Double-deck ovens are the most economical solution for heating large living spaces. Outwardly, they differ from conventional models, but the internal arrangement of the chimneys is similar. Efficiency lies in fuel consumption: if a certain amount of firewood is required for heating with a simple stove, then for 2 floors, it needs half as much.

Two-story stove model with two fireboxes

Advantages and disadvantages of stove heating

The double deck oven has the following advantages:

- The two-storey construction heats rooms with large areas.

- It has very good heat dissipation: 2-3 hours are enough for heating to ensure uniform heating and retention of heat throughout the day.

- Despite the bulky design and large dimensions, the stove for a private two-story house makes the rooms more comfortable.

Stock of firewood

Among the disadvantages is the need for a fuel supply. It is necessary to think over a place for storing firewood so that they do not clutter up the space.

The structure has large dimensions, and therefore the room where it will be built must be spacious.

A very important criterion is the skill level of the stove-maker. The operation of the finished structure depends on the correctness of the masonry. If the technological process is disturbed, then cracks may appear in the masonry, through which smoke will penetrate into the room, and condensation forms in the chimneys.

If you wish, you can try to do it yourself by studying the relevant literature on working with brickwork and arranging chimneys.

Benefits of using

The bell-type stove on two floors has a number of positive aspects that developers rely on when choosing the type of heating:

- Lack of alternatives. Stove heating can be arranged in almost any home. Its work does not depend on the conditions of electricity and gas supply to the premises.

- Cheap fuel supplies. Harvesting wood and coal is significantly less expensive than paying bills for using electricity or gas at home. For areas close to forest plantations, the problem of fuel disappears by itself.

- Uniform heating of the house. A Dutch oven in 10 hours will be able to completely heat a room on 2 floors and keep heat for about a day.

- Possibility to install a stove. The heating function is not the only thing a brick building is valued for. A cooking stove can be a great place to cook food, because the taste of dishes is incomparable to those cooked on gas surfaces.

Types of bunk ovens

Brick structures can be of two types:

- With one firebox.

- With two fireboxes.

The main firebox is on the ground floor. If you plan to add additional elements (a cooking stove and a stove bench), then all this is located on the lower floor.

On the second floor, you can equip a fireplace, making the room a place of relaxation. Some of the owners attach a false fireplace, but in any case, whatever the design may be, it speeds up the heating of the room.

With one firebox

A special feature of the double-deck oven is its high heat capacity. She has good heat dissipation. It reaches 5.5 thousand kcal / hour. At the same time, for constant heat, the stove can be heated once a day for 2-2.5 hours, while the bricks heat up well and the air in the room will be warm for a long time. Firewood consumption is no more than 60 kg.

Firewood for one furnace

Description of construction and materials

The design of a single-furnace stove is thought out in such a way that its operating period is much shorter than that of stoves with two fireboxes.

The internal structure consists of chimney ducts. On the second floor, the chimney is laid out vertically. To separate the interfloor heating system, metal dampers are installed. They prevent the free passage of combustion products in the form of gases.

Lingering, the gases begin to cool down, forming condensation on the inner walls of the chimney. As a result of exposure to moisture, the masonry begins to collapse. Two-furnace models are better because they provide quick heating of the furnace, and condensation does not form.

Description of a single-deck structure:

- There is one main firebox on the ground floor.

- In terms of dimensions, the building has the following dimensions: 89x115 cm.

- Height - 715 cm.

- Heating panel on the ground floor 77x102.

- The second floor is supplied with a panel with a smaller size - 77x95.

In order to start laying the stove, you need to stock up on the following tools and building materials:

- You will need red ceramic bricks for lining the stove.

- The inner part is laid out of refractory fireclay bricks.

- Red clay is useful for working with facing material.

- Use refractory clay to lay out the interior of the furnace structure.

- When mixing clay mortar, you cannot do without sand.

- Grizzly grate for the equipment of the furnace (laying firewood in the stove).

- To prevent accidentally flying out coals from falling to the floor and spoiling the coating, a steel sheet is spread in front of the firebox.

- Firebox door.

