Back to full version

Comparison of goods:

clear

Engineering systems ›Ventilation

Dear Clients!

We work in compliance with the norms. We are waiting for your applications! Our contacts

- Price

ventilation system design - Ventilation design software

- Ventilation design tutorials

- Industrial ventilation design

- Ventilation design for an industrial building

- Smoke ventilation design

- Ventilation technical documentation

- Examples of projects

- Design stages

- Promotions

and Discounts - What will you get as a result of the design

- Design time

- Data provided by the customer

- Design features

- Norms

ventilation design (SNiP, GOST)

To receive a commercial offer

, send a request by email or call +7 (495) 745-01-41

Design at EuroHolod is:

- Cost optimization

- Energy efficiency

- Qualification

- A complex approach

- Equipment selection: optimally selected characteristics of ventilation units and not the most expensive brand of the manufacturer in the price-quality ratio, significantly reduce the cost of equipment and do not affect the required parameters.

- Duct optimization: correctly calculated and optimally located air duct routes reduce the required volume of metal products, therefore, costs are reduced.

- Preventing rework: you will not need to change architectural and engineering solutions for related communications that do not require ventilation systems at the design stage, which will save you from unnecessary expenses for alterations, modifications and replacement of equipment.

- Possibly significant reduce operating costs electricity and hot water, taking this into account in the design of ventilation and air conditioning systems.

- For this, systems with heat recovery, recirculation of supply air and equipment with optimal energy consumption are used.

- Practical experience: our designers have not only theoretical knowledge, but also experience in the management of objects and delivery to public services.

- Ready-made solutions from 2 days: plans for premises within 2000 m2 will be ready within 2 - 5 days, depending on the complexity of the object.

- Finalization of the project for free: in most cases, the project needs to be finalized due to changes in architectural, design and technological solutions.

- All the necessary documents are available: certificates of the project SRO and ISO-9001, the license of the Ministry of Emergency Situations, etc.

- We have a lot of completed projects and real customer reviews.

- We design a complex solution in which all sections of engineering systems agreed between themselves.

- EuroCold also organizes selection of equipment, installation and further service.

- We guarantee quality of our services and carry them out in a short time.

- All are counted wishes the customer and the necessary edits are made.

- Air conditioning installation cost

- Ventilation installation cost

Why is it profitable to order ventilation design in IS Ecolife

| VENTILATION SYSTEM FROM A TO Z We are focused on building the entire engineering infrastructure on a turnkey basis. Design, equipment supply, installation and provision of service packages are carried out without the involvement of related performers. High speed of work. By contacting us, you will save not only your money, but also your time. |

| REAL RESPONSIBILITY FOR THE RESULT IS Ecolife has a fully equipped production base, a staff of engineers and installers.We carry out all stages of work on our own, provide end-to-end quality control and are 100% responsible for the result. The company provides a guarantee for all work performed and is interested in long-term trouble-free operation of your equipment without downtime and emergency situations |

| ZERO CHECK PROBLEMS We provide all the norms indicated in SanPin, SNiP, NPB, etc. You are protected from sudden orders and sanctions of supervisory authorities, save on fines and other fees. |

| BEST PRICE We select decent equipment within even a small budget. You get equipment according to the principle "high quality - not necessarily expensive". The calculation of the estimate for services is made immediately after receiving the necessary information. Our principle is complete transparency of the cost of work. The amount specified in the contract is a fixed price that will not be changed by us if you do not want to revise the estimate yourself. For regular customers, special discounts and delivery terms are provided. |

| CONVENIENCE 100% outsourced operation. You can give the maintenance of all engineering networks of the object to one performer -. We work officially under a contract and close all questions about the operation, both planned and urgent, and it is convenient for you to ask from one contractor. |

Ecolife Engineering Systems is a team of experienced and licensed specialists in the installation and maintenance of all types of engineering systems with the subsequent execution of the entire package of documents.

• 5 years on the market of Moscow and the Moscow region • 7 specialized licenses and certificates • 40 employees, 4 official vehicles and 3 work teams for prompt execution of orders • 2 sets of teleinspection and professional European equipment • We will reduce your costs by 20%. The prices for our services are below the market average without any loss in the quality of work and service.

| Quality assurance Ecolife company guarantees high quality ventilation design. |

Design stages

- The design of the ventilation system begins with the preparation of the technical specification, in which the customer indicates the characteristics of the object and the requirements for the final result.

- Study of technical documentation for the serviced object and (if the object is ready) measurement work.

- Selection of the preferred type of ventilation.

- Calculation of air exchange in accordance with the methods and SNiPs in force on the territory of the Russian Federation.

- Selection of ventilation system equipment (fans, air ducts, air diffusers, etc.).

- Aerodynamic and acoustic calculations.

- Final arrangement of ventilation units and air duct routes.

- Drawing up plans, drawings, estimates for installation.

- Project approval.

