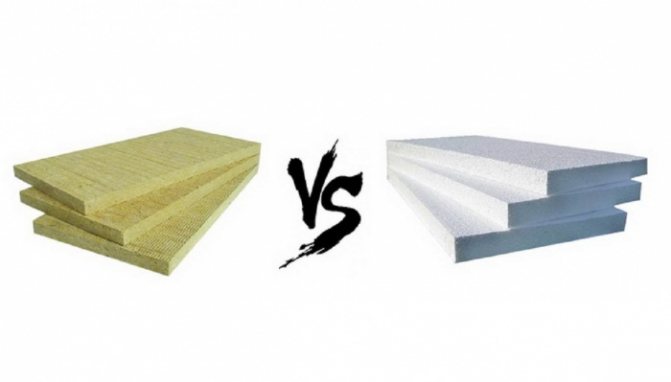

Today we will figure out what is better for foam or mineral wool for home insulation. We will look at the defining characteristics of materials and draw conclusions based only on facts. Looking ahead, we will say that as a result, mineral wool is much superior to polystyrene in a number of characteristics and cost. EPPS is a material with a narrow focus, it is out of competition when it comes to warming the foundation or laying in the ground.

What is better for foam or mineral wool for thermal conductivity

EPS is the warmest.

Oddly enough, but the seemingly obvious choice of thermal insulation drives many into a stupor. Let's start with what is warmer: foam or mineral wool. What better retains heat can be determined by the coefficient of thermal conductivity. Thermal conductivity is the ability of a material to conduct heat. This value is expressed by a coefficient that shows how much heat passes through a unit of length and area of the insulation, per unit of time when the temperature drops by one degree. The thermal conductivity is expressed in watts per meter-Kelvin (W / m * K). The lower the value, the worse the material conducts heat. Accordingly, it is more effective as a heater.

To figure out what is warmer than polystyrene or mineral wool, let's look at the data declared by the manufacturer:

- ordinary foam 0.033-0.037 W / m * K;

- extruded polystyrene foam 0.029-0.034 W / m * K;

- mineral wool 0.036-0.045 W / m * K.

The thermal conductivity of foam and mineral wool is affected by the density of the material. The higher the density, the worse the thermal insulation qualities. This is especially noticeable in the example of fibrous insulation.

If you choose exclusively for thermal conductivity penoplex or mineral wool, then, of course, EPS is better, but it is not suitable in all cases. Even ordinary foam is more effective than mineral wool, since the average lambda of fiber insulation is about 0.04 W / m * K.

