In this article, we will bring to your attention all the products that are positioned by manufacturing companies as environmentally friendly insulation and give their main parameters.

What is considered an environmentally friendly insulation

To understand what an environmentally friendly insulation should be, it is necessary to decide what qualities and properties it should have, what characteristics it should have. Here are the main criteria on the basis of which it is worth choosing the "environmental friendliness" of any insulation material:

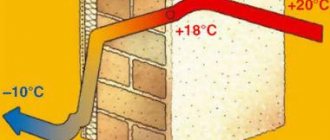

- It should be natural insulation. It should be based only on natural fiber and natural ingredients. There can be no question that thermal insulation releases carcinogens or toxins into the air you breathe. Do not expect that the decorative layer covering the heat-shielding material will become a reliable sarcophagus for hazardous and harmful secretions and vapors. All paints and "protective" coatings are erased over time, and negative substances still enter the building and poison the residents.

- Moisture resistance. The material must be sufficiently dense and not absorb moisture, in addition, by itself, it must repel it. When wet, the fibers lose their thermal insulation, and instead, the heat transfer coefficient begins to grow. In addition, excess moisture favors mold growth, fungal growth and the proliferation of harmful microorganisms and viruses. Breathable insulation is able to absorb a significant amount of water and, with sufficient ventilation, dry out without losing its thermal insulation characteristics and other parameters.

- Thermal conductivity. The best indicators of thermal conductivity are shown by heaters made of natural fibers, which are based on plant fiber. The heat transfer coefficient should be in the range of 0.032 - 0.040 W / m ∙ K. This value is quite sufficient and even optimal to keep the house warm and comfortable.

- Flammability. One of the most important properties of heaters, of those that must be taken into account when insulating buildings and premises. Natural insulation does not support combustion. It can burn when exposed to an open flame and extinguish as soon as the source of the fire is localized. And even in the event of a fire, eco-friendly insulation does not emit toxic and hazardous substances into the environment, such as, for example, materials that use formaldehyde, when they burn, they emit phenols and other substances hazardous to human life and health.

Today on the market of thermal insulation materials there is a sufficient number of heaters that fully meet all the requirements to be considered environmentally friendly.

The main types of ecological insulation

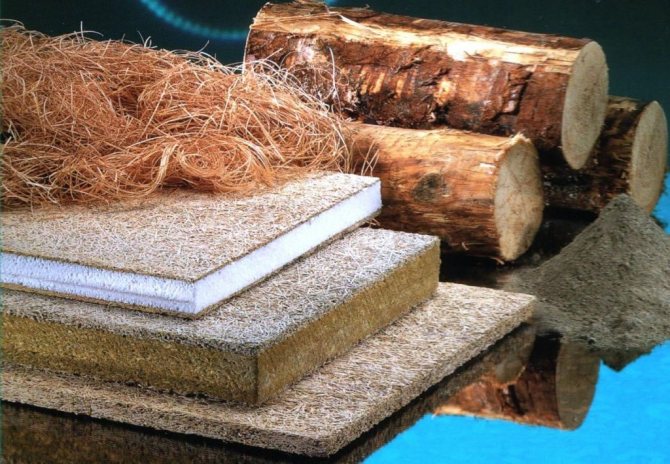

Eco-friendly heaters are vegetable and cellulose.

The first are:

- linen;

- cotton;

- moss;

- hemp;

- other natural materials.

Insulation is made from plant stems and seeds, which are combined with a binder and treated with a fire retardant.

A characteristic feature of these materials is their fibrous structure, which creates high noise and thermal insulation in any room.In addition, such a structure is distinguished by good vapor permeability, due to which the walls will pass oxygen well.

When choosing an environmentally friendly insulation, it is required to take into account that the quality of insulation depends on the thermal insulation qualities of the material and the correct installation of the insulation. It is best to use slabs and mats that adhere well to almost all surfaces. Therefore, there will be no "cold bridges" known to all, and heat losses are minimized. Due to this, they are indispensable for thermal insulation of buildings.

Important! To achieve high-quality thermal insulation of buildings and structures, you need not only to choose the right insulation, but also to properly mount it.

