How to bend a pipe at a right angle

Metal acts as a fairly strong material, but with special exposure it can be bent. To date, there are several ways to address this issue. The first technology is the use of pegs. But you must remember that this method can damage the pipe or even break it. This can be avoided by filling the inner cavity with dry sand. Plugs should be installed at both ends.

The next step is to start flexing. For this, pegs are dug into the ground. You will use them as leverage. If you are not confident in your abilities, then first you should practice on unnecessary pipe sections. If you are faced with the question of how to bend a pipe without a pipe bender, then using this technology you can change the shape of a product, the diameter of which varies from 16 to 20 mm. For pipes of a more impressive diameter, this technique is not suitable, since the process will be rather complicated. It is also important to consider the underlying material. For example, other methods are recommended for galvanizing.

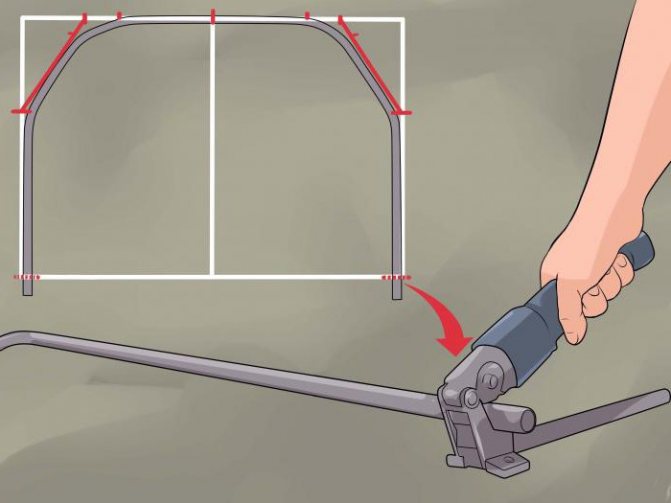

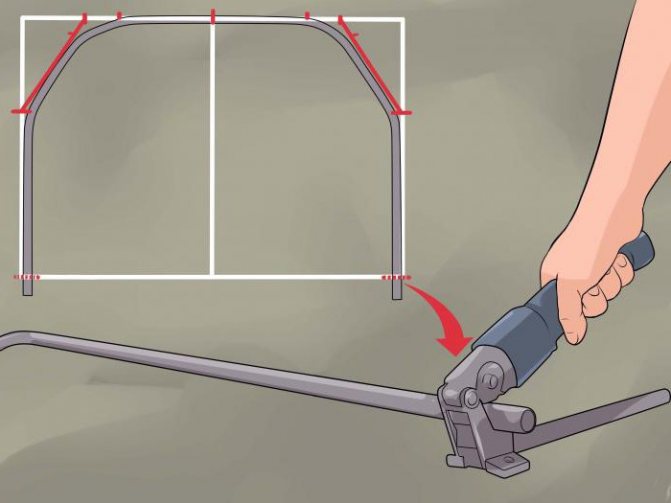

How to make a pipe bender yourself

In some cases, you can do without purchasing manual profile bending machine. This device can be made by yourself. It is suitable for processing small-diameter pipe products, for example, for the frame of gazebos or greenhouses.

For pipe products, the diameter of which does not exceed 2 cm, it is enough just to create structures from

concrete block and steel bayonets... 4 holes are made in concrete, metal pegs are inserted into them, through which a professional pipe is passed and bent in the desired direction.

For pipe structures with a diameter of more than 2.5 cm, it is necessary to create a profile bend using rollers... They are fixed on the concrete base. The value of the radius of the side edges of the rollers must be equal to the radius of the bent pipe. The profiled pipe, placed between the wheels, is fixed at one end. At the other end, it is attached to a winch, which is driven and gives the pipe the necessary bend.

When creating homemade pipe benders for a profile pipe, the following parameters must be taken into account:

- Distance from the pipe to the profile bending drive wheel depends on pipe dimensions: for a product with a radius of 2.5 cm, a gap of 6 mm is required, for larger pipe structures this figure varies from 6 to 12 mm.

- Too small a distance between the wheel and the pipe will result in the need for put in a lot more physical effort for bending the pipe structure.

- Too much clearance will result in uneven bending and violation of the integrity of the structure.