Mineral wool specifications

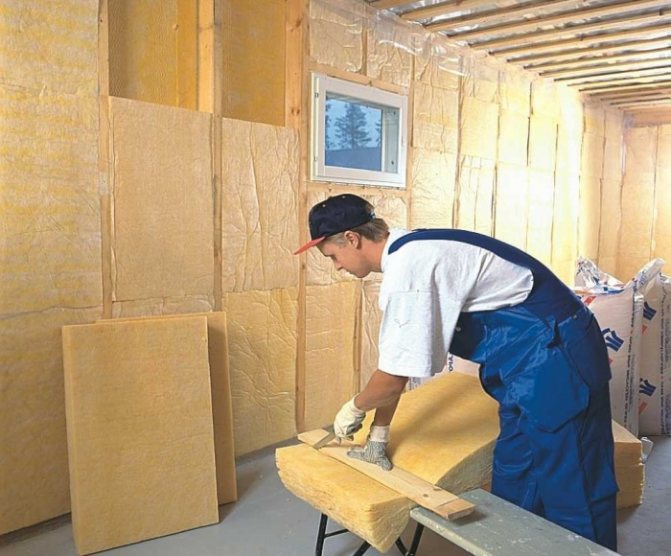

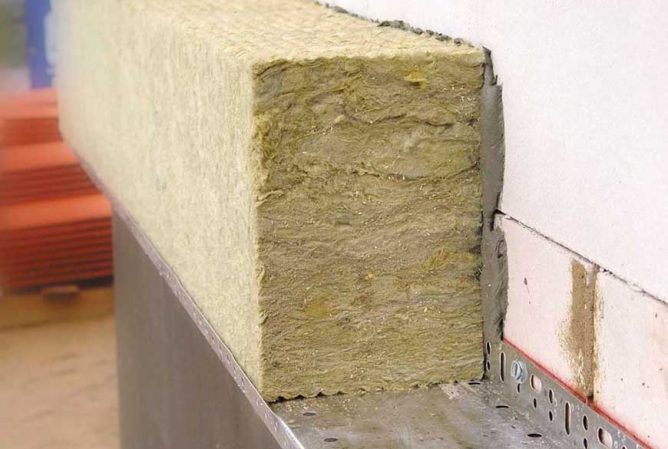

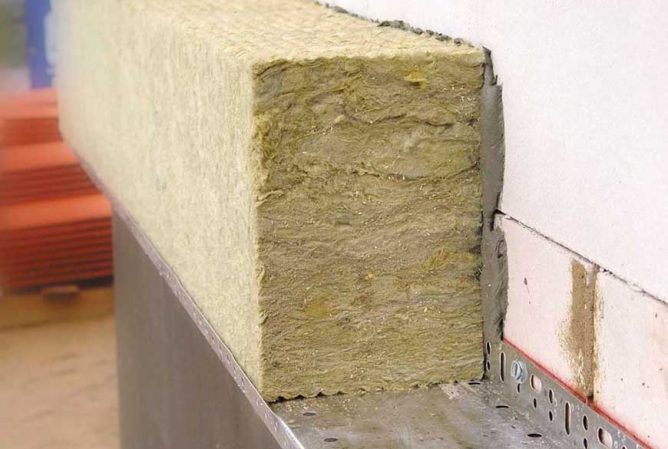

Mineral wool is a building material produced by melting rocksforming a fibrous substance. This building product can be praised for the presence of only natural ingredients in the composition, sound insulation, and high fire resistance.

Mineral wool products are slabs and rolls of elastic material that can be formed without much effort into a surface of any shape. Also, this insulation is good against biological pests (mold, fungus), rodents and more. Alas, the material cannot boast of hygroscopicity: a large amount of moisture, getting into the mineral wool, destroys its thermal insulation properties.

When planning to use mineral wool as insulation, you should know that there are several types of this building material, in the properties of which there are many differences:

- Glass wool... It is used for thermal insulation of non-residential premises, since its composition includes formaldehyde. But due to its composition, it is the cheapest material.

- Slag... It is capable of bypassing oxidation processes in contact with metals, well suited for insulation of external surfaces, pipes, etc.

- Stone wool... Stronger than glass wool and slag wool, but absorbs more moisture.

- Basalt wool... Absolutely non-flammable, soundproofing insulation that is least able to resist moisture.

Hygroscopicity of mineral wool and polystyrene

This is where editing errors lead.

The second equally significant factor that will help determine what is better for foam or mineral wool for insulation is hygroscopicity (the ability of the material to absorb moisture). Moisture absorption is measured as a percentage of the weight of the material per day. That is, how much moisture as a percentage of its own weight is absorbed by the insulation when immersed in water for 24 hours. Declared characteristics:

- polystyrene not more than 1%;

- extruded polystyrene foam 0.04%;

- mineral wool 1.5%.

The degree of water absorption of the insulation determines the possible areas of its application. For example, EPSP practically does not absorb moisture, therefore it is used for laying in the ground. The foam from moisture begins to crumble, and the mineral wool, when it gets wet, does not hold heat at all, so there is not much sense from it either. At the same time, starting only from the hygroscopicity of materials, it is impossible to determine the best way to insulate a house with foam or mineral wool. The question must be considered in a complex and the following characteristic is important.

There are stoves for a house on a long-burning coal that are heated by convection, and there are ones with a built-in heat exchanger for water heating.

You can read about how the Buleryan oven works here.

Comparison by main parameters

- Thermal insulation.

Mineral wool has an index of 0.032-0.046, while penoplex has a coefficient of 0.03-0.032. The lower the indicator, the better, because the heat loss is lower and the indoor temperature is better maintained.

