Requirements

The value of the gravity of the smoke channel

Modern designs must meet the following criteria:

- Structural strength and long service life. The device of chimneys for a fireplace must withstand various temperature fluctuations, the formation of condensation. Resist the influence of aggressive acids, and, most importantly, comply with all fire safety standards and rules.

- Aerodynamics. The installed structure must ensure an unobstructed flow of combustion products. For example, a circular cross-section is able to quickly and easily remove all flue gases from the furnace. Rectangular designs are not as efficient, in which the combustion products encounter resistance, thereby reducing the withdrawal rate.

- Simple maintenance.

- Resistant to erosion and corrosion. To achieve this indicator, when equipping a chimney for brick fireplaces, it is necessary to choose the right materials.

Chimney safety

The desire of the owners to install a fireplace structure in their household is quite understandable, but at the same time they should not forget about the danger posed by fireplaces with smoke. Chimneys made unprofessionally pose a huge threat, which can end very sadly - carbon monoxide poisoning or fire.

If several fireplaces are installed in the house, each of them needs a separate channel or chimney. Some owners, in order to save money, connect two devices to one chimney, and this is strictly prohibited by building codes.

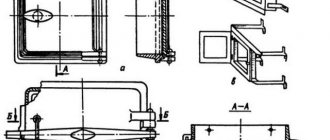

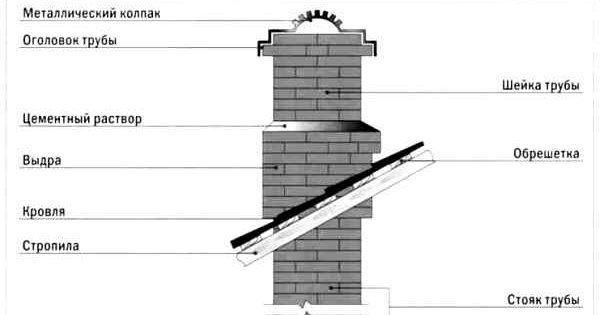

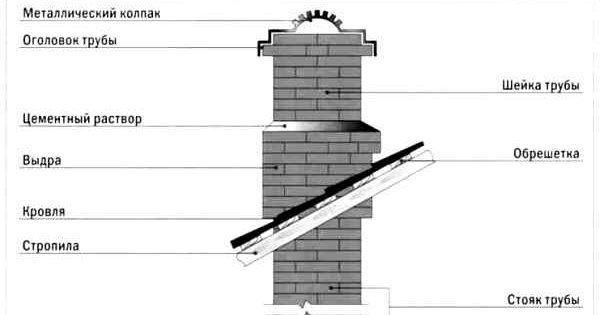

Brick construction device

Before starting the construction of chimneys for fireplaces, it is necessary to deal with the brick structure. It is based on the following elements:

Brick chimney

- Attachment pipe.

- Fluffing.

- Riser.

- Otter.

- Neck.

The shape of the device can be rectangular, round or square. But it should be noted that round shapes are more appropriate for use.

For those who find the chimney arrangement for the fireplace very complicated, you can choose simpler options. To simplify the process, you can use ceramic or stainless steel devices.

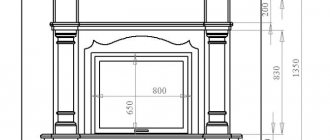

Placement, size and other nuances

You should think about arranging a fireplace in a house even at the design stage. For example, you should think about the fact that the material of the walls and floors should be non-combustible. You can ask for help with drawing up a fireplace chimney diagram to the measurer of the company supplying the chimney. This service is not free, however, it should be noted that a branded installation can cost an amount comparable to the cost of a good firebox.