Exhaust ventilation calculation

The calculation of the exhaust ventilation is carried out after the calculation of the supply ventilation and is based on ensuring the balance of the supply and extract air at the facility. When calculating exhaust ventilation, rooms are distinguished that require separate exhaust systems. In particular, a separate hood is provided for bathrooms and showers. At the same time, an extractor hood is installed in the amount of 50 m3 / h for each displaced person, 25 m3 / h for each urinal and 75 m3 / h for each shower room. Also, a separate hood is provided for kitchens and food preparation rooms. Extraction from kitchens depends on the type of stove and is usually 90 m3 / h. If we are talking about the kitchen premises of cafes and restaurants, then local suction should be provided from special kitchen equipment in accordance with the design assignment. The calculation of exhaust ventilation in office premises is based on ensuring a positive 20% imbalance. So, if the inflow into an office space for 10 workplaces and 5 visitors is 700 m3 / h, then the exhaust air flow rate should be taken as 560 m3 / h. A separate task is to reduce the costs of the supply and exhaust ventilation systems and ensure their equality for the facility as a whole.For calculation and design of ventilation for specific objects, please contact IS "Ecolife". Our engineers will help you make the right ventilation for any type of facility.

To the table of contents

Promotions and Discounts

When carrying out an integrated design in:

- We provide discount on the total cost of complex design subject to the design of 3 or more sections

- We provide delivery discount equipment and materials

- We carry out management briefing mounted systems

- We offer a free one-time service (subject to the implementation of a turnkey project - design, delivery, installation)

Our company together with integrated design provides additional services:

- Providing estimates and equipment selection sheets based on project documentation

- Development of engineering documentation for the tender... We will help you choose the most suitable solution for you.

- Development of measures to ensure compliance with energy efficiency requirements, drawing up energy passport

- Selection and delivery equipment and materials

- Carrying out installation works

- Carrying out service

- Re-selection equipment

Stages of design work

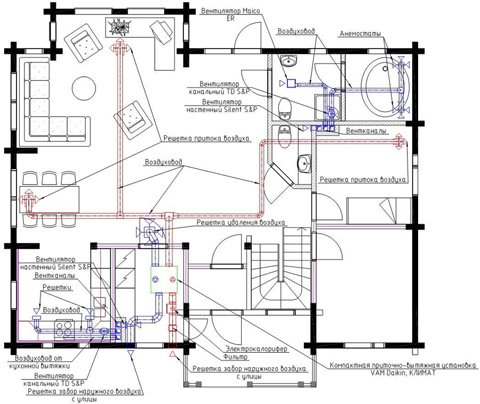

The development of a home ventilation and air conditioning system is usually carried out in two main stages:

- The first stage includes the development of a draft feasibility study. This design phase is followed by careful selection and feasibility studies of the type of system. In addition, at this stage, it is necessary to determine the most suitable technical sites for the installation of the equipment used, as well as to determine some important characteristics: the performance of the heat and cold system, air volume, quantity. It is also necessary to determine the location and type of air conditioners, heat consumption and type of refrigerants, the number and type of pumps and refrigerators, weight and installed capacity of the electrical equipment of the system. After that, a preliminary system diagram is developed. As soon as the customer approves it, the development of the working draft begins.

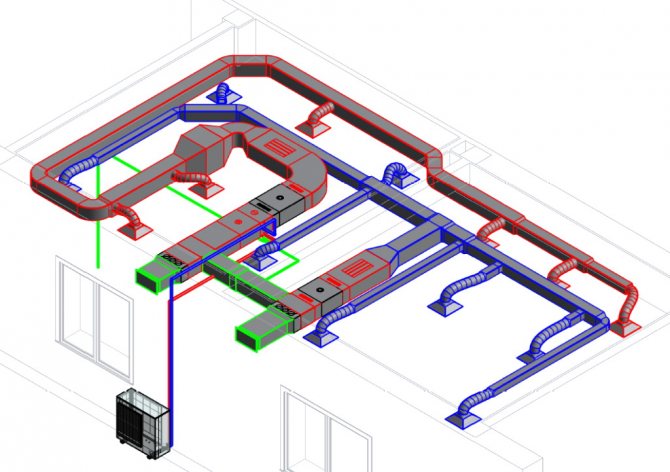

- At the second stage, the development of a working project takes place, which is based on the data of the building layout, thermal technical characteristics of building structures, as well as a technological task. Then the calculation of heat and moisture release is carried out, which allows you to calculate the air exchange for each individual room, capable of providing all the required parameters. The necessary equipment is selected that is responsible for air exchange and pressure in the network. There is a final selection of the most optimal system scheme and determination of all its characteristics. Then a drawing of plans is carried out, where the location of the equipment is indicated, as well as the layout of pipelines and air ducts.

After that, a hydraulic and aerodynamic calculation is carried out, as well as a determination of the noise level. Specifications for materials, equipment, fittings are carefully filled in (at the same time, their cost and manufacturer are indicated). After the customer has agreed on the existing project with the fire inspectorate and the SES, the necessary equipment is ordered. On this we can consider that the design stage is completely completed.

