non-combustible thermal insulation made of stone wool, capable of withstanding temperatures up to 1000 ° C. Insulation of the facade with combustible thermal insulation requires the obligatory device of stone wool diffusers.

In "wet" façade systems, thermal insulation serves as the basis for the plaster layer. In order to withstand the weight of the plaster in difficult temperature and humidity conditions, the peel strength of the layers must be at least 15 kPa, otherwise, after a while, the facade may simply collapse. This requirement is met, for example, by stone wool slabs ROCKWOOL FASAD BATTS D, which have a low thermal conductivity coefficient (0.038 W / m K) and are specially designed for use in facade systems with a thin plaster layer. They are non-flammable, characterized by high vapor permeability, which avoids condensation of moisture in the thickness of the insulation and on the outer surface of the wall. In addition, the service life of stone wool insulation is at least 50 years.

No. 2 - When choosing fasteners

a fairly common mistake is the wrong choice of fasteners for facade systems. Throughout the entire service life, fasteners experience powerful loads, including wind loads (for ventilated facades), the effect of their own weight (for plaster facade systems), as well as constant changes in temperature and humidity conditions and the influence of an aggressive environment leading to metal oxidation.

Poor-quality fasteners are not always able to withstand such conditions, which leads to the destruction of facade systems long before the end of the period allotted to them. From the point of view of reliability, it is preferable not to look for cheaper analogs, but to choose fasteners supplied complete with other components of a particular facade system.

The choice of dowels largely depends on the material from which the walls of the building are built. Dowels designed for fixing in concrete or brick are fundamentally different from dowels for fixing in porous bases - for example, aerated concrete or gas silicate. The problem is that cellular concretes are not able to perceive point pressure for a long time: the material is destroyed, and the dowels lose their bearing capacity.Therefore, for fixing in cellular concrete, dowels with a greater anchorage depth or with anchoring over the entire surface of the expansion zone are used.

Fasteners strongly affect the thermal performance of the entire system. For example, disc dowels with a high coefficient of thermal conductivity serve as "cold bridges", reducing the effect of insulation. In the case of a thin-plastered facade system, this leads to a violation of the surface uniformity and gradual destruction.

The result of the wrong choice of fasteners can be electrochemical corrosion of metals. For example, when installing a ventilated facade system, experts do not recommend fixing an aluminum alloy profile and cladding with self-tapping screws made of unalloyed steel, since over time this leads to metal oxidation.

№ 3

—

Choice of exterior finishes

Several years ago, the Central Research Institute of Building Structures named after V.I. V.A. Kucherenko conducted a series of full-scale fire tests of aluminum composite panels (ACP), which are one of the most popular materials used in the construction of ventilated facades as a decorative coating.

According to the test results, significant restrictions were revealed in the use of some types of composite panels from the point of view of fire safety. For example, any ACP with an inner layer based on polyethylene belong to the G4 flammability group: they ignite already at 120 ° C, and combustion is accompanied by the release of toxic gases that are dangerous to human life and health. In practice, composite panels of this type are widely used in the construction of various types of buildings, including high-rise ones. This is strictly prohibited SNiP 21-01-97 "Fire safety of buildings and structures."

In order to ensure the safety of people in the building, it is necessary to use ACP that have passed fire tests in accordance with GOST 31251-2003. It is only by their results that one can judge the possibility and conditions of using composite panels in the creation of ventilated facades of buildings of various types and purposes.

When it comes to plastering facade systems, the wrong choice of decorative plaster will affect their durability. The thing is that some types of plasters have low vapor permeability. In the construction of "wet" facade systems, they become a vapor barrier, which leads to moisture condensation and, ultimately, to partial or complete peeling of the decorative layer.

No. 4 - Design

In the process of designing facades, serious mistakes can be made. So, for example, in the case of plaster facade systems, there is an incorrect calculation of thermal resistance. Another popular mistake is the lack of thermal insulation of window slopes in the project, which ultimately leads to freezing of the window along the perimeter in winter.

Errors in the design of ventilated facade systems are a serious problem in modern construction and often minimize the effect of facade insulation. Among them is the incorrect accounting for the curvature of the walls. In the desire to align external fences with a minimum overhang of the brackets, builders try to bring the facade panels as close to the wall as possible. This leads to a decrease in the air gap, a violation of air circulation and, as a result, to condensation of moisture inside the structure and a deterioration in its thermal performance.