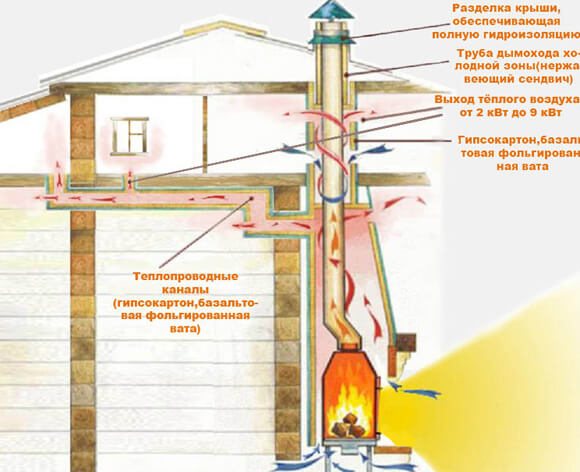

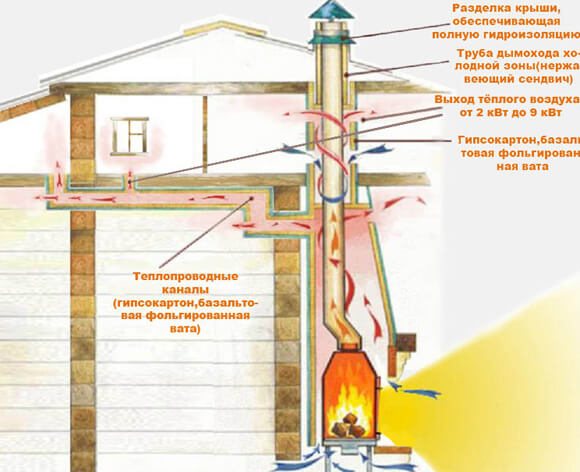

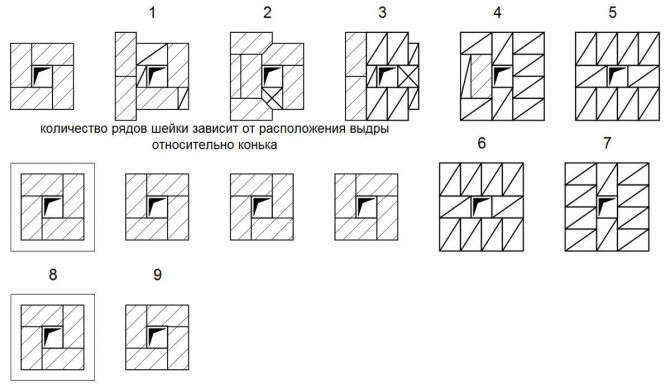

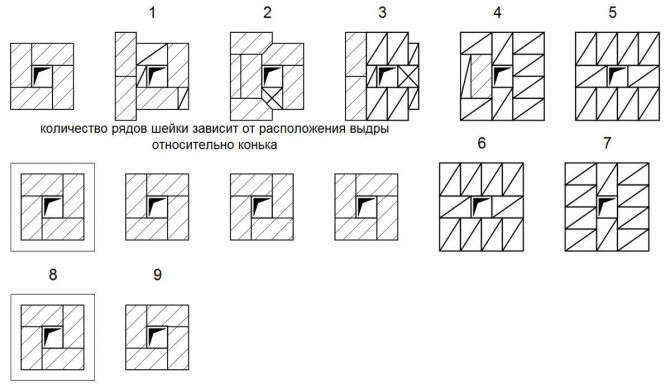

It is also recommended to place the chimney in a warm part of the building. If the circumstances are such that the structure is located near a cold outer wall, additional thermal insulation should be provided. The closer the chimney is placed to the ridge of the roof, the smaller will be the dimensions of the pipe that rises above the roof.