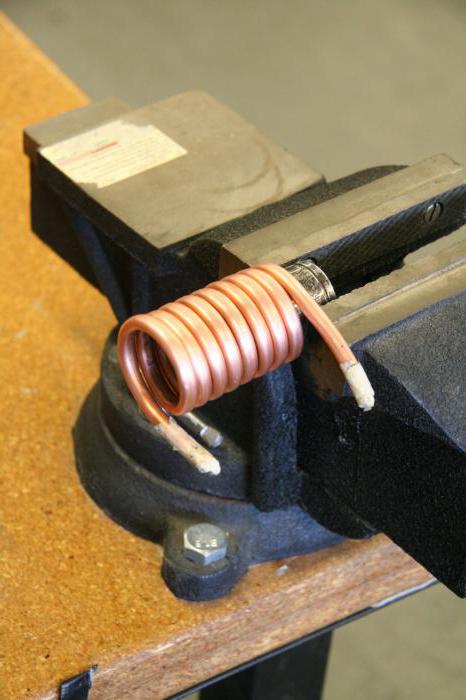

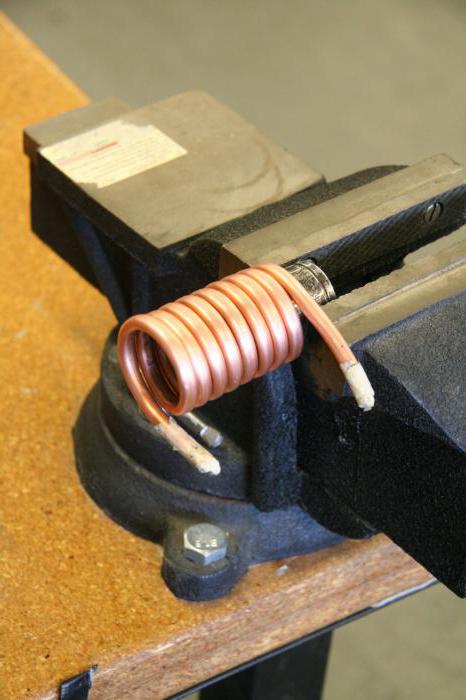

Using heating technology

Before bending a pipe without a pipe bender, you should think about which technology is best for this. Heating may be a great solution. This method is commonly used for steel and aluminum piping. For the procedure, the product is fixed in a vice, but first it should be filled and heated with a gas burner to the place that you plan to bend. The temperature is determined quite simply: when a piece of paper approaches the pipe, it should start to smoke. When a steel billet is used, it should turn red when heated. For safety, the technician should wear gloves.

Plane-parallel plate

If you are faced with the task of how to bend a pipe without a pipe bender, you can use a plane-parallel plate. This technique involves fixing the product in a clamp. After that, you can bend, and this must be done along the plate. This technique is considered not only economical but also simple. In order to achieve a positive result, several plates should be used, each of which has a different curvature. The main condition is the use of a steel pipe. The length of the product should be quite impressive.

Using a metal spring

Quite often, home craftsmen think about the question of how to bend a pipe without a pipe bender at home. A metal spring can be used for this. This technique is excellent for non-ferrous pipes, which have good ductility.

A spring is used to prevent deformation. To obtain a good result, the size of the spring must be taken into account, which must correspond to the inner diameter of the metal structure. This requirement is due to the fact that the pipe is to be inserted into the cavity. Bending can then be carried out by tying the spring with a wire to make it easier to retrieve it later.

How to make stainless steel chimneys with your own hands - design and technology

Chimney design should always be done professionally. To do this, it is necessary to take into account the specifics of the operation of the heater, to know the parameters of the building and the climatic characteristics of the area. Only after taking into account all these parameters, you can choose the optimal technology and material for the manufacture of the chimney (more details about the types were written here).

With the advent of modular sandwich chimney systems, many craftsmen set out to make their own analogs. But is it possible at home? To answer this question, it is necessary to analyze the materials and tools used.