Even if the air gap is of the required width, ventilation openings are often not included in facade system designs. It also impedes normal air circulation and causes moisture removal problems. In addition, when designing ventilated façade systems for high-rise buildings, it is necessary to take into account the pressure drop at different heights. Otherwise, significant heat loss occurs on the upper floors of the house.To efficiently retain heat on the upper floors of high-rise buildings, it is necessary to design a different arrangement of ventilation gaps. In general, the design of ventilated facade systems should be carried out taking into account the characteristics of each building and the climate of the region.

Violation of the technology of installation of facade systems can entail more or less serious consequences, up to the destruction of the facade. In particular, a common mistake when installing "wet" facade systems is insufficiently tight joining of thermal insulation boards and filling the joints with adhesive solution.

This leads to the formation of "cold bridges" and cracks in the decorative coating, which spoil the appearance of the facade.

Preparation of the base plays an important role in the installation. Fastening of thermal insulation to crumbling and non-primed walls leads to its separation. The same happens when there is not enough adhesive solution. A common mistake is made when creating a reinforcing layer: adjacent reinforcing mesh canvases are mounted without overlap. This leads to the formation of long horizontal or vertical cracks on the surface of the façade. To avoid this, when attaching the mesh, an overlap with a width of about 10 cm should be made. Another reason for the appearance of cracks can be the installation of a reinforcing mesh directly on a layer of thermal insulation material.

When using low-quality dowels for fixing thermal insulation, local ruptures of the plaster layer may occur. If the disc dowel protrudes above the thermal insulation plane, bumps appear on the surface of the facade. In turn, excessive deepening of the plate leads to deformation of the landing zone of the driven dowel and a decrease in its bearing capacity.

Some problems can arise during the application of the finishing coat. For example, to reduce the cost of a façade system, too thin a layer of decorative coating is applied. However, with such a thickness, the plaster is not able to level the surface and hide the seams. As a result, immediately after the completion of installation work, joints become visible on the surface, and the appearance of the facade deteriorates. In addition, the service life of such a facade system is reduced.

With an uneven application of the finishing layer, stripes are formed on the facade, indicating the location of the horizontal platforms of the scaffolding. Uneven grouting of the decorative coating causes clear spots to appear on the surface.

Just as in plaster facade systems, in ventilated facades, the fastening of adjacent heat-insulating plates must be carried out without a gap, so that subsequently there are no “cold bridges”. In addition, the thermal insulation in the structure of a ventilated facade system experiences wind loads, therefore, if it is not securely fastened, its service life is reduced.

As practice shows, many mistakes are made when decorating windows. For example, builders often forget to insulate the horizontal part of the wall between the window box and the insulation. It is important to carry out installation work in such a way as to completely exclude the ingress of water into the structure in the future, this applies not only to the elements of the facade system, but also to other structures: in particular, the edging of window openings.

In Russia, it so happened that new technologies for facade insulation reach designers and contractors earlier than detailed information about the features of competent design and installation. This seriously harms the quality, efficiency, reliability and durability of the installed façade systems. As a result, with a service life of at least 25 years, the need for repairs may arise 2-3 years later or immediately after the facility is put into operation. It is not so difficult to avoid all these problems; it is enough to apply a systematic approach to facade insulation.It includes the use of specially designed facade systems consisting of high-quality components, the participation of development companies in the design, technical supervision and installation supervision at the facility, as well as regular inspection control of each facade during its operation.

Roman Ilyaguev

Press service of the company

ROCKWOOLRussia

Magazine "Pricing and Estimated Rationing in Construction" January 2010 No. 1

Organization of the technological process

Competently thought-out insulation of the facade will save up to 50-60% of the consumed heat during the heating season. At the first stage, you need to choose the best option for the fence:

- creating thermal insulation outside the wall;

- installation of elements inside the building;

- laying the insulator in the walls of the facility (during construction);

- combined option.

The most popular method is external insulation, which increases the service life of the structure. For these purposes, polystyrene foam is used in the form of a plate or mineral wool.

Preparation and priming of surfaces

Facade primer is a special ingredient in the primary surface treatment for insulation in order to level and more secure adhesion of materials. Priming will help to strengthen the base and will allow you to save in materials at the next stages of work.