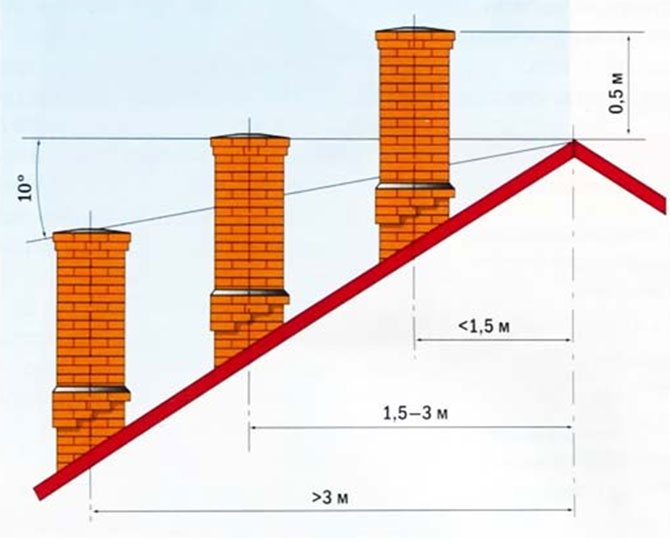

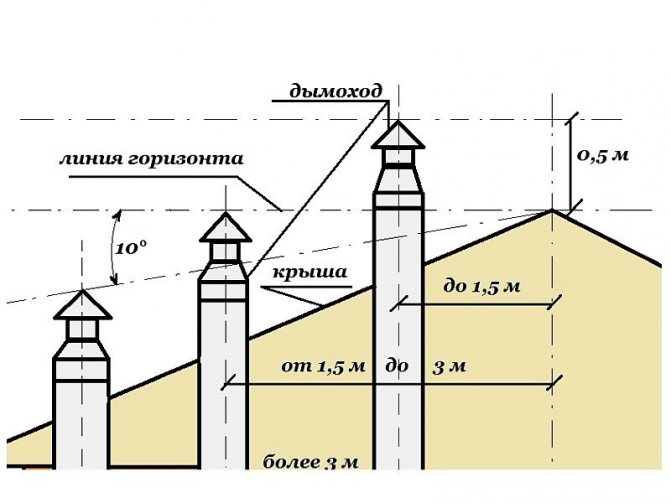

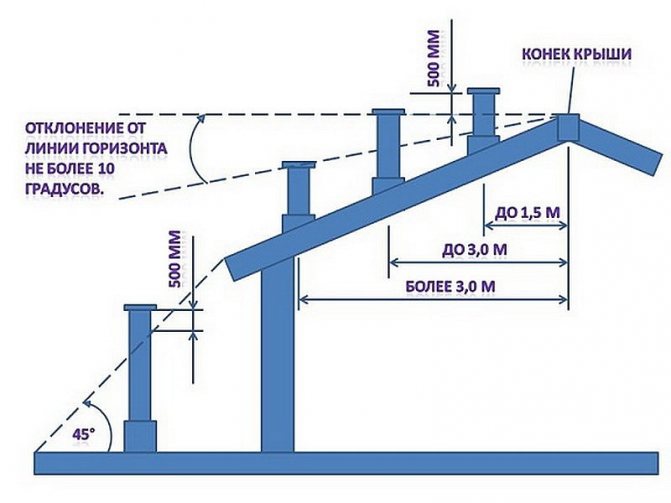

The diameter of the chimney pipe for the fireplace must match the diameter of the flue pipe. If this condition is violated, traction disturbances or incomplete removal of combustion products are possible. The minimum chimney height should be four meters. Above a flat roof, the pipe must rise at least 500 mm. The same dimensions are acceptable if the distance to the ridge of the roof does not exceed half a meter. If the pipe is at a distance of 1.5-3 meters from the ridge, its height should reach the level of the ridge.

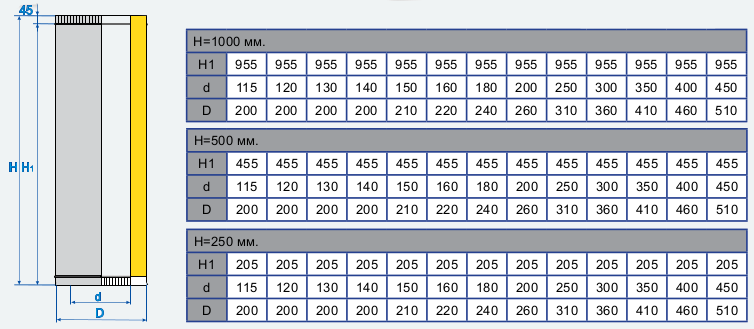

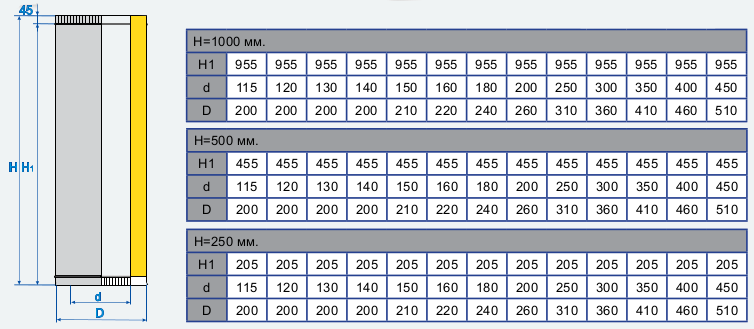

Diameter

In order to calculate all the parameters, it is already necessary to decide on the material that will be used in the construction process. The calculation is most conveniently carried out on paper, creating a sketch of the future structure, it is necessary to take into account some of the nuances:

- The diameter of the chimney for the fireplace must have a certain ratio with the firebox. The calculation of this value has its own subtleties. For example, a 1:10 ratio is used to calculate the diameter of a pipe that joins the open structure of the furnace. This method is only valid for a cylindrical type of flue.

- The calculation of the cross-section for a square type of device contains the proportions of 1:15. But at the same time, the diameter should be less than the size of the blower. With the resulting heat transfer less than 300 cal / h, the cross-section should not be less than 140 x 140.

- In order to determine the optimal diameter of the fireplace chimney, state standards can be taken as a basis, which spell out the permissible cross section under certain conditions.

- In addition, the calculation of the height and diameter is carried out in accordance with the area of the room.