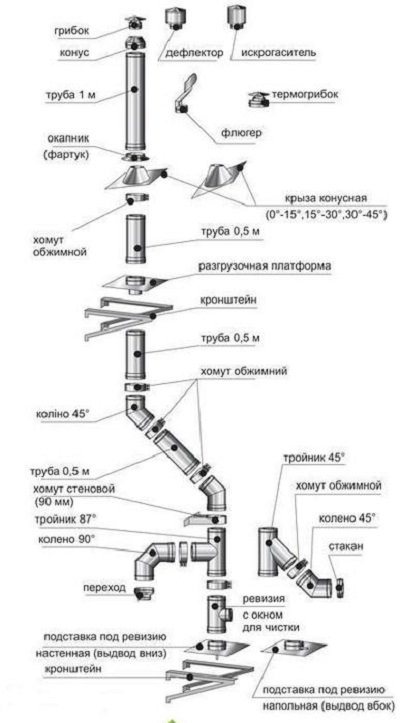

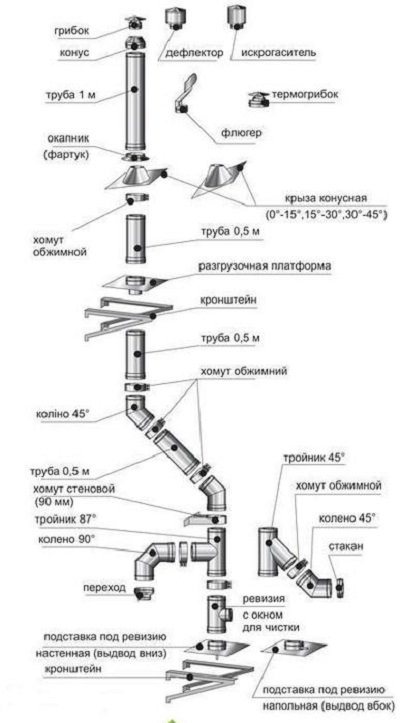

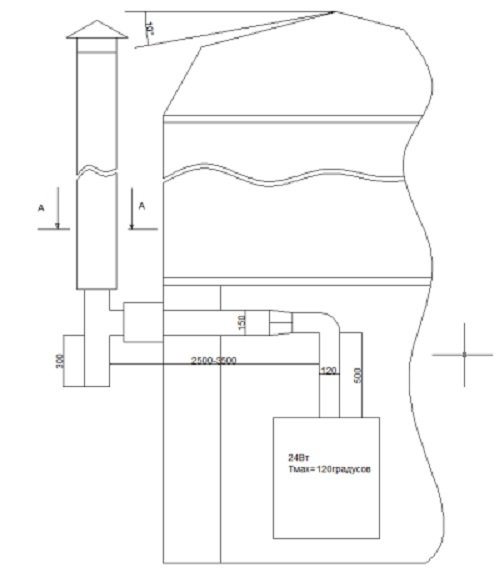

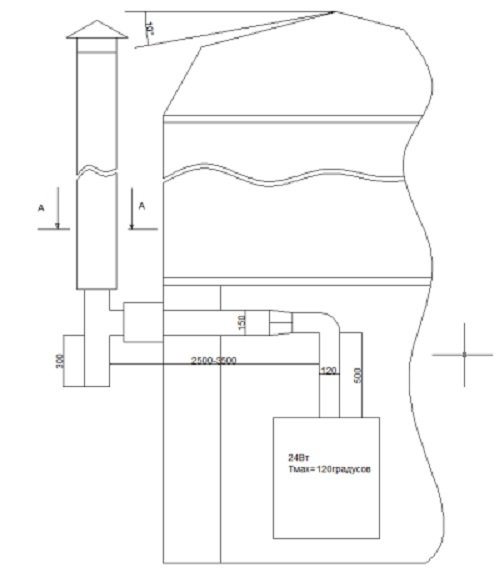

Drafting a chimney

Before making a chimney, you need to know the exact consumption of material. For this, a plan is drawn up, taking into account the specifics of the building and the location of the boiler.

Moreover, it is necessary to take into account the diameter of the pipe, which must correspond to the characteristics of the heater. Often in such cases, mistakes are made when planning long horizontal sections of the pipeline.

This leads to a significant decrease in thrust and a rapid formation of soot in the horizontal pipe.

Requirements for stainless steel chimneys

Material

As a material for the manufacture of industrial chimneys, special stainless heat-resistant steel is used.

