What is a collector?

When installing a water supply system from scratch or changing an old one, it is necessary to think over the location of all consumers: a toilet bowl, a washbasin, a washing machine.

In an ordinary apartment, the number of plumbing fixtures varies from four to ten. Experienced plumbers recommend their customers to install a water collector.

The water collector is a kind of distributor, which is an important plumbing element of the cold and hot water supply and heating systems. It is installed on a central riser and hidden in a plumbing cabinet. Access to the manifold must not be obstructed by furniture or sewn tightly into the wall. However, professional repairmen will give the engineering unit an aesthetic appearance.

Collector device and principle of operation

The direct function of the collector in the water supply system is the distribution of one water flow into several flows of equal pressure.

Combs are available with two, three and four outlets. If more branches are required, the valves are interconnected. Thus, the water supply collector is assembled for the required number of outlets.

The manifold connects directly to the riser. On two opposite sides of the device, a threaded connection is provided (on one side an internal thread, on the other - an external thread) for connecting to the main line and connecting the combs to each other.

A plug or an additional plumbing fixture, for example, a membrane hydraulic shock absorber, is installed on the free end of the collector.

The diameter of the inlet is 20-40% larger than the outlet. For example, on a standard manifold for installing plumbing in an apartment, the diameter of the inlet is 3/4 ", the outlet is 1/2".

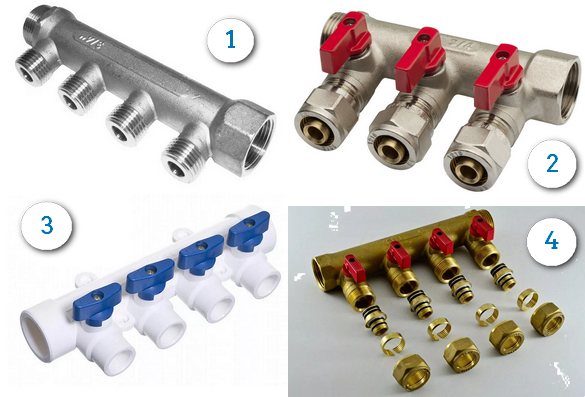

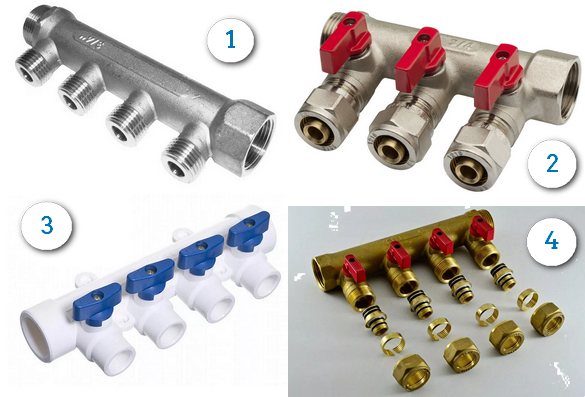

1. Manifold with valves. 2. Collector with ball valves.

At the outlet openings, both ball valves and valves can be installed, allowing not only to open and close the water flow, but also to regulate the flow rate in this area.