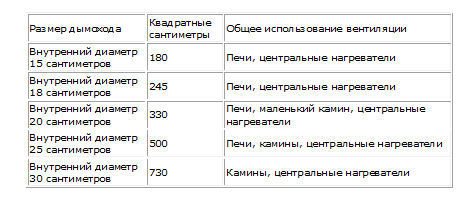

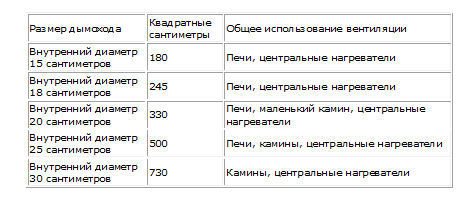

Standard dimensions of internal diameters and cross-sectional areas of brick chimneys

It will not be superfluous to show your calculation to specialists and analyze it together. In addition, a suitable settlement scheme can be posted on the Internet.

It must be remembered that the calculation of these parameters must be done correctly, the efficiency of the heater depends on it.

Stainless steel smoke exhaust structures

Chimneys for hearths of this type are type-setting structures. The length and diameter of a fireplace pipe made of stainless steel can be very different. Such products are often produced complete with ceramic ones and are placed inside steel ones.

Chimneys made of galvanized stainless steel have the following advantages:

- they can be mounted without a foundation, since they are lightweight;

- the collection and installation of the structure is allowed to be carried out after the completion of construction;

- they are cheaper in cost than block and ceramic systems;

- if necessary, it will be easy to replace individual elements.

The disadvantage of steel chimneys is the need for a design solution in the case of interior decoration, if such a structure is installed indoors.

Variety of designs

There are many designs of chimneys for a fireplace, which can be divided according to location and installation method, or material.

Depending on the location and installation method, fireplace pipes can be:

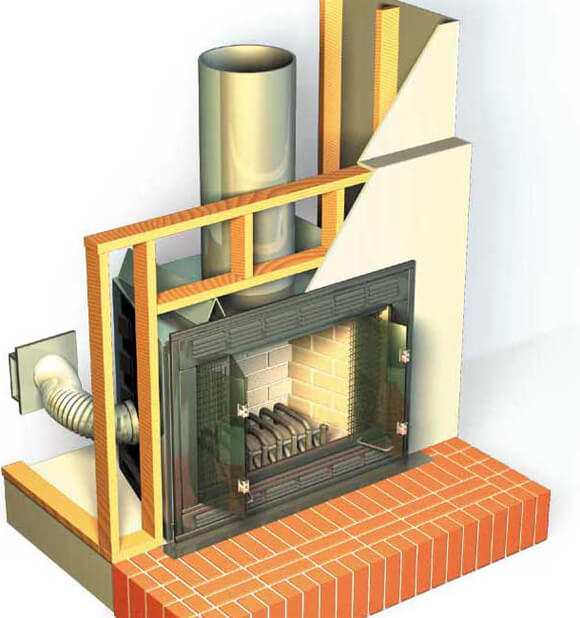

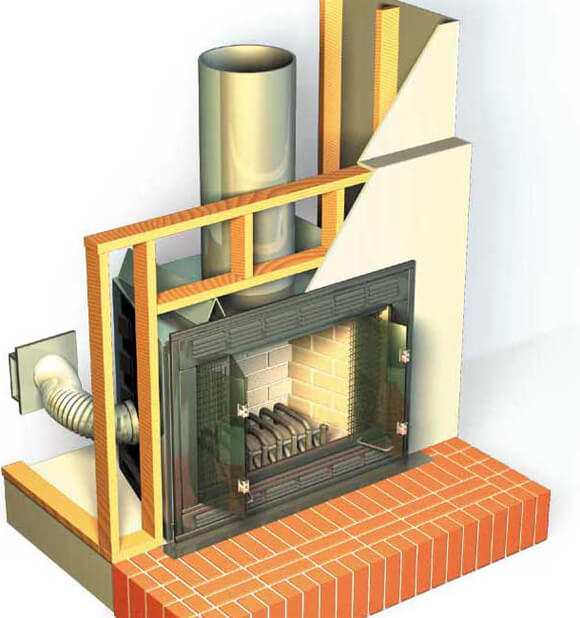

- Built-in. This is a vertical shaft for removing combustion products from the furnace. In addition, devices of this type are considered the most economical.

- Suspended. A chimney for this type of fireplace is installed in a finished room. It is mainly used for island-type outbreaks. The chimney is fixed to the supporting structures of the roof and ceiling slabs. To avoid trouble, metal models are chosen as suspended fireplace chimneys. This is due to the relatively light weight compared to other models.

- Devices based on the hearth. Chimneys of fireplaces of this type are installed on their own foundation, since the weight of the finished product is quite large.

