Furnace types

In our country, many types of furnace equipment are built and operated, we will list some:

- Swede

- Dutch woman

- Baby

- Heating and cooking

- Fireplace

- Stove with fireplace.

Furnace types

Despite the difference in design, all furnaces are characterized by the following parameters:

- Appointment.

- The maximum heating temperature of the furnace.

- Duration of fuel burning.

- The time it takes to warm up the structure and start full-fledged heat transfer.

- Chimney device.

- The scheme of movement of warm gases through the channels arranged in the furnace body.

- Furnace shape.

- Exterior wall finishing options.

- The material used in the construction of the furnace.

Stoves installed in homes have ancient traditions. Our distant ancestors cooked food on it, heated housing with it and used it as a sleeping place.

Brick Russian stove

The brick Russian stove has the following specific advantages:

- maintaining heat in the house due to long cooling;

- the ability to maintain heat in a room with any area;

- fire resistance.

Meanwhile, these devices also have a set of certain disadvantages:

- For the construction of a furnace, it is necessary to have certain skills and knowledge, which is why it is advisable to invite specialists for its construction.

- For the construction of the furnace, it is necessary, first, to equip a separate, recessed foundation.

- The oven is quite large and can take up a fairly large space.

- This circumstance must be taken into account when determining the place where the oven will be installed.

Brick Russian stove

For the manufacture of furnaces, two materials are used - metal and brick (simple red, and refractory, it is also called chamotte).

A stove for a house made of wood, for the manufacture of which I use steel or cast iron, the thickness of which is from 3 to 5 mm.

The wall of this design consists of two layers of metal. There is an air gap between them. This layer is designed to protect the premises from the so-called thermal shock.

Design features

Getting acquainted with the features of metal stoves, first of all, mention should be made of their differences against the background of heating boilers. The latter are designed to provide heating of the liquid circulating through the water supply. As for wood-burning heating stoves, when they are used, heat is distributed through the walls of the structure.

A properly arranged metal stove for heating without fail provides for a number of required elements:

- Combustion chamber or firebox. It serves to place fuel in it, after which it is ignited, and the heat released is distributed to the wall and further into the room.

- Ash pan. In addition to creating conditions for the flow of air into the combustion chamber, it has the function of a storage tank for ash.

- Grizzlies. A place is reserved for them between the ash pan and the combustion chamber. By their design, they represent a grate made on the basis of cast iron, through which air masses enter and small particles of combustion products fall into the ash pan.

- Chimney pipe. It is used to remove carbon monoxide, which occurs during the combustion of fuel.

Considering that the firebox can heat up up to 1300 degrees Celsius, the companies involved in the manufacture of ovens are very careful in the choice of material for it. Most often, the choice is made on special grades of high-strength steel or cast iron.Moreover, it is best for the firebox to be made of the latter material, since it demonstrates superiority in terms of service life against the background of ordinary steel.

Sheet metal is usually used as the material for the outer walls. To provide optimal conditions for rapid heating of air, converter panels are placed on the case. The space formed by them and the stove is used for air circulation: heated masses move upwards through the upper slots, and fresh air enters from below.

The described option is distinguished by the simplest execution. In the case when the problem arises of heating the entire wooden structure, it is necessary to consider other models.

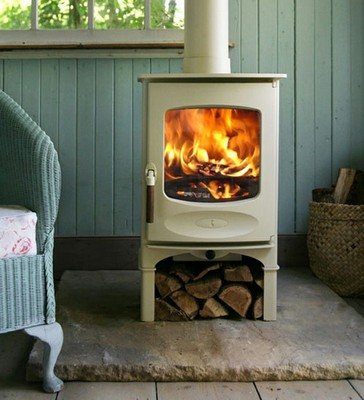

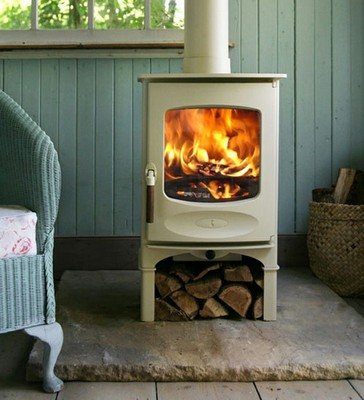

Metal oven

Metal furnaces have the following advantages:

The homeowner has the option of purchasing a ready-made stove, which includes a chimney, equipped with a temperature control system.

Pros of a metal oven:

- Furnaces made of metal can have an interesting look.

- Fast heating, which allows you to warm up the air in the room to the specified parameters in an extremely short time.

- High heat output.

- Long service life.

- The furnace can use any existing fuel to perform its functions.

