Covers for pipes are an affordable tool to update the appearance of the roof, to hide irreversible changes in dilapidated, unrecoverable chimneys. Covers for pipes are made to order, according to individual dimensions, in two versions:

"Dismountable" - for ease of installation and transportation. In the finished version, the casing has vertical stiffening ribs that give the product a distinctive look.

"ALL-METAL" - this option allows you to install the entire casing on the pipe with small dimensions. This saves time on installation work.

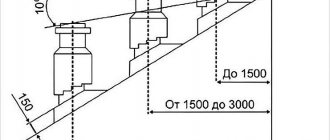

Usually, for chimneys, the following dependence is valid - the higher the pipe, the better the draft. The metal casing should not spoil the impression of the aesthetics of the facade and the interior of the house, therefore, the excessive elevation of the chimney above the roof will turn your building into a kind of industrial boiler station. In this case, the ratio of the cross-section of the pipe and its height must be calculated by a specialist.

As a rule, even a small pipe height is sufficient - its overhead part should rise only 0.5 meters above the ridge, since the atmospheric pressure at the level of the combustion chamber is always higher than the pressure of the air column above the roof.

The metal casing for chimneys has a number of advantages:

- ease of installation - long operating period - mechanical strength - the metal casing weighs significantly less than a pipe made of bricks, so a foundation is not required for them

Our site is not only informational, but also service. It provides a quick calculation of the cost of products.

Some of the owners of suburban housing, bath rooms, do not take into account special nuances when designing chimneys. For an example of today's article, let's take a box on a chimney pipe. Many people forget about it, but this is one of the main safety requirements, especially in wooden buildings. In advance, I would like to stipulate that it is quite difficult and time-consuming to make parts of the apron on your own. After all, this is not just a decorative element, which it certainly is, but not to the extent that it is a technological one, for smoke removal and reliable thermal insulation from ceilings. In order for the work to be done efficiently, you need to know a lot of nuances, among which, for example, the material for the manufacture of the pipe and the materials of the floors.

Types of chimney boxes?

Today, manufacturers offer two main types of casings:

- Galvanized.

- Corrugated (stainless steel).

The "case" of the first type is considered more suitable and in demand. It has high fire resistance properties. In addition, in terms of service life, such a casing for a chimney on the roof is considered the most durable. Galvanizing is, in principle, easy to install, which, of course, is considered an important point when choosing. As a rule, metal with a thickness of 0.40-0.50 mm is taken as a basis.

The corrugated stainless steel cover is also very easy to install. In addition, it is the corrugation that has a decisive advantage, namely, it has the ability to take any design forms, which is quite convenient. By the way, such pipe boxes are highly resistant to temperature and atmospheric extremes. And corrosion is less susceptible.

The casing can even be made independently, with the necessary tools at hand. So which material is right for you:

In addition, do not forget that in addition to the box, you need to choose a heat-insulating material that is characteristic of each product. So, when choosing, be guided by:

- Flue gas duct materials.

- Temperature conditions at the highest peak values.

- Heat-resistant properties of the material itself.

Pay special attention to the choice of chimney insulation if the choice fell on plastic. Like any polymer, it has a number of specific nuances that must be taken into account in any case.

Decorative box

You can easily assemble a pass-through casing yourself, the so-called decorative. Do not assume that such casings will differ in their properties. After all, the main function is one and it is adhered to in any case. It will be about how the body can be processed, how it can be brought into a single modular segment with the rest of the building. The problem is not presentable, it can be easily solved with the help of a decorative coating, which you can easily find in stores. The most common finishing coating today, made of polymers. It is capable of imitating wood, brick, stone and the like, without limitation.

For example, the metal box itself does not represent any decorative highlight and attractiveness. However, finished with polymer, it can imitate brickwork or laid beams, logs.