There are several variations of the primer:

- alkyd, with a high degree of adhesion and impregnation;

- acrylic, water-thinnable.

Before applying a layer of primer, the surface is mechanically leveled and possible cracks and fractures are repaired. The work should be carried out in the temperature range from +5 ºС to + 30 ºС using a roller or spray gun. If necessary, the procedure is repeated several times. After finishing the priming work, it is worth waiting at least a day.

Insulation installation

After the lower level of the insulation zone has been installed to obtain the starting line (if necessary), external window sills are installed, taking into account the need for the window sill to protrude 3-4 cm forward after installing the insulation.

Material - insulation is first glued to the load-bearing wall, and then nailed. Fastening of insulation boards starts from the bottom of the working surface. It is convenient to apply the glue with a small or large trowel. A mixture of glue is applied to the wall surface, simultaneously leveling possible irregularities. Mineral wool or foam strips are attached to form T-joints.

Sheets are applied to the surface with a gap of 20-30 mm and only after that they are put in place as a rule to adjacent elements. Observe the distance between the plates, which should not exceed 2 mm. A toothed connection is made at the corners.

Drilling holes and driving in dowels

The next step is recommended three days after gluing. Otherwise, the foam with poorly dried glue can lag behind the wall. The material is attached to the wall with special plastic mushrooms, which, in turn, are installed on dowels. There are also metal options for fungi, but they are not recommended for installation due to the good thermal conductivity of the material.

Typically, 6 to 8 fixing units are needed per square meter. It is advisable to drill holes in the center and along the edges of the sheet. To create a hole, a perforator is used, taking into account the length of the fungus and the thickness of the insulation layers. It is recommended to drill holes 1 cm deeper fastening element, then the dust will not interfere with the plugging of the dowel. The disc head of the nail should be hammered with a rubber hammer to the level of the insulation material.

Features application of reinforcing mesh

Reinforcing layer is an additional reinforcing element covering the insulation material. In addition, every corner of the building, not excluding decorative parts and slopes window door openings must be protected with perforated corners.Such parts are connected with glue and leveled. After the preparation solution has dried and all the reinforcing parts have been installed, it is allowed to begin the installation of the main mesh for facade work. The mesh is made of wear-resistant fiberglass that can withstand the required loads. Before installation, the working surface is sanded, debris and excess solution are removed. The mesh is connected to the insulation thanks to a layer of glue (width 2mm). Additional glue is applied to the fixed reinforcement mesh. After reapplication, the mesh should not be visible.

Plastering the facade of the house

The next day after the treatment of the reinforcing layer, you can start the sanding process. It is recommended to plaster small sinks. Any unevenness and excess mortar must be removed. For this, coarse sandpaper is suitable. After three days walls dry completely. Further, the walls are treated with a layer of primer with quartz sand in order to better set the decorative top plaster.

Finishing of buildings

To complete the facade, both textured plaster and decorative analogs are suitable. Tinted solutions in plastic buckets can apply without additional finishing paint after application, which cannot be said about the mineral version of the solution.

The composition is thoroughly mixed before use with a nozzle - a stirrer until a homogeneous mass is obtained. Plastering trowels and a trowel are used to apply the material. There are several options for decorative plasters, where it is optimal to use different layer thicknesses. For example, for a variant of the "mosaic" type, it is recommended to use a layer of 1.5-2 grains. In other cases, it is important not to distribute a layer with a thickness less than the grains of the mineral filler, due to the loss of the protective properties of the coating. In 10-20 minutes after applying the layer, it is necessary to start forming the textured pattern. The final grout is done with simple strokes without heavy pressure. If the technology is preserved, the insulation will be able to serve for a long time.

| Apartment entrance doors | 7,0 |

| Balcony doors and windows of residential buildings with wooden frame, industrial buildings with air conditioning | 6,0 |

| Balcony windows and doors with aluminum and plastic cover | 5,0 |

| Doors and windows of industrial buildings | 8,0 |

Wet facade installation technology

Before starting work, check the evenness of the walls. They should not contain humps, holes, mortar drips and fasteners. All angles must be checked with a plumb line or level. If curvature is found, alignment is required, otherwise you can splurge on plaster... All holes must be carefully covered..