Metal oven

But, furnaces made of metal also have some disadvantages, among them the following can be called:

They are not suitable for use in large rooms due to their high fuel consumption.

Rapid heating also means rapid cooling.

Metal stoves are classified as fire hazardous objects and the operation of the stove must be constantly monitored, and a fire extinguisher and other fire extinguishing means must be within reach.

If a low-quality metal was used for the manufacture of the furnace, then after the first heating, it can deform.

Furnace materials

Brick

If you plan to install a stove in a country house with your own hands, then first you need to decide on the material. The main material for the stove is brick. Brick can be different:

- Ceramic

- Silicate

Silicate bricks are not used for ovens. Ceramic bricks, in turn, are:

- Hollow

- Corpulent

Hollow bricks are not suitable for ovens.

The stove is plastered hot after it has dried and warmed up as much as possible!

Solid brick is subdivided according to purpose:

- Fireclay

- Clinker

- Ceramic

Of all the above, the following solid bricks are most common for laying stoves with their own hands:

- Ceramic

- Fireclay

Brick has two important indicators:

- Strength

- Frost resistance

The strength of ceramic bricks is 100, 150, 200, 250, 500 (kg / cm²). For stoves, bricks with a brand up to 250 kg / cm² are used.

Before laying the brick, it must be soaked in water; the brickwork of the brick oven will be strong if the dressing of the seams is observed.

How to choose a brick for a stove

Competent installation of a stove in a country house requires high-quality materials:

- Brick for laying stoves should be of the same red color, without burnout or underburning, cracks, chips, swelling

- The brick for laying the stove must have the same geometric dimensions.

If you do not take these conditions into account, the labor costs for building a furnace with your own hands can be very large. The dimensions of the brick used for laying stoves in the country or in a wooden house are standard 250x125x65mm, although there are one-and-a-half and double bricks.

Oven solutions

For laying a stove in a wooden house or in a country house, there are two types of solutions:

- Red clay for red ceramic bricks

- Fireclay refractory clay for fireclay bricks

If there is an opportunity to purchase ready-made fireclay or red clay or a ready-made mixture for laying a stove, you should take it without hesitation.The prepared solutions in industrial conditions are much higher in quality than those prepared by hand.

Furnace fittings

The stove is being installed in a wooden house or in a country house using metal fittings, it is recommended to choose parts from cast iron, and for the stove you will need:

- Furnace doors

- Blowing doors

- Cleaning doors (soot cleaners)

- Grate

- Gate valves or dampers

- Plate

- Oven

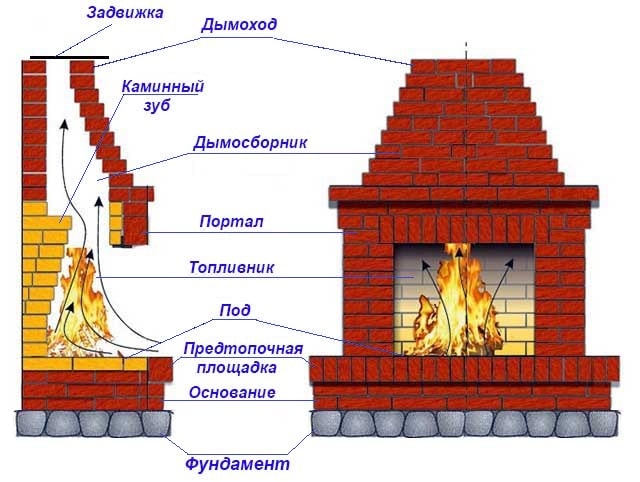

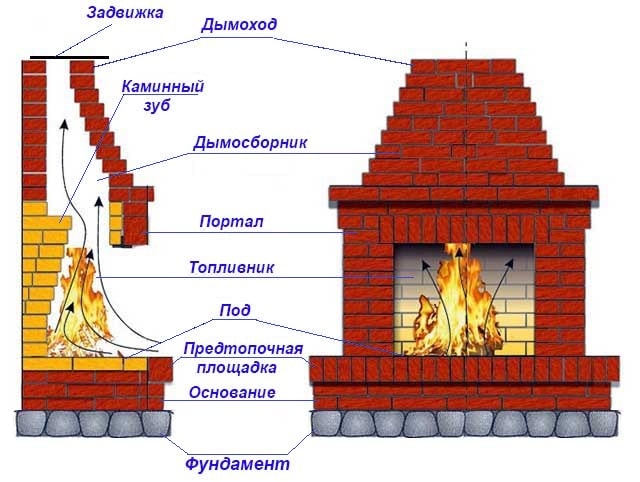

The device of a classic fireplace

Fireplaces installed in modern houses have collected all the best from those used in the Middle Ages and Russian stoves, which with high efficiency transfer heat to the home.

