In most European countries, they are abandoning the use of cast iron radiators in favor of aluminum or bimetallic ones, which have more compact dimensions, high efficiency and an attractive design. But they are characterized by two significant drawbacks:

- High price;

- Increased wear due to poor-quality heating agent of the centralized system.

Therefore, for the CIS countries, cast iron heating devices are still relevant and in demand. They are characterized by:

- Long service life;

- Corrosion resistance;

- Compliance with existing heating systems.

Design features of cast iron radiators

Cast iron devices are made from an alloy of cast iron, which has high strength and is homogeneous.

The battery sections are produced separately by casting, then connected, obtaining the devices of the required thermal power. The tightness of the joints is achieved by using sealing elements made of various materials.

There are three types of cast iron radiators: single-channel, two-channel and three-channel.

The principle of operation is very simple, it is as follows: the heated coolant circulates inside the device, gives off heat to its walls, which is then transferred to the surrounding air.

- Heating equipment of this type is characterized by the following features:

- Internal ribs are vertically positioned in order to increase the heat exchange surface;

- Good strength and ability to withstand high pressures;

- Relatively low coefficient of linear expansion of the material and high temperature resistance;

- Thermal power ranges from 100 to 150 W;

- A high degree of inertia of products, in connection with which their heating and cooling occurs rather slowly, thermoregulation practically does not make sense.

Power and heat dissipation

It is worth saying a few words, considering the technical characteristics of cast-iron heating radiators, about heat transfer and power. Manufacturers, as a rule, indicate values for one section in the technical documentation, so their number must be counted before installation.

If we consider cast-iron models of radiators, their heat transfer is significantly inferior to modern bimetallic and aluminum versions about 2 times. However, low inertia eliminates this disadvantage, since cast iron keeps warm for longer and emits useful energy.

The average power of one section reaches 160 watts

against 200 for aluminum. Cast iron models are most effective in systems with natural circulation of the coolant.

Video - comparison of the efficiency of a cast iron and aluminum radiator

Advantages and disadvantages of cast iron batteries

Like any heating devices, cast iron radiators have both advantages and disadvantages. Among the advantages are the following:

- Resistance to the effects of chemically active components in the composition of heat transfer fluids. Unlike the materials used in the production of other types of radiators, cast iron practically does not rust.

- Long service life. Some cast iron batteries that have served 50-60 years still function today.

- There is no need to connect a circulation pump, since cast iron radiators create a small hydraulic resistance for the coolant.

- Do not require cleaning for a long time due to the large diameter of the channels;

- Thermal inertia, which acts as an advantage and a disadvantage at the same time. Radiators are able to keep warm for a long time, but temperature control is not possible.

Disadvantages:

- Large dimensions, mass of devices, which significantly complicate their installation;

- Difficulty adjusting temperature conditions;

- Slow warming up when the system is turned on;

- Intercostal joints are quite complex, which interferes with cleaning and painting the product.

Features of the MC-140-500 radiator

Cast-iron radiators MS-140 with a center distance of 500 mm are designed to heat buildings of any purpose, from private residential buildings to industrial and industrial buildings. They have good heat dissipation and resistance to aggressive coolants. Cast iron "accordions" stubbornly do not want to leave the heating equipment market, as they are considered the most unpretentious type of radiators.

Cast iron batteries are among the most durable. This is due to the physical and chemical properties of the metal.

The main advantage of cast iron batteries is their long service life. Cast iron reluctantly reacts with water and aggressive compounds, resisting corrosion well. The top layer protected by primer and paint is not affected by it either. Even in the absence of external protection, cast iron practically does not deteriorate and does not become thinner. It comes to the point that in some cases these radiators can outlive the building itself in terms of service life.

Heat transfer of MC-140 cast-iron radiators with center-to-center distance is from 140 to 185 W per section. This is a pretty decent figure, which allows cast iron to compete successfully with other types of radiators. Today, cast iron batteries are produced by many domestic factories and are not going to leave the counters of plumbing stores.

Differences in the technical characteristics of cast iron heating batteries from other popular types of batteries.

What are the advantages of MC-140-500 cast iron radiators?