Types of eco-friendly insulation

As mentioned above, ecological insulation is a natural insulation consisting of natural fibers. Of the entire abundance of heat-saving materials, the following can be distinguished:

- ecowool;

- ecotherm;

- eco-thermal;

- ecolen;

- damask;

- bung;

- hemp;

- peat blocks;

- cotton insulation.

To evaluate all the possibilities and advantages of each insulation, let us dwell on each of them in more detail.

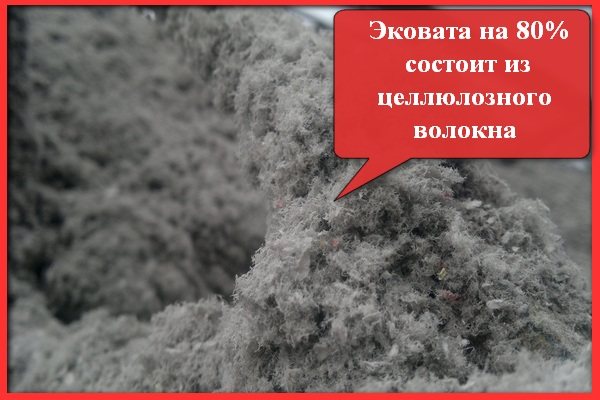

Ecowool

It is a breathable insulation made up of eighty percent cellulose fiber, which is simply waste paper. Twelve percent of the total composition is an antiseptic, represented by boric acid, and the last eight percent is borax, which acts as a fire retardant. Ecowool is also classified as environmentally friendly materials.

There are three ways to use insulation:

- Manual. The insulation is fluffed in a large container using a mixer nozzle on an electric drill or perforator. Specialists have a "gun" device for applying this insulation. Then they are stuffed by hand into the prepared cavities or niches in the quantities provided by the process technology.

- Mechanized or dry. Everything is exactly the same as with manual laying of insulation, only for large volumes of work, cellulose fiber is blown using a compressor or the same pistol. This greatly simplifies and speeds up the work process.

- Mechanized wet laying. Ecowool is fluffed up in a special bunker of a blow molding machine, and blown out under pressure, moistened with an aqueous solution through special nozzles. If necessary, an adhesive composition can be added to the cotton wool.

Ecowool from waste paper

Ecowool has the property of absorbing water, therefore, it is mounted with a gap for ventilation.

Environmentally friendly insulation, which is made from all types of waste paper (paper, cardboard, corrugated board, drywall) with the addition of boric acid and borax. The resulting material has strength, fire resistance, high heat, moisture, and sound insulation. The composition includes an antiseptic that prevents the formation of mold.

A layer of ecowool accumulates moisture over time and this increases its thermal conductivity. Therefore, when installing ecowool insulation, it should be possible to ventilate so that moisture does not linger inside.

The material tends to settle, so it must be applied with a volume margin. Installation of thermal insulation made of ecowool requires professional skills and equipment, since the material is supplied in the form of a mass that is blown by a compressor onto a dry surface or onto an applied glue.

Ecowool manufacturers: Ecovilla (Finland), Greenfiber (USA), OOO Ekovata Extra (Russia), Equator (Russia). The choice of a domestic manufacturer of ecowool is preferable due to the low price.

Ecoterm

Ecoterm is an eco-friendly insulation, which is 70% flax and 30% bicomponent polyester fiber. This fiber is the one that gives it sufficient strength and resilience.The ability to keep their shape well is an additional advantage during installation - the slabs can be installed between beams and joists without additional fasteners.

The main advantages of linen insulation:

- Durability - Expected service life of 60 years.

- Safe insulation. This means that it is absolutely hypoallergenic, leaving pleasant sensations from touching.

- Not subject to electrification.

- Antiseptic - parasites do not start in it, perfectly absorbs odors and purifies the air.

- Breathable - absorbs and releases moisture well, regulating heat exchange and humidity.

Natural antiseptic, absorbs excess moisture well and prevents the formation of mold and mildew. By its properties, the fiber is close to wood, and the use of linen thermal insulation in a frame house will help you easily get the effect of a “house made of logs” - the material allows the walls to breathe.