Fireplaces can be used not only as a source of heat, they can decorate the interior of the room where it is installed.

The device of a classic fireplace

Fireplaces installed in modern homes have the following properties:

Cain can be installed directly into the wall, and those that are installed next to the wall. There is another way to install it as an island.

Fuel port type. Fireplaces are open and closed. The first version is a classic version with an open firebox, in the second version, this opening is closed with doors.

The type of fuel used is coal, gas, electricity.

The design of the fireplace directly affects the efficiency. So, the efficiency of an open fireplace is 15%, the closed type shows an efficiency of 70 - 80%. A closed fireplace can act as the only source of heat in the house.

Each homeowner can build such a structure in his home, this requires certain knowledge, a set of tools and the ability to work with it.

Some details require special attention:

- design and construction of the base (foundation), the larger the size of the fireplace, the larger the base should be;

- chimney design;

- volume of construction and finishing materials

- the overall appearance of the structure;

- fire safety, fire safety measures must be provided at the stage of design work;

- Tools that will be needed when performing construction work.

- trowel for working with mortar;

- hammer-pick for cutting bricks;

- jointing used to seal the seam;

- building level and plumb line, square;

- a container for preparing a solution and soaking clay.

Fire safety

In addition to the correct installation of the stove, installation must be carried out in accordance with fire safety standards. Especially if the summer cottage is built of wood.

When installing the oven with your own hands, you need to adhere to the following rules:

- The floor is lined with non-combustible materials. The place is covered with concrete, ceramic tiles or iron sheet. The parameters of this place should exceed the dimensions of the furnace by 50-70 cm.

- The surrounding walls or furniture are also separated by non-combustible material. For example, an asbestos sheet. Then the minimum distance from the hot stove to the wall can be 20 cm.

- If there is no insulating material, then the distance increases to 1 meter.

- The chimney system is equipped with protective elements. They protect the passage from clogging and nesting by birds.

- The distance from the ceiling to the upper surface of the equipment case is 1.2 meters.

- It is advisable to protect the device with a decorative fence.

- If passages are made in the walls for heating adjacent rooms, then heat-resistant materials should be used during operation.