- A blower door for regulating the air supply, which is necessary for good combustion of the flame.

- Cleaning doors for installation in the chimney in order to have access to the ducts (the number depends on the length of the chimney and the design features).

- Chimney valves to regulate the outlet of warm gases.

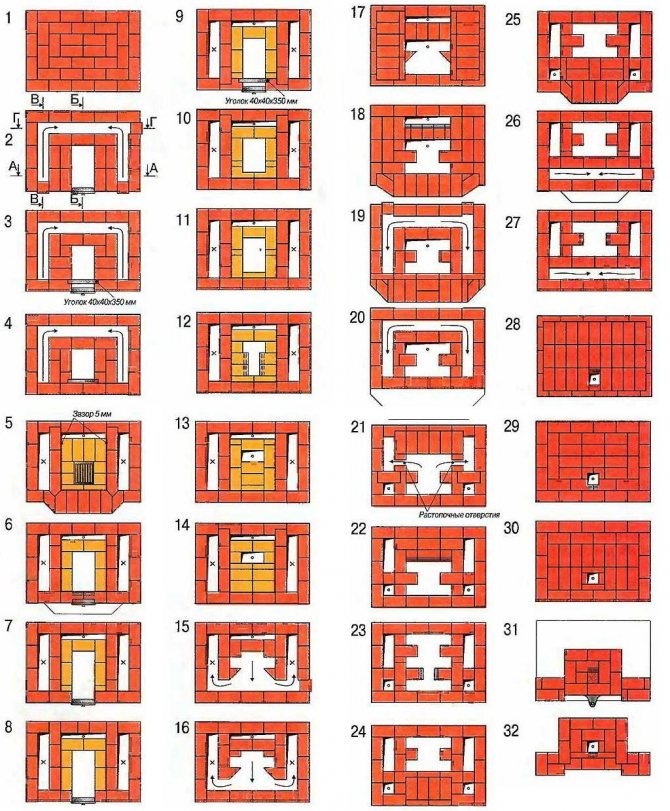

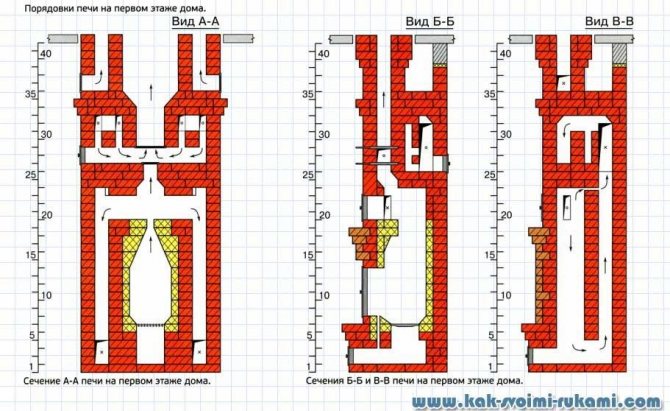

Construction sections and masonry scheme

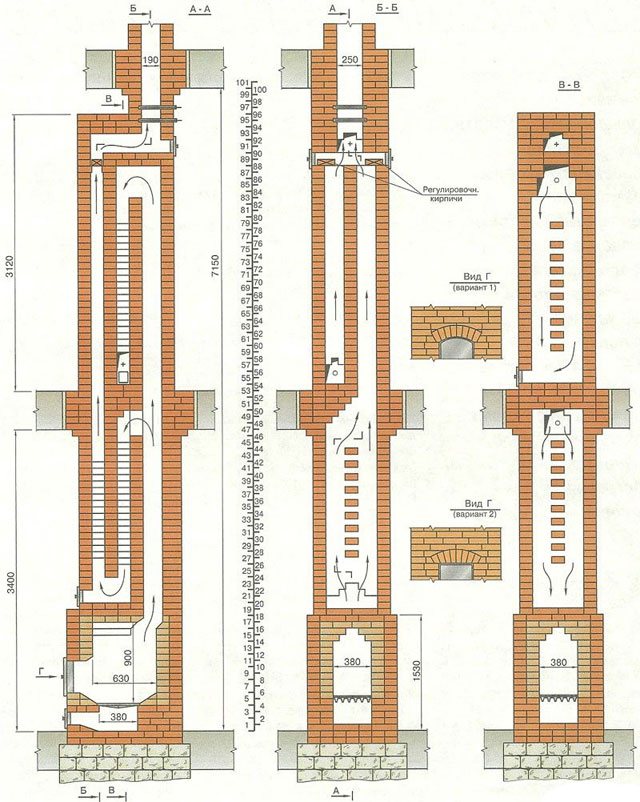

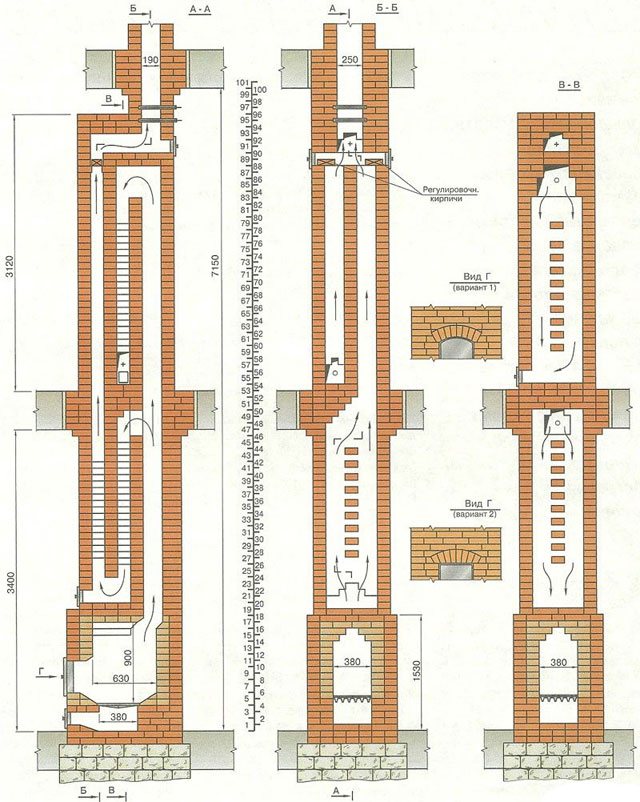

Having carefully examined the drawing of a two-story oven in section, you can see the device of the flue ducts and how the gases should move along them.

Internal organization

In the section, it is easy to distinguish between refractory bricks and facing bricks - they differ in color from each other.

It is unacceptable to use ceramic bricks for bonding with a refractory row. The same applies to the binding of the facing row with refractory bricks.

The construction is completed by a packing tube, which is erected above the furnace.

If you use the presented diagram, then the structure shown in the drawing is erected with ceilings with a height of 3 m 40 cm. If necessary, the height of the furnace structure can be easily changed. To do this, you need to make the appropriate adjustments during construction in rows 26 to 46, as well as from 60 to 82.

Attention! Changing the data that has been entered into the project will entail a deterioration in the operation of the finished furnace.

Erection of the foundation

A two-story structure weighs much more than a brick oven for a one-story house. For this reason, the base on which the structure will be erected must be more massive, capable of withstanding significant loads.

Stove foundation

In size, such a foundation exceeds the base of the stove. For example, if the base is 1000x1000, then the pillow will be 1100x1100 mm.

Before pouring the foundation, you need to prepare the following building materials:

- For concrete mortar, sand, cement and crushed stone.

- Before the concrete is poured, the formwork is built. To do this, you will need boards (old, but necessarily strong, capable of withstanding the load from the expansion of concrete are suitable).

- The bond is reinforced with reinforcement or mesh reinforcement.

- To protect the concrete from moisture, waterproofing is laid on the surface of the soil. It can be roofing material.

The foundation area can be higher than the base of the floor or at the same level with it. To do this, you need to follow these steps:

- Cover up with a sand pillow.

- Assemble the formwork from solid planks.

- Reinforce the site.

- Fill with concrete.

The foundation must be dried. The drying period lasts at least a month. Then several sheets of roofing material are laid on the base for reliable waterproofing. The construction of the stove begins on them. The base must be level, without slopes.