An example of a complete ready-made calculation of a house ventilation system

And after that, they proceed directly to the installation of the ventilation system.

Design time

The timing of the design depends on the completeness of the information provided by the customer, the accuracy of the technical assignment, the degree of readiness of the facility (reconstruction or new construction), coordination of design solutions with the designer, architect and other related engineering design sections. Estimated terms:

| Object area | Timing | |

| Stage "P" | Stage "R" | |

| Up to 300 m2 | from 7 working days | from 7 working days |

| 300-600 m2 | from 10 working days | from 15 working days |

| 600-1000 m2 | from 20 working days | from 25 working days |

| 1000-2000 m2 | from 30 working days | from 40 working days |

| Over 2000 m2 | Determined individually | |

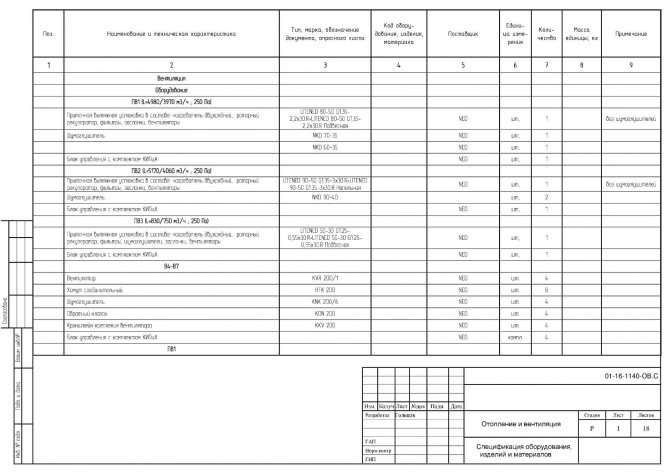

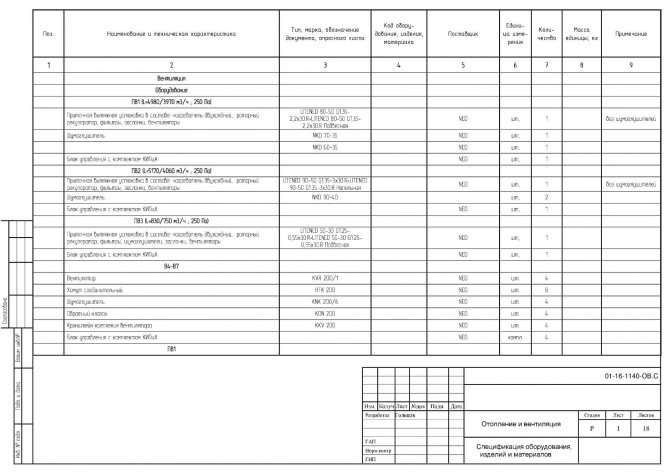

Composition of the ventilation project

Let us consider in more detail the composition of the sheets that are necessarily included in the project:

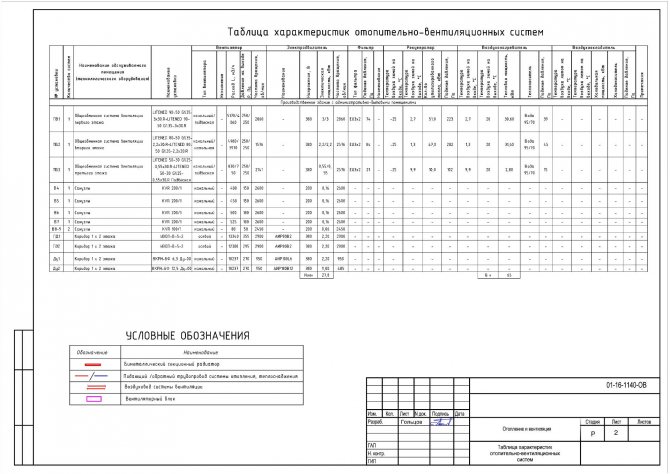

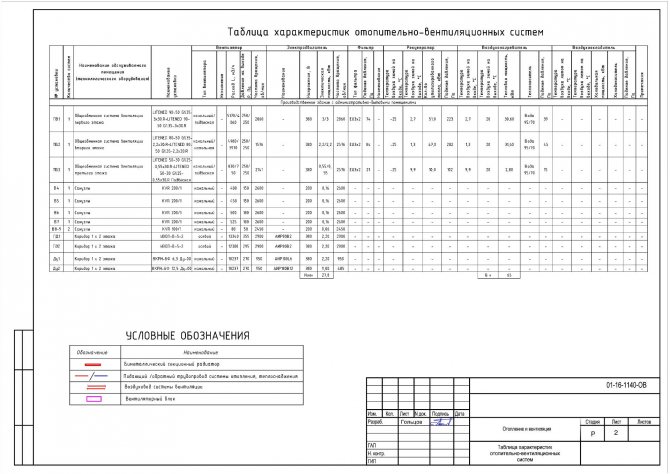

- General data on drawings

Includes a brief description of the systems so that any installer and builder can quickly navigate the project. The general data includes a summary table of the characteristics of ventilation systems with the parameters of all ventilation equipment and the loads on the power supply and heat supply system of the building.