Both the distributor and the regulator

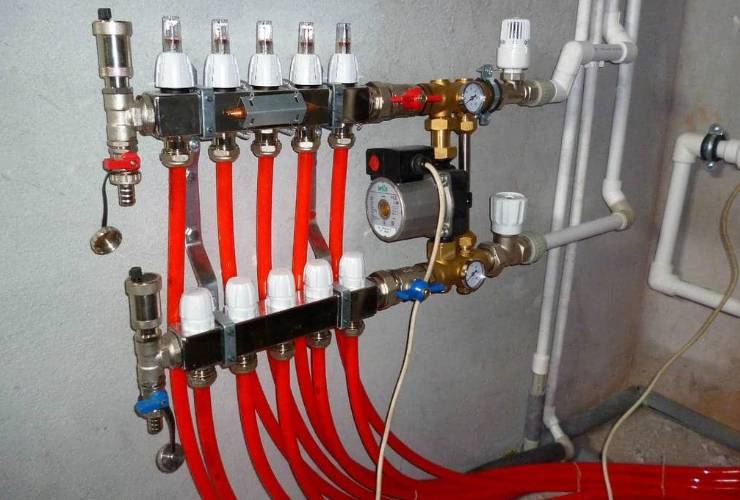

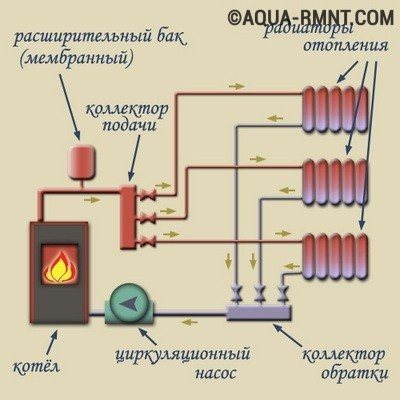

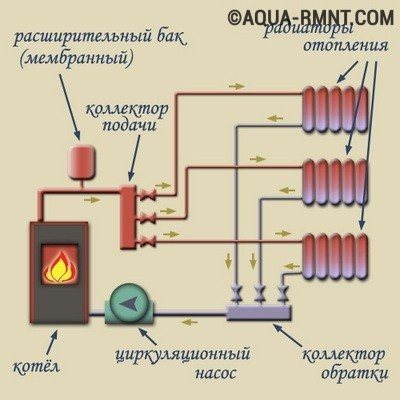

At its core, a manifold is a centralized unit that allows the coolant to be distributed to its destination. In the heating system, it performs no less important function than a circulation pump or the same boiler. It distributes heated water through the mains and regulates the temperature.

This diagram shows the general principle of operation of the collector block, consisting of two combs: through one, the coolant is supplied to the system, and through the second it is returned

This unit can be called a temporary coolant storage. It can be compared to a barrel filled with water, from which the liquid flows out not through one hole, but through several. In this case, the pressure of the water flowing out of all the holes is the same. This ability to provide a uniform distribution of the heated liquid at the same time is the main principle of the device.

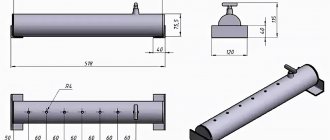

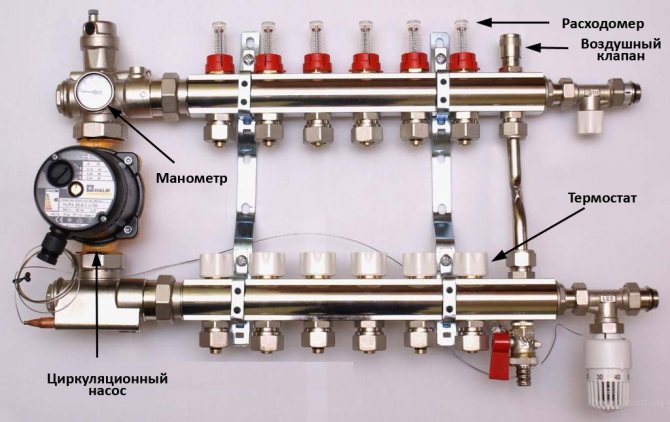

Externally, the collector looks like a two-comb assembly, made, most often, of stainless steel or ferrous metal. The outputs available in it are designed to connect heating devices with it. The number of such terminals must correspond to the number of serviced heating devices. If the number of these devices increases, the node can be increased, so the device can be considered dimensionless.

In addition to the terminals, each comb is equipped with locking mechanisms. These can be of two types, installed at the outlet:

- Cut-off. Such taps allow you to completely stop the supply of coolant from the general system to its individual circuits.

- Adjusting. With the help of these taps, the volume of water supplied to the circuits can be reduced or increased.

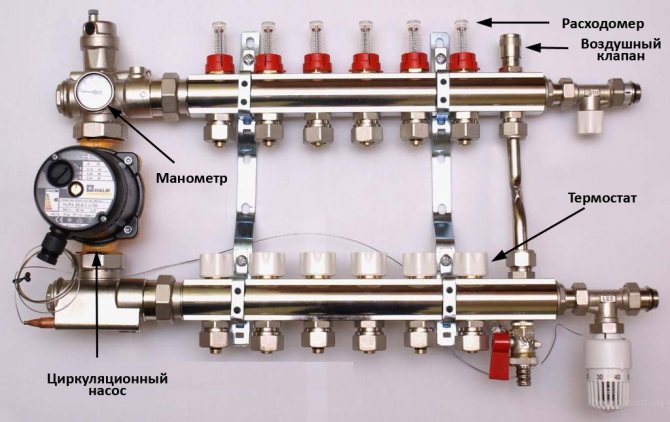

The manifold includes water drain and air release valves. Here it is most convenient to arrange the measuring equipment in the form of heat control meters. In this case, everything that is necessary for the effective operation of this node will be in one place.

Why does the manifold block include two manifolds? One serves to supply the coolant to the circuits, and the second is responsible for collecting already cooled water (return) from the same circuits. All elements necessary for effective functioning must be on each of the combs.

What is a collector for?