Flax is non-flammable, hardly flammable, and even when burning does not emit hazardous substances. In terms of fire safety, it is comparable to good quality basalt wool. Has excellent sound insulation. The use of plant fiber makes linen one of the safest insulation materials. It is produced in the form of plates with a thickness of 50 and 100 millimeters.

The qualities and properties of linen insulation allow you to work with it without fear, even when installing thermal insulation in children's rooms.

Environmentally friendly thermal insulation for home

Mineral wool and fiberglass

Safe insulation for walls and ceilings

Glass wool is widely represented on the Russian market with products under the Knauf, Isover and Ursa brands. These insulations are made from quartz sand and contain about 40% recycled glass. In fiberglass and basalt mineral wool (Izover, Izorok, Isobond and others), a small amount of formaldehyde or acrylic binders is used as a binder, as in URSA PureOne mineral wool.

During installation, inorganic thermal insulation - mineral wool and fiberglass - has significant drawbacks. When installing basalt slabs and mats indoors, the level of contamination with microscopic fibers significantly exceeds the norm. Particles of these insulation materials do not have a carcinogenic effect, but they can irritate the respiratory tract. Their disadvantages include the ability to absorb moisture and the possibility of settling.

Insulation for the house made of ecowool

Eco-wool also belongs to environmentally friendly insulation - insulation that is quite new on the Russian market. The material consists of two-thirds of cellulose and shredded waste paper, in addition to recycled paper, straw is also used. During production, substances that prevent combustion - fire retardants - are added to cellulose. The advantages of ecowool include the ability to absorb and quickly release moisture.

The disadvantages include the fact that cellulose insulation can rot and mold with constant moisture. Since ecowool consists of waste paper, it is a combustible insulation and cannot be called insulation that mice do not eat. This environmentally friendly insulation for the floor in a wooden house or walls in a frame house is easy to install and safe for the environment and human health.

Cotton home insulation

A photo. Choosing an environmentally friendly insulation

Organic cotton insulation is one of the most environmentally friendly materials today, as it is made from recycled jeans. Cotton slabs and mats can be laid independently without the use of personal protective equipment. Insulation has excellent sound insulation, so this material is often used in home theater equipment.

Cotton is a combustible material, therefore, during production, fire retardants are added to the insulation - substances that prevent combustion and the spread of fire.When installing cotton insulation, its slabs are quite difficult to cut, and laying the material will take a little longer than when working with mineral wool. Do not forget to use a vapor barrier when installing fiber insulation to protect it from moisture.

Linen home insulation

Linen mats have recently appeared in Russia under the Ecoteplin trademark. From the point of view of ecology, linen mats are absolutely pure insulation that does not emit toxic substances during operation. Linen, due to its natural origin, is safe for health and can be used in premises where safety requirements are especially high, for example, in hospitals and in kindergartens.

According to the manufacturer's assurances, the service life of linen thermal insulation is about 60 years, the material retains its original properties throughout its entire service life. The insulation is not exposed to mold and mildew, does not settle over time. Linen thermal insulation is difficult to ignite and does not support combustion, and in terms of heat resistance it significantly exceeds the glass wool considered earlier.

Sprayed polyurethane foam (PPU)

A photo. PPU frame house thermal insulation

Sprayed polyurethane foam is a safe material, since pure water acts as a foaming agent. Due to the absence of cold bridges and seams in the thermal insulation layer, a decrease in heat loss is achieved in comparison with traditional slab and roll materials by 1.5 times. Polyurethane foam (sprayed polyurethane foam) reduces the risk of condensation and mold on the treated surface.

The disadvantages of this insulation should be attributed to its relative high cost, the application of polyurethane foam on the surface is carried out using special equipment. Hydrofluorocarbons can be harmful to humans during application. Also, the disadvantages of insulation include the fact that polyurethane foam is destroyed under the influence of direct ultraviolet rays, thermal insulation quickly ignites and spreads fire.