During its production, there is a process of alloying with chromium, nickel and molybdenum. This gives it special properties that allow it to maintain the integral structure of the material when exposed to high temperatures. These include the following brands - AISI 316 L, AISI 310 S, AISI 304 and AISI 321.

Depending on the percentage of alloyed elements, certain characteristics of the material change:

- Chromium significantly improves hardness and corrosion resistance.

- Nickel is responsible for ductility and strength.

- Molybdenum - Increases strength when exposed to high temperatures.

All this indicates the importance of the choice of material when making your own stainless steel chimney. Attempts have been made to make them from ordinary food steel. Its main disadvantage is its high chromium content, i.e. it will quickly deteriorate when exposed to high temperatures.

Examples of the manufacture of such structures are shown below:

As you can see from the photographs, the canvases are simply twisted in several layers and held by a number of rivets. However, this design raises a number of questions:

- If the rivets are not made of heat-resistant stainless steel, then under thermal influence they will lose their shape and simply fall out of the structure.

- Lack of a connecting socket. If the installation is carried out "butt-joint", then there is a high probability of flue gases entering the space between the steel layers. This will lead to rapid wear.

- Steel grade. Installation of such a structure should be carried out only after the main, reliable chimney. Otherwise, otherwise, the pipe will quickly burn out due to high temperatures.

If you want to make a stainless steel chimney yourself, you should choose the correct steel grade. The self-made sandwich chimney should consist of heat-resistant steel inside and outside pipe with good weather resistance.

The space between the pipes is insulated with basalt wool.

Manufacturing technology

After purchasing the material, you should consider the method of processing it. In production, special rollers and welding machines are used for the manufacture of cylindrical elements. At home, it is quite problematic to “cope” with a stainless steel sheet. On some resources, it is advised to do this with the help of wide clamps, and treat the joint of the sheet with a special heat-resistant sealant. But this manufacturing method does not meet the most basic safety requirements for chimneys.

Therefore, if it is not possible to process a steel sheet using professional equipment, it is recommended to use ready-made elements of a prefabricated stainless steel flue.

In order to be convinced of the laboriousness of the manufacture of stainless chimneys, you can watch a video about the process of their production:

Profile pipe and its modification

This type of metal structure is quite popular when building greenhouses and gazebos on a personal plot. The main feature of the building material is that it can be damaged when bent. A way out of this situation can be filling the inner cavity with fine sand or water. These actions eliminate the possibility of damage to the pipe and achieve an excellent result. This technique is suitable for brass and duralumin piping.

If you are thinking about the question of how to bend a pipe without a pipe bender for a canopy, then you can use a rubber mallet for this. It is used for square shaped products. The pipeline is installed on reliable supports, and then a mallet is used. Actions must be accurate and smooth to eliminate the possibility of damage. If it is necessary to achieve a large angle, then to facilitate the process, it is necessary to heat the pipe in the place where it should be bent.

The shape of stainless steel pipes for chimneys, sandwiches, stoves, baths: square, round

A round pipe is a type of product that is in demand among industrial enterprises. Finds application in the creation of pipelines in the oil and gas industry, in the construction industry, water supply and heating, in mechanical engineering, in the creation of vessels and cylinders.

Forms can be very different, if you need something unusual, make an order to a specialist

Corrosion-proof rectangular pipes are common for supporting structures, supports and equipment stands. The main plus is lightness compared to round products. Experts also note such an indicator as excellent strength - due to the stiffening ribs of the profile.

The square tube is indispensable when creating structures for the food industry, pharmaceutical and chemical industries. The profile view of the product is capable of withstanding decent loads, for example, in ventilation systems. Often they are bought by private traders for the construction of fences, greenhouses and other summer cottages.In addition, the lightweight and durable profile is suitable for the production of swings and slides.

The differences are purely external and do not in any way affect the quality of the goods.

Methods of bending metal-plastic

Quite often, owners of suburban real estate are wondering how to bend a pipe themselves without a pipe bender. When there is metal-plastic available, you can use your own strength without using the tools at hand. The product is clamped and bent smoothly. In this case, it is important to eliminate the likelihood of an inflection. It is important to be guided by the rules, which state that for every 2 cm of the workpiece, the bending angle can be 15 °.