Padding

Since the insulating layer will first be glued, the walls need to be prepared for this. Preparation consists in applying a deep penetration primer. This will help to avoid wastage of glue and provide better adhesion to the surface. For brick walls, diluted cement milk is quite suitable as a soil. But if the wall is rough and not very strong, it is better to give preference to water-based soils. Acrylic and silicone primers work well, but if you need the wall to breathe, it is better to refrain from using them.

Insulation should be started no higher than the bottom of the floor. Find this height and spread it with a level around the entire perimeter of the house. Sometimes in retail chains a special basement profile and fasteners to it are sold. Such a profile is placed end-to-end, a gap is provided between two adjacent ones.

The profile can be taken for drywall. It is attached with ordinary dowels and self-tapping screws. The only recommendation: choose self-tapping screws made of metal that does not rust. They have a flat hat.

Gluing insulation

Use glue.For mineral wool, cement compositions are suitable, for polystyrene - polyurethane. You can, of course, glue on liquid nails or epoxy, but such materials in large quantities will be very expensive.

The glue is diluted according to the instructions on the package, after which it is applied to the edges and middle of the mat. It is important not to allow breaks in the adhesive layer around the perimeter, so that air does not circulate between the insulation and the wall. The mat is then glued to the wall. During work, you need to control the position of each element with a level.

Bonding is carried out in a checkerboard pattern, with bandaging at the corners. Avoid overlapping the seam with a window or door jamb - water can get there.

If you insulate the house with expanded polystyrene, a fire cut-off made of mineral wool is made between the floors. Its width is set by standards, and cannot be less than 20 cm.

After pasting, the gaps are eliminated. If you insulate the house with cotton wool, the cracks are clogged with it, and polystyrene foam insulation is corrected with polyurethane foam. After the foam dries, remove the remains of it with a clerical knife.

Now you can leave your house for three to four days for the glue to set properly, and proceed with the fasteners.

Fasteners

It is performed with the help of "fungi" - it is not difficult if you have chosen them correctly. They look the same, but in fact, just like regular fasteners, they are made for different types of walls. Somewhere you can just wrap it with a screwdriver, but somewhere you need to drill and insert the dowel inside. The length of the dowel should be such that it protrudes into the wall by at least 5 cm.

The density of the fasteners is 4 pieces per square meter. If your insulation is smaller, it is better to fasten it more often, or put dowels on the joint of three plates and in the middle of each mat.

After that, all the dowels must be covered with glue and the surface must be leveled.

Installation of corners, planks and mesh

You will need plaster diluted according to the instructions or the same glue. It is applied in a thin (up to 2 mm) layer over the surface. First, this must be done at the corners and near the window openings: after application, PVC corners and strips with a mesh strip are installed on them. They must be sunk into the plaster and leveled. After that, you can proceed to the main array of walls. Plaster is applied to them in the same way and a fiberglass mesh is embedded in it.

For convenience, it is better to cut the mesh into strips about a meter wide. Never cover the mesh from above - this will reduce the quality of grip. This can be done when you are using a thick masonry or plaster mesh with a wide mesh and a cement-sand mortar - but in this case, the mesh must be attached to the wall during the fastening of the insulation.

After the reinforcement is completed, it is necessary to allow the first layer of plaster to grab, and then proceed to finishing work.

Finishing wet facade

The further plastering process depends on what layer you need for the final leveling and how much you can apply plaster in one step. Some formulations do not allow application of more than 5 mm at a time, with others it is easier. It is better not to deviate from the instructions here.

The main thing when applying the last layer is the maximum leveling of the wall.

If you use heavy solutions, it is worth installing beacons that are pulled out after applying a layer. You will have to do the same when you have not leveled the wall in advance.

Decorative plasters look very good as a finishing touch on a wet façade, but if this seems costly to you, exterior paint is fine.

Plastering Home Facade Guide

Reading Time: 4 minute (s)

It is necessary to cover the facade of the building with plaster not only in order to decorate the structure, but also in order to protect the external surface of the building from destructive climatic influences (sunlight and excessive humidity). In addition, plaster protects the building surface from mechanical damage. Due to the peculiarities of the facade plaster, any idea related to the design of the building can be realized. Read about what types of facade plaster are available on this page.

The photo shows the process of applying plaster to the facade.

Snip plaster of facades

Most people, before starting repairs, think about the issue of plastering. This point should be given special attention, because the service life of the building depends on the quality of these works. Plastering is a finishing process that involves leveling the vertical and horizontal surfaces of the building using dry mixes.