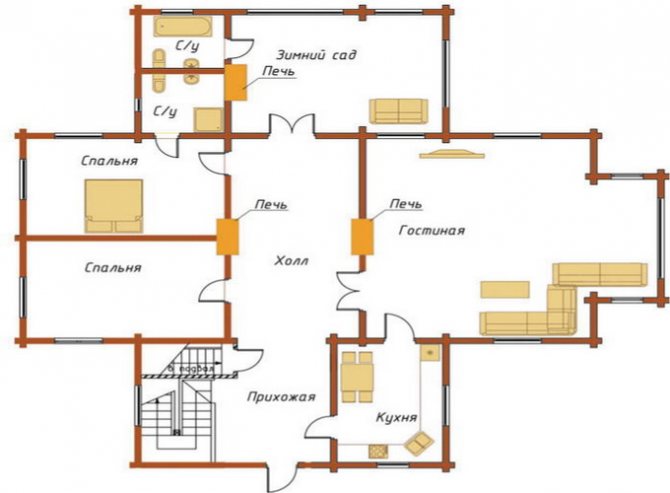

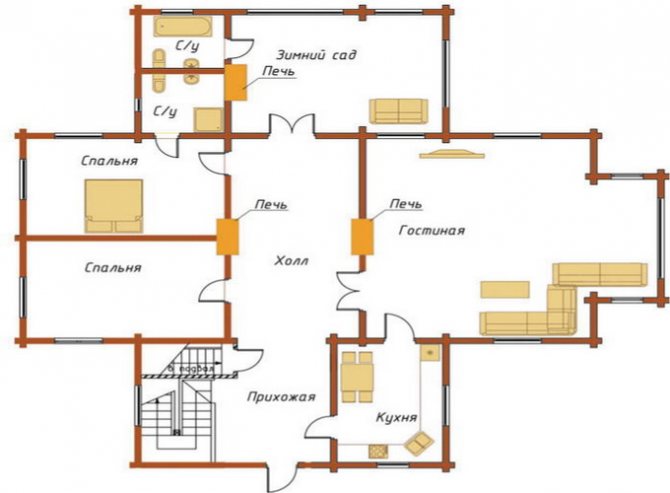

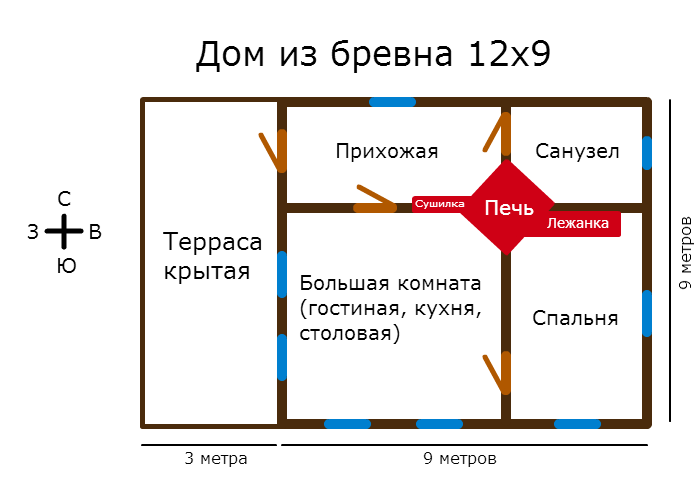

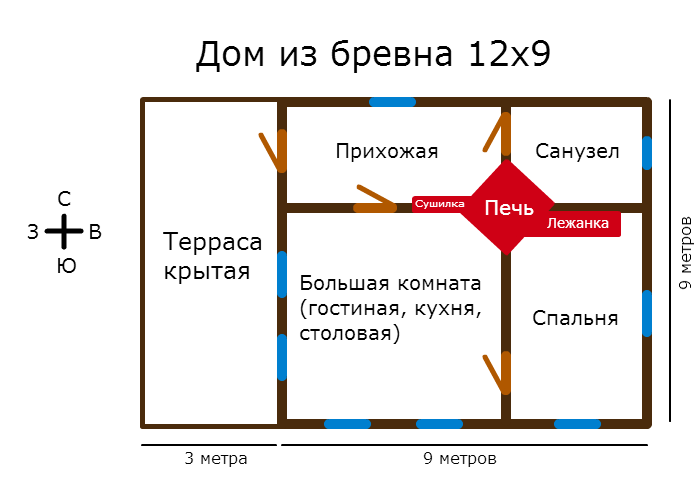

Where is the best place to put a stove in a wooden house

As a rule, the place for installing the stove must be determined at the design stage of the house. This is necessary in order to ensure both efficient heating of the house and to secure it as much as possible. What criteria should the homeowner be guided by when planning the installation site of the future stove?

Where is the best place to put a stove in a wooden house

The heat source can be installed in rooms with an area of at least 16 sq. M. the installation must be carried out in such a way that there are no floor beams under the stove intended for the installation of floors. And in the place where the chimney exits there should be no ceiling beams, rafters.

To reduce the size of the chimney pipe, it makes sense to determine in the center of the house. In this case, the chimney will go out to the roof in the area of the roof ridge. The construction of a stove in the immediate vicinity of the wall is impractical, since a significant part of the heat will be directed to heating the street. In addition, placing the furnace near wall structures increases the fire hazard. Based on the foregoing, we can conclude that the best placement of the stove will be in the center of the room.

A wood-burning stove will show maximum efficiency if all its surfaces give off heat. This design can easily cope with heating one or several adjacent rooms. This can be taken into account when placing rooms at the planning stage.

To provide heat to adjacent rooms, the stove is installed between the rooms in a partition. In order to keep warm in a four-room house, it is best to install it at the junction of the partitions so that one of the walls of the stove goes into the room. With this arrangement, it is possible to organize the exit of the firebox to the kitchen.

Installation

So, we figured out the types of equipment, now we will consider how to install a metal stove in a wooden house, which, as we found out, is the best option. This work, although not difficult, requires strict adherence to the rules.

So, the installation process takes place in this order:

- Before installing an iron stove in a wooden house, you need to prepare a place for it. The floor and the nearest wall should be covered with non-flammable material. For example, ceramic tiles or even just a sheet of galvanized steel can be laid on the floor.

- A border should be made around the location of the device. This is necessary so that accidentally dropped charcoal cannot roll out onto the wooden surface.

Correct installation of the Bavaria stove in a wooden house

- Further, the structure is installed on the legs provided by the manufacturer and set horizontally. In this case, the distance to the wall should be at least 35 cm.

- Then you need to do the installation of the chimney with your own hands. This work is the most difficult and responsible. For this, sandwich pipes should be used, consisting of two nozzles, the space between which is filled with a heat insulator.

However, even such a chimney does not guarantee fire safety. Therefore, it should also not be located closer than 35 cm to the wall.