Making a wooden frame

Making a frame is one of the most important things when working. Indeed, the durability and stability of the entire structure will depend on its characteristics. Often, wooden lathing is used for gas boilers and channels, which will subsequently be processed with a picket fence or OSB sheets. It is not justified to mount wooden frames for metal or plastic parts. After all, more space will be required for a slot in the base of the roof, which will have a rather negative effect on the bearing capacity.

- Measure the dimensions you want on the roof.

- By size, hold, drank in the rafters and floors.

- Make four U-shaped bar blanks, which will subsequently be joined in the overlap itself.

- Consider extreme lathing and vapor barrier.

- Also, don't forget that the bottom will need to be made.

Given the temperature changes, it is better to make it from metal or, in extreme cases, from plastic. A tree for such purposes is not the best option, since it will play and constantly “take” a different overall structure.

It is better to make a chimney box with an assistant. This makes it easier to dock and fasten a weighty structure.

Manufacturing of a metal box

Let's say a hole in the wall, the overlap has already been made, now it's only about the manufacture of the case. Therefore, we carefully study the stages of work and instructions. So:

- After cutting the required hole, we recommend to strengthen the edges with "support", use a bar with a section of at least 40 to 40.

- We cut out two plates from metal, keep in mind that they should be 50 mm. more hole. Next, we bend them so that an angle of 90 degrees is formed, thereby obtaining two U-shaped figures.

- The strips are screwed to the hole.

- The next stage involves the manufacture of similar U-shaped structures, but of a different size, according to the initial parameters and dimensions of the already bolted strips. New elements need to be overlapped.

- Next, we prepare the bottom and the "roof". Cut out two identical sheets, corresponding to the size of the hole. Cut a hole in the middle for the chimney.

- Next, we mark four identical stripes from the center. We bend it at an angle of 90 degrees, so we get a mount. Consider the optimum width of 20 mm.

- Further, the bottom and the lid are attached to the U-shaped forms and screwed on. After that, you can insert the pipe, pay attention not to its fastening, use clamps. Further, the entire space is filled with the selected thermal insulation.

The chimney box is a structure that is assembled from different materials and serves as a heat insulator, as well as additional protection for the chimney.In addition, such a case performs one more function - an aesthetic one, giving the chimney a presentable appearance. If desired, it can be completely or partially dismantled, which is very convenient and functional.

The metal casing, put on the chimney, performs a protective and heat-insulating function

Chimney box: types and design drawings for a pipe on the roof, do it yourself

Hello dear readers! A good chimney made of stainless steel or other reliable material is an important part of a home's heating system. But an equally important role is played by such a device as a chimney box. About its meaning, what it is, what types there are, whether it can be made by hand, and will be discussed in our article.

What is it and what is it for

Any chimney is designed to remove combustion products outside. Naturally, they pass through it in a hot state, therefore, in places of overlap (ceiling, attic, roofing), a hot chimney or chimney will be a fire hazardous object.

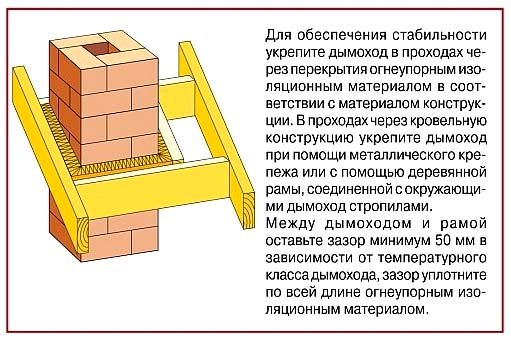

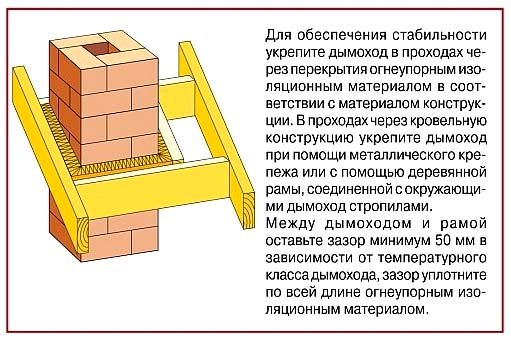

For fire protection, thermal insulation of the chimney is provided, in particular by the so-called cutting. Here, the construction of a box around the chimney plays an invaluable role. The cutting material is placed in a casing made of non-combustible material and can be of different heights.