Ecolin

One of the safest materials for linen thermal insulation is eco-linen. The mass fraction of flax plant fibers in the insulation is 85%. The remaining 15 percent are thermo-bonding fibers, thanks to which the insulation perfectly keeps its shape and does not lose volume, which makes it possible to use it for insulating surfaces of complex shapes.

Material release form - mats 5 or 10 centimeters thick. The heat transfer coefficient is ekolna 0.034 W / m ∙ K. The insulation is breathable enough, therefore, with a packing density of 25-30 kg / m3, it provides sufficient breathing to the walls, without allowing moisture to pass through. The service life should be 75 years.

Ecological heaters for frame houses

Sprayed polyurethane foam

Insulation of the strip foundation outside the PPU

Polyurethane foam is an ecological material; when thermal insulation is sprayed, ordinary water acts as a foaming agent. The material forms a continuous coating on the insulated structure without seams and cold bridges. The sprayed layer of polyurethane foam improves thermal insulation in comparison with board materials by 1.5 times and, due to moisture resistance, reduces the appearance of condensation.

When spraying polyurethane foam, fluorocarbons can adversely affect human health, therefore, PPE should be used when working. The disadvantages of the material include the flammability of the material and the destruction of the heat-insulating layer under the influence of sunlight. Therefore, polyurethane foam is best used to insulate a frame house or brickwork.

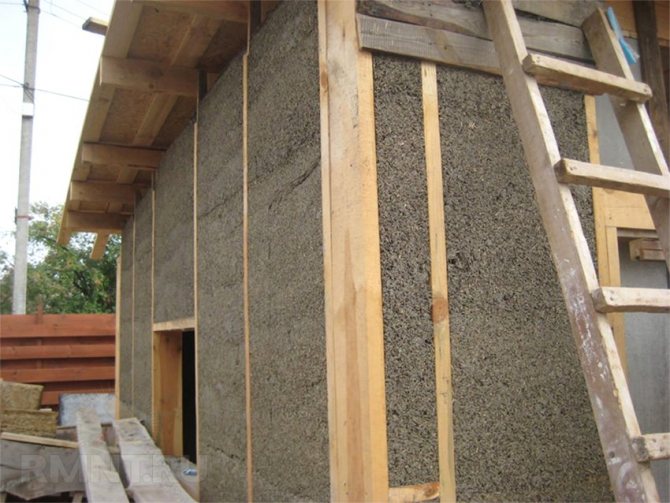

Ecowool insulation

Ecowool spraying on walls and floor blowing

Ecowool is one of the safest materials for insulating living quarters; the material consists of 75% waste paper and wood pulp.The material is used for insulating horizontal surfaces, as well as for laying between walls in a frame house. When working, protective equipment and respirators should be used, since fire retardants are added to the cellulose to prevent combustion.

The disadvantages of cellulose insulation from any manufacturer include high moisture absorption, but at the same time, ecowool quickly releases all the accumulated moisture into the environment. The vapor permeability of cellulose is two times lower than that of mineral and basalt insulation. Do not forget that ecowool is a combustible insulation, despite the flame retardant additives used in the production.

Bung

This eco-friendly insulation for walls and floors is made from the bark of branches or trunks of cork oak, which is widespread in the Mediterranean. The material has a cellular structure - there are up to 40 million cells in a square centimeter, filled with a special gas that resembles air in composition, but does not contain carbon dioxide.

The inner layers of the cork contain suberin - a natural glue, which is sufficient in the manufacture of cork insulation so that no additional synthetic adhesives are added during the agglomeration process. The wax protects against water penetration into the structure. Both of these components give the cork its firmness and elasticity.

The material does not burn without a source of open flame. Poorly flammable. When smoldering, it does not emit toxic vapors and substances.

Cork insulation is produced in the form of rolls of 1000x100 millimeters in size, plates or plates with a thickness of 1 millimeter to 5 centimeters. It is used for insulation of floors and walls of residential premises and premises with high humidity, and thanks to excellent sound insulation - and music studios.