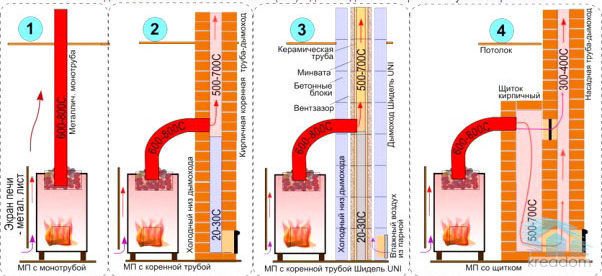

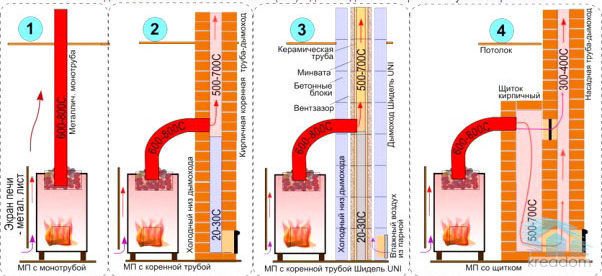

Examples of the device of metal and brick chimneys

Various materials can be used in the production of chimneys for a fireplace. Based on this, several varieties can be distinguished:

Brick pipe

Such a structure can be made by hand, several types of bricks are used as a material: corpulent, burnt and clay bricks. The construction of brick chimneys for a fireplace is considered quite effective. Brick chimney is more suitable for fireplaces using solid fuels.

Brickwork has proven itself well at high combustion temperatures. In this case, condensation is not possible. Burning damp firewood is more harmful.

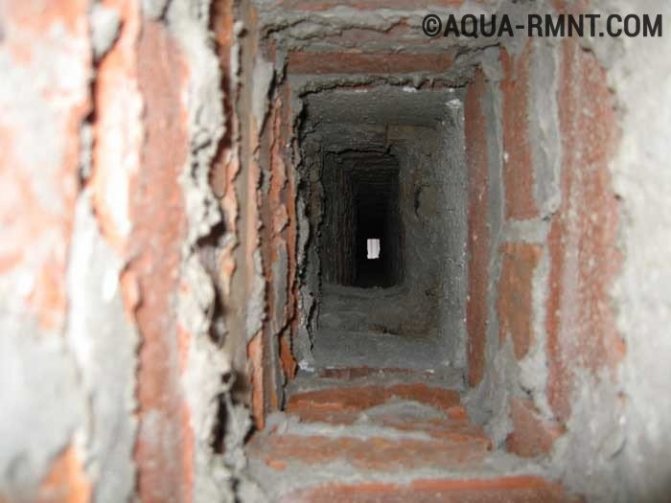

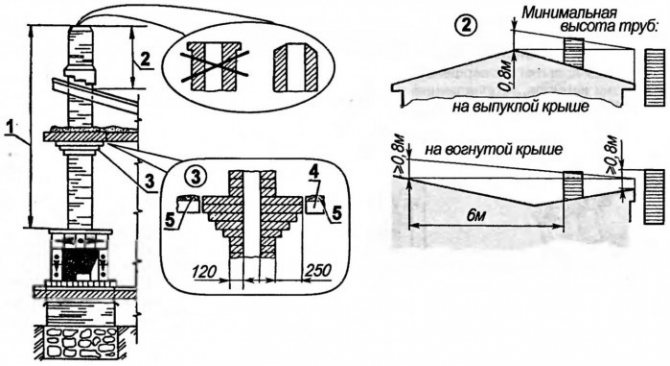

Brick otter ordering otter

The brick chimney must have a solid masonry. To prevent the formation of condensation, a brick pipe is finished with a metal liner.

Of steel pipes

The chimney for fireplaces of this type is made of stainless steel, which has heat-resistant properties. This type of pipe is much lighter than the brick version. Steel chimneys of fireplaces are quite durable. They are resistant to corrosion and are used for various types of hearths. The round section of the steel pipes prevents soot formation.

But, despite all the pros, there are also disadvantages:

- High price.

- Small self-supporting capacity.

Such pipes can be produced in several versions:

- Sandwich. They are a steel pipe with a circular cross section, and a special layer of thermal insulation, which is located inside.

- "Hot" pipes. Such pipes imply a steel structure without an insulating layer.

Chimney dimensions

Chimney insulation

From ceramic pipes

The chimney for fireplaces of this type is quite expensive, but the long service life pays for all the costs.

Glass constructions.

The advantages of chimneys for a fireplace are the absence of corrosion, low rates of thermal inertness and absolute immunity to moisture.