Its second important function is to decorate the pipe protruding from the roof, especially if the pipe does not fit into the overall design.

Principle of operation

The casing is put on the chimney and acts as an additional thermal protection of buildings when it passes through the ceilings.

On the roof, it not only protects the brick chimney from destruction, but also serves as a design element.

Advantages and disadvantages

The construction of the box creates the following advantages for the owners of the chimney:

- the chimney will be protected from the destructive effects of natural forces - wind, rain, snow;

- protects brick chimneys from the formation of condensation, its destructive effects;

- insulating the pipe, provides normal traction;

- pipes with a beautiful finish look aesthetically pleasing on the roof;

- a properly erected element reliably protects the building from fire.

The disadvantages include:

Types and designs of boxes

Boxes are:

- oven;

- for the roof;

- for ventilation;

- decorative.

Usually the boxes are made of metal. They are painted in a suitable color, they serve for a long time.

Stainless steel products are used for decorative elements on the roof, indoors.

Galvanized devices, complete with plastic elements, are cheaper, so they are used more often.

Boxes in the form of a wooden frame are installed only for cladding brick chimneys. In addition, they must be additionally covered with a metal casing.

Fireproof drywall boxes are installed indoors for decorative purposes, in attics, they are used to close channels embedded in the wall.

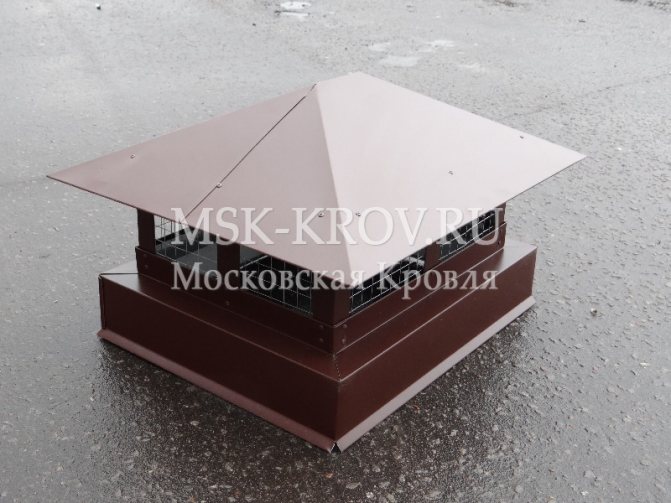

The chimney section on the roof is protected with a metal decorative casing with an umbrella.

Do it yourself or buy

The box device is quite simple and it is quite possible to build it yourself. However, this requires skills in working with the metal, the appropriate tool. In addition, most of the installation work will have to be done on the roof. Therefore, it will not be superfluous to use the services of professionals.

Tips and tricks for choosing

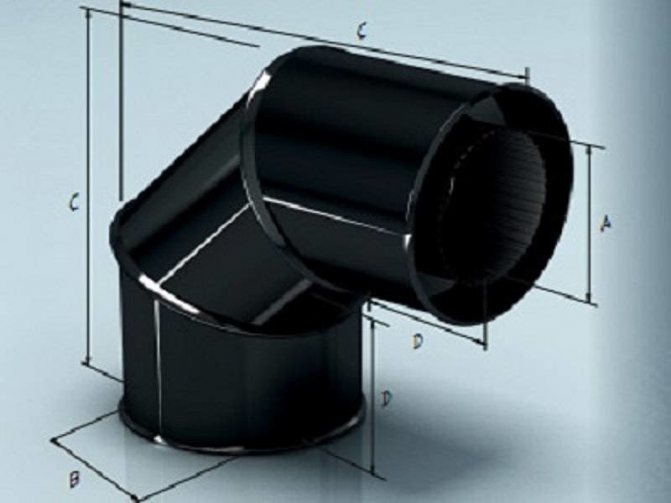

The choice of the duct is determined by the type and size of the chimney. The main selection criterion is the diameter for the pipe passage.