- Resistance to aggressive heat carrier - centralized heating systems do not spare even the most hardy modern radiators. Cast iron practically does not react with caustic and aggressive compounds;

- Large internal capacity - thanks to this, radiators are almost never clogged or clogged. Also, the internal volume helps to reduce hydraulic resistance;

- Long service life - the manufacturer's warranty reaches 10-20 years. As for the actual service life, it is up to 50 years and even more, you just need to properly care for the batteries and tint them on time;

- Long-term preservation of heat - if the heating is turned off, cast iron will retain and give off heat for a long time, heating rooms and rooms;

- Affordable cost - the price for cast iron radiators MS-140-500 starts at 350-400 rubles per section (depending on the manufacturer).

Let's list a few disadvantages:

One of the main disadvantages of cast iron batteries is their instability to water hammer, here they are inferior to their bimetallic counterparts.

- Heavy weight is perhaps one of the most important drawbacks. One section weighs over 7 kg, which is why the weight of a battery of 10 sections is over 70 kg;

- Difficulty in installation - if aluminum or steel radiators can be mounted independently, then two or three will have to work on a cast-iron battery. In addition, for mounting to a wall, you need a good hardy fastener (and the walls themselves should not crumble under the weight of the batteries);

- Lack of resistance to high pressure - cast iron batteries are oriented towards operation as part of autonomous heating systems (installation in low-rise buildings connected to centralized systems is allowed).

How to choose a cast iron radiator - selection options

The main selection criterion is the heat output of the device.

Each model is characterized by a certain amount of heat energy released. Its amount is largely influenced by the color of the coating.Black products emit 25% more heat energy than white products.

When choosing a cast-iron radiator, you should also pay attention to the method of installation, connection, permissible temperatures of the coolant and its pressure.