The disadvantages include:

- High price;

- Expensive installation.

Installation work

The installation of a chimney in a house can be done not only with the help of a master, but also with your own hands, however, the first thing to do is to choose the appropriate type of chimney hood, taking into account the type of heating boiler, its functionality, type of fuel and other parameters.

The installation of chimneys, the price of which depends on the type and materials of manufacture made by hand, also implies whether you are going to build a brick or steel chimney. A brick chimney is often installed for similar stoves and fireplaces made of brick, while steel and other systems are often connected to modern furnaces and innovative boiler equipment.

If it is necessary to use fuel such as firewood, coal or peat to operate and kindle your heating unit, it is quite possible to do with assembling a brick chimney with your own hands. If the system is more modern, capable of heating to the highest possible temperatures, and liquid-based fuel or gas is used for operation, the brick surface of the chimney hood simply cannot be corrected and will begin to crack, in this case, give preference to a ceramic or modular chimney.

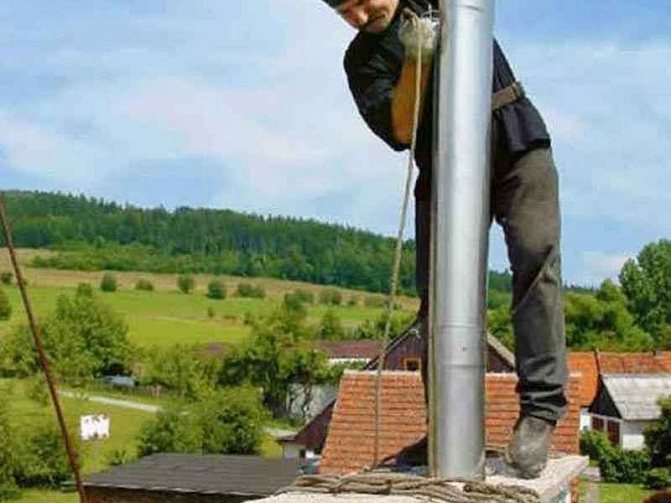

The simplest and most affordable to install and erect with your own hands are stainless steel chimneys, they tolerate high temperatures well, have a small mass, while the main disadvantages of such systems include the fragility and rapid formation of corrosion on the inner surface of the pipes, which arise as a result of the formation and accumulation a large amount of condensation.

A turnkey chimney for classic solid fuel stoves and fireplaces is often assembled from bricks; as it you can make a special box or a so-called shaft in the wall of the house. However, in order for such a hood to function correctly and at full capacity, the chimney must be in a strictly vertical position and have ventilation ducts and special doors along its entire length through which soot can be removed.

A brick chimney, the price of which is quite high due to complex installation, is often plastered inside, but this must be done with high quality so that the plaster does not start to fall off during work and exposure to high temperatures. Plastering the chimney inside will not allow a large amount of soot and other combustion products to accumulate on the surface, it is also important that the structure is made in the form of a cone and does not differ in complexity and intricacy.

In order to decide and choose a chimney of a suitable length, section for your stove, fireplace or boiler, it is necessary to take into account such indicators as the area of the house and the power of the heating unit. If we take into account the existing norms and requirements for the construction, remember that one outlet channel should be about five meters long, but not more than six.

The installation of gas chimneys or ventilation made of stainless steel also requires a special and competent approach, although such a structure is assembled according to the principle of a designer, however, in order to get a high-quality hood at the output, it is important to adhere to the existing plan and the indicated sequence of work.

In modern model hoods and stainless steel chimneys, heating is carried out strictly in the direction from the bottom and gradually rises up, in this case, special attention should be paid to the quality of joining of each element that is inserted into the previous one, if necessary, the edges of the joints should be sealed with a special heat-resistant substance.

a stainless steel chimney should not just be inserted into one another, but docked and secured by means of special clamps, while all the joints and joints of such an exhaust structure should be in your field of vision and in no case be masked in walls, ceilings and other objects.

The chimney, the installation of which is due to a high total mass, must also be additionally fixed to the wall of the house inside or outside; for this, special brackets are used that must hold the pipe every 1.5-2 meters of length.

The chimney, for which stainless steel is chosen as the main material of manufacture, should not be tightly connected to the bracket itself; in this case, experts recommend leaving a little margin of about 1-2 centimeters between them, since the bracket may undergo slight expansion when heated.

It is strictly forbidden to contact gas-fired boiler equipment with any other communications located in the house, as this may result in a fire or explosion.

Materials (edit)

The properties of fireplace chimneys largely depend on the materials purchased. To do this, you need to know which material you need to give your preference to.

The materials used have the following properties:

Ceramics.