Penoplex is a fairly hard material that does not lend itself to rotting, drying out and crumbling. Insulation has a long service life under the correct storage conditions, when it is reliably protected from prolonged sunlight and excessive heat. Mineral wool also does not dry out. Without the impact of high physical exertion, it is able to serve for a long time, is not afraid of high or low temperatures and long exposure to sunlight on the surface.

It is not threatened by the occurrence of mold and other harmful organisms, and it also does not lend itself to destruction by rodents. But the mineral wool is capable of crumbling and settling on the wall. In general, both materials have an enormous service life of at least 50 years.

- Environmental friendliness.

Both materials are manufactured without the use of any hazardous ingredients that could harm human health, but nevertheless, it is required that absolute isolation is carried out to protect the respiratory tract.

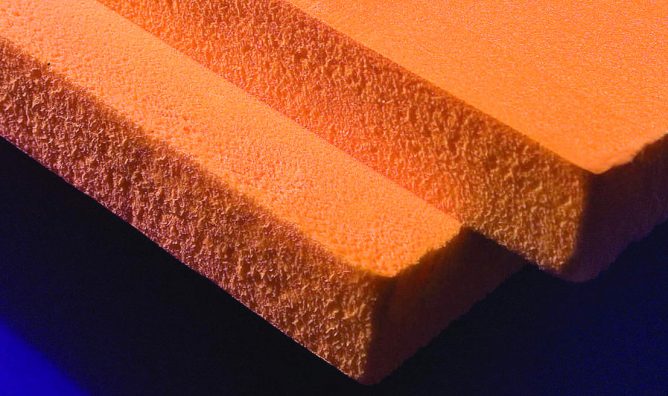

When insulating a perfectly smooth surface, work with foam is carried out much faster. It is lightweight, easy to cut and amenable to grinding, and in the presence of an L-shaped edge, it excludes the formation of cold bridges. When using it, it is not necessary to cover with a vapor barrier. If there is no thorn-groove edge, then it is tedious to seal the seams or to lay them in two overlapping layers, which will lead to unnecessary costs.

Mineral wool has a slightly higher weight, but it is much more effective, and simplifies installation with existing heavy disproportionate areas and structures. But when working with it, you must purchase special clothing in advance, along with a respirator and goggles.

In the case of use for warming the facade of a house, if the penoplex will have a thickness of 50 mm, then the mineral wool must have a thickness of 60 mm in order to have a similar effect. The difference is not entirely dramatic. Depending on the situation, each of them is good in its own way, because cotton wool is able to pass air, unlike foam, which has an absolutely sealed structure.