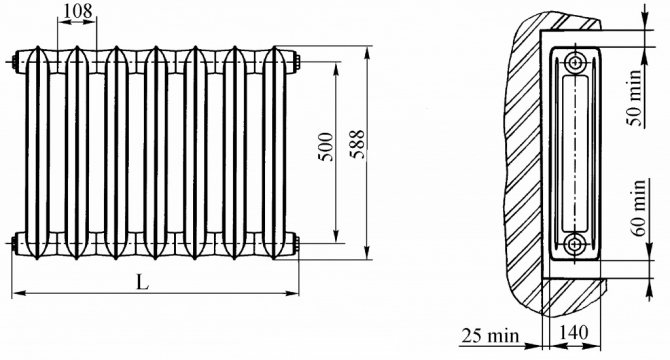

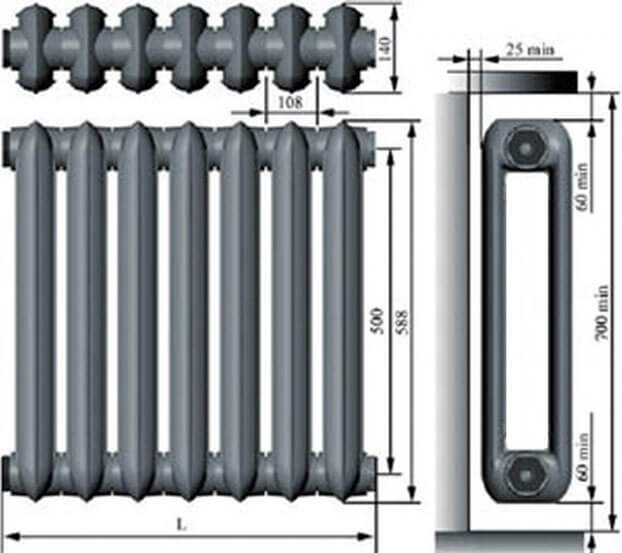

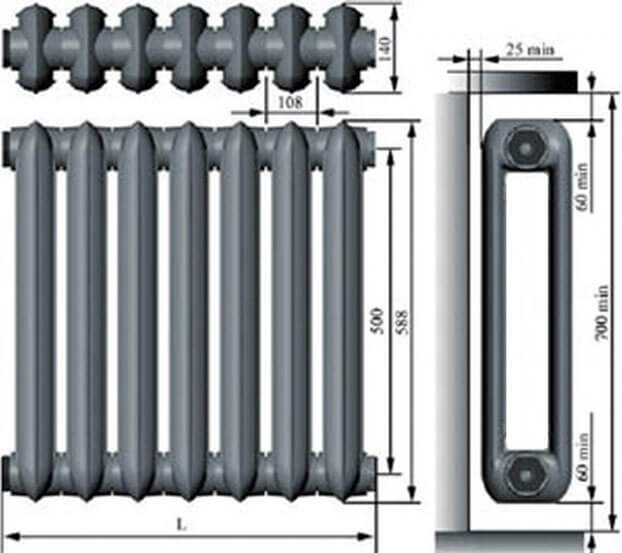

Dimensions and weight of cast iron heating radiators

The parameters of cast-iron radiators using the example of the domestic product MC-140 are as follows:

- height - 59 centimeters;

- section width - 9.3 centimeters;

- section depth - 14 centimeters;

- section capacity - 1.4 liters;

- weight - 7 kilograms;

- section power 160 watts.

From the side of real estate owners, you can hear complaints that it is quite difficult to transfer and install radiators consisting of 10 sections, the weight of which reaches 70 kilograms, but I am glad that such work in an apartment or house is done once, so the dimensions of cast-iron heating radiators must be calculated correctly.

Since the amount of coolant in such a battery is only 14 liters, then when heat energy comes from the boiler of an autonomous heating system, then you will have to pay for extra kilowatts of electricity or cubic meters of gas.

How many kW in one section - calculation of heat transfer

In the data sheet for the device, the manufacturer indicates the main characteristic of the battery section - thermal power (heat transfer).

The actual and declared values are often very different. This is possible in the case when the actual temperature of the coolant differs from that indicated in the passport for the device.

To calculate the actual heat output, use the following formula:

Q = K * S * dT

Where:

- S is the area of the heat exchange surface;

- dT is the temperature head expressed in degrees Celsius;

- K is the heat transfer coefficient of cast iron.

To calculate the temperature difference, you need to know three parameters:

- Coolant temperature at the inlet (tinlet);

- Coolant temperature at the outlet of the radiator (tout);

- Average room air temperature (tair).

We get the formula:

dT = 0.5 * (tinput + toutput) - tair

The difference between the actual and the declared result can be caused by the following factors:

- The underwater pipes are too long;

- Low head of the coolant;

- Insufficient coolant temperature.

To calculate the required number of sections, it is necessary to find out the required amount of heat for heating the room. There are two calculation options: by the area of the room and by the volume of the heated space.

For any of the options, select the normalized value of the amount of heat required to heat a unit of area and volume of space, respectively.

Then, the total amount of heat required to heat the entire room is obtained as the product of the normalized value by the area or volume (depending on the chosen calculation option).

The required number of sections is equal to the quotient of dividing the required amount of heat by the amount of heat generated by one section of the device.

The procedure for calculating the number of sections

There are different methods for performing technical calculations for radiators. Precise algorithms allow calculations to be made taking into account many factors, including the size and placement of the room in the building. You can also use a simplified formula that will allow you to find out the desired value with sufficient accuracy. So, you can calculate the number of sections by multiplying the area of the room by 100 and dividing the result by the power of the section of the cast-iron radiator in cotton wool.

At the same time, experts recommend:

- in the event that the total is a fractional number, round it up. The heat reserve is better than its lack;

- when the room has not one, but several windows, install two batteries, dividing the required number of sections between them. As a result, not only the service life of the radiators increases, but also their maintainability.Batteries will be a good barrier to cold air coming from windows;

- with a ceiling height in the room of more than 3 meters and the presence of two external walls in order to compensate for heat losses, it is advisable to add a couple of sections and thereby increase the power of the cast-iron heating radiator.

Which manufacturer to choose?

Cast iron radiators are now made by not so many manufacturers as aluminum and bimetallic models, but we will consider three main brands on the Russian market.

Konner

Cast iron batteries of this company have the following advantages:

- Long service life;

- Low hydraulic resistance;

- Compliance with centralized heating systems;

- The declared high level of heat transfer from the section (up to 150 W);

- Ease of installation;

According to some consumers, these devices actually produce less thermal energy than stated in the passport. Another disadvantage is the rather high cost.