Furnace erection

The construction of the stove is impossible without additional elements such as grates, doors and other details. The most important thing is to prepare a high-quality clay solution. The quality of the entire structure depends on this.

Due to the violation of the proportions of clay, sand and cement, the stove will crack, carbon monoxide gases will penetrate into the room, and this is dangerous to human health.

The number of components in the solution depends on the fat content of the clay: the kneading is done either 1: 1 or 1: 2, but there is a very oily clay, which requires a 1: 3 ratio.

To test, you need to make several different solutions and roll them into balls, leaving them to dry. After drying, the material is selected, the balls from which did not crack.

External finishing

The outer side of the object can be laid out with refractory bricks and, after plastering, painted or other refractory finishes can be applied.

Finishing option

Some people prefer simple ceramic brick cladding. There are several color options for this finishing method.

You can recommend ceramic tiles, but a stove of this size will require a lot of this material.

More information about laying the stove on two floors can be found in this video:

Dimensions (edit)

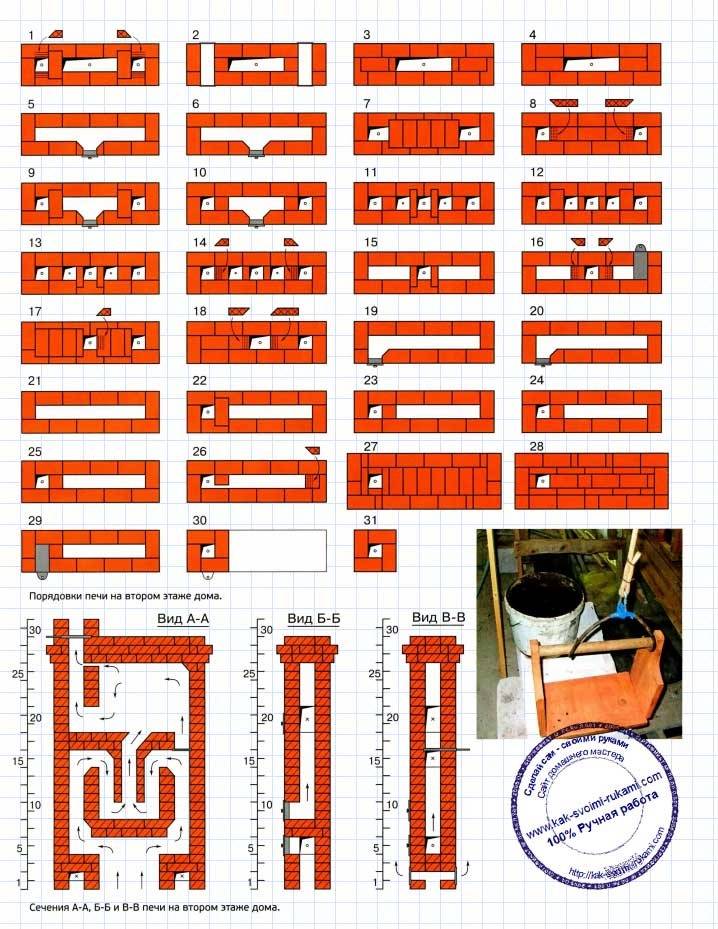

The dimensions of the firebox are designed for a single load of about 50 kg of dry logs 50 cm long and up to 10 cm thick. Moreover, the logs are placed vertically in the firebox. From the firebox, gases rise up the first ascending chimney. At a height of about 3.2 m from the floor level, part of the gases is separated into the smoke circuits of the heating panel of the first floor, and the other rises to the top of the stove and enters the smoke circuits of the second floor. Special heat exchange nozzles (outlets) - bricks protruding from the masonry into the channel - are made in the lowering channels of the smoke circulation of the heating shields of both floors and in the last lifting channel of the first floor. They increase the heat-absorbing surface in the smoke circulation and the heating rate of the furnace masonry. The last lifting smoke channels of both floors (see rows from 60 to 88 in Fig. 1 and 2) have a cross section of 120 × 190 mm and end in the upper part of the furnace with a common chamber (rows 89 and 90 in Fig. 2). In this chamber, adjusting bricks are installed, with the help of which the corresponding amounts of flue gases are distributed into the smoke circuits of each floor. These adjusting bricks rest on special projections 1.5-2 cm wide, made when laying out the channels in the 88th row. Adjustment of the distribution of flue gases is done once during the first test furnaces, moving the bricks and achieving uniform heating of the furnace masonry on the lower and upper floors. After the final installation of the adjusting bricks, the side windows of the chamber are tightly closed and covered with clay. The chimney is a top-mounted chimney, built directly above the furnace. The overlap of the pipe channel and the regulation of the draft is carried out by two sequentially installed valves. In places of possible accumulation of soot and ash settling in the chimneys, cleaning holes were made, closed with cleaning doors.

