Greenhouse - rescue in adverse climatic conditions, in some areas it is impossible to get a high-quality harvest without installing it.

Equipping the greenhouse with a heating stove additionally expands its capabilities - Plants are no longer afraid of long periods of lower temperatures, when an ordinary greenhouse inevitably gets cold.

The use of the greenhouse becomes possible even in winter, that is year-round... The greenhouse oven also allows for cultivation more exotic thermophilic varieties vegetables and fruits.

Odnoklassniki

Wood burning stoves for heating greenhouses

The choice of options for heating devices for the greenhouse is also variedas for home. Most often, factory models are used, which are purchased in stores, but the manufacture of such a device is available with your own hands.

Furnaces differ as by fuel type - wood, gas or electric, and by material of manufacture - metal or brick.

Most often they choose for self-construction solid fuel apparatus, which is heated with wood, pallets of chips, husks, dry pieces of peat.

Plain greenhouse stove

This type of device can be made of metal or brick.

Metal a potbelly stove is quite simple to build, it is recommended to cook it from an old barrel or gas cylinder, size 1.5 mx 0.5 m... A distinctive negative feature will be the inability to retain heat, therefore, as soon as the fuel in the stove burns out to the end, the greenhouse begins to dry out.

Has the meaning uneven heating - the stove has a high heat transfer due to the metal body, therefore, the air in the immediate vicinity of it overheats greatly, which negatively affects the soil and plants.

Furnace construction brick will allow you to get longer, gradual heating premises, as well as long-term heat transfer after the firewood has already burned out. The construction of an elongated horizontal smoke channel will significantly increase these indicators.

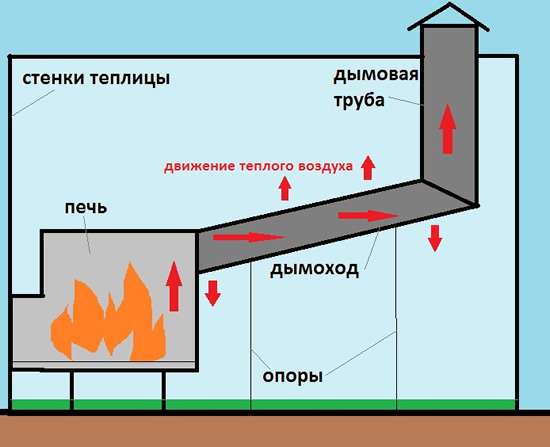

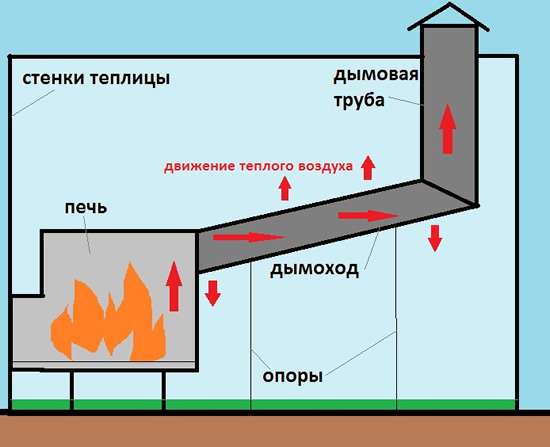

The dimensions of such a device can be different, depending on the area of the room, smoke channel usually gives all the best the entire length of the greenhouse - being located in the center, it contributes to high-quality, uniform heating of the air.

Important! The task of the greenhouse oven is primarily warming up the soil, therefore, the smoke channel and the device itself are located as close to the ground as possible.