Exemet

Advantages of devices from this manufacturer:

- Environmental friendliness and reliability;

- High heat output produced by one section;

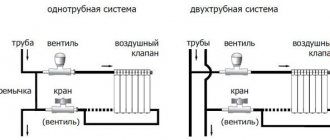

- Able to work in one- and two-pipe heating systems;

- Powder coated;

- Unique design stylized as 19th and early 20th century.

In the production of cast-iron radiators, the method of artistic casting is used, which increases the cost of the devices. Also, their unique design is not suitable for every interior.

GuRaTec

Advantages of radiators of this brand:

- High quality of products, the control of which is carried out in a pressure chamber and hydraulic tests;

- Long service life;

- Environmental Safety;

- Sufficiently high thermal power of the sections (up to 150 W);

- Unique design.

The devices are decorated with various decorative elements that give them an attractive appearance. However, this also affects the cost of products.

4.9 / 5 ( 37 votes)

Determine the power of a cast iron radiator

The required power of the radiators is determined depending on the volume of the heated room and its individual characteristics:

- the presence of internal and external walls;

- angular arrangement;

- number of windows and doors;

- the material from which the walls of the building are composed;

- the quality of the room's thermal insulation, etc.

The average required power is determined at the rate of 1 kW per 10 m² (if the ceilings are not higher than three meters). For example, a room with an area of 18 m² requires the installation of a 1.8 kW cast iron radiator.

If the room is located at the end of a building or at a corner, then the amount of required power is calculated using a factor of 1.2 (we increase the number of sections by 1.2 times and round up).

If the ceiling height is higher than three meters, then the required power is calculated as the product of the area of the room, the height of the ceiling and a factor of 40.

If the room has two windows and two walls from the end of the building, then the power increases by 30%, if the window is in the north or north-east orientation - increase by 10%, if the radiator is covered with a panel - increase by 15%. There are many corrections that should be taken into account when calculating the number of sections.

The calculation of power should also take into account such a value as the temperature of the coolant. Standard indicators are 70 ° С and 60 ° С.

Having calculated the required power to maintain a normal room temperature and knowing how many kilowatts are in one section of a cast-iron radiator, you can determine the number of radiator sections to be installed.

How to add cast iron sections to a cast iron battery assembly

How much does one section weigh

Let's carry out a comparative analysis of heating devices for this indicator, and we will take the old Soviet "accordions" as a starting point. So, the weight of one section of the traditional cast-iron MS-140 battery is 7.12 kg, and the capacity is 1.5 liters of water with a standard center-to-center height of 500 mm. That is, the total mass of 1 section of the radiator in working condition is 7.12 + 1.5 = 8.62 kg.

An example of calculating the mass. As a rule, in private houses, heating devices are used with the number of sections from 4 to 12 pcs. Take the average number - 7 sections, then the mass of the old-style battery will be 8.62 x 7 = 60.34 kg, and without water - 49.84 kg. It is not easy to install such a colossus alone, an assistant is definitely needed.

Below in the table we will present various options for new heaters, including cast-iron euro batteries, where we will indicate indicators of concern to homeowners - the weight of the rib, its capacity, heat transfer and the price in conventional units.

| Radiator brand and model | The country | Weight, kg | Coolant volume, l | Thermal power, W | Price, cu e. |

| Viadrus KALOR 500/70 | Czech Republic | 4 | 0.8 | 70.3 | 20.05 |

| Viadrus Bohemia 450/220 | Czech Republic | 9.9 | 2.4 | 110 | 78.25 |

| Demir Dokum Nostalgia 500/200 | Turkey | 9.6 | 2.3 | 163 | 52.20 |

| Retro Style Anerli 560/230 | Russia | 17 | 3.29 | 189 | 229.60 |

| EXEMET Modern 600/100 | Turkey | 4.3 | 0.7 | 102 | 32 |

| EXEMET Classica 500/176 | Turkey | 9.3 | 1.95 | 145 | 76.85 |

Note. The numbers after the brand name and model mean the following: distance between the axles of the plugs / depth in mm.

As you can see, we have selected products of approximately the same height and different depths, which affect the massiveness of each rib. To estimate the real mass of radiators, we suggest calculating it based on the required heat output for heating a standard room with an area of 20 m². Putting 100 W of heat on the square of the area, we get the required heating power of 2 kW.