Rating of the best heaters for a wooden house

| Nomination | a place | Name of product | rating |

| Rating of the best heaters for a wooden house | 1 | Basalt wool | 5.0 |

| 2 | Glass wool | 4.9 | |

| 3 | Ecowool | 4.8 | |

| 4 | Slag wool | 4.7 | |

| 5 | Jute | 4.6 | |

| 6 | ISOLON | 4.5 | |

| 7 | PENOFOL | 4.4 | |

| 8 | PENOPLEX | 4.3 |

Basalt wool

Rating: 5.0

Basalt wool has become the most popular insulation for wooden houses today. It is made from a natural, environmentally friendly material that melts at high temperatures and stretches into the finest fibers. Blocks and mats are subsequently formed from the stone threads. The heat insulator is characterized by non-flammability, versatility, good vapor permeability and moisture resistance. Experts first of all highlight the low thermal conductivity of basalt wool. On the basis of the insulation, many modifications have been created with an additional foil or fiberglass coating. The material deserves the highest step of the pedestal.

Homeowners note the ease of cutting and installation, sufficient strength and density, resistance to biodegradation.

Dignity

- environmental friendliness;

- low thermal conductivity;

- resistance to moisture and biodegradation;

- breathability.

disadvantages

- not detected.

Glass wool

Rating: 4.9

Until recently, glass wool was the undisputed leader among the few heaters for a wooden house. But today it is gradually losing ground. Experts attribute this fact to the fragility of fiberglass. During work, the smallest sharp pieces of glass are formed, which get on the skin and in the respiratory organs of the builders. Glass wool has a number of advantages. It keeps warm well, withstands the test of moisture and microorganisms. The advantages include vapor permeability and elasticity. Currently, manufacturers have developed modifications with a foil film.

Many builders know that it is necessary to work with glass wool using PPE. Homeowners should also remember this when it becomes necessary to contact the insulation.

Dignity

- low price;

- strength and elasticity;

- resistance to moisture and biodegradation;

- efficient heat preservation.

disadvantages

- danger to human health.

Ecowool

Rating: 4.8

The choice of a wooden house is largely due to the desire of a person to live in an environmentally friendly structure. Therefore, the insulation must meet this requirement. Ecowool is a waste of pulp and paper production. The heat insulator consists of 80% wood products. Experts recommend using ecowool to create the most comfortable microclimate. The insulation is breathable, it does not cause allergies in people, mold or mildew does not form in it. The material is produced both in crumbly form (in bags) and in pressed (plates). The disadvantage of the material is called flammability by experts.

Users appreciate the environmental friendliness of the insulation. But with installation, difficulties often arise, so it is better to entrust the work to professionals.

Dignity

- environmental friendliness;

- ease;

- vapor permeability;

- resistance to biological damage.

disadvantages

- flammability;

- hygroscopicity.

Slag wool

Rating: 4.7

Since the days of the Soviet Union, the slag formed at metallurgical enterprises has been used in the construction of houses as insulation. Today this heat insulator has acquired a modern appearance; it is supplied to the retail network in the form of familiar mats and plates. There are modifications with a one-sided foil surface. Experts believe that the advantages of slag wool are flexibility, low thermal conductivity, and noise insulation. The smell of slag scares away insects and rodents, which is important for a wooden house. And another advantage of the material is its low price.

Russian builders have well studied the strengths and weaknesses of slag. They call hygroscopicity a minus; after getting wet, an acidic environment is formed in the insulation, which corrodes the hands.

Dignity

- affordable price;

- flexibility;

- noise insulation properties;

- scares away rodents and insects.

disadvantages

- hygroscopicity;

- causticity.

Jute

Rating: 4.6

When building a house from a bar, an obligatory operation will be the insulation of the joints between the joints. Since the tree deforms over time, shrinks, gaps may appear between the logs or beams. Jute helps to solve the problem, it replaced the traditional moss and flax fiber. The most convenient option, according to experts, is to purchase a jute tape. It rolls out over the surface of the timber and targets the tree with metal staples. The advantages of jute include environmental friendliness, resistance to moisture, adhesive ability, high heat-saving properties.

The builders faced such a negative moment when warming with jute as stiffness. Therefore, the width of the tape should be less than the timber, and it is better to caulk the cracks with a cord.