If you are faced with the question of how to bend a pipe without a pipe bender for a greenhouse, then you can use pieces of wire that fill the inner cavity. This allows you to achieve an even and smooth bend in the shortest possible time. Dry fine sand can be used as a filler. It is poured inside, and the edges are closed with plugs. Then one end of the product must be fixed, ensuring the reliability and strength of the fastening. Use a gas torch or blowtorch to heat the fold. The material is checked for readiness with a piece of paper.

Pipe bending devices

There are many ways to bend the pipe, even by hand, but there is a high risk of breakage. Therefore, it is best to use special equipment or materials at hand for bending, which will greatly facilitate the bending procedure.

Pipe bender

In order to bend a metal pipe, special devices are used - professional pipe benders, different in design:

- The manual tube bender is used to bend pipes with small cross-sectional diameters. As a rule, this device can bend pipes made of non-ferrous metals and stainless steel. Before bending an aluminum or stainless steel pipe, insert one end of it into a pipe bender and use a lever to gradually bend the product to the desired angle.

- hydraulic pipe benders are devices designed for bending large diameter pipes. In this device, all the forces applied for bending are compensated by hydraulic cylinders. How to bend a large diameter pipe using a hydraulic pipe bender? First, you need to determine the place of the bend, then fix one end of the pipe in the grooves of the pipe bender and use the lever to perform translational movements.

- to bend pipes with different cross-sectional diameters, electromechanical pipe benders are used. They are characterized by high productivity, accurate pipe bending and no need for operator physical strength. Such devices are expensive, so you shouldn't buy them for private use.

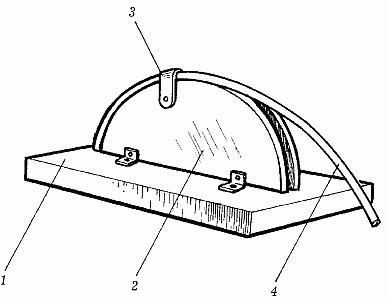

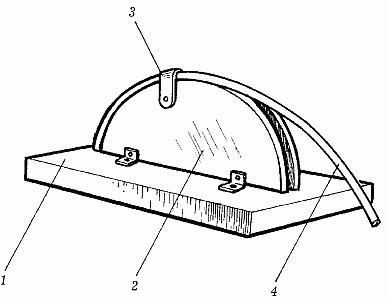

Plane-parallel plate

If it is extremely necessary to bend the pipe, and there is no pipe bender at hand, then a plate can be used to bend the pipe - an already bent workpiece with a groove, which is suitable for bending metal and metal-plastic pipes with a diameter of up to 45 mm. The pipe to be bent is inserted into a special clamp on the plate, clamped and bent along the plate along the groove. This method of bending without a pipe bender is rather primitive, but, as practice shows, it is very reliable.

Important! Only short pipes can be bent with a plane-parallel plate.

The figure shows the simplest design of a plane-parallel plate, where 1 is a plate, 2 is a plate, 3 is a clamp, 4 is a pipe that needs to be bent. You can make such a device yourself.

Steel spring

To bend pipes made of non-ferrous metals, which are sufficiently soft and pliable, which are often damaged or burst when bent, a steel spring of medium hardness is used, the diameter of which should allow it to enter the inside of the pipe.The spring is introduced to the place of the future bend, after which the pipe can be bent on the knee or by fixing it in a vice. The steel spring will allow the pipe walls to bend easily without deforming or bursting, because it takes on all the forces of compression and stretching of the metal.

Remember! Before inserting the steel spring into the pipe, attach a long wire or strong cord to its end, with which you can easily pull the spring out of the pipe after bending.

Polypropylene pipe bending methods

If it is necessary to change the direction of bending of a polypropylene pipe, one of two possible methods can be used. The first involves heating the fold. For this, a construction hairdryer is usually used. The optimum heating temperature is 150 ° C. Hands should be protected with gloves that are resistant to high temperatures.

At the final stage, the product is bent to the required shape. The thickened wall should be located on the outside of the bend. Once the material has cooled, it will need to be checked for cracks and dents. Another way to bend such a pipe is cold. However, the bending radius should not be more than 8 diameters, otherwise the product may break.