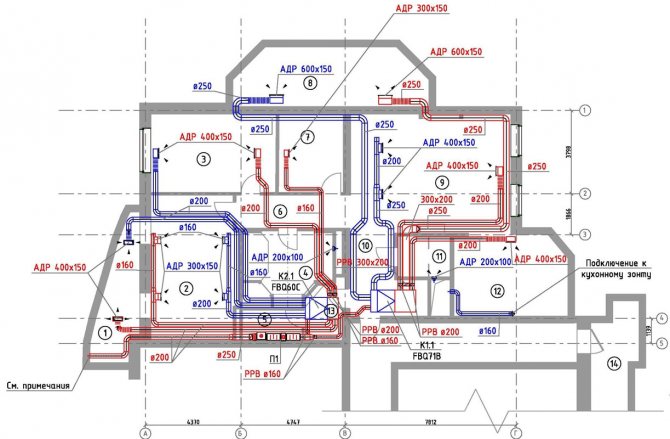

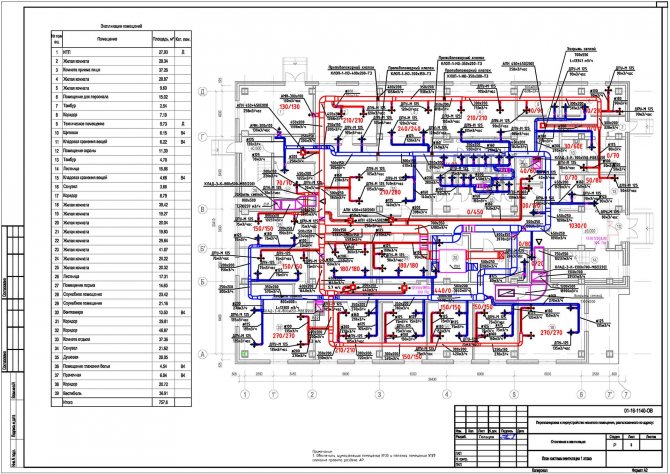

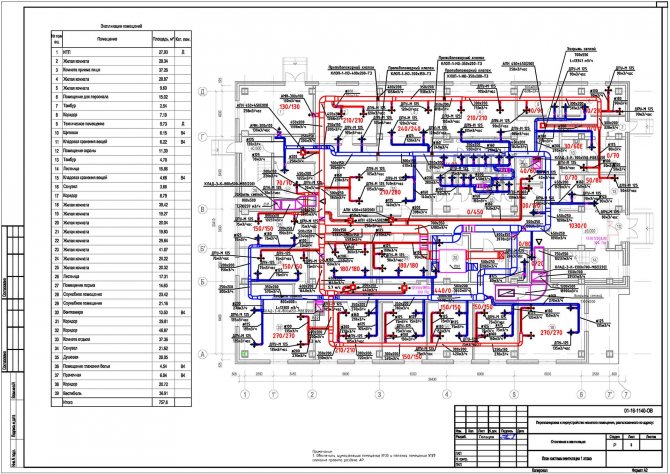

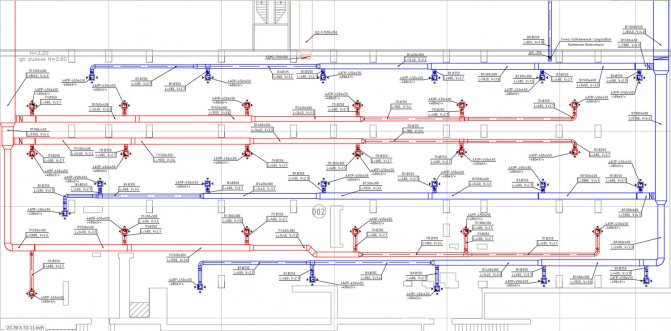

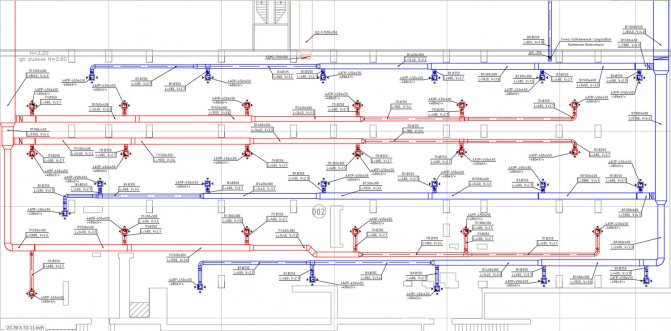

- Ventilation system plans

Key sheets of project documentation. They are used for installation work, coordination of engineering systems and subsequent service. The plans show the routing of the air ducts, their dimensions, air flow rates at each site, the brands of grilles and ventilation equipment.