For the passage unit in the ceiling, a product is selected, consisting of a stainless steel plate and a neck, the diameter of which is slightly larger than the chimney.

The design of the stainless steel platform is quite suitable for mounting on the ceiling of the house.

The photo shows the main configurations of the boxes produced:

The roof box shown in the lower photo can be purchased according to already predetermined dimensions or ordered to be manufactured.

The cost of finished products varies from 550 to 1900 rubles and more.

Work progress

A homemade box is made of galvanized sheets, cut to size:

- in the bottom, the center is found through the drawn diagonals;

- punch a hole with a nail, draw a circle;

- a hole is cut through the hole with scissors for the diameter of the pipe.

The sides are made of 4 sheets, fastened with a riveter at least 4 rivets per seam.

Previously, the lower parts are bent to a width of 5 cm and through them the resulting structure is riveted to the base.

for installation

How to sheathe a chimney:

Making a homemade box:

Ceiling penetration:

Frequent errors and problems during installation

Violation of the standard dimensions for the placement of the box and smoke channels in the ceiling opening, which leads to conflict situations with the fire service.

An umbrella that is too large on the top can cause brown streaks on the roof. Condensation formed on its cold surfaces throughout the winter. The area of the umbrella must be reduced.

The same situation can arise with a metal box on the roof, which immediately closes the smoke and exhaust ducts. Expanded clay poured to the edges of the channels in this casing will help.

A wide gap between the pipe and the penetration - as a result, the laid fine expanded clay pours down.

Use of penetration without backfilling of thermal insulation material. There is practically no protection whatsoever.

Expert advice

It is better to close the casing through the ceiling slab from above with a metal sheet with a hole for the chimney.

The final element of the entire chimney structure is a beautifully crafted or purchased umbrella. It protects the system from rain, large debris.

What is a pipe casing for?

The chimney on the roof is a very important part of the chimney structure. Its location, the material from which it is made, as well as accessories on the chimney - all this affects the traction indicators in the system. This part of the chimney structure is located outside the building, therefore, various destructive environmental factors affect it all year round: precipitation, wind, temperature changes.

Regardless of what material the chimney is made of, these factors gradually destroy it, which inevitably leads to a deterioration in the traction performance in the system. And as you know, thrust is the main indicator that determines the operational characteristics of the system as a whole.... Therefore, the installation of a protective case on the chimney pipe provides not only its protection, but also prolongs the operational life of the chimney structure.

Pipe protection (pipe box)

We can manufacture an additional metal casing for your chimney, which will not only serve as an excellent protection against atmospheric precipitation, but will transform the design of your chimney. Many of our clients, having come to our office to order caps, ordered additional protection for a brick pipe. Nowadays, unfortunately, we often find that the bricks used in the manufacture of the chimney are not of very good quality. Our clients ordering a weather vane or a chimney for a chimney from our company MK-profile or starting the reconstruction of a “grandmother's” house are faced with the following problem:

Destroyed chimney

Agree that it is not very pleasant to see such an engineering solution on the roof of a house. This is of course an extreme case.

Let's avoid this.How do you ask? We are pleased to offer you our special, reliable, well-proven solution for almost any chimney - a protective cover.

The protective casing not only protects the chimney from precipitation, snow and rain, but also creates additional protection against fire. Another plus, your chimney will acquire a unique design to the delight of you and the envy of your neighbors.