Methods of bending pipes without a pipe bender from different materials

It often happens that it is necessary to bend the pipe immediately in order to have time to complete the laying of the water supply system, install the heated floor or finish the creation of a curved product, but there is no pipe bender at hand and it is very far to the nearest workshop. What to do in such a situation? And how to bend it without a pipe bender?

Tips for bending a metal-plastic pipe

In the construction of private houses, metal-plastic pipes are often used, as a rule, bent. But it is not recommended to bend them with a pipe bender! Therefore, it is better to bend them manually - this is easier and faster. But it is not worth bending the pipe in one fell swoop. After all, there is a great risk of damage. Therefore, it is best to perform flexion gradually, slowly, in a forward motion. To do this, you need to take the pipe in your hands and bend it at the desired angle in 5-6 approaches.

We bend a polypropylene pipe

Bent polypropylene pipes, as a rule, are used when laying water supply, heating, sewage systems bypassing some kind of obstacle. But polypropylene is a fairly hard material that does not lend itself to bending; when bent, it is springy and returns to its original position.

Then how to bend a polypropylene pipe? Using an industrial hair dryer! Gradually warming up in the place of the fold, you can bend it at any angle. The main thing is to constantly warm and at the same time bend it with smooth movements. But remember that it is also impossible to strongly heat up a polypropylene pipe, because it will begin to melt.

How to bend a plastic pipe

In order to bend a PVC pipe, you need to buy fiberboard. From them, you can build a frame, which is needed to give the structure a certain shape. As soon as you give the plate the desired shape, it should be sanded, it is better to use fine sandpaper for this.

The next step is to form a silicone shell for the plastic blank. It will act as a fastener for the PVC structure in the frame. In addition, it will play a protective role against chips, mechanical damage and scratches. The object is placed in a prepared protective shell, and then the place of bending is heated. The plastic softens and sits on the frame. Doing so will produce the desired shape of the plastic blank. The product is left until it cools down. This will take 15 minutes. After that, the PVC pipe can be removed from the frame, leaving it to cool completely.

Specialist recommendations

If you are faced with the question of how to bend an aluminum pipe without a pipe bender, then you can use a grinder to carry out the work, with which several thin cuts must be made at the place of the intended bend. The product is preliminarily clamped in a vice. As soon as the cuts are made, they should be cleaned of chips, only after that you can begin to bend the pipe.

Sometimes the product needs to be bent in a circle. As soon as the ring closes, the holes are welded, and some craftsmen even use a soldering iron for this. In order to make the place of the fold neat, it is additionally sanded and covered with a protective agent. This eliminates corrosion and premature destruction of the joint.

Features of pipe bending

All methods of bending workpieces can be divided into manual and mechanical, as well as hot and cold. Sometimes the bending process is accompanied by undesirable consequences for the tubular product, which have a significant impact on the subsequent operation of the element. The degree of manifestation of these consequences depends on the material from which the pipe is made, its diameter, bending radius, as well as the method by which the bending procedure was performed.

The negative consequences of bending include the following points:

- Reducing the wall thickness of the workpiece located along the outer bending radius.

- Formation of creases and folds on the wall, which is located along the inner radius of the bend.

- Changing the configuration of the section (reducing the size of the lumen and its shape-ovalization).

- Change in bending radius due to the springing effect of the material.

The most common drawback of bending is changing the configuration of the section and wall thickness. Due to metal stresses, the outer wall at the bend becomes thinner, and the inner wall, on the contrary, thickens. This results in a noticeable weakening of the tubular element. This phenomenon is dangerous by rupture of the outer wall of the pipe, since it is it that is subjected to greater pressure from the transported medium.

It also significantly weakens the workpiece ovalization. Such a phenomenon is especially dangerous when bending a pipeline intended for transporting a substance under conditions of a pulsating load. If such elements are used as building structures, then ovalization will affect the appearance of the element. That is why, in the process of bending, they seek to minimize such phenomena as much as possible.

If folds are formed on the inner wall due to the thickening of the material, then they will entail not only a decrease in the section, but will also create resistance for the moving stream. This in turn will increase the likelihood of corrosion. In addition, the load-bearing capacity of the tubular structural member will decrease.