A water supply system with a separator and a separate pipe supply to each consumer will cost more than a classic wiring. Is it worth overpaying for the collector for water and heating?

- The device is used to regulate the water pressure in the apartment. In standard wiring, the pressure in an open tap often decreases if someone opens another tap or flushes the toilet. This threatens not only with discomfort, but also with burns due to too hot water, which suddenly begins to pour. The well thought-out diameter of the manifold eliminates pressure problems. No matter how many taps are open in the apartment, the water pressure remains unchanged.

- Each outlet is provided with taps that allow you to regulate the flow of water along the branch. If the mixer is being repaired, it is not necessary to completely shut off the cold and hot water supply from the risers. It is enough to re-float only a certain branch.

- The absence of joints and tees embedded in the wall minimizes the risk of leaks. If a faucet or fitting fails, it is easy to replace it by disassembling the manifold system in the cabinet. The lining in the bathroom will not be damaged.

- If it is necessary to supplement the water supply system with another consumer, you will not have to redo the entire wiring. The connection will be inexpensive and not time-consuming.

With collector installation of a water supply system, its cost increases. The number of pipes to the collector, be it metal, metal-plastic, polypropylene or cross-linked polypropylene, in comparison with tee wiring, increases by 8-10 times. However, modern pipes, especially metal-plastic and polypropylene, are not very expensive, so such a system is available to most residents.

Disadvantages of the collector system

Note that the collector wiring has one significant drawback - it is high price. This option is one of the most expensive. Among other disadvantages is that a do-it-yourself heating comb will not function without a circulation pump. You will also need a large number of pipes, since separate pipes go from the collector to each heating device.

Assembling a collector system and installing a heating manifold is a rather laborious process when compared with installing other types of systems, so additional costs await you here.

In general, the collector system is one of the most reliable and efficient heating systems. Despite the high cost and some disadvantages, such a system is a fairly common option. Therefore, if the construction budget is somewhat limited, then it is better to give preference to a reliable heating system than expensive finishing.

Reservoir classification

Dividing combs for water supply differ in their design and materials. Before choosing a collector, study the entire range on the market.

Spacers are made from different materials:

- Stainless steel is resistant to corrosion, fire and high temperature. The weight of the stainless steel collector is small, which makes it easy to fix it to the wall. This is an absolutely harmless material that gives the product an attractive appearance.

- Brass is an incredibly durable metal that is not afraid of corrosion and high temperatures. Combs made of brass are very expensive, but they guarantee maximum durability.

- Separators made of polypropylene are not afraid of rust and are lightweight.

Polypropylene manifold.

Some craftsmen can make a collector with their own hands from polypropylene pipes, which is in no way inferior in quality to factory products.

Collectors differ in the way they are attached to pipes. A comb model is selected depending on the material of the pipes used.

1. A comb for the installation of taps and any plumbing fixtures at your discretion. 2. With compression fittings - designed for the installation of pipes made of metal-plastic or cross-linked polyethylene. 3. For the installation of polypropylene pipes. 4. Under the Eurocone. Suitable for installation of pipes made of almost any material through an adapter (eurocone).

The dividing combs differ in the number of branches. Minimum - 2 outlets, maximum - 6. Outlets that are not currently used can be closed with plugs. If it is necessary to make more than 6 outputs, several collectors are interconnected.

How to choose a collector for a warm floor

The main parameter for choosing a collector for a warm floor is the number of circuits to be connected. Masters recommend purchasing a comb, with a margin for one output, in case it becomes necessary to split a too long circuit into two branches or connect additional monitoring equipment (thermometer, manometer).

The second selection criterion is the comb body material. Reliable products are brass or stainless steel collectors, as well as bronze, produced according to domestic GOSTs or European quality standards. "Chinese" alloys from dubious alloys can be purchased only after the seller demonstrates the certificate of conformity, and the comb itself will be comprehensively examined for cavities, cracks or traces of corrosion.

Although in fact most of today's products, if not all on the market, are produced by Chinese enterprises, when choosing them, one should give preference to well-known brands. After all, reputable European firms carefully monitor the quality of the work of their, even those brought to the Celestial Empire. First of all, pay attention to products under the brands: Rehau, Kermi, Valliant, Valtec, FIV, Rossini. It is best to purchase a collector for underfloor heating from such companies in a complete set. The purchase of individual elements will cost more, and components from other manufacturers may be incompatible in terms of installation parameters.

Products on the market

In the catalogs of accessories for the collector plumbing system, a wide variety of not only combs, but also their components is provided.

- Separators without taps are much cheaper. They allow you to assemble a device that will be most suitable for the object. This option is preferable, since it makes it easy to replace only a failed crane. While the one-piece design will require a complete replacement.