Chimney protection

Our company MK-profile will manufacture a protective casing for a pipe strictly according to your dimensions and, if necessary, our specialists will install it at your facility.

We use various types of steel in our work:

- galvanized

- polymer coated steel

- copper

- it is possible to paint with powder paint in the chamber in any color

Making a box according to your size will take only 1 - 2 days, and the result will delight you for a very long time and will serve as an excellent protection for the chimney.

Many do not pay due attention to the protection of the pipe, which leads to very sad consequences.

In our company you can buy a box for a chimney pipe of any size made of galvanized sheet and sheet with a polymer coating, as well as order copper boxes for chimney, ventilation and stove pipes.

Varieties of casings for the chimney pipe

Today, the most popular are two versions of such casings. Consider them:

- galvanized casing for pipes;

- corrugated cover made of stainless steel.

The chimney case made of galvanized steel sheet is the most demanded. Galvanized steel has high fire resistance, corrosion resistance and long service life. The galvanized casing is easy to install, which is also a very important factor affecting the popularity of this product. Such products are made from galvanized steel sheet with a thickness of 0.45 mm.

The corrugated case made of stainless steel is also easy to install and has one very important advantage - the design of the corrugated box allows it to be bent, to give it the required shape, which is very convenient. Such a casing is resistant to corrosion and temperature extremes.

It is best to use chimney hoods that are made of metal that is resistant to corrosion.

Protective cases can perform the function of organizing thermal insulation for the chimney. Covers for thermal insulation of chimneys can be made from different materials with your own hands. Consider these materials:

- galvanized;

- roofing iron;

- aluminum;

- plastic;

- profiled sheet;

- slate.

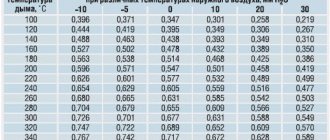

When insulating the chimney on the roof, a suitable thermal insulation material must be used. The heat insulator is selected individually for a specific situation. When choosing a heat-insulating material, it is worth considering the following indicators:

- chimney material;

- chimney heating temperature on the roof;

- thermal stability of heat-insulating material.

The thermal insulation material must be resistant to the heating temperature of the chimney in order to avoid ignition. You need to be especially careful when choosing a heat insulator if you are installing a casing made of polymer material. A plastic pipe box is easy to install, however, it is considered the least safe option, so you need to provide the necessary thermal insulation of the chimney, taking into account all fire safety rules and regulations.

Protective structure can be decorative

Features, types and purpose of the chimney

A steel chimney made of ferrous metals, which is based on zinc, is an integral component for any furnace or boiler that uses solid fuel, which requires the timely removal of all combustion products and decay to the street.

Before you buy black steel chimneys, you need to think over exactly where such a structure will be installed, indicate all its features, dimensions, select suitable materials and accessories for successful implementation.

The chimney pipe, black steel, for the manufacture of which is very popular among stove-makers, can be made of the following materials:

| Chimney photos | Manufacturing materials | Description and features of materials |

| Steel | The most common material is steel. They have a lot of advantages, first of all, it is an affordable price, as well as a low weight, which together allows you to create a durable and effective structure, by the efforts of one person. The steel chimney quickly warms up and cools down quickly, it is unnecessary for it to equip an additional foundation, it does not have a significant and negative effect on the walls and ceiling of the house. |

| Cast iron | An expensive material from which furnaces are often made with high efficiency and good heat capacity. Also, pipes are made of cast iron, from which chimneys are assembled. The main disadvantages of this option are the high cost and high weight. The advantages are good retention, accumulation of thermal energy. |

| Zinc | This variety was in great demand and popularity for another 20-30 years. However, today it has been proven that pipes made of zinc-based materials are hazardous to human health. When heated and there is a sharp change in temperature, they begin to emit harmful and hazardous products into the air. Therefore, today, it is strictly forbidden to make chimneys from galvanized components. |

a stainless chimney, Moscow and the region for which these are the main delivery regions in our online store, will serve you for more than one year and at the same time will not cause problems and unpleasant moments during its operation, maintenance and cleaning.