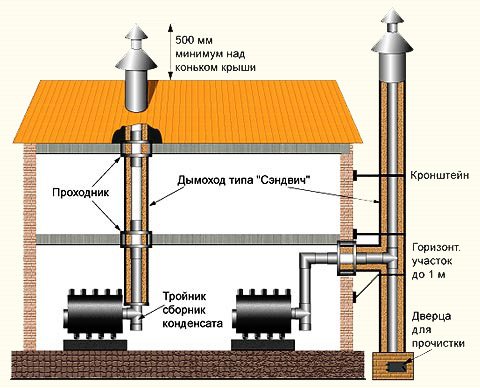

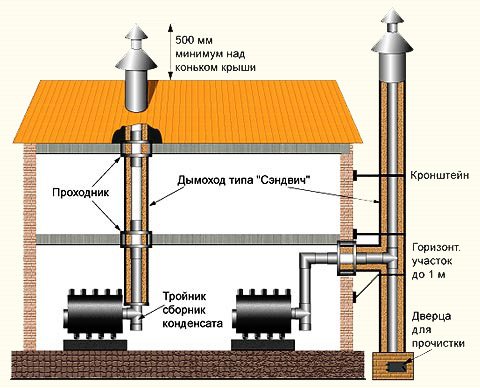

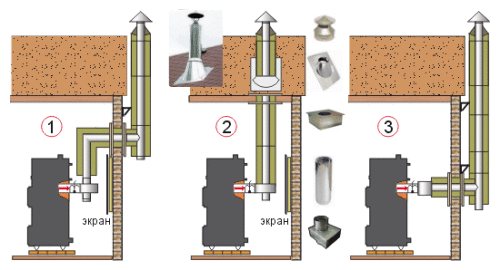

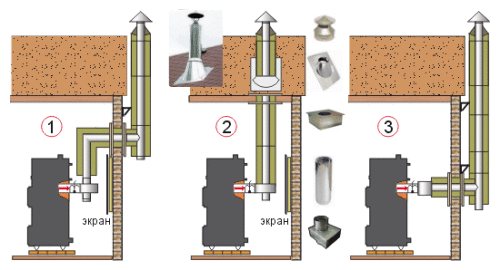

In the photo - an example of the arrangement of the passage

In addition, it is necessary to correctly pass the chimney through the ceiling and roof. For this, a special box is used, the space of which is filled with mineral wool. Thanks to this, the chimney heated to a high temperature will not come into contact with the wooden surface.

- Further, all elements of the chimney are assembled into a single structure and connected to the stove. In this case, it is important to ensure the correct installation of the elbows - the lower ones should be inserted into the upper ones, but not vice versa. Asbestos thread can be used to seal the joints.

If necessary, the chimney should be fixed on the steppe with clamps and brackets.

- Now that the stove is connected to the chimney, it is necessary to melt it and carefully inspect the structure for the absence of smoke.

Chimney device options

Note! The height of the chimney must be at least four meters from the surface of the stove, and its diameter must be at least 15 cm.Compliance with these parameters will ensure high-quality smoke removal to the outside.

This completes the installation of the furnace. I must say that the chimney can be brought out not only through the ceiling and roof, but also through the wall. However, in this case, it is still necessary to provide a correct, fire-safe passage.

Advice! Often, companies that sell ovens also offer installation services. True, the cost of this work is usually quite high, so in most cases it makes sense to do it yourself.

Here, in fact, is all the basic information on how to properly install a stove in a wooden house.

Furnace foundation

If there is a desire to build a fireplace in your home, then first of all you need to think about arranging the foundation for it. A properly executed foundation will ensure its long-term and safe operation. In the case of negligence or committed mistakes, it will undoubtedly lead to deformations, sinking of the fireplace, and the occurrence of cracks.

The main requirements for the foundation can be determined as follows - reliability and lack of connection with the foundation of the entire building.

The optimal solution would be to erect a capital foundation, and, moreover, it can be built along the way with the construction of the base for the main building. At the same time, the creation of a single foundation is unacceptable. The thing is that each foundation is designed for a certain load and, as a result, they have different shrinkage.

There must be a gap of at least 50 mm between them, it must be filled with sand or other loose material and carefully tamped.

The dimensions of the foundation in the plan must be larger than the size of the base of the fireplace. That is, it should protrude from the fireplace by 100 - 150 mm. The depth depends entirely on the properties of the soil. In practice, it shows that for a house on one floor, it is enough to deepen the fireplace foundation by 0.5 - 0.6 m, if the house is higher, then the depth should accordingly be greater - up to 1 m.