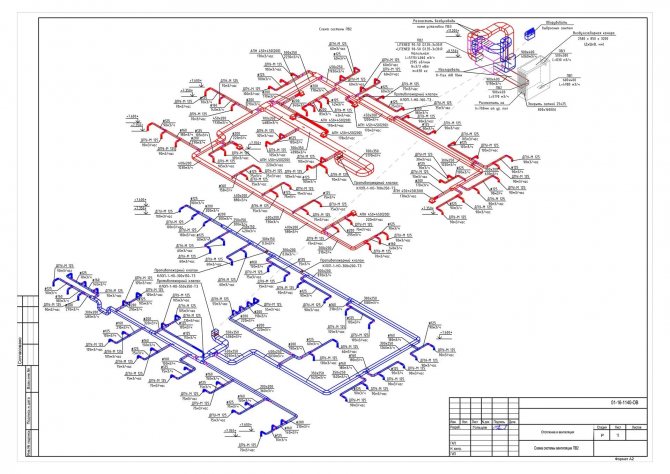

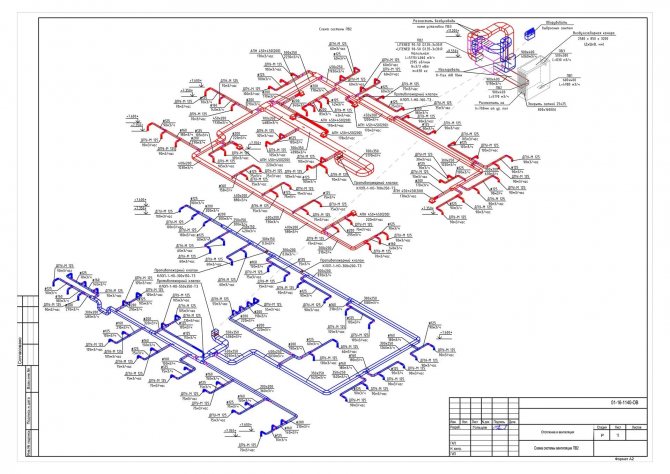

- Ventilation system diagrams

The diagrams show the vertical placement of the ducts and possible drops at the intersections. In our team, circuits are built in the 3D program MagiCAD. The program automatically calculates air flow rates and balances the branches.

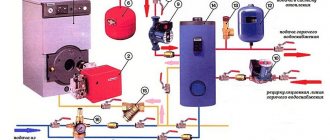

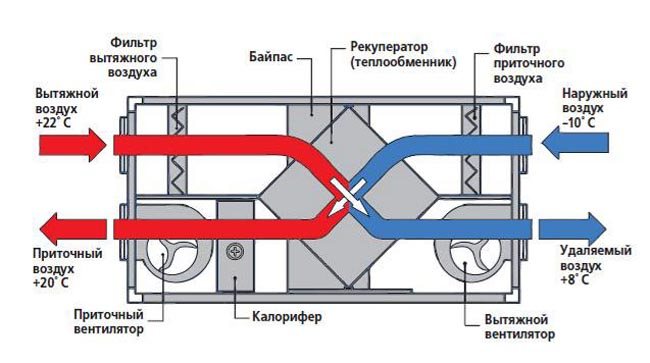

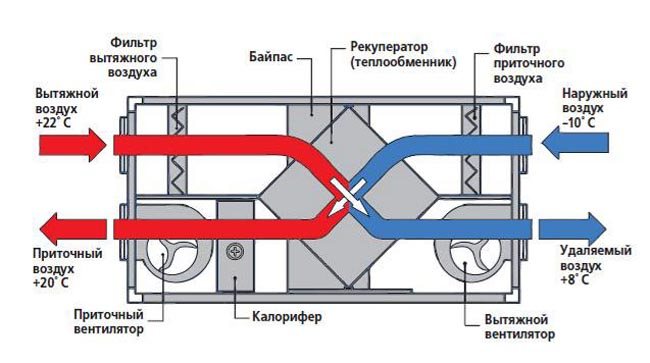

- Heat supply system plan and diagrams

The ventilation project kit necessarily includes a section for heat supply of air handling units. The supply air must be warmed up in winter. For this, a water heater and a recuperator are most often used. The air is heated in the recuperator and then passed through the water heating section, which is connected to the heating system. The heat supply pipes and all the piping of the heaters must be calculated by the design engineer. The heating system must be balanced with other consumers.

Without heat supply plans and schemes, it is impossible to start ventilation in the winter! This work must be performed by the ventilation design engineer.