Dignity

- environmental friendliness;

- adhesive ability;

- low thermal conductivity;

- ease of installation.

disadvantages

- high price;

- rigidity.

ISOLON

Rating: 4.5

At all stages of the construction of a wooden house, modern insulation Izolon can be used. It is done by foaming polyethylene with propane, the output is a heat insulator in the form of plates, rolls or tapes. Manufacturers offer different modifications, there is Izolon with a foil surface, some heaters have a self-adhesive layer. Experts have highlighted several advantages of synthetic material. Along with low thermal conductivity and lightness, high resistance to moisture is considered an important advantage. Builders like the simplicity of Izolon installation. The heat insulator gets a place in the TOP-6 for its versatility.

Users appreciate the environmental friendliness of the insulation, heat resistance, durability. Of the minuses, a high price is mentioned.

Dignity

- excellent thermal insulation properties;

- soundproofing ability;

- zero water absorption;

- ease of installation.

disadvantages

- high price.

PENOFOL

Rating: 4.4

When you need to make a thin layer of thermal insulation in a wooden house, you should pay attention to Penofol. Despite its small thickness, the insulation effectively retains heat in the house. The material is available in several versions. There is one-sided and double-sided foil coating, and manufacturers also offer a reflective aluminum layer on one side, and a self-adhesive surface on the other. Since Penofol is not afraid of moisture or frost, it can be fixed both on internal and external bases. Experts have no complaints about the heat insulator regarding environmental friendliness, ease of installation and durability.

However, builders argue that it is not always possible to use only Penofol. More often you have to combine it with another insulation.

Dignity

- lightness and elasticity;

- high reflectivity;

- variety of models;

- durability.

disadvantages

- narrow scope.

PENOPLEX

Rating: 4.4

Penoplex is a very effective heat insulator for wooden buildings. He became popular with the inhabitants of the Far North and Siberia. It is made of expanded polystyrene using innovative technology. The result is a strong protection against cold, which can be applied to such types of finishing materials as plaster, putty or paint. Experts have highlighted such advantages of Penoplex as lightness, ease of use, durability. Insects and rodents do not start in the synthetic layer, mold and fungus do not form. Only poor vapor permeability did not allow the insulation to take a higher place in our review.

To solve the problem with high humidity in the house, you have to arrange a ventilation system. In addition, the material has a high price and burns well.

Dignity

- low thermal conductivity;

- strength;

- finishing materials can be applied;

- ease.

Hemp

As a heater for a wooden house, hemp has recently been widely used. Generously endowed with antiseptic properties by nature, it is not susceptible to the formation of fungus and mold itself and helps to protect the structures of the house from them.

It does not lose its qualities and properties under the influence of water - due to this, it is used for warming rooms with a high level of humidity.

Recommendations for choosing insulation for a wooden house

Environmental friendliness

... Since the construction of a wooden house implies the desire of future residents to live in a comfortable and harmless microclimate, then at the first stage you should limit your choice in terms of environmental friendliness.

- Heaters made from natural raw materials are considered the safest. It can be mineral (stone, slag, glass) or organic (flax, jute, cellulose) materials. But it is important to pay attention to the manufacturing technology. If phenolic or formaldehyde resins are used as a binding component, then harmful compounds will get inside the wooden house.

- With synthetic insulation, the situation is even more complicated. Most technological chains contain compounds that are harmful to human health. However, the output can be a completely safe and environmentally friendly product. Here you have to completely rely on the opinions of experts.

Durability.

As the history of Russian wooden architecture shows, the service life of houses made of logs or beams reaches 300 years. Therefore, during construction, it is important to choose a durable insulation. With the correct use of the heat insulators selected for our review, they will last at least 100 years.

Water vapor permeability.

In order for a wooden house to breathe during operation, it is necessary to choose heat insulators with high vapor permeability. Only in this case it will be possible to maintain normal humidity in the premises and prevent the appearance of mold and mildew. Otherwise, you will have to build an expensive ventilation system.

Appointment.

The house should be insulated from all sides; not every heat insulator is suitable at all stages of construction.