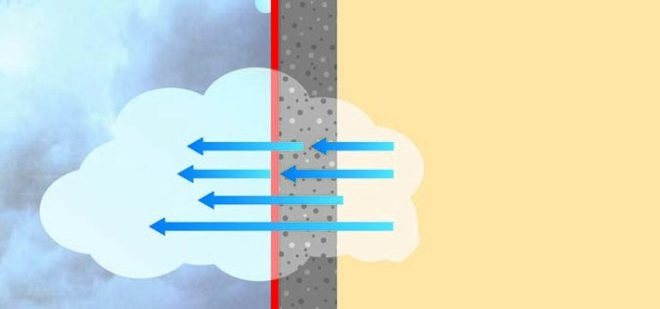

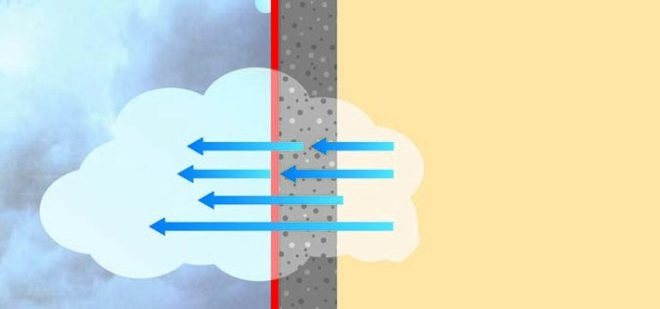

Water vapor permeability of mineral wool and foam

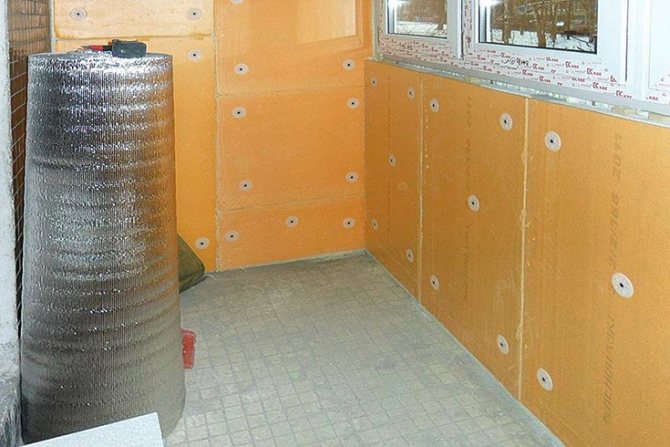

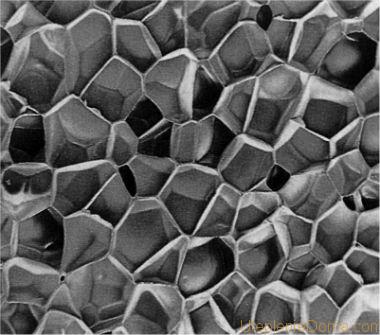

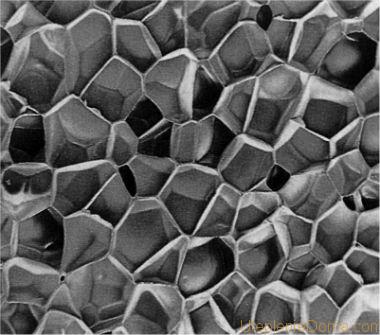

Closed-cell structure of the foam due to which it does not allow steam to pass through.

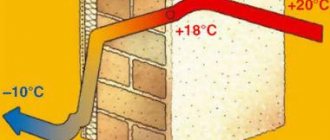

Vapor permeability is the ability of a material to conduct steam, as people say - to breathe. Water vapor permeability is expressed in mg / m * h * Pa. This is a pair in mg, which passes in an hour through 1 square meter of insulation with a thickness of one meter. In this case, the condition must be observed that the temperature on both sides of the insulation is the same and the water vapor pressure is 1 Pa. The value of vapor permeability is especially important when you decide the best way to insulate a wooden house with foam or mineral wool. Although this indicator is also relevant for bricks with concrete. The accumulation of moisture leads to negative consequences - the formation of fungus, a decrease in the thermal resistance of the enclosing structure, and a reduction in the service life.

Let's look at the manufacturer's declared values:

- foam 0.05 mg / m * h * Pa;

- extruded polystyrene foam 0.013 mg / m * h * Pa;

- mineral wool 0.3-0.5 mg / m * h * Pa.

Foam plastics are materials with a closed-cell structure, so they practically do not allow steam, especially EPS.

You can make a Bubafon stove with your own hands from a barrel or a gas cylinder in just one day.

It turns out that you need to know how to properly heat a stove with wood. Details here.

Pricing

rock wool roll

A square meter of 100 mm thick polyurethane foam costs from 300 to 500 rubles, depending on the grade. The minimum wire thickness of 100 mm per square meter ranges from 75 to 150 rubles, depending on the type and grade.

Mineral wool is the most suitable insulation material for a limited budget. If the funds allow you to insulate, for example, a wooden house in the open air, then it is better to carry out other materials. In this case, pay attention to the foam insulation.

Which material is better in operation

Polystyrene burns, a house can catch fire like a match.

In principle, the installation is almost identical, so there is no particular difference that mineral wool or foam is used. What shows itself better during operation is another question. Here we will look at several aspects:

- shrinkage;

- fire safety;

- toxicity;

- mouse.

Polyfoam and its derivatives do not shrink at all. Mineral wool of low density can settle, but above 85 kg / m3. cube and wall heights up to 3 meters is unlikely. If you select thermal insulation according to the recommendations of the manufacturers and adhere to the correct installation technology, then this problem is completely removed.