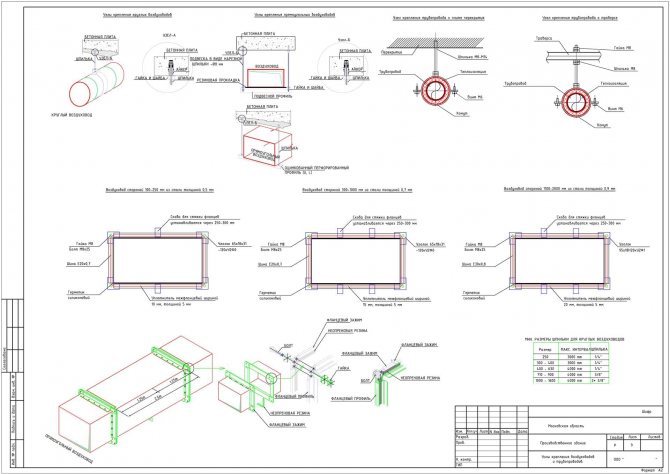

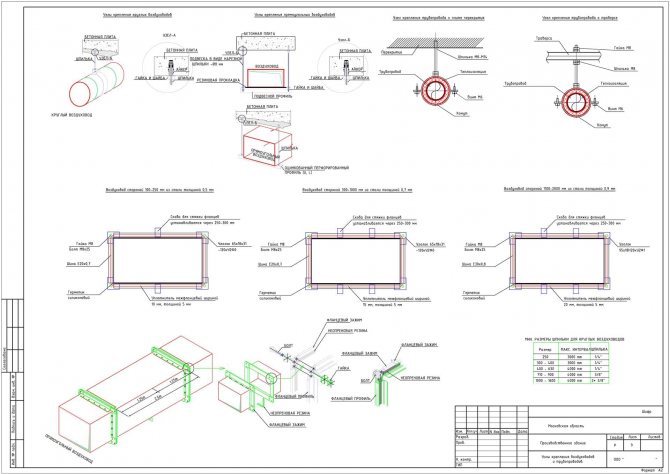

- Air duct attachment points

Standard elements of any project. Air ducts of different sizes and configurations are attached in different ways. Fasteners are additionally ordered by the installer and must strictly comply with the requirements specified in the project.

- Specification of equipment and materials

BOM is the exact amount of materials and equipment that will be needed to install systems. In modern design, this has become much easier. MagiCAD automatically calculates duct lengths from the drawing. It remains for the designer to check the calculation and independently supplement the missing elements.

Without a project, it is impossible to choose the right size of air ducts, grilles, accurately purchase the required amount of materials. Without a project, it will be difficult to balance the system.

In the course of design work, the following calculations are performed:

- calculation of air changes. The air consumption in each room is calculated according to the rates of frequency or additional calculations for the removal of excess heat or moisture.

- aerodynamic calculation. During the calculation, we solve 2 problems. First, we find out the total pressure that the fan must provide in order to guarantee the supply of air to all rooms. Secondly, we balance the branches of the ventilation system with each other. One ventilation branch is longer and the other is shorter. Air always follows the shortest path, and we need to balance the system so that air is supplied evenly through all branches of the system.

- additional calculations for the removal of excess heat and moisture. In some rooms, the main task is not to supply air for breathing, but to remove excess heat (for example, in the kitchen) or moisture (for example, in swimming pools).There are many rooms where air exchange is not considered according to the norms, but a separate calculation is performed.

Design features

To create a comfortable microclimate, it is necessary to determine and balance many parameters:

- the power and performance of the fans, the pressure they create, taking into account the dynamic resistance of the ventilation ducts;

- section of ventilation pipelines and their layout, taking into account building structures, location of ventilation and other equipment;

- location of exhaust and air supply points;

- composition and placement of air conditioning equipment;

- the composition of monitoring and control devices, their location, connection;

- measures to reduce the noise level produced by the operating equipment, including that propagated through the air ducts.

Signs of a high-quality ventilation project can be considered:

- air circulation is established in all rooms

- silent operation of equipment and air ducts

- no drafts and cold zones

- use of energy saving technologies

- easy adaptation of the system to warm and cold seasons

By ordering a professional design of ventilation now, in the future you will be able to avoid many problems, such as: violation of the aesthetics of the interior, noise, high energy consumption, decrease in system performance.

A professional project provides for the smallest nuances of object operation and creates optimal conditions for people living or economic activity.

The ventilation system design is created at the early stages of construction of the facility - as part of the overall design work. It must take into account the requirements of fire safety and sanitary standards, and also harmoniously fit into the overall architectural composition. Timely creation of a ventilation project will allow you to create the most efficient system with minimal costs for equipment and communications.

Ventilation system design software

VentCalc V.2.

VentCalc V.2. - one of the programs for calculating ventilation, which will be useful to all people working with ventilation systems. It allows you to efficiently calculate the ventilation network in the shortest possible time. To get the information you need, you just need to indicate the total length of the main branch, the initial and final air flow rates, as well as some other data. After some time, you will receive a ready-made image of the ventilation network, which is most closely approximated to the real picture. In addition, the program will display its resistance, with the help of which you can select the most optimal capacity of the ventilation unit at the initial stages of project preparation.

Working window of the program for planning ventilation Ventcalc

By using this program, you can avoid the need for complex mathematical calculations when they, as such, are not required. Simply put, the main purpose of the program is a convenient and fast calculation mechanism, which will greatly simplify many design tasks.

This program can be used to solve issues related to the regulation and coordination of ventilation networks, as well as to select the most suitable fan power in the shortest possible time.