Manufacturing material

The most common material used in the oven is refractory steel... In such devices, the outer walls are at least 2 mm thick. Among other features of this equipment, one should highlight a rather low weight and an affordable price. A small amount of time is spent on heating the air in the room, the same can be noted in relation to cooling. But when using such furnaces, the owners should remember that the observed temperature fluctuations negatively affect the metal, causing the occurrence of processes such as oxidation and thinning of the material.

Cast iron stoves

In addition to steel stoves for heating a house, the consumer has the opportunity to purchase cast iron models... One of the significant advantages of the material is the ability to accumulate heat. In the case of using cast iron products, heating takes a long time. However, after a thorough burnout of the wood, the residual heat generated will be able to maintain a comfortable room temperature for some time. If we consider the disadvantages that are characteristic of cast iron stoves, then the main ones should be called the high cost and high weight.

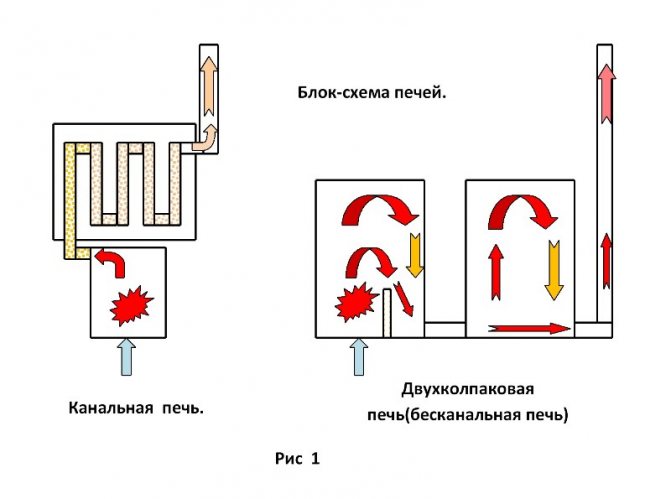

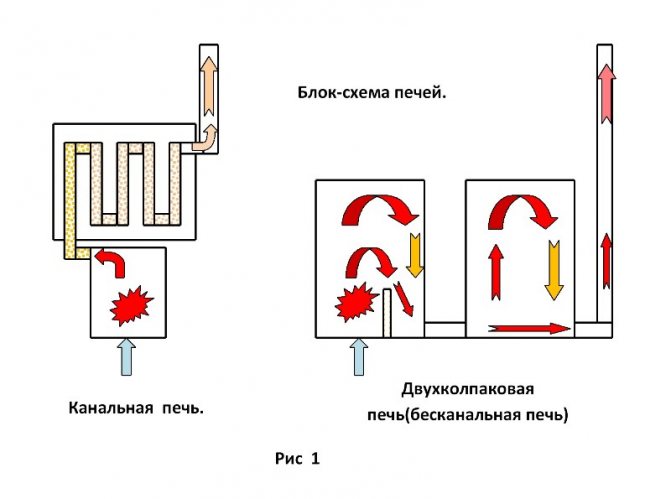

Channel and channelless ovens

Channel and channelless ovens

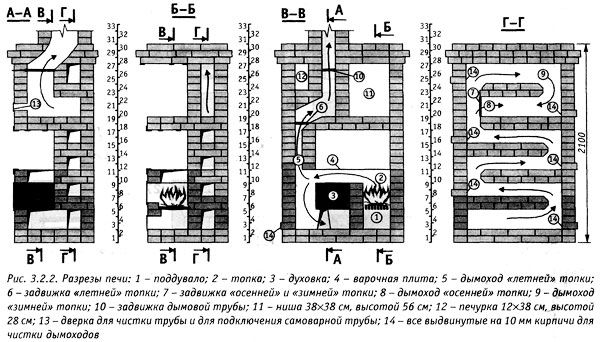

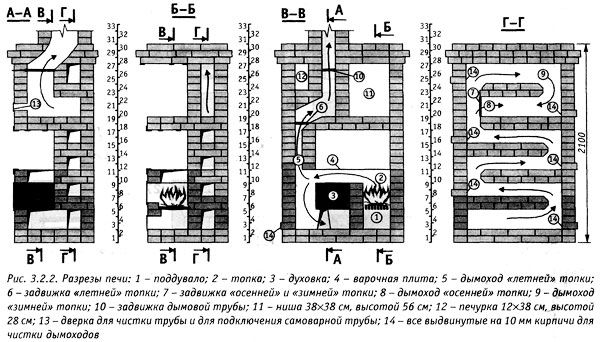

The peculiarity of channel furnaces is that their design includes channels made in the horizontal and vertical planes. Heat moves along them, which in direct-flow structures simply goes up. It should be understood that the movement of heat through the channels can be difficult. Therefore, the design of the furnace provides for the presence of elbows. To prevent stagnation of warm air, some devices are arranged that regulate combustion modes. There is a summer mode, during which the stove warms up and after that you can switch to full heating.