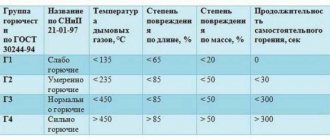

Polyfoam and EPS cannot boast of fire safety. Both materials support combustion while emitting toxic fumes. With this material, you need to be extremely careful, if a fire source occurs, the insulation will burn out very quickly. Minvata does not burn at all, it can withstand temperatures of 750 degrees. It is even used to insulate chimneys. Foam plastics are toxic and full of carcinogens, so that marketers do not say there about its environmental friendliness. Many types of mineral wool are also harmful, as they contain phenol-formaldehyde, while there are acrylic-based materials that are absolutely safe.

Another problem is mice. They successfully live both in polystyrene and in mineral wool, although they like polystyrene more. In the book "10 thousand tips and teachings for all occasions" from the cartoon "The Enchanted Boy" of 1955, little Niels read: "To get rid of rats and mice once and for all, it is best to get a young and healthy cat." The advice is still relevant.

Minwata and its features

Mineral wool is a fibrous material. It is made by melting silicate alloys of rocks and mixtures of metal slags... Mineral wool is often used to insulate residential buildings, namely:

- walls;

- ceilings;

- facade;

- roofs.

Minvata has many positive qualities, so it is one of the most popular in building insulation. Its main advantages include:

- fire resistance, even in direct contact with fire does not support combustion;

- vapor permeability - this quality allows you not to create condensation on the surface;

- good thermal insulation properties allow for indoor and outdoor use;

- sound insulation, this quality often becomes decisive when choosing thermal insulation materials;

- environmental friendliness

Mineral wool also has several drawbacks., so you should pay attention to negative properties:

- hygroscopicity, so that moisture does not penetrate, it is necessary to perform waterproofing;

- in the process of working with glass wool, it is necessary to observe safety measures;

- in some grades of material in the composition there is the presence of formaldehydes;

- for the material in the slabs, it is necessary to create a powerful crate.

The difference in the cost of foam and mineral wool

Cost in Moscow for 2020.

The last aspect is selfish, it lies in the fact that foam or mineral wool is cheaper? Consider the prices in Moscow for 2020:

- polystyrene 50 mm costs 145 rubles. for 1 sq.m .;

- extruded polystyrene foam 50 mm costs 238 rubles. for 1 sq.m .;

- mineral wool (universal) 50 mm costs 70 rubles. for 1 sq. m.

As you can see, mineral wool is 2 times cheaper than conventional foam and 3.5 times cheaper than EPS. The installation of mineral wool involves the use of steam and waterproofing, but even in a complex it will be cheaper.

Based on all the characteristics we have considered, we can say for sure that foam or mineral wool is better for insulation. In our opinion, the mineral wool won this competition. It is practically not inferior to foam in terms of thermal conductivity. At the same time, the fibrous thermal insulation allows steam to pass through, does not burn, and is environmentally friendly. The high degree of water absorption is compensated by the installation of steam and waterproofing films. And most importantly, mineral wool is twice as cheap as polystyrene and three times as cheap as EPS.

What is insulated with mineral wool

Mineral wool has its own characteristics, which must be taken into account during its installation:

- This material is most often used to insulate wooden houses. This is due to the fact that wood walls need to "breathe". Polyfoam for insulation in this case is not suitable. In this case, the beneficial properties of the tree will be nullified. If the facade is insulated, it must be of the hinged ventilated type. In such walls, a vapor barrier membrane is required.

- Minvata is used to isolate attic rooms.

- Basalt wool is used in three-layer concrete panels.

- Since mineral wool is capable of perfectly tolerating high temperatures, it is used to protect a room from heating objects.

- It is better to insulate any frame buildings with mineral wool. In addition to thermal insulation, it insulates the premises well from external noise.

- Heat pipes are often wrapped with this material.

These features of the use of mineral wool should be taken into account before starting insulation. Now, knowing the features of popular heaters, it is much easier to figure out which is better - foam or mineral wool.

Comparative analysis of the main criteria for insulation

To understand which insulation is better to choose for solving the task at hand, it is worth considering the technical characteristics of both options.

Steam permeability

Vapor permeability indicators for thermal insulation materials differ:

- foam - 0.03 mg / (m.h.Pa);

- mineral wool - about 10 times higher.