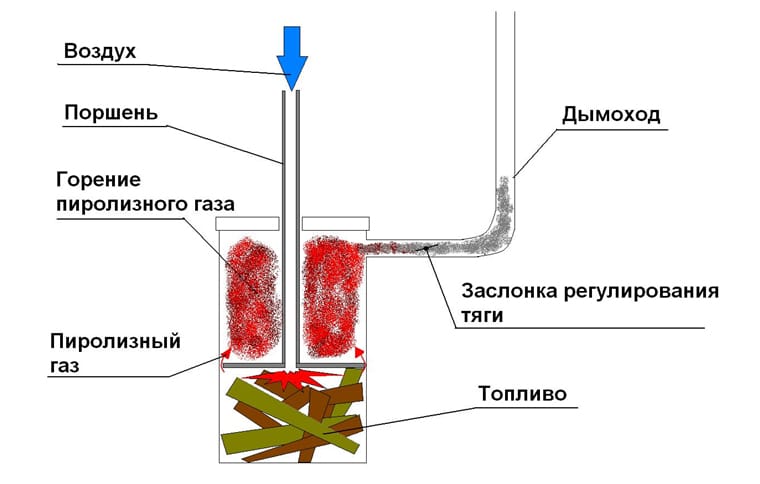

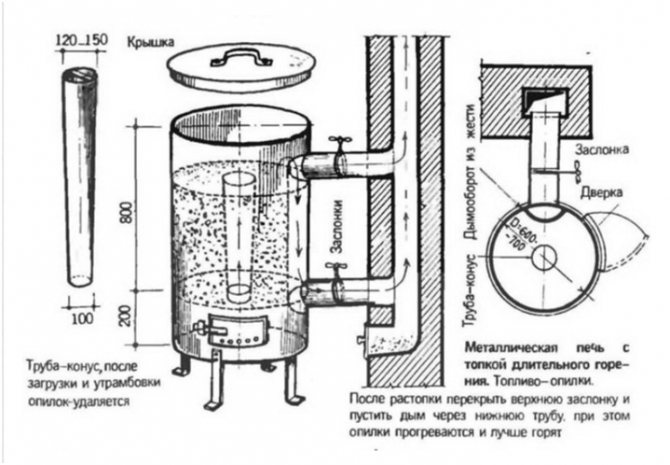

Long burning device diagram

To increase the efficiency of the oven, it is often equipped with double combustion chamber - this allows to extend action of one bookmark of firewood for 12-18 hours... This is achieved through the process pyrolysis - due to the controlled ingress of air into the furnace, the wood does not burn in an open flame, but smolders very slowly, emitting a large amount of smoke and hot gases. Second chamber the furnace is used for the final combustion of the released combustion products.

Photo 1. Diagram showing the device of any long-burning furnace with limited oxygen supply.

With this method of heating, you have to report fuel much less often, and pyrolysis combustion leaves almost no waste, therefore you do not have to often clean the furnace from ash... The savings in fuel and time required for maintenance make this option the most sought after option. Dimensions (edit) can be quite small - 1.5 mx 1 m, more efficient heating of the air will be provided by the installation horizontal smoke channel.

Furnace types

On sale you can find a wide variety of modifications of greenhouse stoves that can operate on various fuels. The most common is diesel fuel.

It is also not difficult to find stoves that use wood as fuel. But there are stoves that use non-standard fuels, for example, all types of oils.

Most often, diesel ovens are bought ready-made. And since the fuel for such stoves is not cheap in itself, homemade stoves are made on wood or other readily available material to save money.

A wood-fired greenhouse oven can be located in the center of the greenhouse. In this case, it is better to provide for the circulation of warm air, for example, using a fan. You can run a chimney along the entire length of the greenhouse for more rational heating, because not only the stove itself heats up during the firebox, but also the smoke exhaust pipe.

However, due to the increasing danger of fire, the stove can be lowered below ground level, and the chimney can be laid underground, thereby also heating the soil in the greenhouse. It is possible to make water heating in a greenhouse using a wood-burning stove as a boiler.

Gas ovens are more commonly used for heating in large greenhouses. Their advantage is a stable fuel supply. However, the installation of stationary equipment is expensive.

But if you want to heat a small greenhouse, and even for a short time, then you can purchase only a few gas cylinders. This does not require a lot of investment.

But the most common option for heating greenhouses are do-it-yourself ovens. They can use almost everything as fuel, from construction waste (wood chips, sawdust) to cones and husks from seeds.

Making a stove with your own hands

The choice of the project of the future device is mainly depends on the conditions and the desired functions... If heating is required small greenhouse, the device will work only periodically, for example, to ensure an earlier sowing of seeds in the spring, a small potbelly stove of a simple design will do.