Overview and rules for installing ovens

Before moving on to the question of how to put a stove in the house, it will not be superfluous to consider the features of the types of stoves considered. After that, you can proceed to the installation itself.

Brick ovens

A brick oven, regardless of size, will look appropriate only if the house is intended for permanent residence in the cold season. Compared to metal ones, they have more inertia, so the room will heat up a little longer.

The project of a wooden house with a Russian stove necessarily provides a separate foundation for it. The wooden floor simply cannot withstand the weight of the brickwork, so a separate slab foundation with reinforcement with rods or mesh is arranged under it.

A brick stove can be not only heating, but also used for cooking, all that is needed is to arrange a horizontal surface above the firebox.

There are several options for brick ovens:

- compact "Dutch women" look like a neat parallelepiped, they quickly warm up the room;

The Dutch woman is compact

- traditional Russian stoves;

Note! Without making changes to the design of such a furnace, at best a third of the generated heat will be spent on heating the room. It is recommended to use a more advanced smoke circulation system; you can also divide the firebox into 2 chambers (for heating the house and for cooking).

- among the compact ones, one can also note Swedish stoves, they will perfectly cope with heating a room with an area of 30-40 m2.

Multifunctional Swedish

A significant disadvantage of brick ovens can be considered the fact that you cannot do without an experienced stove-maker. Of course, you can try to build it yourself, but the result will be unpredictable.

Note! The task can be somewhat facilitated by using a metal firebox, which is then lined with bricks. The metal is thick enough so that it is guaranteed not to burn out, even with an intense fire.

The metal firebox is lined with bricks

Also brick ovens are difficult to restore. Repairing a stove in a wooden house may require replacing part of the brickwork, and this is quite inconvenient (both in terms of finance and in terms of time spent).

Compact ovens for the home

Modern small stoves can easily heat an area of the order of 40-60 m2.

The fundamental difference between the existing models lies in the design of the firebox:

- in furnaces that operate on the principle of a conventional stove-stove, most of the heat energy that is called flies into the chimney;

- in long-burning stoves, the fuel burns out almost completely, which reduces its consumption.

Note! In pyrolysis furnaces, the fuel smolders rather, and the resulting pyrolysis gas burns out, releasing the required heat.

In terms of appearance, all manufacturers try to make their products look good. Some of the stoves are additionally equipped with hobs, cooking and heating stoves for wooden houses are perfect for country houses, where there may be problems with electricity or gas.

Even the simplest stoves look great

If the budget allows, then you can purchase a compact fireplace. By design, it does not differ much from a conventional oven, but a transparent tempered glass door is used, behind which burning logs will be visible, the heating efficiency is somewhat lost, but the appearance is at a height.

Also, compact stoves outperform brick ones in ease of installation. Installation of a stove in a wooden house is that you just need to put it on a prepared base and bring the chimney out into the street. Moreover, the chimney can be taken out even through the wall.

The scheme of laying the chimney through the wall

Rules for installing a small stove

The main thing during installation is to ensure fire safety and the normal removal of combustion products through the chimney.

The installation instructions are as follows:

- during operation, there is a risk that the ember will fall to the floor, so the base must be non-combustible. For this, you can use asbestos-cement slabs, and thick tiles, and even a metal sheet. The dimensions of this sheet should be about 70 cm larger than the dimensions of the furnace from the side of the firebox;

The oven is fenced from all sides with non-combustible material

- if the stove is placed in a corner, then the part of the wall next to the stove should also be non-combustible. You can even do without wall decoration, but simply install a reflective screen from any non-combustible material;

- as for where to place the stove, the location of the stove in a wooden house should be such that the heat is distributed as efficiently as possible throughout the room. That is, the location of the heat source in the center of the room can be considered optimal. This is often impossible, so you can place it in the corner, but it is forbidden to install it right next to the wall of the house.

One of the options for placing the stove, 4 rooms are heated at the same time

The installation process also includes the installation of a chimney. When using ready-made sandwich chimneys, the main thing is to pay attention to its laying through combustible ceilings. The holes in them are made larger than the diameters of the pipe, and the space is filled with non-combustible material.

How to properly heat the second floor

Supplying heat to the second floor of a house is a rather difficult task. Alternatively, you can consider the device of the fireplace, equipped with additional equipment. The fireplace has a number of advantages. Among them, you can name the following:

- ease of use;

- small size;

- use of almost any fuel.