Ceramic chimneys

- High heat capacity indicators.

- Resistant to temperature extremes.

- Long service life.

Stainless steel.

- Easy installation and low weight of the finished product.

- Not exposed to acids.

Brick.

- Long service life.

- High heat capacity.

Asbestos-cement pipes.

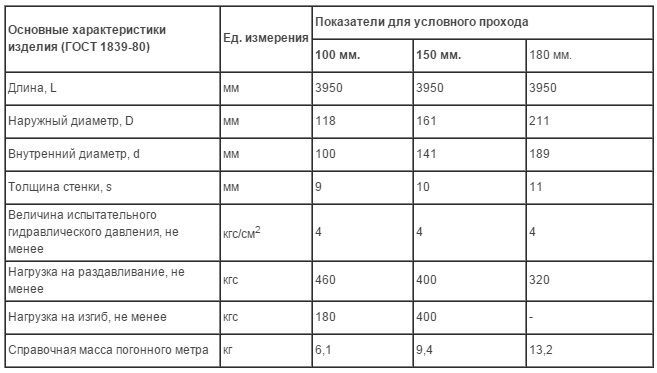

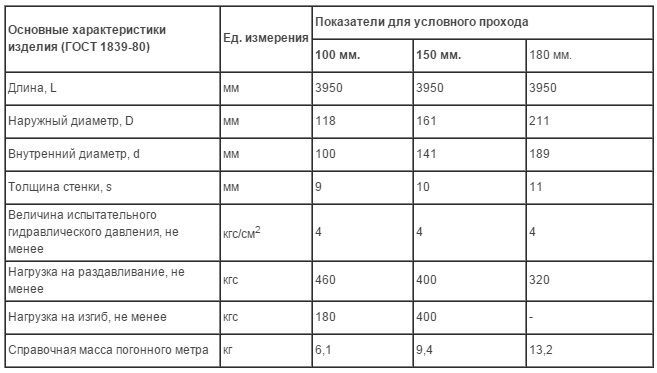

The main characteristics of an asbestos-cement chimney

- Flue gas outlet temperature limitation. The optimum temperature for such pipes is 300 degrees.

Do not place deflectors and probes at the chimney outlet.

Rule four. Do not install baffles and probes at the flue outlet. This will impair the function of the fireplace. If, in addition to the chimney, there are ventilation ducts in the chimney (head), then you can cover this chimney with a common umbrella. But then the chimney of the fireplace must pass through the probe.

If this is not done, then with insufficient air flow, the smoke coming out under the common umbrella will be sucked back into the room through the ventilation ducts that go under the same umbrella, and the smell from the fireplace will spread throughout the premises of the house. Deflectors are designed to enhance traction. They increase traction if there is wind. This means that when there is no wind, the deflector is an obstacle.

Installation

Installation of structures is always considered on an individual basis. This is the most crucial stage, in order to install a chimney for a fireplace with your own hands, you need to calculate its diameter and location.

A suitable place for placing a fireplace chimney is considered to be a place near the roof ridge. This will make the protruding part of the pipe smaller.

The height must be at least 4 meters. The calculation of the maximum values depends on your building.

Calculation of the pipe diameter will also be required in order for the structure to go through all the overlaps without difficulty.

Special attention is always paid to the installation of equipment in wooden buildings. Such buildings are most susceptible to fires. In order to avoid this, it is necessary to use a transition pipe, which will not only protect against fires, but also provide high-quality insulation between the roof and the chimney of the fireplace.

In order to make a hole in the roof, it must be remembered that its size should be slightly larger than the diameter of the pipe.

In addition, you need to pay attention to possible joints. They can not only reduce the efficiency of the heater, but also worsen the safety parameters. In addition, the service life will be significantly reduced.

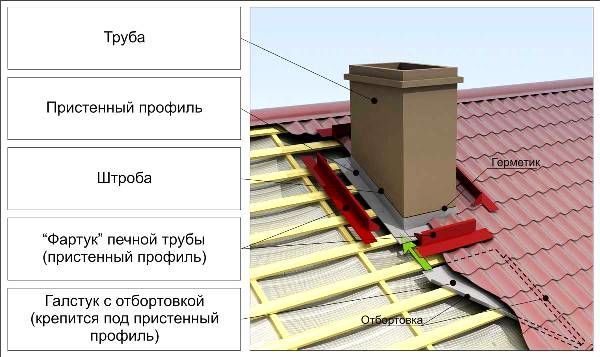

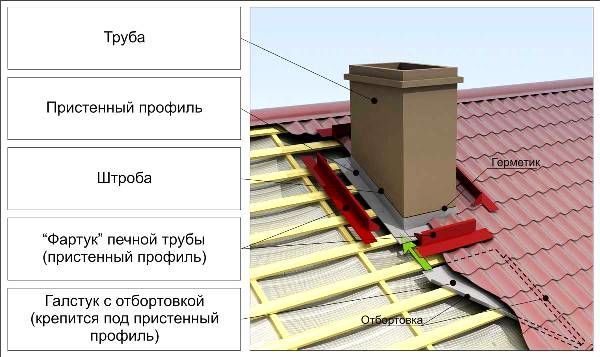

Sectional view of the chimney pipe on the roof

The most difficult stage of installation is considered to be the place of passage through the roof. The main parameters that you need to pay attention to are quality and safety.