The main purpose of covering the wall with plaster is to obtain a perfectly flat surface:

- align the width of the doorway

- plaster the slopes,

- giving parallelism to the walls of the building and room.

- In addition, perpendicular angles are set using plaster.

Plaster mixes by quality are divided into three main types:

- High quality plaster mixes;

- Improved quality plaster mixes;

- Simple plaster mix.

The documentation that regulates the quality and technology of this type of construction work is regulated by the government. Facade plaster must meet all GOST criteria. Moreover, the conditions are prescribed for both machine application of plaster and manual. To change the design of the facade, it is enough to cover it with facade paint for application on plaster.

The photo shows the facade of the house, covered with plaster

Facade finishing technology with plaster

At the moment, there are many technologies for finishing the facade of a building with a plaster mixture. The most common of them are:

- Facade plastering technology on a grid. Thanks to the use of mesh, the strength of the solution applied to the wall surface will significantly increase. This technology makes it possible to apply plaster over large areas and transitional segments between different materials from which the wall itself is made. Most often, this technology is used when working with new buildings, in which the complete settlement of the building has not yet occurred.

Depending on the area in which the structure is used, the reinforcing material can be:- polymeric,

metal,

- fiberglass.

What can be a mesh for plastering work?

In order to prevent the finish coating of the wall from cracking and peeling off, a mesh structure is mounted on the wall. Today, four types of metal mesh are used:

- Woven mesh. This type of mesh is flexible and durable. This mesh is created by weaving from wire elements of different sections. In order to plaster the wall with your hands, use a galvanized mesh with a mesh size of 1x1 cm.

- Rabitz. Such building material is fixed in the event that it is supposed to apply a thick layer of plaster. The mesh is used with a 2x2 cm cell.

- Welded metal mesh with square meshes. All cells are located at right angles to each other, it is made of low-carbon galvanized material.

- Screen mesh. It is produced by welding the intersections of the wire fiber at an angle of ninety degrees. Used to prevent cracking of the wall surface.

Check out the technology for cladding a base with porcelain stoneware on this page.

Builders call this type of facade finishing "wet", because all construction work is carried out using wet material, which takes time to dry out.

It goes without saying that before starting work, you should pay special attention to the choice of material.

Thermal insulation of the facade for plastering

This method is considered the most democratic and popular for finishing the facade of a building with a thin layer of plaster with preliminary wall insulation.

The essence of the technology lies in the fact that insulation plates are attached to the outer surface of the building, on top of which a layer of plaster is applied.

In hardware stores, they offer plastering systems (a full set of necessary materials) for insulating an object. But often in such a kit there is everything except the insulation plate.

Facade plaster repair

It assumes grouting of microcracks and more cracks formed during operation. The easiest method to repair the facade of a building is to putty the crack with a layer of paint of the same color. If this is not done, then you can get the most serious damage to the facade of the building. Because climatic precipitation can damage the structure. How to sheathe a plinth with a professional sheet, read here: https://frontfacade.com/vidy-materialov/proflist/instrukciya-po-obshivke-cokolya-proflistom.html.

You can also clean and prime the crack formation site, and then cover it with a new layer of plaster, but you should be careful here, because a thick layer may fall off and you will have to overhaul the facade.

But it is best to cover the facade with a mesh, first remove all the exfoliated elements and then apply a layer of plaster to the reinforcing mesh.

Facade plastering materials

When performing finishing work on the facade of the building, you should acquire the following material:

- dry mixes for facade plastering,

- facade mesh for plaster.

Here you should carefully consider the choice of mesh, the entire finishing process depends on it. - facade panels for plastering and, lastly, facade insulation for plastering. It is needed if insulation work is expected.

The price of work on finishing the facade with plaster

The cost of such construction work differs depending on the region, the facility and the company that will conduct the entire construction process. It is for this reason that it is not possible to say what the price for finishing will be.

Video

Watch the video instructions for applying plaster and facade insulation:

Finishing the facade of the house is necessary, since such a measure protects the foundation and walls from destruction. Facade plastering is a measure of decoration and protection of walls, which allows you to change the design of the building as you wish during the renovation. Read an overview of manufacturers of basement siding and its cost.

Did this article help you? We will be grateful for your rating:

0 0