Stream - a program for calculating heating systems, cooling heat supply for heaters and equipment

The "Stream" program is used in cases when it is required to perform a hydraulic calculation of 1-2 pipe and collector heating and cooling systems, as well as when calculating data for central water heating using various heat carriers (solution or water), with a sliding or constant temperature difference in buildings, where centralized or separate heat metering is provided. Cold and warmth is delivered to the premises by means of local heating devices, fan coil units or air heaters.

Ventilation design standards (SNiPs, GOST)

The design of ventilation systems is carried out in accordance with SNiP 41-01-2003 and SP 60.13330.2012. At the heart of any project is a careful calculation of system performance. Depending on the purpose of the room, air exchange can be calculated in volumetric values (m3 / h) or the frequency of complete air replacement. The performance of the entire ventilation system is determined by the performance of the supply ventilation.

For residential premises, the required volume of supply air is usually determined at the rate of 60m3 / hour per person. For a bedroom, this figure can be reduced to 30m3 / hour, since during sleep, oxygen consumption is significantly reduced. The simplest formula for calculating ventilation capacity by volume is as follows:

V = N * Vn, where:

V - ventilation capacity in m3,

N is the maximum number of people in the room,

Vn is a correction factor that determines the volume of air consumption by one person, depending on the type of room. SNiP 41-01-2003 contains tabular values:

| Object type | With natural ventilation | Without natural ventilation |

| Manufacturing, industrial facilities | 30 | 60 |

| Public, administrative, municipal buildings (full time) | 40 | 60 |

| Public, administrative, municipal buildings (attendance - no more than 2 hours daily) | 40 | 20 |

| Living quarters, area for 1 person more than 20 m2 | 30 | 60 |

| Living quarters, area for 1 person less than 20 m2 | 3 m3 for each m2 of living space | 60 |

This table shows the calculation of ventilation based on human factors only. At production facilities, the volume of required air exchange can be influenced by:

- the nature of the technological process,

- Type of equipment,

- presence of additional sources of pollution.

When calculating ventilation performance for health care facilities, education, public catering, the supply air rate must be calculated in accordance with the requirements of the profile ND.

Air exchange is calculated individually for each room, then the numbers are summed up and rounded up - this will be the required ventilation capacity.

Taking into account all additional factors (household appliances, heaters, pets, etc.), the ventilation performance of residential buildings is:

- Apartments and small private houses - from 100 to 500 m3 / h

- Cottages, townhouses, small hotels - from 500 to 1000 m3 / h

- Apartment buildings, hotels, sanatoriums - from 1000 to 10000 m3 / h

Another popular method for calculating ventilation systems is multiple. The supply air volume is calculated using the formula

V = n * Vp, where:

Vп - the volume of the room,

n is the rate of air exchange, it is:

- bathrooms - 7

- kitchens - from 5 to 10

- office premises - 3

- residential buildings - 2

The group is ready to implement complex solutions for the arrangement of internal engineering systems and building networks. We provide a guarantee for the equipment purchased from us and all installation work!

We are waiting for your call by phone: +7(495) 745-01-41

Our email

About us, Reviews, Our objects, Contacts

See further

- Ventilation

- Ventilation system design prices

- Ventilation design software

- Ventilation design tutorials

- Industrial ventilation design

Supply ventilation calculation

The calculation of supply ventilation is the main calculation in the design of ventilation systems. It is from the calculated air flow rate in the supply system that they are repelled when calculating the exhaust systems. Let us consider several examples of calculating supply ventilation: • The office has three rooms - for 4 workplaces and 4 visitors, for 5 workplaces and 5 visitors and a secretariat with one workplace and two chairs for visitors. The required supply air flow rate is determined as follows: L = 4 · 60 + 4 · 20 + 5 · 60 + 5 · 20 + 1 · 60 + 2 · 20 = 820 m3 / h • The dance studio has a hall for 20 people and a living room with one workplace and 5 chairs for visitors.The required supply air flow rate is: L = 20 · 80 + 1 · 60 + 5 · 20 = 1760 m3 / h • In the administrative building there are a total of 150 workplaces, 60 places for visitors and 4 meeting rooms with the required air exchange rate, three different , with a room volume of 150m3. The required supply air flow rate will be: L = 150 60 + 60 20 + 4 3 150 = 12000 m3 / h However, in practice, the situations turn out to be more complicated - there are foyer rooms, living rooms, corridors, reception rooms, specific rooms, such as, for example, massage rooms, archives, warehouses, etc. For the correct calculation of supply ventilation, please contact the engineers of the Group. We will answer all your questions, advise on the operation and installation of ventilation systems, carry out the design of ventilation systems, as well as the supply of equipment and installation of ventilation at your facility.