Each design has a basic set of requirements that need to be addressed.

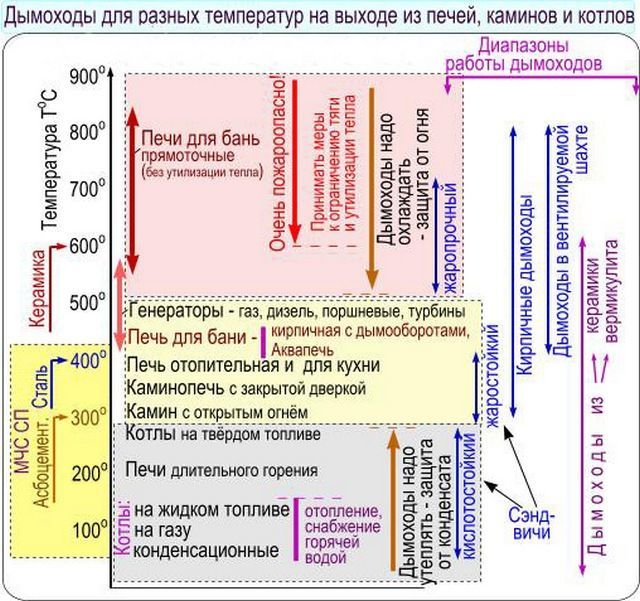

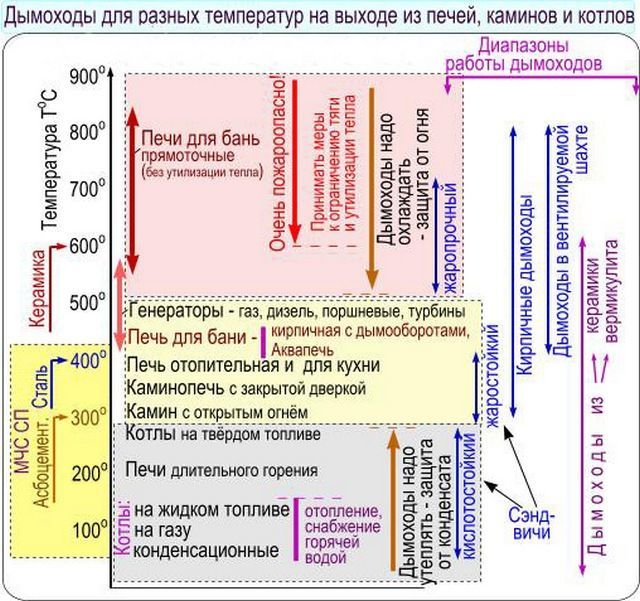

Diagram of the dependence of the type of heater, temperature in the chimney and the material of its manufacture

For example, for a brick building, the work scheme looks like this:

- Foundation.

- Solution.

- Masonry.

- Mop.

- Head.

- Smokebox.

For a ceramic device, the work scheme is as follows:

- foundation,

- Fixing modular elements.

The construction and installation of chimneys for fireplaces is carried out taking into account the expansion of the material under the influence of heat. In addition, it is necessary to take care of the tightness of the equipment during operation.

A properly equipped chimney will last long enough.

Chimney installation

For each chimney, the order of installation, assembly and fastening is decided individually:

- when building a brick smoke exhaust structure, a foundation is required, observing the correct location of the rows of masonry. The composition of the solution is important, a mop, a head and sometimes a chimney are necessary;

- for a ceramic chimney, a foundation is needed, reliable fastening of modular elements. When connecting, you will need a revision with a tee;

- the installation of a stainless steel chimney needs fasteners and brackets, bends are used to ensure the deviation of the channel from the vertical. The device of passages going through the ceilings and the roof is being carried out; a head and a chimney are also needed.

During the construction process, when deciding how to make a chimney for a fireplace, one should not forget about the thermal expansion of materials that occurs during operation.

It is necessary to carry out the installation so that the tightness of the smoke exhaust channel cannot be broken and fire safety is ensured.