This means that rock wool is more vapor permeable. Practice shows that thermal insulation is multi-layer, and each layer has its own vapor permeability coefficient.

If the insulation assumes the presence of a polymer structure, then roll heat insulators are not recommended to be used.

The base and the outer layer of the thermal insulation system, made with the participation of polymers, are minimally moisture-permeable. The ingress of condensate inside is fraught with a deterioration in the basic thermal insulation characteristics of the insulation.

Vapor permeability

Polyfoam is not able to pass moisture, but it cannot accumulate it. Steam escaping from the side of the rooms is easily discharged through irregularities and gaps. It is unequivocally difficult to say whether this is a disadvantage or an advantage.

Moisture build-up

In the manufacture of mineral wool insulators, adhesives are often used, but the material is characterized by increased water absorption. Indicators vary depending on the density. For foam, this indicator is less and almost tends to zero.

Fire resistance

This parameter is at a height for mineral wool heaters - mineral wool wool does not burn, does not contribute to the ignition of a flame, but melts only at very high temperatures, which can only be achieved in industrial conditions.

Fire resistance

Stone wool mats and slabs can easily withstand temperatures up to 1000 ° C.

Expanded polystyrene resists high temperatures poorly - it melts, burns itself and easily supports combustion. To improve performance, special compounds are added to the material in production - fire retardants. But their action ends over time with prolonged exposure to fire and high temperatures. Therefore, foam plastic cannot be considered fireproof.

Environmental friendliness

Previously, in the production of foam, freon was added to the composition, which gave off dangerous fumes. Today, foreign and Russian manufacturers have stopped adding this element due to high environmental requirements.

Ecological cleanliness

For external insulation, expanded polystyrene can be used without restrictions, but for internal insulation it is worth reducing the amount of material, as an alternative - replacing it with roll insulation, characterized by high environmental friendliness.

Resistance to heat loss

Coefficients of thermal conductivity of heaters indicated by manufacturers practically do not differ from each other. However, when insulated, foam shows better results. Although the wool in the slabs is not inferior to expanded polystyrene in terms of thermal conductivity, rolled counterparts cannot boast of this.

Note that the room insulated with mineral wool cools much faster than the one where the foam insulation was carried out.

Even inexpensive expanded polystyrene outperforms heat insulators in rolls. In case of joint multilayer insulation, the outer layer should be mineral wool, and the inner layer should be foam.

Ease of installation

Extruded or ordinary polystyrene foam is the material that is most convenient to work with. It is easy to cut, no special equipment and tools are required for processing.

Dense and lightweight, it is available for work even with the participation of amateurs in the process. Minus - loose edge joining. This leads to the appearance of cold bridges. The solution to the problem is the use of plates with an L-shaped edge. They fit together without gaps and, accordingly, cold bridges.

Mineral wool insulation also has a low weight, although more than that of foam. No complicated and expensive tools are required to cut them to size.

Cons - the occurrence of dust during the installation process - fragments of mineral fiber, as well as a lower density (in order to avoid caking and slipping, it is better to use mineral wool boards). But the joints of the material are so tight that blowing and cold bridges are simply excluded.

Durability

Polyfoam is not considered one of the most durable insulation building materials. Over time, it can be destroyed under the influence of moisture, wind, ultraviolet rays of the sun.But it is worth remembering that usually the design implies a protective layer over the insulation. These can be both facing materials and special plasters, putties.

Competent installation and protection of expanded polystyrene allow you to achieve a fairly long service life of the heat-insulating layer - up to 50 years.

Life time

Mineral wool can last for centuries. It is made from volcanic rocks for maximum durability. The only thing that can cause a decrease in the thermal insulation characteristics of the material is caking of mineral fibers. To prevent this from happening, you need to choose the right type of mineral wool insulation. For horizontal surfaces, mats of sufficient thickness are often used, vertical ones are better to be insulated with plates. They are denser, so they do not cake or slip.

Price

The cost of heat insulators is about the same. The price is influenced not only by the density of materials, but also by the fame of the manufacturer. In addition, it may also differ in different hardware stores.