With constant use of heating, for heating large areas, a significant amount of fuel consumption, the most suitable option will be economical designs based on pyrolysis combustion. Compactness and ease of installation are important - small device of steel easier to install and commission, brick the structure, due to its massiveness, will require laying the foundation, and the construction work will be more labor-intensive and time-consuming.

Preparation of materials, tools, places

The following materials are suitable for building a furnace:

- metal barrel suitable diameter;

- trimming metal pipes;

- steel in sheets sufficient thickness;

- old gas bottle.

To make the body of a long-burning furnace, a barrel or cylinder would be a suitable option. volume of 200 l for body and pipe cutting for chimney equipment, pieces of steel, fittings.

In addition to materials, you need to prepare special tools:

- marker for marking;

- Bulgarian with discs for cutting steel;

- welding machine;

- protective gloves and mask.

Then a place is selected and prepared - it would be best to install the oven in the middle of the greenhouse... Required the foundation is being built... Although an apparatus made of metal does not have such a large mass as of a brick, a reliable base must be made for it - it will do paving slabs, bricks... The materials are laid out in even rows on a compacted, leveled piece of land.

Assembly order

The work starts from the body:

- From a balloon the upper part is cut off, in lower part an aperture is cut out for storing fuel, sideways - hole for chimney equipment.

- The resulting metal circle grindso that it passes freely into the barrel.

- The circle is carved blower hole, the circle itself becomes heavier fittings or pieces of metal.

- Welded to the lid pipe cut with a damper that acts as a blower.

- Welded chimney, doormade from a bent sheet of steel or a barrel wall.

- Is attached metal fittings or legs.

Operating principle such a home-made device - providing smoldering firewood with a limited supply of oxygen. Under its weight, the lid gradually lowers, at the same time showing the level of fuel burnout.

Why do you need an oven

A greenhouse stove is an irreplaceable thing if you plan to use it even in winter. Of course, the summer version of the greenhouse in this regard is much easier to design, and less costs will be required. In summer, there is enough sunlight for plants: it performs both the function of heating and lighting. However, in winter, the greenhouse room lacks heat.

Even if we take into account the fact that at the stage of building the greenhouse you insulated the walls, this will still not be enough. That is why it is worth thinking about the need for equipment in a greenhouse for a heating system even at the stage of construction planning. How to make a furnace for a greenhouse with your own hands, and which device to give preference to - we will consider in detail.

Possible difficulties

When assembling, it is advisable to avoid the following mistakes:

- Placing directly on the base causes overheating, bottom burnout; there must be an outflow of hot air from the bottom, so the device is placed on strong legs.

- Furnace installation near unprepared walls may be unsafe as steel devices become very hot and therefore there is a high risk of fire if placed near objects.

- Excessively large blower diameter leads to the flow of excess oxygen, which is why the firewood ignites, and does not smolder; corrected with well adjustable gate valve.

The device has quite simple design, so if you approach your work carefully, you will be able to avoid most of the mistakes.

Polycarbonate greenhouse heating: options

Content:

1.Furnace heating 2.Use of gas 3.Electric heating 4.Infrared radiation

Recently, many consumers have begun to equip greenhouses on the territory of a summer cottage or a country house, because this is a great opportunity to eat fresh and environmentally friendly vegetables even in winter (read: "Heating a greenhouse in winter - basic principles").

It is also indispensable in those regions where it is not possible to grow thermophilic crops in the open field due to the harsh climate. But you can not even dream of a big harvest, if you do not take care of heating the greenhouse. In this regard, the question often arises of how to heat the greenhouse.

One of the best materials for its construction is polycarbonate - you can see how such structures look in the photo.

Currently, there are the following methods for heating greenhouses:

Wood burning stoves for heating greenhouses - model overview

This prevents cracking.

Fuel for the country the stove is suitable for everyone. Comfortable ordinary wood, fuel briquettes, self-adhesive, packaging materials, old fabrics. However, it is worth monitoring the moisture content of the fuel, otherwise it creates a stove and condensation on the pipes, which will require cleaning the building due to a decrease in heat output and an increase in fuel consumption for heating the greenhouse.