So how does this chimney differ from those made of stainless steel? The fact is that pipes, which are based on stainless steel, are more durable and of higher quality, they retain heat very well, do not freeze in winter and do not form a large amount of condensation on their inner walls if they are properly insulated.

If we talk about the features of black steel chimneys, then they, in turn, are not made of simple stainless steel. They contain a carbonaceous base, which is inherently completely safe for human health, even with strong heating, it does not emit harmful decay products. Also, such pipes differ in more affordable and budgetary cost, in comparison with stainless steel pipes and sandwich systems. However, with all its advantages and positive qualities, such hoods also have several disadvantages. The fact is that they are not as durable, much less durable and wear-resistant than those made of stainless steel.

However, this option is ideal for a number of specific cases where unnecessary spending is inappropriate. This option can be installed in a country house, in a bathhouse where there are other sources of heat generation, as well as in places where there is no need for frequent and daily heating of a fireplace or boiler. The best option would be to install and buy pipes based on low-alloy steel, which has increased resistance to the formation of plaque, rust and corrosion.

If you want such a structure to serve you as long as possible, we recommend giving preference to pipes made of thick-walled steel, which will not become thinner so soon. Also, the best option would be to assemble a chimney from long pipes and similar connections.Which, in turn, form the minimum number of seams and joints, with which the very first and most serious problems arise.

Decor of a steel box for a chimney pipe

Pipe covers are not only functional structures, but also, as mentioned above, affect the exterior of the structure. Today, you can easily order a product that will decorate your home decor and will please the eye for many years. If we compare a metal box for a chimney pipe with casings made of other materials, then it is the least presentable.

However, this problem can be easily solved with the help of special decorative coatings, which can be purchased at any specialized store or ordered with home delivery using the Internet. Decorative coating for metal casings will give your box a presentable appearance. Today you can find a wide variety of colors and textures of such coatings, so everyone can choose the option they need.

A decorative coating consisting of a polymer material must be applied to the metal. The polymer material mimics the structure of another material (wood, stone, etc.). The use of such decorative coatings makes it possible to make a brickwork pattern on a metal cover, while a real brick pipe will be reliably protected by this cover from environmental influences.

Advantages and disadvantages

The use of a box for a chimney pipe helps to improve the operational and decorative characteristics of the device:

- the formation of condensate on the walls of the gas outlet is leveled;

- the intensity of soot and soot deposits is reduced;

- the possibility of large thermal differences between the temperature of the flow of combustion products and the inner surfaces of the gas duct is neutralized, since the coefficient of heat capacity of the material of the smoke channel is improved;

- deterioration of traction is excluded

- reliable protection against aggressive atmospheric influences is provided;

- the level of fire hazard of the chimney structure is reduced.

A big plus in the piggy bank is considered a presentable view of the chimney on the roof, which is equipped with a protective and decorative box in the same style of the facade.

The disadvantages of the device include the need for drawing work in the manufacture of a box with your own hands and serious safety requirements for installation on the roof.

Installation of the steel case

A steel case is the most common option for organizing a protective casing for a chimney. Consider the process of installing a steel casing on a chimney:

- The case can be purchased or made by hand, using steel sheet, profiles and ordinary screws for this.

- A steel casing is installed on the main pipe.

- At the third stage, the space between the main pipe and the case is filled with heat-insulating material, which must be selected based on the heating temperature of the chimney.

- Finally, the case (made of galvanized or stainless steel) must be painted with oil paint.

Installation of a box for an asbestos-cement chimney

Consider how the casing is installed on an asbestos-cement chimney pipe:

- First of all, it is necessary to prepare the pipe for the installation of heat-insulating material and a box. To do this, it is necessary to clean it from dust and dirt.