- Devices with shut-off valves greatly simplify the installation of the water supply manifold. They simplify the assembly of the unit - no need to install cranes.

- Accessories allow you to adapt the system according to your wishes: valves, pump groups, plugs, valves, brackets, couplings, tips, servos, fittings.

- Collector cabinets are sold separately, which are wall-mounted and provide an aesthetic appearance, as well as access to the engineering unit.

Choosing a place to install the TP collector

It is very important to determine the optimal place where the installation of the underfloor heating collector will be carried out. It is desirable that it be located in the geometric center of the building at an equal distance from the main consuming circuits and the heating boiler. Of course, in practice, it will not be possible to maintain the exact distance from the comb to the heating loops. And the loops themselves rarely have the same length, which leads to an imbalance in their hydraulic resistance. As a result, the coolant will tend to circulate in a short branch, while long ones can have a shortage of its flow rate. And although this problem is eliminated by installing rotameters or variable valves, you should still strive to achieve symmetry in the laying of pipelines.

When choosing a place to place a collector for a warm floor in typical apartments or small cottages, you have to take into account the peculiarities of their layout. Since the manifold cabinet is not distinguished by the smallest dimensions, in conditions of limited living space, it is usually located in a closet or in a technological wall niche. However, if the house is larger and there is already a separate boiler room in it, then the distribution manifolds with all the piping are placed directly next to the heating boiler. In large houses with two or three floors, it is even easier to maintain a geometric mounting center. In them, the installation of the collector can be carried out in the space under the stairs.

Manifold cabinet

Its presence in the set of equipment does not at all affect the functioning of the water floor heating system. However, the manifold (mounting) cabinet is responsible for the aesthetic component of the perception of the thermal installation, as well as for the safety of its units and their settings. It protects the system controls, some of which are quite sensitive to external mechanical influences. Sometimes the material itself, for example, a polypropylene collector, despite all its reliability, can be damaged. Considering these factors, it is recommended to choose drawers with closing doors.

The mounting height of the enclosure is selected based on local conditions and the wishes of the site owner. It is not strictly regulated by regulatory documents. It should be borne in mind that placing the combs lower than 50 cm from the floor level is undesirable. The recommendation is due to the practical convenience of supplying pipes for connection and fastening to the manifold. The optimal height for fixing the cabinet is about 1 m.

How to install?

Before installing a water distribution unit for cold and hot water supply, give a precise answer to the following questions and consider the following points:

- How many water consumers are there? The number of collector outlets should be the same or slightly more than the consumers. Excess taps are closed with plugs.

- What type of pipes will be used for plumbing installation? It is necessary to purchase devices intended, namely, for pipes made of the selected material.

- Estimate in advance the position of all engineering elements in the space of the sanitary cabinet (you can make markings on the wall). Please note that a meter and a water filter are installed in front of the distribution manifold. Convenient location of all devices facilitates maintenance and repair work.

- Get a secure fit - a loose distribution unit can lead to leakage of connections and damage to the pipeline.

- Before installation, make sure you have all the necessary consumables at hand: sealing material, gaskets, adapters.

The installation of the water distribution unit takes place in the following sequence:

- Install the inlet shut-off valves on the water supply riser.

- Install meter, filter and check valve.

- Plug in the manifold and fix it securely to the wall

- Install plumbing to each consumer. Secure the pipes with fasteners.

This work algorithm will avoid mistakes. Regardless of whether you need a collector for water supply or heating, its installation is the same. Such wiring requires more time, skill and money, but pays off quickly and provides comfort in future use. Collectors are appropriate not only in cottages and large houses, but also in apartments.

Design

The collector heating system of a private house is able to provide an even distribution of heat and a constant temperature regime in the room, and, consequently, both comfort and coziness. Together with a room thermostat, the manifold can guarantee precise flow control.

Remember that in systems where there is a collector for heating with your own hands, a circulation pump is a prerequisite. Thanks to its operation, the temperature difference between the heat carrier at the inlet and outlet of the system is reduced, which means that the heating will be of better quality.

Before making a heating comb, you must study all the necessary information about the components of the system.

Each of the collector outlets must have a ball valve, due to this device, the heating devices will be cut off without affecting the system. This kind of system can be equipped for a horizontal one-pipe or two-pipe system.

Manifold for heating system

The supply and return manifolds are located on each floor of the main riser. From the collectors, pipes are mounted to the floor or walls, after which they are connected to each radiator. If the supply and return pipes are located in the floor screed, each heating device must be equipped with an air valve or air vent.

Heating distribution manifold