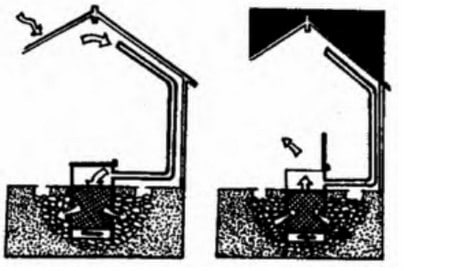

Heating a greenhouse with an underground chimney from a stove

The shape of the furnace, foundation, brick around the frame remains unchanged.

But here the chimney will lie in the ground and will not be on supports under the greenhouse roof.

Chimney from underground potbelly stoves

The distance between adjacent parallel pipes must be between 60 and 100 cm.

The depth of the pipe is 25-40 cm. The pipes are located at a slope in excavated trenches covered with rubble or expanded clay. The ends of the pipes extend outside the greenhouse. Such warm air from the stove enters the chimney, heats the floor and the air, and the smoke from the combustion of fuel falls outside, but not in the greenhouse gas space.

A do-it-yourself dacho burger is a budget and quick way to increase the number of crops and protect against adverse environmental conditions.

With properly installed heating in the country, greenhouses will bloom roses, and there are cucumbers, bell peppers, grapes and other fruits of thermophilic crops on the table.

Heating the greenhouse is necessary even in southern latitudes to protect the seedlings from the cold at night. In the middle and, especially, the northern regions, it makes no sense to arrange a greenhouse without heating. However, it justifies itself with a good yield of vegetables and fruits.

Greenhouse heating

Suburban areas are being built for early harvest heated greenhouses.

It is especially important to heat the stove in the north of the country in harsh climates. Simple ovens, usually metal, are installed in greenhouses. Fire can warm an area of greenhouse gases and protect shoots from temperature changes, as well as all solid fuels, including briquettes and saws. Combustion products (ash and ash) can be used as fertilizer.

The lowest temperature in the greenhouse is 18 degrees.

When calculating the dimensions of the oven, the dimensions of the greenhouse are measured. One bourgeois is successfully faced with heating a greenhouse with a capacity of 15 square meters. The distance between the heating parts of the stove and the walls of the greenhouse is at least 25 cm and at least 15 cm from the chimney to the upper ceiling.

When installing the greenhouse, the chimney is buried in the ground or mounted on supports under the roof, depending on the climate and the crops cultivated.

The oven itself is installed in such a way that the oven opening extends outside the greenhouse. This is necessary to protect the plants from any smoke, as well as the comfort of laying solid fuels. If the stove is completely outside the backrest, it will result in a heat loss from the metal parts of the turbine.

Heating a greenhouse with an oven

The form consists of:

- hamburger ovens;

- the chimney is located horizontally (burs);

- The outbreaks.

To increase towing efficiency, the chimney is located at a slight angle (revaluation towards the chimney).

Tilt one and a half centimeters for each meter of pipes.

How it works: when burning fuel wood in the oven, a huge amount of heat accumulates in the chimney, where it accumulates, and the associated heating of the air around the chimney. Smoke goes through the chimney.

How greenhouse gases work

Materials and tools:

- Metal corners for carriers;

- chimney and chimney pipes;

- metal plates and rods for fastening the furnace;

- welding machine, bulgarian and materials required for them (in the absence of bulgarian and metal scissors, file);

- screws, couplings for connecting pipes;

- brick and clay mortar;

- Roulette.

Step by step for making a hamburger

We measure greenhouse gases for hamburger collection and chimney length calculation.

Remember to leave the brick area they face. The upper hole will be located outside the greenhouse, the oven itself will be inside. Creation of drawings

future design.

We assemble the furnace from welded iron sheets. This will make the furnace volume large enough to increase heat transfer and reduce fuel loading.

On the sheet we produce labels and Bulgarian cut walls and bottom

the next bar is rectangular.

Drain the bottom and three sides of the oven.

Then we weld inward metal corner plugs

on which we will place the grid.

Itself lattice

We collected from longitudinal and transverse metal rods associated with welding. Alternatively, the wire is bent in a zigzag pattern.

The grate must provide fuel safely and ensure that combustion products do not enter the ash collection box.

On the roof of the stove we cut a hole for installing a chimney, fix it by welding roof oven

.

On the front of the hamburger, there should be a fireplace door and an ash-pan door, through which the oven will be cleaned of combustion products at the same time.

