A do-it-yourself heat gun is made in the case when it is necessary to heat a room that does not have central heating, and there is no opportunity to purchase an industrial heater. In addition, a homemade heat gun will be an excellent way out of a situation when the owner needs to maintain a certain temperature in a non-residential premises, for example, a workshop or hangar, in order to ensure the operability of production.

Classification

If we consider this equipment from the point of view of power, then it is possible to distribute the guns on household and industrial. If we consider heat guns by their power source, then they are divided into:

- diesel;

- infrared;

- electrical;

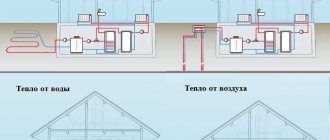

- aquatic;

- gas;

- multi-fuel.

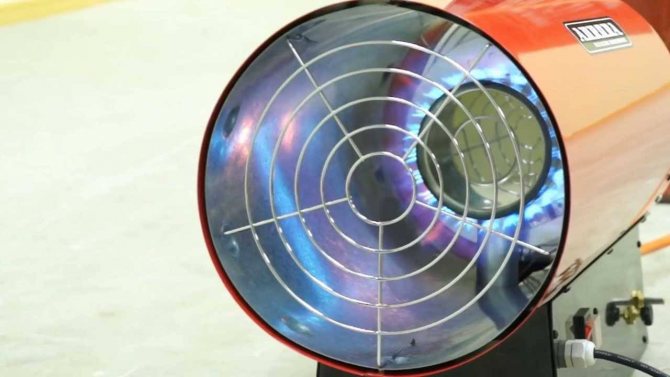

Diesel heat guns run only on diesel fuel and are lightweight. They can also be direct heating or indirect. For safety reasons, indirect heating is preferable, since combustion products do not enter the room, but are displayed outside.

Electric heat guns have the widest consumer audience, as they

safe and environmentally friendly, they also do not burn oxygen and have an automatic shutdown / shutdown mode to maintain the desired air temperature.

Water heat guns represent a container of water, a heater and a fan. Cannons of this kind are often used in agricultural purposes. Gas-fired heat guns are also very economical, they can be stationary (connected to the gas communication system) and mobile (connected directly to the gas cylinder).

Infrared heat guns are complex mechanisms that generate heat using infrared radiation, it is important to note that there are no fans in them.

And, finally, multi-fuel heat guns are excellent in that they can work on a used engine and hydraulic oil. It should be noted that those types of guns that run on liquid fuel are not recommended to be installed in crowded places and in hard-to-reach airing places.

With a certain set of knowledge about the principles of the operation of units, some of the types of guns can be made independently.

https://youtu.be/T933E7F48t0

What should you pay attention to when making?

When self-assembling a heating device such as a heat gun, it is worth remembering a few points. The average power of such devices ranges from 1.5 kW to 45 kW. If you need more power, then it is recommended to design a diesel heat gun with your own hands.

During manufacture, all connections should be carefully checked for isolation. You should not engage in self-assembly of an electric heater in the case when you do not even have basic knowledge of electrical engineering.

A self-made heat gun must be registered with the fire authorities. This will save the owner from a fairly large fine for non-compliance with fire safety rules.

DIY electric heat gun

The most readily available in its manufacturing method is an electric heat gun. For its construction, it is necessary coil from a heating device (old iron or electric stove). Further, the sequence of actions is as follows:

- To enhance the heating function, the coil is slightly shortened.

- An asbestos-cement pipe is taken and a heating coil is fixed inside it, there should be a free space on one end of the pipe, since there will be a fan.

- Wires are attached to the spiral, which will be connected to the network, do not forget about the rheostat, which will be responsible for the degree of heating.

- The propeller is put on an electric motor, which is also mounted in the tube.

It is worth remembering that the power supply of the spiral and the power supply of the fan are made separately. The electric heat gun is ready!

Functional features

When you do not have the material opportunity to purchase a patented factory-made apparatus, then a home-made heat gun is the only way to fulfill your planned repair or construction plan.

The principle of operation of such a unit is simple: heating elements are installed in a pipe made of asbestos or some metal, or a spiral is placed in a special way. On one side, a powerful fan is inserted, which blows air into the pipe, where it heats up and is discharged into the room through the opposite hole.