Video double deck oven:

Two-story stove with hob and fireplace

A structure with one firebox is equipped with a fireplace insert on the second floor; it can also be equipped on the first floor.

The design is supplied with a hob, which is indispensable in the kitchen.

Oven with hob

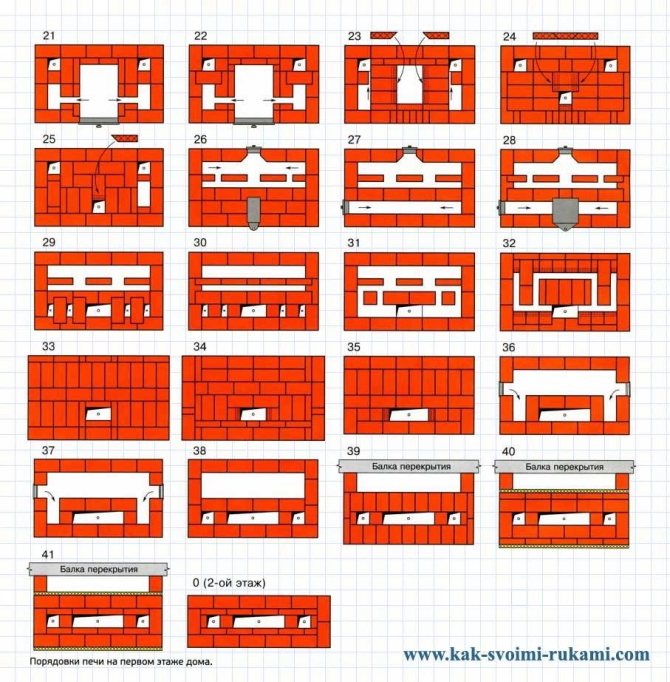

Ordering

Laying ordering requires knowledge and experience. Here it is necessary to take into account the peculiarities of the masonry of each row with all its nuances.

With such laying, the operation of the equipment is greatly simplified.In the building, red and fireclay bricks are used in approximately equal quantities.

Materials:

- 300kg sand and clay mortar

- 550pcs bricks standard 250 * 120 * 65 (soak)

- + base for the oven

- 1 furnace door 21 * 25cm

- 1 blower door 14 * 25cm

- 3 cleaning doors 12 * 12cm

- 550 red brick

- 1 oven 45 * 25 * 29cm

- 1 grate 20 * 30cm

- 1 latch 25 * 13cm

- 1 cast iron stove with 2 burners 41 * 71cm

- 1 valve from the hood 13 * 13cm

- 30 fireclay bricks ША8

- 1 steel corner 45 * 45 * 700mm

- 5 steel corners 45 * 45 * 905mm

- 2 steel strips 50 * 5 * 650mm

- 1 drying shelf 190 * 340mm

- 1 overlap sheet for drying chambers 800 * 905mm

- 1 pre-furnace sheet 500 * 700mm

Up to 11 rows will include. the laying of the furnace is made in half a brick, after 11 r - on the edge.

And a little from us: Swedish stoves and Buslaev stoves are slightly inferior to modern bell stoves in terms of efficiency and heat capacity. Also, slightly improved models have already appeared - for example, the Moskvichka oven. Choose carefully!

best native ads network 2019whitelabel

Share on social media networks

0

Tweet