After marking the oven door and wall, metal metal hinges and door handles are attached. From old furniture sheds that can be misused, high temperatures will quickly turn them off.

The shorter part of the pipe is welded onto the furnace roof.

We'll get the whole chimney. The assembly design will facilitate maintenance and repair of the oven.

At the end of the work, on the bottom or end of the oven, we fix the legs from pieces of metal corner, which are connected with diameters for greater stability of the structure.

We fix our legs from pieces of metal corner

fund

The foundation is necessary to prevent possible overloading of the slab, destruction of the structure struts in the ground and to protect the greenhouse from fire.

The base for the bourgeoisie is similar to the base for other stoves and fireplaces.

And in the same way it shouldn't work with greenhouse gas. If they are very close, be sure to place a layer of sand at least five centimeters wide. All stages of work are carried out by checking the horizontal level of the building level.

Foundation construction phases:

- Preparation of a ditch depth of about half a meter;

- Filling the pit in the foundation (a mixture of small broken bricks, ruins, sand);

- Installation of panels made of wood panels and cement mortar (between the formwork and the ground filled with sand);

- Drying with dry cement mortar;

Solvents of roofing material over dry cement mortar

- The brick is of two types of baked bricks.

chimney

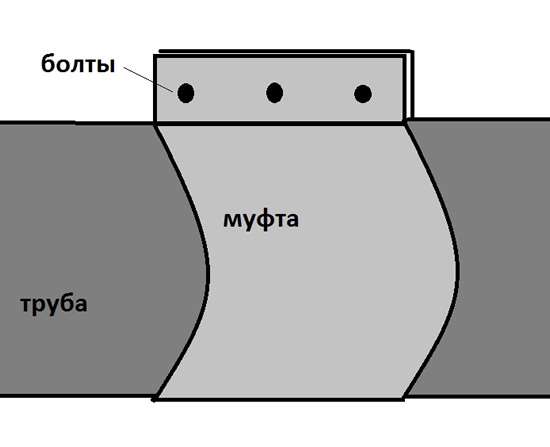

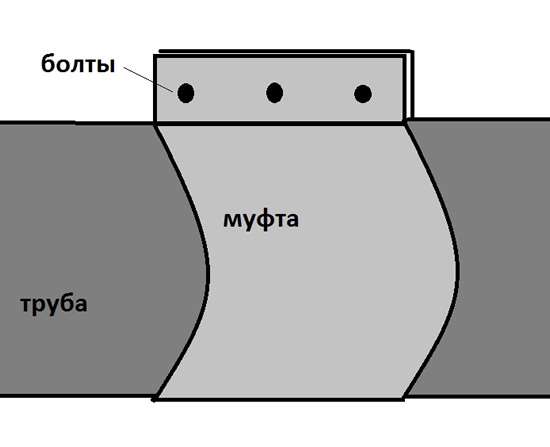

The chimney does not consist of a single pipe.

Fairly suitable pieces of the same diameter, fastened together.

It is best to use steel, cast iron or ceramic hoses. Asbestos cement is cheap, but very fragile, requires frequent cleaning and can cause fire, breathing in the room.

Chimney hood

Connection to the furnace and pipes is carried out by welding or coupling. The sleeve is a small rectangular sheet of metal that covers the pipe and secures it with wire or bolts.

Under the coupling, the joints are replaced with an oven (or a layer of heat-insulating material is laid).

Connecting to the oven with a coupling

To prevent the structure from deforming, the chimney is mounted on metal brackets glued to the floor.

The chimney must be covered with lime or chalk.

White surfaces better reflect the sunlight needed for plants, as well as deformation of pipes and smoke, immediately reveals the location of damage.

Oven burner for greenhouse (chimney)

Dima Tyube

The chimney passing through the upper ceiling of the greenhouse must be wrapped in thermal insulation material.

It protects from dirt and rain at the top of the pipe, which is located at the outlet of the spark and cone. A spark plug grinder is easy to make from a standard can that fits the diameter, with many holes. The protective cone is made of a conventional tin cover that is attached to the wire tube.

However, you can buy the finished part.

chimney

To calm the draft regulation, chimney heating and cleaning, a hole is drawn in the chimney - view.