Such electrical devices really quickly heat up rooms of various sizes. It all depends on the power of the heating elements: the more powerful, the faster the optimal temperature is created. There is only one negative point - this is a large energy consumption and rapid air drying. When used in a residential area, an open container of water should be placed next to it to humidify the air.

A do-it-yourself heat gun is often made by garage craftsmen to heat these rooms in the winter.

DIY Diesel Heat Gun

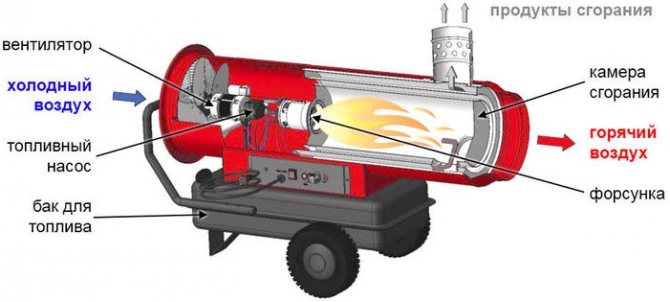

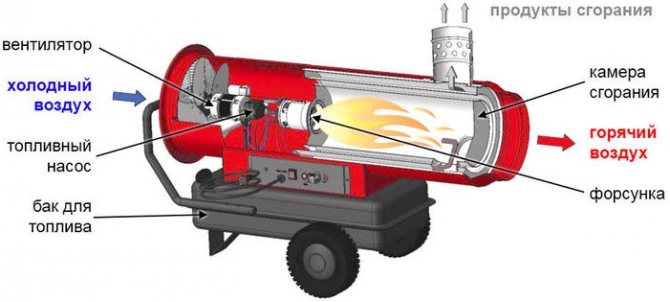

If you need to make a diesel heat gun, then you should understand principle of operation this unit: when burning diesel fuel, warm air and combustion products are blown out.

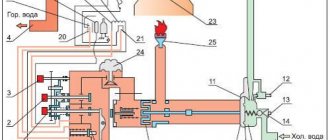

This type of heat gun consists of two bodies. The lower body is a fuel tank, it must be made of some material that has low thermal conductivity. It is also recommended to lay an additional thermal insulation layer. Further above the fuel tank at a height of 15-20 centimeters is located gun body. The material of execution can be a steel pipe or a pipe made of another metal with thickened walls. The manufacturing process contains the following steps:

- An electric motor with a fan, a fuel pump with a nozzle and a combustion chamber are installed and fixed inside the pipe.

- The ends of the pipe are covered with gratings.

- Between the body of the gun and the fuel tank there is a pipe with a filter, passing through which, the fuel enters the nozzle and ignites.

- The combustion chamber is a pipe half the diameter, firmly fixed in the center of the body. It has a vertical outlet - it is from there that the combustion products will be removed.

This heat gun is already for more advanced "users".

Self-made diesel cannon

The unit, running on diesel and diesel fuel, can not only be purchased at a special equipment store, but also made by hand.

It is important to know that assembling that device is a rather complicated process. It is available only to experienced home craftsmen who know how to handle a welding machine and other sophisticated equipment.

The diagram shown in the figure is not the only possible design option for a heat gun. The arrangement of the components can be varied based on ease of use (+)

Having decided on your own creation of a diesel heat gun, first of all, take up the choice of the model design. Devices with indirect heating have the best technical characteristics, but they are much more difficult to assemble than devices with an open source of heat.

Main structural elements

To make a diesel device with your own hands, you need to take care of three components, each of which is an independent design.

These include:

- Housing (shroud) a device that requires a thick sheet of metal or thick wall pipe.

- The combustion chamber - galvanized or other thick-walled refractory pipe, the diameter of which is half that of the casing.

- Fuel tankequipped with a pump and filter. This element, usually located in the lower part of the housing, is made of a refractory material, which it is desirable to additionally cover with a heat insulator.

You will also need a fan with an impeller, with the desired power of 220 watts. Such a detail is necessary to create an air flow, which, after flowing around the heated combustion chamber, will come out.

For the installation of a heat gun, you can use ready-made components or get by with the material at hand. In the first case, the cost of a homemade device will be higher, but its quality will be close to the factory one.

Assembly instructions

Before starting the assembly of the diesel gun, you need to prepare all the devices and materials, and then carefully inspect them for possible defects.

A casing of the device is made from a pipe or sheet of metal (in the latter case, it should be rolled up and the edges connected). A fan is mounted through a hole in the housing inside it, with the help of which air from the room will be pumped into the interior of the device.