- To protect the floor from the cold, it is recommended to use moisture resistant materials. Basalt wool or penoplex can cope with this task.

- Jute tape or rope will help create an insulating layer between the crowns of the house.

- The widest range of heat insulators can be used to protect walls from cold. Moreover, some should be mounted outside, while others - from the inside. For internal insulation, it is necessary to choose the most environmentally friendly products, and external decoration is best done using non-combustible, frost-resistant and moisture-proof materials.

- Insulation materials with high moisture resistance, which do not attract insects and rodents, will be used in the roofing cake and in the attic. If it is not planned to make living rooms in the attic, then both natural and synthetic heat insulators will do.

We have selected the 8 best heaters for a wooden house in our review. You can buy them in hardware stores in our country. When allocating seats, the editorial staff of expertology magazine relied on the opinion of the expert community, taking into account the reviews of Russian builders and homeowners.

Peat blocks

Peat block is a natural, eco-friendly insulation for your home. Peat raw materials are ground with the addition of water, after which a filler is added to the resulting composition, which can be used as natural sawdust or shavings, straw, hemp or flax fire. The resulting mass is molded and dried until completely solidified.

The blocks are used to lay out walls, floors, and sometimes even ceilings of buildings. However, there are factors that can negatively affect the insulation - this is moisture. By accumulating water, the material changes its structure and quality characteristics.

The material is quite flammable and belongs to the G1 group.

Cotton insulation

Probably the most environmentally friendly home insulation is cotton mats. The material can be rolled up. Cotton insulation is made from recycled cotton fabric, simply from jeans and polyester fibers. The percentage of the components is 85% cotton and 15% heat-bonding fibers.

It is produced in the form of mats with a size of 1000 x 600 millimeters, a thickness of 20 or 50 mm and a density of 45 kg / m3 or 80 kg / m3, respectively. The thermal insulation qualities of cotton insulation are not inferior to basalt wool, while it has excellent sound insulation.

Due to its properties, cotton as insulation is used for paneling and interior decoration of such specific premises as home theaters. Insulation work can be carried out independently. Environmental friendliness of the product allows you to do without the use of personal protective equipment.

The disadvantage of using this heat-saving composition is the difficulty of cutting it.

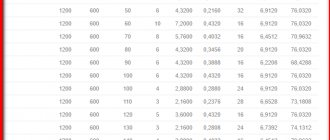

Comparative table of environmentally friendly heaters

| Insulation | Thermal conductivity coefficient, W / m ∙ K | Density, kg / m3 | Price |

| Ecowool | 0,032-0,041 | 30-75 | 30-40 rubles / kg |

| Ecoterm | 0,038-0,04 | 20-34 | From 5.15 rubles / mp |

| Ecoteplin | 0,038-0,04 | 32-34 | From 1200 rubles / pack |

| Ecolin | 0.0366 | 15-20 | From 1250 rub / pack |

| Damask | 0.087 | 80-90 | 200 rub / m2 |

| Bung | 0.04 | 245 | From 1020 rub / pack |

| Hemp | 0.036 | 20-30 | From 2500 rubles / pack |

| Peat blocks | 0,047-0,08 | 200-380 | |

| Cotton insulation | 0,037-0,041 | 80 | From 2360 rub / pack |

Material prices are for comparison purposes only. Each category of thermal insulation materials is represented by product lines that differ in both physical characteristics and the size of the packaging of the material that fall into the retail chains. More detailed and accurate prices for the material you have chosen can always be found on the manufacturer's website.

Output

Natural insulation based on natural natural fiber was presented to your attention.Manufacturers of these products position them as safe for use and environmentally friendly. When choosing a material, you need to build on not only the cost of the insulation. Do not forget that your home should be comfortable, cozy, and most importantly, safe for your health and the health of your children, family and friends.

Insulating the outer walls and the facade of the house, it would seem, it is possible to neglect the requirements for environmental friendliness and safety of thermal insulation. But the cracks and cracks that open to ventilate the window are all that open up direct access to all harmful and toxic substances in your home. Therefore, once having saved on seemingly small things, you run the risk of having serious health problems.