This hole is closed by a small door, and a hatch is installed inside the hose, which is cut from pieces of sheet metal and welded to a piece of wire thickness.

The ends of the wire are transversely removed from the pipe and the shutter is secured by welding.Thus, when the wire is turned, it changes the position and the damper, which increases or decreases the gap in the chimney.

Smoke in the chimney

If the chimney has a rectangular or square cross-section, the view is made in the form of a detachable state of iron.

Square chimney view

Water tank for giving a potbelly stove

The last important detail for giving a potbelly stove is a water tank.

It can be placed on top of the oven, or it can be removed, if necessary, near a heated oven wall. This way, the greenhouse will maintain sufficient humidity and the warm water will always be warm water for planting.

To increase heat dissipation, improve heat transfer and additional fire safety, all heated parts of the oven should be lined with the oven or oven at a short distance from the frame.

The bricks are used in fire retardants and are fastened together.

DIY greenhouse stove: stages of creation

A DIY greenhouse stove will save you money. And in terms of efficiency, it will be similar to the purchased one.

Consider creating a furnace using a barrel as an example:

In order for a homemade stove to work correctly, you must insert a cone-shaped pipe into the inside of the upper barrel. You need to insert so that the narrow part goes a couple of centimeters into the opening of the partition. Fill the space around the pipe with dry sawdust.

Heating the greenhouse with stones

The air inside any greenhouse is warmed up by solar energy. The sun's rays penetrate through glass or film, heating the structure inside. This is possible in winter when the days are sunny. But at night the temperature drops to unacceptable for plants.

Natural stones can well maintain a favorable regime in the greenhouse. They are also heated by solar energy. The stones are placed along the back wall of the greenhouse or under the floor. So that the sunlight hits them. Stones should be selected with a diameter of up to 5 cm in several places to put a fan. The air temperature will not be too high during the day, and at night it will be evenly distributed around the entire perimeter of the greenhouse.