How to properly heat the second floor

For the sake of fairness, it should be noted that most of our people consider it a luxury item, but this design is capable of combining democratic and aesthetic properties, and excellent performance of its main task - heating the room.

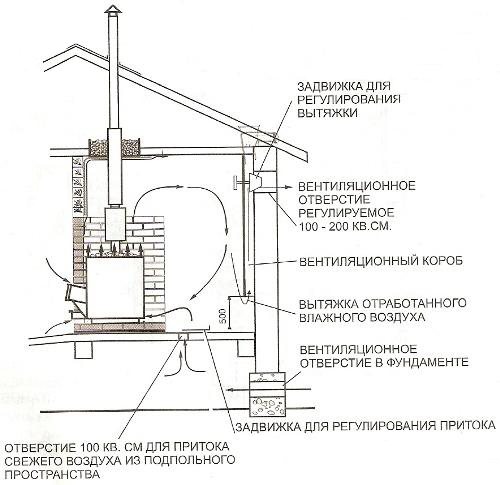

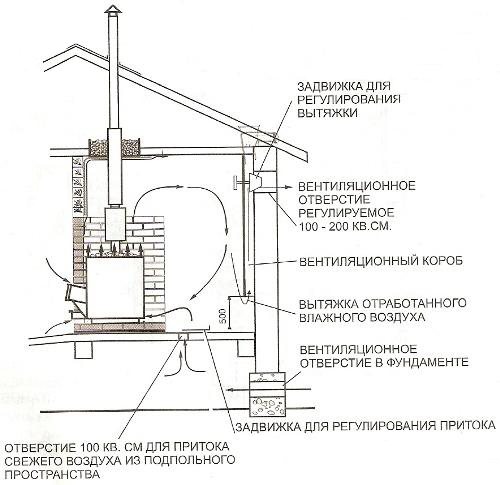

Heat supply to the second floor by air convection. That is, passing by a heated fireplace wall, the air receives thermal energy and continues to move upward along a special box. Warm air is supplied to the rooms located on the second floor through ducts, which must be covered with thermal insulation. This is necessary to minimize heat loss and ensure fire safety.

Self-installation of the Russian stove

For the construction of a classic Russian stove, you will need about 1650 pieces of bricks, a gate valve with a size of 260 by 240 mm and a certain volume of clay and sand, which is enough for 80 buckets of mortar.

Self-installation of the Russian stove

To carry out the work, it is necessary to use red bricks; refractory (chamotte) bricks are used to lay out the firebox. When performing masonry, it must be remembered that the seams that form during masonry should be small. no more than 5 - 7 millimeters.

Each level must be installed using a building level and a plumb line. It depends on how well the oven will be laid as a whole.

The construction of the stove must be carried out, guided by the requirements of the order. This is the name of the scheme, which indicates the placement of bricks in each separate row. Such orders exist for almost all types of Russian stoves.

It should be noted that the laying of a stove is a rather complex construction process and requires high qualifications of a bricklayer. It is not for nothing that there is a separate specialty as a stove-maker. And for the construction of a furnace at home, it is better to invite just such a specialist.

Features of correct installation

The actual installation of stoves and fireplaces is a standard process.However, there are several points that affect not only the efficiency of the oven used, but also the convenience of its use. They also provide some other benefits.

For example, the installation of an iron stove in a house with an underfloor can be performed as follows:

- The stove is placed approximately in the middle of the heated room.

- In front of the ash pan of the furnace, through which air is supplied under the grate, a ventilation hole is made.

- Or the oven itself is placed just below the floor surface.

- The air in the blower is taken from the underground volume, where this air enters through the ventilation holes from the first floor.

Thus, the installation of a stove in a house with an extract from the subfloor dries the subfloor and does not allow moisture to accumulate there.

One more point. Often the installation of a metal stove in a house is done directly on the floor covering of the first floor. At the same time, a minerite sheet and an iron sheet are placed under the furnace.

However, when unloading the ash from the ash pan, some of the ash ends up on the floor. If the installation of a heating furnace is combined with the manufacture of a small podium for it from a non-combustible material, then the ash will be unloaded “without losses”. The podium can be made of bricks, paving slabs or expanded clay concrete blocks. Some comrades even use two adjacent concrete curbs for this.

Do not just use fireclay bricks for this purpose. Although it is heat-resistant, it transfers heat too well. The floor under such a podium will be very hot. The place of fireclay bricks is in the furnace firebox or brick shield for better heat removal from flue gases.

As you can see, the installation of a stove - fireplace with your own hands is possible, but with strict observance of all fire safety requirements.