To the table of contents

Recommended equipment types

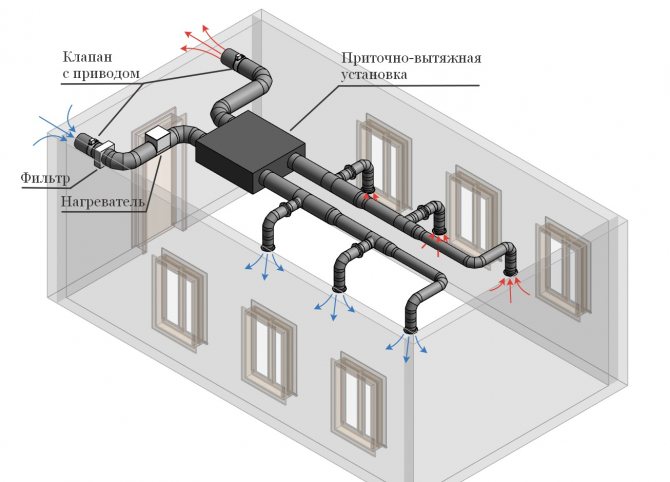

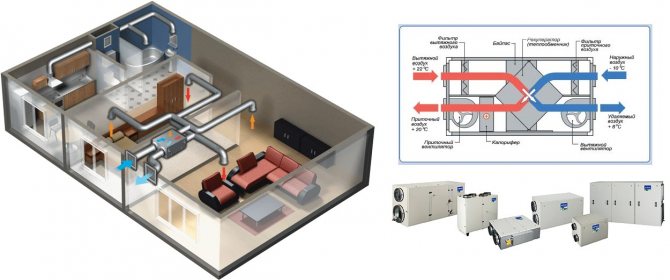

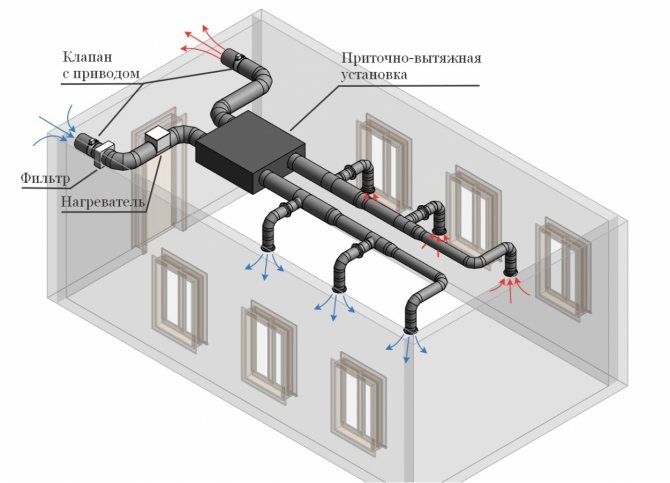

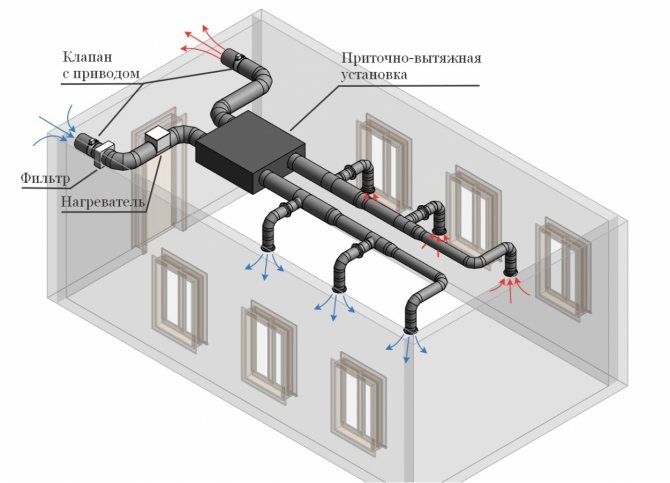

Supply and exhaust ventilation system for a small private house

Low-power ventilation units are used for housing, the optimal solution is the supply and exhaust ventilation scheme.

Systems are subdivided according to the criteria:

- air supply option;

- appointment;

- method of exchange of streams;

- constructions.

Some installations use fans, others require air conditioning. Household recuperators are used to supply heated air masses. The system uses dehumidifiers or flow humidifiers, ionizers, filtering installations, valves and air dampers are installed.

Typesetting system

Type-setting supply and exhaust ventilation system

The scheme got its name due to a certain composition of units, which are sequentially recruited according to technical parameters. Modularity facilitates a variety of options and system selection for the needs of a particular house or apartment. Typesetting systems provide air exchange at the level of 50 m³ / h - 15 thousand m³ / h. The circuit nodes are connected to rectangular and round air ducts.

The systems work effectively when ventilating offices, housing in private and multi-apartment buildings, sales areas, warehouses and production workshops.

Monoblock system

Air reclaim ventilation

The functional equipment is combined in one unit. The system includes heat recovery to save heat while creating comfort.

The following units are installed in a single body:

- filter;

- heat exchanger;

- turbine;

- absorber of noise and vibration;

- automation elements, etc.

Monoblock systems with recuperators operate autonomously or combined with air conditioners. The removed heated streams pass through the exchanger, where they give off part of the heat to the fresh air, which minimizes the use of heaters for heating.