This is how this heating looks schematically

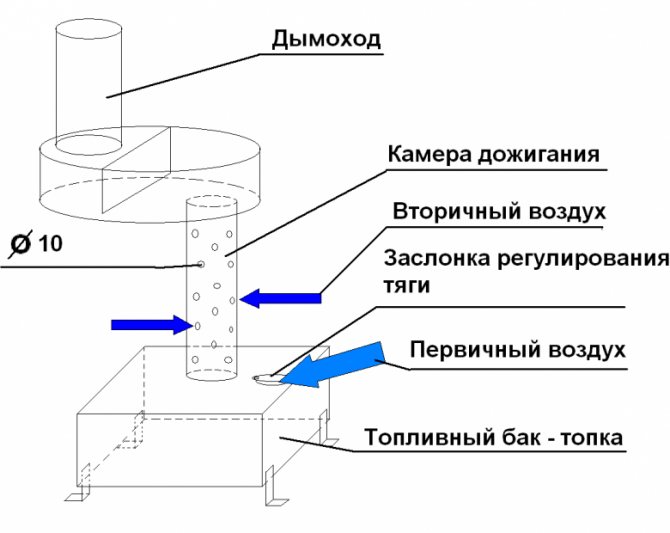

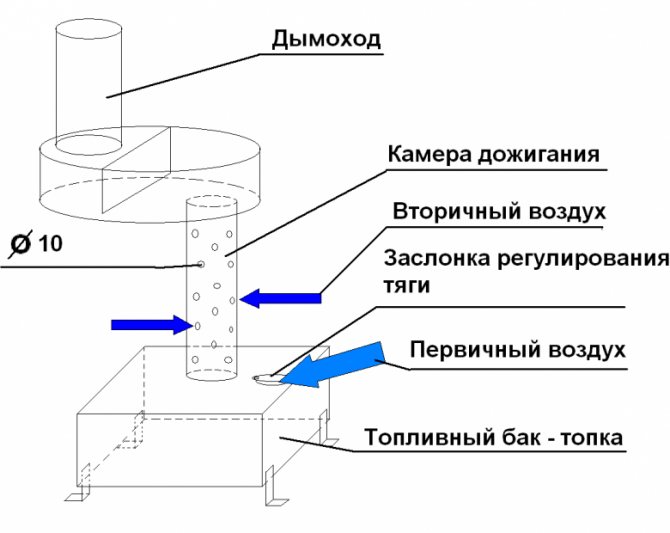

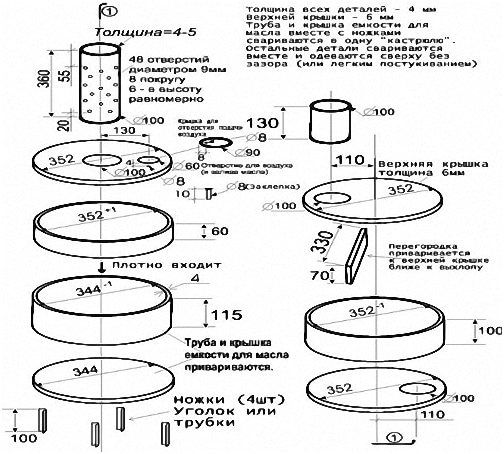

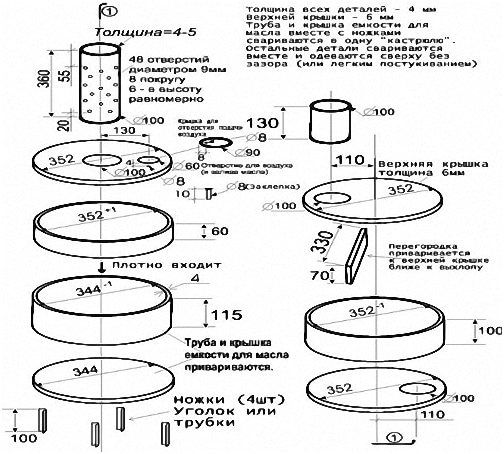

Method number 3: oven for a greenhouse from two metal barrels

The third method allows you to make a sawdust oven. The creation is not difficult. To complete the task you need:

- two standard metal barrels;

- steel pipe for the chimney;

- fittings or metal corners are used as legs.

Outwardly, it is a simple container with a resealable lid. A metal partition is created inside. The lower part of the structure is equipped with legs and a door. The upper part of the product is connected to the chimney.

- You need to cut out the top of the first barrel. A chimney is mounted in it.

- At the bottom of the barrel you need to make a Ø10 cm hole.

- The second barrel is cut exactly in half.

- In one part, a hole is created where the door will be.

- Legs are welded to it.

- By welding, the stove is connected to the chimney pipe and to the firebox.

- A lid is made from the material that remains from 2 barrels.

A sawdust oven for a greenhouse with your own hands is ready. Its performance is checked. A metal cone is made to load the furnace. Its upper part should be 15 cm. The cone is set inward, before the sawdust is laid. When the fuel is filled up, the cone is removed. It turned out a hole into which chips are poured and ignited.

To make a stove, you need two standard barrels and a chimney pipe.

Output

Long-burning stoves are popular with domestic amateur gardeners and farmers, thanks to their undeniable advantages:

- reliability and long-term operation,

- no need for constant monitoring of the installation,

- a high level of heat transfer with low fuel consumption,

- the ability to build an installation yourself from available materials without large financial investments.

The use of such ovens to heat the greenhouse will not harm the plants and will create and maintain optimal environmental conditions for the growth and development of a wide variety of crops.

Method number 4: furnace operating on waste oil

Used oil is cheap and it is possible to negotiate with the owners of the nearest service station on the purchase of fuel. Such an oven will have the following components:

- chimney;

- a hole into which liquid oil is supplied;

- pressure regulating valve;

- waste oil reservoir.

The top of the structure will be very hot, which means it can be used to heat water or cook food. To create it, you need to use the following scheme:

Used oil is a cheap and affordable fuel

The chimney will be a vertical pipe. The essence of the construction is as follows:

- Fuel is poured into the oil container. Enough from 2 to 3.5 liters.

- Then a paper wick is ignited, which is installed in the hole for the oven.

- The hole is covered with a flap. You need to leave a gap of up to 2 cm.

- When the oil has caught fire, its combustion can be controlled by the position of the damper.

- In just 5 minutes, the structure will start working and heat the greenhouse.

- The adjustment consists in adding fuel and adjusting the position of the damper.