- In the second step, you need to place the thermal insulation material in a case made of galvanized steel or roofing iron. Mineral wool can be used as a heat insulator. The thermal insulation material is located along the entire length between the casing and the pipe.

Helpful information! When choosing an indicator of the cross-section of the case, one important factor must be taken into account, namely, the distance between the casing and the chimney must be at least 6 cm.This space is necessary for free placement of thermal insulation material.

- The upper part of the pipe is mounted with a slight slope.

- The niche between the asbestos-cement chimney and the pipe must be filled with cement mortar. For these purposes, concrete of the M-150 brand is perfect.

Mineral wool can be used to fill the space between the pipe and the casing

It is recommended to assemble such a case from several parts. This is a necessary measure to simplify the installation of the heat insulator.

Brick chimney box

For a brick pipe, you can choose a standard galvanized steel cover or another option. For example, plaster a brick chimney over a heat insulator. Let's consider this process step by step:

- First, it is necessary to clean the brickwork of the pipe from dirt and dust.

- Next, you need to install metal profiles on the chimney. For this, ordinary dowels are used. First of all, it is necessary to fix the upper and lower profiles, and then insert the racks into them. Racks are fixed with self-tapping screws.

- At the third stage, the installation of heat-insulating material is carried out. It must be placed between the grilles and fixed by means of special dowels with "skirts". The heat insulator must completely cover the surface of the brick chimney.

- Then the thermal insulation material must be covered with a vapor barrier material, which is represented by a special film.

- At this stage, it is necessary to fix the plaster mesh over the vapor barrier film. The mesh must adhere tightly to the surface, therefore it is recommended to use dowels with "skirts".

- The chimney is plastered with a pre-prepared cement mortar. It is necessary to apply the plaster in an even layer over the entire surface of the structure.

After the layer of plaster has dried, you can revet the chimney with decorative tiles or galvanized sheets.

For the box, you can use wooden, plywood boards, fiberboard or chipboard, but they must be protected from moisture by an outer coating

Purpose of chimney / weather vane

Chimneys, or, as they are also called, wind vans, are used in the arrangement of chimneys and perform the following functions:

Box of wooden boards

A wooden board case can be made in two ways. Let's consider the first way:

- First of all, you need to make a wooden frame, focusing on the size of the chimney.

- Further, the finished frame is revetted with slate.

- In the third stage, wooden shields are installed around the pipe.

- Finally, it is necessary to fill the space between the metal pipe and the wooden panels with thermal insulation material. The following can act as heat-insulating material:

- glass wool;

- slag;

- dry land.

Consider the installation technology of the second method:

- Wooden shields are mounted around the pipe, forming a box. The distance between the metal pipe and the wooden board must be at least 5 cm (preferably 10).

- In the second stage, the internal seams are lined. For this you can use asbestos sheets.

- Further, slate is mounted on asbestos sheets.

- At the fourth stage, you need to cover up the outer seams of the box made of wooden panels.For this, you can use a cement mortar.

- Next, slabs of cinder concrete are mounted (at a short distance from the metal pipe).

- Plates must be reinforced using ordinary wire.

- At the end, the space between the plates and the pipe is filled with mortar. For the solution, you must use gypsum and clay.

Protecting the chimney from destruction under the influence of natural factors is an important measure that will extend the life of the chimney. For the protective box, you can use different materials that are available to any craftsman today.

Thermal insulation of pipes with concrete slabs

This category includes slag concrete and reinforced concrete. Plates are mounted around the pipe, fastening the structure with strong wire, which plays the role of reinforcement. A mixture based on gypsum and clay is poured into the space formed between the walls of the chimney and the plates.

The construction of concrete slabs is rather bulky, therefore, in private housing construction, such heat insulation of chimneys is not used.

There are many more ways to insulate chimneys, and each specialist can offer his own. In our article, only some of the options for thermal insulation of chimneys are considered.