All operations for the assembly of a diesel heat gun are carried out in a strictly defined sequence. Particular attention should be paid to the quality of seams, fasteners and joints to prevent fuel leaks.

Strictly in the central part of the casing, the combustion chamber is installed and secured, at the end of which the nozzle is fixed. The element is sealed on both sides, while it is necessary to make two technological holes in it: one for the chimney, the other for the nozzle.

For comfortable use and fire safety, it is advisable to mount a piezo ignition in the combustion chamber. For this, the factory version is suitable, which can be purchased at a specialized store.

The fuel tank of the required size and capacity is located below the housing. The high pressure fuel pump and the fuel fine filter must be secured in the connected space.

Using a dimmer, connect the fan to the household power supply. This element allows you to regulate the temperature of the heated air without increasing fuel consumption.

It is also necessary to weld a chimney pipe to the combustion chamber, where the combustion products will be removed.

When designing a diesel heating device, it should be taken into account that the distance between the fuel tank and the burner with the tank must exceed 15-20 millimeters.

At the end, it is necessary to cover the ends of the device with a thick metal mesh (you can use two layers). This is necessary to ensure safety, since the temperature of the air mass at the outlet can exceed 250 degrees.

All connections must be performed extremely carefully, avoiding leaks, the consequences of which can be fatal. Before pouring diesel fuel into the tank intended for it, it is important to check all the components of the device well. If you are unsure of your knowledge, it is better to use the help of a specialist.

A homemade diesel heat gun is an effective way to warm up the garage during the cold season. It is important to ensure that heating elements do not come into contact with frozen machine parts.

The advantage of home-made thermal diesel guns is their low cost, at the same time, their technical characteristics and ease of use are inferior to factory-assembled models.

Another disadvantage of such homemade products is the difficulty in determining the power of a self-made heat gun, which is why the device may not heat the room enough or too much.

Oil cannon

Some garage craftsmen make devices using waste oil with their own hands, but why reinvent the wheel when there are factory settings that are approved for use in any premises. They run on any hydraulic or motor waste product that can be purchased inexpensively.

A waste oil heat gun made by a garage craftsman will be much cheaper, but what about safety? Who will answer if something happens to the installation operating on oil mining? In the factory version, all combustion products are discharged through the pipe to the outside, and in a home-made unit, oil often burns in a dirty cup from a blowtorch aimed at it. The factory version has an efficiency of 100% and the combustion of oil does not violate the ecology of the room, which cannot be said about handicraft production.

Main characteristics

Well-made heaters are durable, reliable and durable. The body of the device must be resistant to mechanical shock, corrosion and sudden temperature changes. In addition, all parts of the heat gun should not be afraid of high humidity, especially when used in premises such as greenhouses and greenhouses. It must be taken into account that the device should be lightweight for ease of transportation and movement. It is strongly recommended to use heat guns in rooms with a high-quality and reliable ventilation system, or the ability to periodically ventilate the entire space.

Electric cannon

Before proceeding with the manufacture, a detailed electrical diagram of the device is made, all the components are assembled.

Electric gun diagram

To make a DIY heat gun, you will need the following materials:

- Asbestos — a large diameter zinc tube for the fan to enter. Some people prefer to make a case of galvanized metal with a thickness of at least 1 m, and the whole home-made device is more mobile.

- Electric motor and impeller for fan assembly - can be purchased in stores or assembled from scrap materials, for example, use an old fan and motor from a vacuum cleaner.

- Heating elements can be made of special wire by winding it over the electrode. You will get a spiral, like for an electric stove, only you need to make preliminary calculations, otherwise such a gun can cut out the light in the entire area.

- Purchase or select ceramic insulators, copper wire with a cross section of at least 2 mm, 24 A fuses, a connection wire with a plug and other trifles.

Only after that we begin to assemble the electrical part according to the diagram drawn up earlier. An electric heat gun is assembled as follows:

- we prepare the body and support with an insulating lining;

- we stretch the spiral in the form of a star and fix it inside the body, or install the heating elements in the center of the pipe;

- we connect the power wires to the terminals;

- we fix the fan, bring in the wiring;

- we install protective grilles on both sides of the case;

- we mount the control unit and connect all the wiring to it;

- we install the wire connecting the device to the network.